The efficient progress in nanotechnology has transformed many aspects of food science and

the food industry with enhanced investment and market share. Recent advances in nanomaterials

and nanodevices such as nanosensors, nano-emulsions, nanopesticides or nanocapsules are intended

to bring about innovative applications in the food industry. In this entry, the current applications of

nanotechnology for packaging, processing, and the enhancement of the nutritional value and shelf life of foods are targeted. In addition, the functionality and applicability of food-related nanotechnologies are also highlighted and critically discussed in order to provide an insight into the development and evaluation of the safety of nanotechnology in the food industry.

1. Introduction

Nanotechnology offers attractive opportunities in the food industry such as for food safety and quality control as well as the production of new food additives/supplements and other flavors [

1]. In the food industry, nanotechnology can also be used for the production of packages with enhanced thermal and/or mechanical properties and safety. Indeed, nanosensors embedded in food packaging systems are used to alert consumers when foods have expired. Nanotechnology can also be used to make healthier foods [

2]. The variety of nanostructures with diverse properties makes them suitable for addition to foods as well as in packaging products that enhance the nutritional quality of foods [

3]. Out of 633 available nanomaterials, 55 are exploited in agriculture and food sciences [

4]. A recent report pointed out that food products linked to nanotechnology will account for around 50% of total food products in 2020 [

5].

