Hollow fiber membranes (HFMs) are a good candidate for the membrane separation process due to desirable properties such as high permeability and surface area, good filtration efficiency, small footprint, etc. However, they are often possible to break during the high-pressure cleaning and aeration process. Tubular braids a supported is proposed to improve the mechanical strength of HFMs due to high tensile strength.

1. Introduction

Membrane technology, including polymeric membranes, is one of the best-advanced separation and treatment systems that have been widely used in different applications such as desalination, wastewater treatment, oil/water separation, and water reuse applications [1,2]. Hollow fiber membranes (HFMs) possess desired and competitive advantages relative to flat-sheet membranes for many membrane separation applications due to high membrane surface area per volume of a module (e.g., the ratio of area per volume is reported 40 m 2/m 3 for flat sheet and 170 m 2/m 3 for HFMs [3]). They also have high permeability and porosity, desirable filtration efficiency, proper mechanical properties, self-supported structure and characteristics, small footprint, high packing density relative to other configurations, ease of handling and maintenance [4,5,6,7,8,9,10,11,12]. Due also to the spacer-free module, the assembly cost will be reduced. Hollow fiber membranes had been widely used for microfiltration and ultrafiltration alone or as the pretreatment of nanofiltration and reverse osmosis in seawater desalination, forward osmosis, and membrane bioreactor to the treatment of industrial wastewater (such as medicine, food, and textiles) and generation of drinking water. Hollow fiber membranes are often possible to break or damage during high-pressure cleaning, module preparation, aeration process. It is due to sponge-like and asymmetric finger-like morphology that led to making brittle and porous structures. Hence, their lifetime may reduce despite their many advantages [4,11,13].

In order to design membrane structure, lifetime prediction and reliability, understanding, and analysis is important to evaluate the mechanical behavior under actual operating conditions. Mechanical abrasion of membranes arising from physical and chemical damage by harsh feed water, fouling, chemical cleaning, and back-washing bring about the reduction in membrane strength [4,14]. Generally, the mechanical properties of polymeric flat sheet membranes are improved by a polyester support layer. The nonwoven polyester possesses strong mechanical strength can tolerate vigorous hydraulic impact [15,16,17,18,19]. Hosseini et al. [15] utilized polyester support in order to improve the mechanical strength in high pressure. Recently, using tubular braid (or threads/fabric) as reinforced support is proposed to improve the mechanical strength of hollow fiber membranes. Braid-reinforced hollow fiber membranes have attracted attention and interest due to their low cost, efficient separation, relatively simple preparation, and high mechanical properties [6,7,11,20,21]. This type of hollow fiber membrane possesses a supreme tensile strength (contributes to the long lifetime of the membranes), and thus they could apply under higher pressure conditions relative to common hollow fiber membranes. A braid hollow fiber membrane (BHFM) is fabricated by coating a thin film on the surface of tubular braid (i.e., reinforced fiber). The presence of braid support increases the flux of ultrafiltration/microfiltration due to the thinner thickness of the selective layer, thanks to tolerating relatively higher pressure compared with the typical HFM [4,21,22,23,24]. The first studies in reinforced HFMs are related to the patents. Cooper et al. [25] introduced the concept of braided membrane for the first time. They cast the membrane on a supporting surface such as fabric-like material consisting of monofilament material (e.g., polyesters, nylon, rayon, polyolefin, Teflon, acrylic) with a small diameter. Zenon Environmental Inc. produced a type of hollow fiber membrane consisting of tubular macro-porous support and a tubular semipermeable thin film of the polymer. The prepared braid hollow fiber membrane could endure to 10.3 MPa in hydraulic compaction forces [26].

