Innovations related to textiles-based sensors have drawn great interest due to their outstanding merits of flexibility, comfort, low cost, and wearability. Textile-based sensors are often tied to certain parts of the human body to collect mechanical, physical, and chemical stimuli to identify and record human health and exercise. Until now, much research and review work has been carried out to summarize and promote the development of textile-based sensors. As a feature, we focus on textile-based mechanical sensors (TMSs), especially on their advantages and the way they achieve performance optimizations

- textile-based mechanical sensors

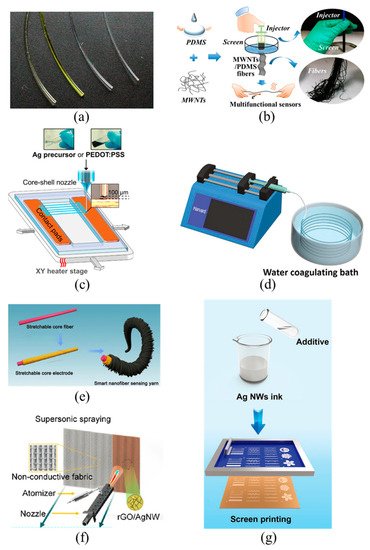

1. Resistive Sensor

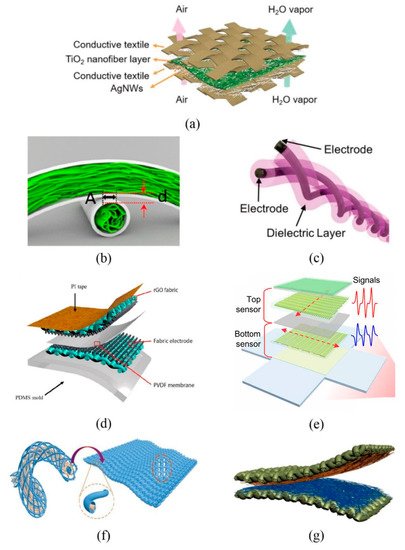

2. Capacitive Sensor

3. Piezoelectric Sensor

4. Triboelectric Sensor

This entry is adapted from the peer-reviewed paper 10.3390/ma14206073

References

- Pizarro, F.; Villavicencio, P.; Yunge, D.; Rodríguez, M.; Hermosilla, G.; Leiva, A. Easy-to-build textile pressure sensor. Sensors 2018, 18, 1190.

- Gong, Z.; Xiang, Z.; OuYang, X.; Zhang, J.; Lau, N.; Zhou, J.; Chan, C.C. Wearable fiber optic technology based on smart textile: A review. Materials 2019, 12, 3311.

- El Gharbi, M.; Fernández-García, R.; Ahyoud, S.; Gil, I. A review of flexible wearable antenna sensors: Design, fabrication methods, and applications. Materials 2020, 13, 3781.

- Neves, A.I.; Rodrigues, D.P.; de Sanctis, A.; Alonso, E.T.; Pereira, M.S.; Amaral, V.S.; Melo, L.V.; Russo, S.; de Schrijver, I.; Alves, H. Towards conductive textiles: Coating polymeric fibres with graphene. Sci. Rep. 2017, 7, 4250.

- Li, Y.; Zheng, C.; Liu, S.; Huang, L.; Fang, T.; Li, J.X.; Xu, F.; Li, F. Smart glove integrated with tunable MWNTs/PDMS fibers made of a one-step extrusion method for finger dexterity, gesture, and temperature recognition. ACS Appl. Mater. Interfaces 2020, 12, 23764–23773.

- Wang, W.; Ouaras, K.; Rutz, A.L.; Li, X.; Gerigk, M.; Naegele, T.E.; Malliaras, G.G.; Huang, Y.Y.S. Inflight fiber printing toward array and 3D optoelectronic and sensing architectures. Sci. Adv. 2020, 6, eaba0931.

- Sheng, N.; Ji, P.; Zhang, M.; Wu, Z.; Liang, Q.; Chen, S.; Wang, H. High sensitivity polyurethane-based fiber strain sensor with porous structure via incorporation of bacterial cellulose nanofibers. Adv. Electron. Mater. 2021, 7, 2001235.

- Qi, K.; Zhou, Y.; Ou, K.; Dai, Y.; You, X.; Wang, H.; He, J.; Qin, X.; Wang, R. Weavable and stretchable piezoresistive carbon nanotubes-embedded nanofiber sensing yarns for highly sensitive and multimodal wearable textile sensor. Carbon 2020, 170, 464–476.

- Liu, R.; Li, J.; Li, M.; Zhang, Q.; Shi, G.; Li, Y.; Hou, C.; Wang, H. MXene-coated air-permeable pressure-sensing fabric for smart wear. ACS Appl. Mater. Interfaces 2020, 12, 46446–46454.

- Kim, T.; Park, C.; Samuel, E.P.; An, S.; Aldalbahi, A.; Alotaibi, F.; Yarin, A.L.; Yoon, S.S. Supersonically sprayed washable, wearable, stretchable, hydrophobic, and antibacterial rGO/AgNW fabric for multifunctional sensors and supercapacitors. ACS Appl. Mater. Interfaces 2021, 13, 10013–10025.

- Luo, C.; Tian, B.; Liu, Q.; Feng, Y.; Wu, W. One-step-printed, highly sensitive, textile-based, tunable performance strain sensors for human motion detection. Adv. Mater. Technol. 2020, 5, 1900925.