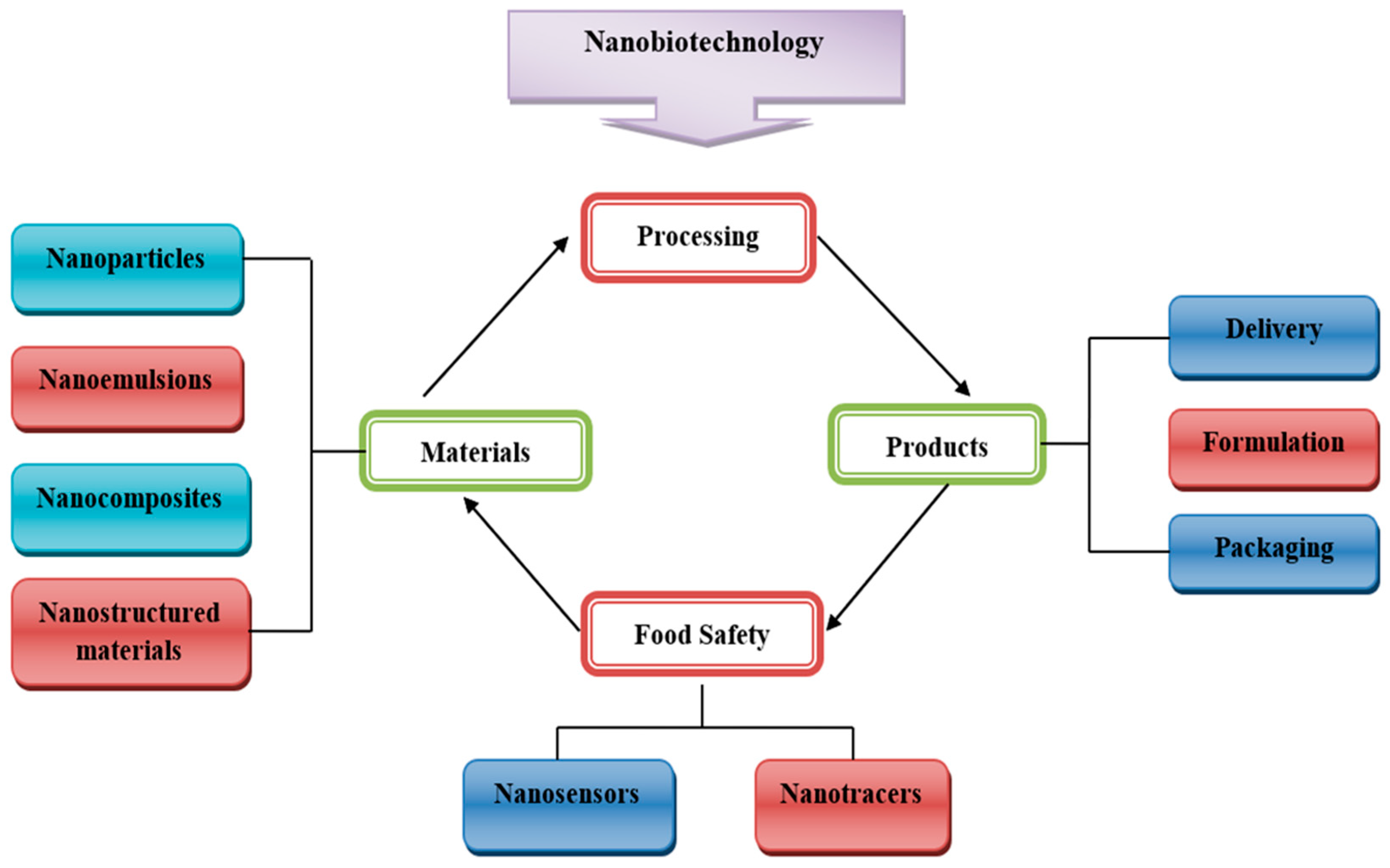

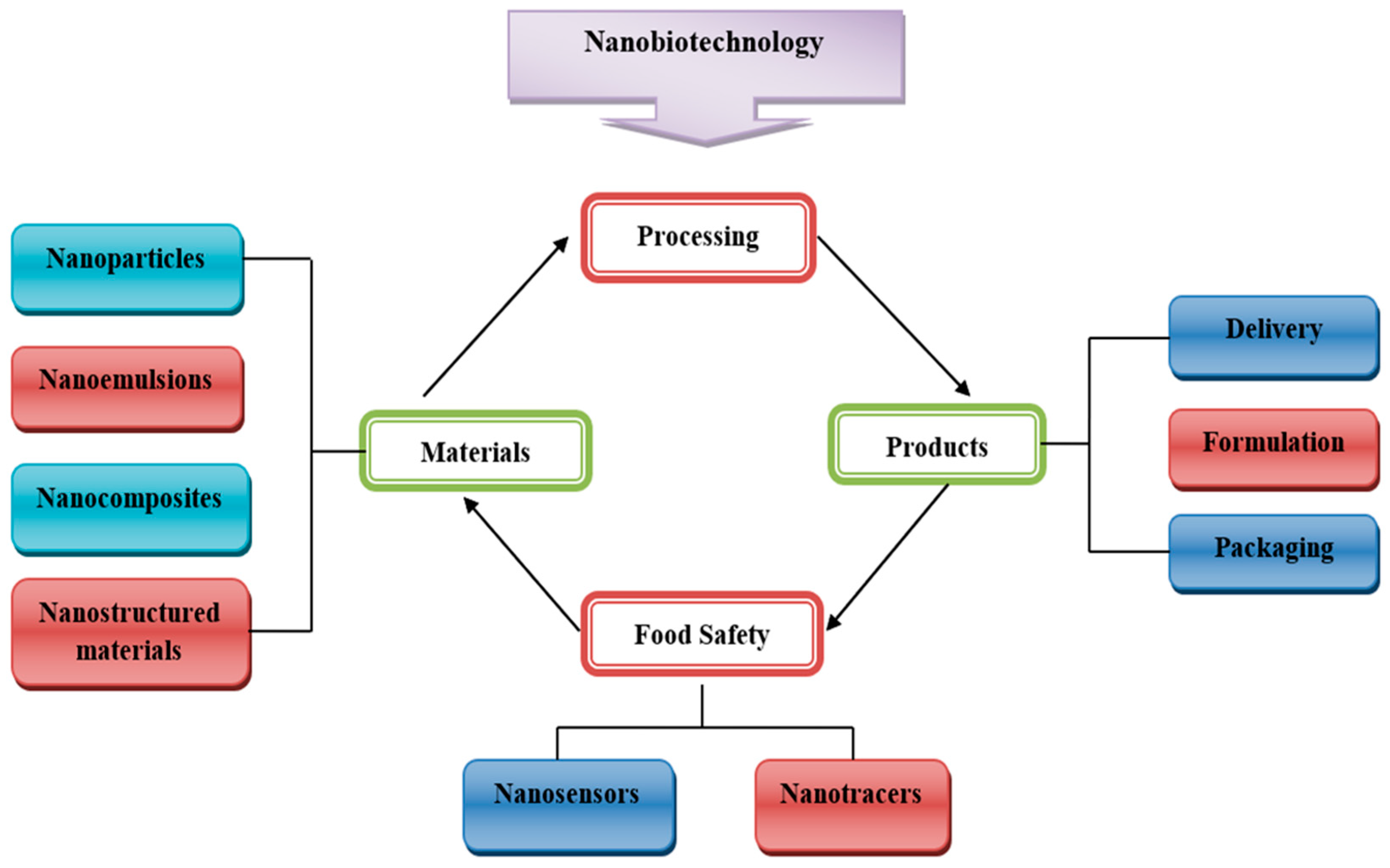

Undoubtedly, nanotechnology is revolutionizing the food industry. Most of the reported applications of nanostructures in food include (i) the improvement of food quality, (ii) bioactive fortification, (iii) controlled release of bioactive compounds using nanocarrier encapsulation, (iv) modification of food structures and textures, and (v) the detection and neutralization of biochemical, microbiological and chemical alterations using intelligent packaging systems (

Figure 1) [

6]. Different nanomaterials have vast applications in the formation of food products and the improvement of nutritional values. For example, protein nanoparticles are used in the manufacture of food products because protein solubility is helpful in the assembly of protein nanoparticles with preferred functional properties in food substances [

7].

Figure 1. Role of nanotechnology in various sectors of the food industry.

2. Different Aspects and Roles of Nanotechnology in the Food Industry

There is an increasing interest in nanotechnology in the food industry. Several applications have been reported in various dimensions, such as the targeted delivery of nutrients and/or bioactive molecules through nanoencapsulation, the use of biosensors to detect and quantify pathogens and alteration of food composition, or fruit and vegetable preservation by edible films (

Table 1) [

11].

Table 1. An overview of various applications of nanomaterials in the food industry.

| Nanomaterials |

Type of Nanomaterials |

Applications in Food Industry |

References |

| Nanoparticles |

Ag, ZnO, Mg, SiO2 |

Food packaging, oxidation of contaminant, anti-bacterial |

[12,13,14] |

| Nanosieves |

Specific nanoparticles |

Removal of pathogens or contaminants |

[15,16] |

| Nanocapsules |

Bioactive compounds |

