There is great interest in developing biodegradable biopolymer-based packaging materials whose functional performance is enhanced by incorporating active compounds into them, such as light blockers, plasticizers, crosslinkers, diffusion blockers, antimicrobials, antioxidants, and sensors. However, many of these compounds are volatile, chemically unstable, water-insoluble, matrix incompatible, or have adverse effects on film properties, which makes them difficult to directly incorporate into the packaging materials. These challenges can often be overcome by encapsulating the active compounds within food-grade nanoparticles, which are then introduced into the packaging materials. The presence of these nanoencapsulated active compounds in biopolymer-based coatings or films can greatly improve their functional performance. For example, anthocyanins can be used as light-blockers to retard oxidation reactions, or they can be used as pH/gas/temperature sensors to produce smart indicators to monitor the freshness of packaged foods. Encapsulated botanical extracts (like essential oils) can be used to increase the shelf life of foods due to their antimicrobial and antioxidant activities. The resistance of packaging materials to external factors can be improved by incorporating plasticizers (glycerol, sorbitol), crosslinkers (glutaraldehyde, tannic acid), and fillers (nanoparticles or nanofibers). Nanoenabled delivery systems can also be designed to control the release of active ingredients (such as antimicrobials or antioxidants) into the packaged food over time, which may extend their efficacy.

1. Introduction

The main factors reducing the quality, shelf life, and safety of foods are microbial spoilage, chemical reactions, and respiration, which are exacerbated by improper packaging and storage conditions. The deterioration of foods through these mechanisms increases food waste and foodborne illnesses, thereby reducing the sustainability and health of the food supply. The development and utilization of advanced packaging materials is an important strategy to overcome these problems [

1]. Currently, petroleum-based packaging materials are primarily used for this purpose because of their low cost, ease of large-scale production, and excellent functional performance [

2]. Nevertheless, synthetic plastics cannot be produced sustainably due to their poor biodegradability [

3]. Furthermore, they cause environmental pollution and have negative effects on human health [

4]. For these reasons, the design and development of eco-friendly sustainable packaging materials has received considerable attention [

5]. Biopolymer-based packaging materials, which are typically constructed from proteins and/or polysaccharides extracted from animal or plant sources, are being explored as possible alternatives to petroleum-based ones [

6,

7]. However, these biopolymer-based materials often have limitations in terms of their functional properties. The functional performance of this kind of packaging material can often be improved by incorporating additives, such as light blockers, plasticizers, crosslinkers, diffusion blockers, antimicrobials, antioxidants, and sensors [

8,

9,

10,

11,

12,

13]. These additives can be used to alter the optical properties, mechanical strength, barrier properties, and stability of packaging materials, as well as to provide an indication of the quality, safety, or age of a packaged product. In some cases, the active agents incorporated into a packaging material may be designed to diffuse into the food over time so as to provide a prolonged effect, e.g., antimicrobials or antioxidants [

14]. However, the direct incorporation of many of these active agents into biopolymer-based films is challenging because they are volatile, water-insoluble, chemically unstable, matrix-incompatible, or adversely impact film properties [

14]. Nanoencapsulation of active agents can be used to overcome many of these problems [

15,

16]. In this case, the active agents are first incorporated into a well-designed nanoparticle, which is then introduced into the biopolymer-based packaging material.

2. Overview of Nanocarriers for Active Compounds

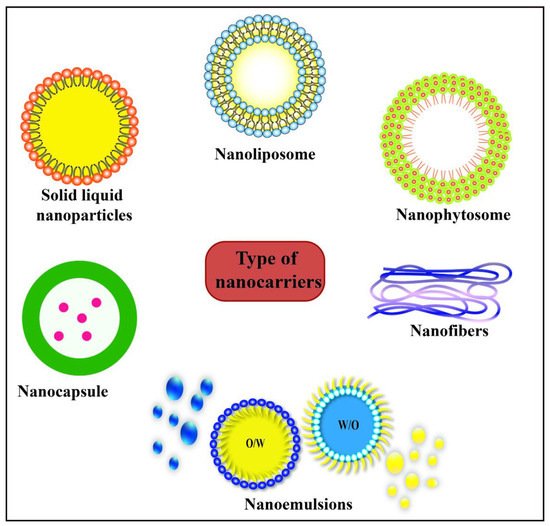

Numerous kinds of nanocarriers are available that could potentially be used to incorporate active agents into biopolymer-based packaging materials, including microemulsions, nanoemulsions, solid lipid nanoparticles, nanostructured lipid carriers, nanoliposomes, biopolymer nanoparticles, and nanogels (