The peeling of the surface layer from the tubular braid is the drawback of the braid hollow fiber membranes due to thermodynamic incompatibility between these two layers [21]. The braid hollow fiber membrane can significantly enhance the effective area due to fewer sticking fibers together in the assembled module [27]. The braid support absorbs the molecules of water due to the porous structure. The thin separation layer of the BHFM also contributed to the water flux enhancement because of lower thickness compared to self-support HFMs [24]. Chen et al. [28] reported that the flux of braid PMIA- BHFMs was higher than the PMIA-HFMs. It is due to the PMIA-BHFMs containing an inner layer with a relatively porous structure that leads to a reduction in membrane resistance for water transfer. The BHFMs with the dense outer surface can prevent the adsorption of foulants and the pore-blockage in the inner pores of the membrane. Therefore, the occurred fouling is forming the cake layer type, can easily remove by washing, while the open pores of the HFM easily adsorbed the molecules of protein. In this case, the pores of the membrane will be blocked. This type of fouling is irreversible and hardly eliminated through water washing. Therefore, the case of irreversible fouling required a combination of chemical cleaning and back-washing [29].

2. Applications of Hollow Fiber Membranes

Hollow fiber membranes are desirable for numerous membrane applications. They are favored for use in water treatment processes due to the desirable properties mentioned above [

9]. Submerged membrane bioreactor is usually utilized to remove common pollutants from municipal and industrial wastewater because of many advantages such as high-quality effluent, low sludge production, and reduced footprint. The module can be prepared by the flat sheet or hollow fiber membranes, but the HFMs have been more widely used due to easy assembling and high permeability per installation area. However, HFM in the submerged MBR is required high mechanical properties because of easily broken during the high-pressure back-washing and cleaning process or aerated airflow [

37,

40,

58]. Fan et al. [

37] investigated the BHFM in the MBR process. The tensile strength of prepared BHFMs was higher than 11 MPa, which this content increased with the increase in polymer concentration in dope solution.

Generally, the hollow fiber membranes are not applicable in high-pressure applications such as NF and RO processes because of their poor mechanical strength. Whereas they are good candidates for wastewater treatment, removal of heavy metals, and drinking water purification [

10,

15,

51]. Thin-film composite (TFC) membranes are excellent candidates for RO and NF processes in water and wastewater treatment applications due to the ultrathin selective layer. The TFC design possesses desired performance in terms of salt rejection and permeability when united with asymmetric membranes. The cross-linked aromatic polyamide as a selective layer on the ultrafiltration membrane porous or other supporting substrates fabricated by interfacial polymerization of proper monomer (e.g., trimesoyl chloride (TMC)) is the most successful and famous commercial product in the last decades [

10,

50,

59]. As mentioned, TFC membranes consist of a support layer and selective layer. The selective layer that typically cross-linked polyamide is a thin, dense, and poor mechanical film with high selectivity. The second layer is a porous film that plays the role of the substrate with high mechanical strength under pressure. This layer generally is formed from polyethersulfone and polysulfone.

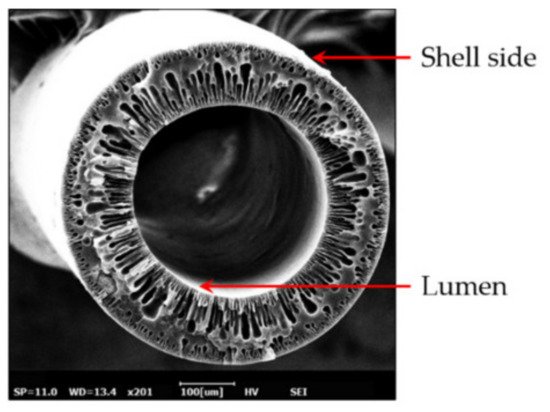

Figure 11 illustrates the shell and lumen side of HFM. Generally, it is difficult to apply a thin film on the shell or lumen side of the HFM during fiber manufacturing. The HFMs designed for liquid filtration have large lumens due to reducing resistance in mass transfer and pressure drop liquid stream. In high-pressure applications, the walls of HFMs must be thicker, but it is not desirable for liquid flow applications. It is reported several studies on the fabrication of HFM with high-pressure tolerance and improvement of mechanical stability. These studies propose using a polymer/additive with intrinsic high mechanical strength, optimization of spinning parameters, and braid reinforced composition [