Increased efficacy and water solubility, local and controlled release |

[17,18] |

| Nano-emulsions |

Tweens or spans; gum arabica or modified starch, soy, caseinate |

Food encapsulation, food processing, antimicrobial and storage, stability, colorant |

[19,20,21] |

| Nanospheres |

Starch nanosphere |

Food encapsulation, synthetic adhesives |

[22,23,24] |

| Nanosensors |

Aptasensors |

Detection of micro-organisms, food deterioration control |

[25,26,27] |

| Nanocochleates |

Coiled Nanoparticles |

Enhanced nutritional value of food, antioxidant, food protection and stability |

[28,29,30] |

| Nanocomposite |

Fe-Cr/Al2O3

Ni/Al2O3 |

Enhanced shelf life of food, food protection and food packaging |

[31,32,33] |

| Nanomicelles |

Aquanova, novasol |

Liquid carrier, enhanced solubility |

[34,35,36] |

In the food industry, production processes are enhanced by nanotechnology, which provides products with better characteristics as well as with new functionalities.

The use of nanotechnologies can be considered from the production phase, which allows a technical innovation in precision agriculture to improve plant growth, but also the detection of and/or resistance to pests and allelopathy. The nanoencapsulation of conventional fertilizers, pesticides and herbicides allows (i) a slower and longer release of nutrients for more efficient use, allowing the optimal growth of plants; while, for agrochemical products, (ii) it allows safer handling, more efficient usage and a more precise dosage of these compounds with less exposure to the environment, thus guaranteeing the better protection of the environment. In addition, the rapid and early detection of plant diseases based on nanotechnology is also attracting attention. The potential uses and benefits of nanotechnology in precision farming are discussed in detail by Anjum et al. [

38] and Duhan et al. [

39].