Figure 1). Because nanocarriers based on proteins [

17], polysaccharides [

18], lipids [

19], and other food-grade polymers [

20,

21] have been reviewed in detail elsewhere, we only give a brief overview here. For food applications, nanocarriers constructed from natural organic substances are preferred because of their lower environmental impact and toxicity, such as those fabricated from proteins, polysaccharides, phospholipids, and/or lipids [

22]. In general, there are two main approaches for fabricating food-grade nanocarriers: top-down and bottom-up methods. Top-down methods involve the physical, chemical, or enzymatic disruption of macroscopic materials or large particles until they fall into the nanoscale range. Bottom-up methods typically involve the physical or chemical assembly of nanoparticles from molecules. The selection of a particular approach depends on the nature of the food product and the type of nanoparticles being produced. For example, bulk liquids can be broken down into nanoparticles by high pressure homogenization or microfluidization (top-down), whereas surfactant molecules will spontaneously assemble into nanoparticles due to the hydrophobic effect (bottom-up) [

21].

Figure 1. Types of nanocarriers for use in food packaging material.

Nanocarriers can be produced that exhibit a wide range of different particle characteristics, such as compositions (e.g., proteins, polysaccharides, phospholipids, lipids, and/or minerals), sizes (e.g., 1 nm to 1 µm), shapes (e.g., spherical, ellipsoid, rectangle, or fibrous), electrical charges (e.g., positive, negative, or neutral), surface hydrophobicities (e.g., polar to non-polar), interfacial thicknesses (e.g., thin to thick), surface chemistries (e.g., unreactive to reactive), physical state (e.g., solid or liquid), rheology (e.g., hard or soft), digestibility (e.g., digestible to indigestible), and biodegradability (e.g., degradable or not). Consequently, the packaging manufacturer must select ingredients and preparation methods that can be used to create the nanoparticle characteristics required to obtain specific functional performance. One of the main factors impacting the selection of a suitable nanocarrier is the nature of the active agent to be encapsulated. A few examples of different kinds of delivery systems are highlighted here. Biopolymer nanocarriers can be assembled from various kinds of proteins and polysaccharides such as casein, whey protein, lactoferrin, soy protein, zein, starch, alginate, carrageenan, and pectin [

17,

18]. These nanocarriers typically consist of small spherical particles that contain a network of aggregated biopolymer molecules inside. Nanogels can also be assembled from proteins and polysaccharides but they have a more porous structure inside that contains more water [

23]. Nanoliposomes can be assembled from different kinds of phospholipids, such as milk, egg, soy, or sunflower lecithin [

19]. These nanocarriers usually consist of one or more phospholipid bilayers assembled into concentric shells around an aqueous core. Nanoemulsions consist of emulsifier-coated fluid lipid droplets suspended in water and can be assembled from different kinds of emulsifiers and lipids [

21]. Solid lipid nanoparticles (SLN) and nanostructured lipid carriers (NLC) consist of emulsifier-coated solid fat particles that may be fully or partially crystalline, respectively [

24,

25]. Active agents may be incorporated into these nanocarriers before or after their fabrication. Once prepared the encapsulated active agents can then be incorporated into the food packaging materials to control their functional performance [

26]. The type of nanocarrier used for a specific food packaging application depends on numerous factors, including their loading capacity, encapsulation efficiency, stabilizing properties, light scattering/absorption properties, stability, interactions, and matrix compatibility. Each kind of nanocarrier has its unique advantages and disadvantages, which should be carefully considered. In the following section, we consider several active compounds that can be used to modulate the properties of packaging materials, with an emphasis on natural substances.