- Duan, L.; D’hooge, D.R.; Cardon, L. Recent progress on flexible and stretchable piezoresistive strain sensors: From design to application. Prog. Mater. Sci. 2020, 114, 100617.

- Chen, L.; Lu, M.; Yang, H.; Salas Avila, J.R.; Shi, B.; Ren, L.; Wei, G.; Liu, X.; Yin, W. Textile-based capacitive sensor for physical rehabilitation via surface topological modification. ACS Nano 2020, 14, 8191–8201.

- Ferri, J.; Llinares Llopis, R.; Moreno, J.; Ibañez Civera, J.; Garcia-Breijo, E. A wearable textile 3D gesture recognition sensor based on screen-printing technology. Sensors 2019, 19, 5068.

- Keum, K.; Eom, J.; Lee, J.H.; Heo, J.S.; Park, S.K.; Kim, Y.-H. Fully-integrated wearable pressure sensor array enabled by highly sensitive textile-based capacitive ionotronic devices. Nano Energy 2021, 79, 105479.

- Fu, M.; Zhang, J.; Jin, Y.; Zhao, Y.; Huang, S.; Guo, C.F. A highly sensitive, reliable, and high-temperature-resistant flexible pressure sensor based on ceramic nanofibers. Adv. Sci. 2020, 7, 2000258.

- Guan, F.; Xie, Y.; Wu, H.; Meng, Y.; Shi, Y.; Gao, M.; Zhang, Z.; Chen, S.; Chen, Y.; Wang, H. Silver nanowire-bacterial cellulose composite fiber-based sensor for highly sensitive detection of pressure and proximity. ACS Nano 2020, 14, 15428–15439.

- Zhang, Q.; Wang, Y.L.; Xia, Y.; Zhang, P.F.; Kirk, T.V.; Chen, X.D. Textile-only capacitive sensors for facile fabric integration without compromise of wearability. Adv. Mater. Technol. 2019, 4, 1900485.

- Tan, Y.; Yang, K.; Wang, B.; Li, H.; Wang, L.; Wang, C. High-performance textile piezoelectric pressure sensor with novel structural hierarchy based on ZnO nanorods array for wearable application. Nano Res. 2021, 1–8.

- Hong, Y.; Wang, B.; Lin, W.; Jin, L.; Liu, S.; Luo, X.; Pan, J.; Wang, W.; Yang, Z. Highly anisotropic and flexible piezoceramic kirigami for preventing joint disorders. Sci. Adv. 2021, 7, eabf0795.

- Zhang, X.; Wang, J.; Xing, Y.; Li, C. Woven wearable electronic textiles as self-powered intelligent tribo-sensors for activity monitoring. Glob. Chall. 2019, 3, 1900070.

- Guo, Y.; Zhang, X.-S.; Wang, Y.; Gong, W.; Zhang, Q.; Wang, H.; Brugger, J. All-fiber hybrid piezoelectric-enhanced triboelectric nanogenerator for wearable gesture monitoring. Nano Energy 2018, 48, 152–160.

- Li, J.; Fang, L.; Sun, B.; Li, X.; Kang, S.H. Recent progress in flexible and stretchable piezoresistive sensors and their applications. J. Electrochem. Soc. 2020, 167, 037561.

- Zhang, C.; Fan, W.; Wang, S.; Wang, Q.; Zhang, Y.; Dong, K. Recent progress of wearable piezoelectric nanogenerators. ACS Appl. Electron. Mater. 2021, 3, 2449–2467.

- Park, C.; Kim, H.; Cha, Y. Fiber-based piezoelectric sensors in woven structure. In Proceedings of the 2020 17th International Conference on Ubiquitous Robots (UR), Kyoto, Japan, 22–26 June 2020; pp. 351–354.

- Wen, D.-L.; Liu, X.; Deng, H.-T.; Sun, D.-H.; Qian, H.-Y.; Brugger, J.; Zhang, X.-S. Printed silk-fibroin-based triboelectric nanogenerators for multi-functional wearable sensing. Nano Energy 2019, 66, 104123.

- Jeon, S.-B.; Kim, W.-G.; Park, S.-J.; Tcho, I.-W.; Jin, I.-K.; Han, J.-K.; Kim, D.; Choi, Y.-K. Self-powered wearable touchpad composed of all commercial fabrics utilizing a crossline array of triboelectric generators. Nano Energy 2019, 65, 103994.

- Zhu, M.; Shi, Q.; He, T.; Yi, Z.; Ma, Y.; Yang, B.; Chen, T.; Lee, C. Self-powered and self-functional cotton sock using piezoelectric and triboelectric hybrid mechanism for healthcare and sports monitoring. ACS Nano 2019, 13, 1940–1952.

- Liu, J.; Gu, L.; Cui, N.; Xu, Q.; Qin, Y.; Yang, R. Fabric-based triboelectric nanogenerators. Research 2019, 2019, 1091632.

- Liu, L.; Shi, Q.; Sun, Z.; Lee, C. Magnetic-interaction assisted hybridized triboelectric-electromagnetic nanogenerator for advanced human-machine interfaces. Nano Energy 2021, 86, 106154.

- Chen, G.; Au, C.; Chen, J. Textile triboelectric nanogenerators for wearable pulse wave monitoring. Trends Biotechnol. 2021, 39, 1078–1092.

- Fan, W.; He, Q.; Meng, K.; Tan, X.; Zhou, Z.; Zhang, G.; Yang, J.; Wang, Z.L. Machine-knitted washable sensor array textile for precise epidermal physiological signal monitoring. Sci. Adv. 2020, 6, eaay2840.