10,

60]. Xia et al. [

10] fabricated a TFC-HFM that uses a braid-reinforced ultrafiltration-HFMs as a substrate, consisting of a PVDF coating layer and polyester braid. The selective layer is formed using interfacial polymerization of TMC and piperazine (PIP). The presence of the reinforced support devoted high-pressure endurance proprieties to the HFM. The prepared membranes could tolerate pressure up to 0.5 MPa while possessing high selectivity for divalent/monovalent ions. Turken et al. [

51] fabricated reinforced TFC-HF NF based on PSf ultrafiltration membranes and polyamide layer prepared from PP and TMC monomers. The membranes were investigated in solutions with different organic matter and salts. Their results evidenced the prepared membranes are a good candidate for water-treatment applications.

Figure 11. The illustration of shell and lumen side of an HFM [

61].

Another application of BHFMs is the oil/water separation process. Oily wastewater is produced by different industries such as metal finishing industries, leather, food, petrochemical, oil exploration, refining, and transportation of oil products. This type of wastewater is a severe threat to human health and the environment. Membrane technology is a proper option for oily wastewaters treatment owing to advantages such as low costs, no secondary pollution, high energy efficiency, sustainability, and no additives. Two parameters are essential for the oil/water separation process: the selective wettability for oil or water (lipophilicity/hydrophobicity) that provide the required driving force and the connected pores with a suitable pore size for filtration. Both hydrophobic and hydrophilic membranes could be utilized for the separation of oil/water. Hydrophilic membranes increase the water permeation relative to oil permeation leading to higher water flux and good antifouling properties. Nevertheless, the hydrophilic membranes must provide a large volume of water permeate fluxes in separations of oil/water. They required high energy consumption and large membrane areas. Generally, the present pollutants in oily wastewater are mainly due to the oil phase, but their contents are relatively low. Therefore, hydrophobic membranes are better candidates for oily wastewater treatment based on workload [

38,

43]. Hao et al. [

38] prepared (PET-) braid-reinforced PVDF/graphene hollow fiber membranes. PVDF-BHFM shows appropriate hydrophobic properties for oil/water separation and good mechanical strength. Graphene was also used to enhance the hydrophobicity of the membrane. Their results showed that the prepared hydrophobic BHFMs ultimately rejected water during the separation process.

3. Conclusions

Hollow fiber membranes (HFMs) are a good candidate for the membrane separation process due to desirable properties such as high permeability and surface area, good filtration efficiency, small footprint, etc. However, they are often possible to break during the high-pressure cleaning and aeration process. Tubular braids a supported is proposed to improve the mechanical strength of HFMs due to high tensile strength. The peeling of the surface layer from the tubular braid is the drawback of the BHFM due to thermodynamic incompatibility. Depending on the type of application, the kind of polymer/additive and their content are the essential parameters that affect the performance of BHFMs. PAN, PVC, CA, PSf, and PVDF are the common polymers used in BHFM preparation. The interfacial bonding strength between the braid and the separation layer is an essential issue in BHFMs. Because the separation of two layers reduces its lifetime and limits its application; hence, the affinity between the two layers will be improved. The interfacial bonding strength between the braid and the separation layer is an essential issue in BHFMs. Hence, the affinity between the two layers will be improved by hybrid braids, alkaline pretreatment, and the use of additives. Recently, the BHFMs have been used in RO and NF applications. Although it is required a comprehensive investigation that optimizes the membrane performance in terms of flux, mechanical properties, rejection, and fouling; it is expected that the applications of these types of the membrane will be enhanced in different aspects and the gap between studies and apply in large scales would be reduced.

This entry is adapted from the peer-reviewed paper 10.3390/membranes11110884