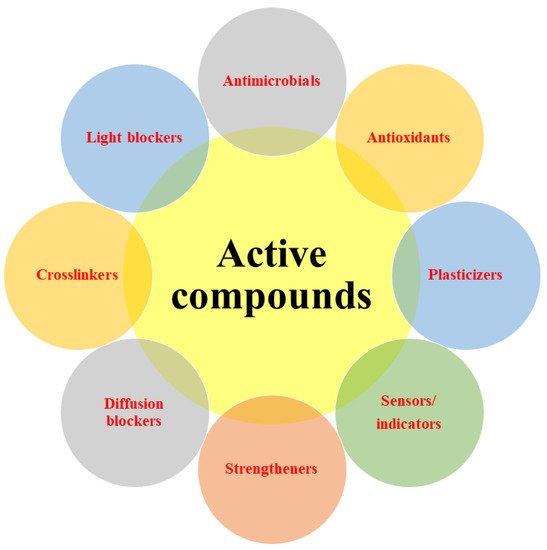

3. Active Compounds for the Production of Smart/Active Packaging Materials

The active compounds and agents that play an important role in improving the functional, mechanical, barrier, and structural properties of packaging films are presented in Figure 2.

Figure 2. Active compounds for the production of smart/active packaging materials.

3.1. Antimicrobials

Natural antimicrobials can be isolated from various kinds of plant-based materials, where they are often naturally produced by the plants as secondary metabolites to defend against microbial contamination [

27]. However, many of these antimicrobials are difficult to incorporate into biodegradable packaging materials because they are volatile, chemically unstable, and/or have low solubility in water. Consequently, they need to be encapsulated prior to utilization [

28]. Some of the most commonly used natural antimicrobials are essential oils and phytochemicals isolated from various kinds of plants [

29]. Studies have shown that essential oils exhibit good antimicrobial activity against a broad spectrum of foodborne pathogens, which has been related to their ability to disrupt microbial cell membranes and to interfere with key biochemical pathways inside the cells [

30]. As an example, thymol, eugenol, and cinnamaldehyde are essential oils that have been used in food packaging materials to control bacteria [

31]. The most widely used phytochemical in biodegradable packaging materials is curcumin, which is a polyphenolic compound. Numerous studies have shown that curcumin exhibits strong antimicrobial properties when incorporated into packaging materials [

32]. For antimicrobials, it is important that they can be incorporated into the packaging materials at a sufficiently high level, that they remain stable during storage, and that they can diffuse to the site of action (bacterial cell membranes) at a sufficiently high rate and level. The many other types of essential oils and phytochemicals that may be utilized as natural antimicrobials have been reviewed elsewhere [

33,

34,

35,

36].

3.2. Antioxidants

Many foods contain lipids or proteins that are susceptible to oxidation, which can reduce their shelf life, quality, and nutritional value [

37]. Antioxidants can be incorporated into biodegradable food packaging materials to inhibit oxidation reactions [

38]. There is increasing emphasis on the utilization of natural antioxidants for this purpose, especially plant-based ones. Like antimicrobials, many of these antioxidants are secondary metabolites that can be isolated from plant materials, such as essential oils and phytochemicals, which also have health effects [

39]. For instance, quercetin is a phytochemical that can be isolated from onions that exhibits strong antioxidant activity when incorporated into packaging materials [

10]. Similarly, many kinds of essential oils have also been shown to exhibit strong antioxidant properties when incorporated into packaging materials [

38]. As an example, oregano (which contains thymol and carvacrol) has been shown to have good antioxidant properties when used in packaging applications [

40]. The numerous kinds of essential oils and phytochemicals that can potentially be used as natural antioxidants have been reviewed in detail elsewhere [

41,

42,

43,

44,

45].

3.3. Light Blockers

Light blockers are compounds that can block light, thereby protecting food components from photodegradation [

46]. They may do this by scattering light waves (particles) and/or absorbing light waves (chromophores). Typically, there is a range of wavelengths where specific particles or chromophores are able to effectively block light. Many researchers are trying to increase the performance of food packaging materials by incorporating light blockers into them [

47]. These light blocks are especially important for preventing UV light waves from penetrating into foods and promoting oxidative damage [

48]. For example, bixin is a carotenoid found in annatto seeds (

Bixa orellana L.), which has been used in packaging materials due to its ability to absorb light [

49]. Many other natural substances exhibit the ability to absorb light at specific wavelengths, including proteins, carotenoids, and curcumin. In addition, nanoparticles can scatter light waves strongly in the UV region, which can help protect foods from photodegradation.