3. Nanosensors as Emerging Devices in the Food Industry

Nanosensors are bioanalytical devices that are developed by using various nanostructured materials and biological receptors in an integrated system design. Nanosensors play an important role in the food industry and have attracted much attention in recent times due to their quick detection capacity, integrity and cost-effectiveness [

87]. Nanosensors have the potential to be integrated with an array of analytes due to their high sensitivity and specificity. These devices have a high surface-to-volume ratio and excellent optical and electric properties due to conjugation with various types of nanomaterials such as carbon nanotubes, nanoparticles (metallic, non-metallic and metal oxide), semiconductor nanoparticles, nanorods, nanowires, nanobiofilms, nanofibers, and quantum dots [

88,

89]. Currently, nanosensors are being used in the detection of food-borne pathogens, adulterants, toxins, chemicals and pesticides which are present in different foodstuffs [

90]. They also used to monitor the freshness of food and food packaging integrity [

77]. Different types of techniques/methodologies such as cyclic voltammetry, surface plasmon resonance, differential pulse voltammetry, interdigitated array microelectrode-based impedance analysis, amperometry, flow injection analysis and bioluminescence are employed as nanobiosensing tools to rapidly and accurately detect different pathogens, toxins and adulterants present in foods [

91,

92,

93,

94,

95].

4. Nanomaterials and Devices in Food Safety

In the food industry, the safety of food products is an important issue. According to a recent survey, more than 45% of processed and packaged food items are prone to degradation and contamination [

185]. Nanotechnology has played a positive role in solving various issues related to the quality and safety of food products [

171]. Currently, different types of nanomaterials and nanodevices such as polymeric nanoparticles, liposomic nanovesicles, nanoloaded emulsions and temperature–time indicators are used for the improvement of the quality of food by increasing shelf life, sensing freshness, and detecting chemical, heavy metal, and allergen contamination in food items [

186,

187,

188]. Different nanosensors and nanotracers conjugated with various nanomaterials such as gold nanoparticles, silicon nanorods, magnetic beads, quantum dost, single-walled and multi-walled carbon nanotubes, immunomagnetic liposomes, aptamer conjugated gold, and palladium nanoparticles are also highly efficient in detecting various contaminants and degradants that influence the quality of food [

126,

189,

190]. Additionally, the newly developed radio frequency identification technique (RFID) is found to be well suited for numerous operations in food engineering and supply chain supervision due to its speed and effectiveness [

191]. RFID technology may also deliver safety and security improvements for food corporations by tracing the source of contaminants in various food products [

192].

5. Safety Issues of Nanomaterials in the Food Industry

As is well known, the use of various nanomaterials in the food industry has numerous advantages; however, at the same time, they also pose serious threats to human health, the environment, and other ecosystems due to their cytotoxic effects [

219,

220,

221,

222,

223,

224,

225,

226,

227,

228]. Some serious concerns have arisen recently regarding the use of nanomaterials, even those with no toxic element in their composition, but they have an inherent potential risk due to their small size and subcellular interaction with cells [

229]. For example, some nanoparticles have the ability to penetrate within skin and cause health problems in humans as well as in animals. Nanoparticles can cause genomic and proteomic changes even in plants and can affect their growth rate [

230]. Experimental studies have shown that single and multi-walled carbon nanotubes can induce fibrosis as well as oxidative stress in the lungs of models animals such as mice and rats [

231].

The bioaccumulation of nanomaterials derived from either nanopackaging or nanoprocessed items has been confirmed in food and human beings [73]. Therefore, the risk assessment procedures must be strictly followed while processing food items [74,75]. Even with the advent of nanotechnology, the challenges to the development of a healthy and sustainable food industry remain obscure. With the intervention of nanotechnology in the food industry, the public should be educated regarding the possible risks associated with nanomaterials to human health and the environment. Several EU and non-EU countries have designed several regulatory frameworks for dealing with nanomaterials to ensure the safety of nanoproducts in feed, agriculture and food sectors [236]. Additionally, supervisory authorities such as the FDA and Environmental Protection Agency (EPA) have made several amendments to various criteria intended for marketable foodstuffs in terms of health and the quality and safety of products [237].

This entry is adapted from the peer-reviewed paper 10.3390/foods9020148