3.4. Plasticizers

Plasticizers are compounds used in biopolymer-based packaging materials to increase their flexibility and reduce their fragility [

50]. Plasticizers function by reducing the intermolecular attractive forces and increasing chain mobility in the biopolymer matrix [

51]. Polyols are often used as plasticizers in biopolymer films, such as glycerol, mannitol, sorbitol, and xylitol [

52]. Other active compounds that have numerous hydroxyl groups can also be used as plasticizers in these films. For instance, tannins have been shown to act as plasticizers in these films due to the high number of hydroxyl groups [

53].

3.5. Crosslinkers

The functional performance of biopolymer-based packaging materials, such as their mechanical, thermal, and barrier properties, can be improved by crosslinking the biopolymers [

54]. The efficacy of crosslinking depends on the nature of the crosslinking agents and biopolymers present, particularly their type and concentration [

55]. Crosslinks may involve physical interactions, such as electrostatic, hydrogen, hydrophobic, and van der Waals bonds, or covalent interactions such as disulfide bonds. A number of analytical methods can be used to characterize the bonds formed in biopolymer films, including X-ray diffraction, electrophoresis, Fourier transform infrared spectroscopy (FTIR), and nuclear magnetic resonance (NMR) spectroscopy [

56]. Some natural phytochemicals are able to crosslink proteins and polysaccharides through hydrophobic or hydrogen bonding. For example, catechins have been shown to crosslink methylcellulose-based biopolymer films [

57]. Crosslinking has been shown to improve the mechanical, stability, and barrier properties of biopolymer-based foods, thereby increasing their potential applications in foods [

58].

3.6. Diffusion Blockers and Film Strengtheners

The barrier and mechanical properties of biopolymer packaging materials can be increased by adding inorganic or organic nanomaterials, such as titanium dioxide (TiO

2), zinc oxide (ZnO), silver (Ag), nanocellulose, zein nanoparticles, starch nanoparticles, and other particulate substances [

59]. These nanomaterials are usually spheroids, cuboids, or fibers. Inorganic nanoparticles are mostly used to fill the pores in the structure of biopolymer matrices. For example, TiO

2-Ag nanoparticles were shown to fill in the pores in a gelatin matrix, which modulated the physicochemical properties of the gelatin films [

60]. Organic nanoparticles are often incorporated into packaging materials to increase the strength and cohesion of the biopolymer networks. For instance, chitin nanofibers have been used to strengthen methylcellulose films [

61]. Similarly, chitosan nanoparticles (CNPs) have been used to modulate the gas barrier properties, tensile strength, and thermal stability of biopolymer films [

62,

63]. The incorporation of silver nanoparticles into polylactic acid (PLA) films has been shown to increase biodegradation [

64].

3.7. Sensors/Indicators

Smart sensors/indicators are being developed for use in biodegradable food packaging materials to provide information about the quality, spoilage, and safety of food products [

65,

66]. Natural pigments, such as anthocyanins and carotenoids, are often used for this purpose [

67]. These pigments are selected because they change color in response to a specific environmental trigger, such as pH, oxygen exposure, temperature, or gas concentration. These natural pigments can often be extracted from plants and their by-products such as tomato peel, citrus fruit, potatoes, and soybean meal pulp. Anthocyanins change color in response to alterations in the pH of their environment, which are often indicative of changes in food quality or safety [

46,

68]. For instance, food spoilage often leads to the release of gases such as nitrogen, which changes the pH of the environment and leads to changes in the color of the pigments in the packaging materials, thus informing consumers about the status of the product [

69]. As an example, barberry anthocyanins have been incorporated into biodegradable films comprised of methylcellulose and chitosan nanofibers, which were useful for monitoring changes in the freshness of meat by changing color during storage [

12].

This entry is adapted from the peer-reviewed paper 10.3390/polym13244399