Due to its characteristics, fresh fish is a highly perishable food with a very short shelf-life under refrigeration. Several methods have been introduced to slow down its deterioration, such as by means of oxygen depletion of the food package (vacuum packaging), or by changing the natural atmosphere that is in contact with the fresh fish (modified atmosphere packaging), or by the use of chemicals generally recognized as safe: such compounds can be directly applied (by dipping or spraying) or incorporated into packaging materials and slowly migrate to the product, exerting a hurdle effect against microbial development and lipid oxidation (active packaging).

1. Introduction

Fish is a highly consumed and nutritious food with a high protein and low saturated fat content, and is a source of high quality polyunsaturated fatty acids (PUFAs), such as omega-3 (DHA—docosahexaenoic acid and EPA—eicosapentaenoic acid, for example) that are truly relevant for cardiovascular disease prevention and exhibit anti-inflammatory properties

[1][2]. Due to their nutritional characteristics and composition, fish products are highly perishable foods. Their degradation, coupled with economic pressures, results in large quantities of product waste which, even with increased public awareness and investment from organizations, leads to over 20% of the annual production of fish products not being consumed

[3].

Fish is increasing in popularity mostly as a fresh product due to the convenience for subsequent preparation and cooking, but it can easily deteriorate due to its elevated water content, postmortem pH, and the presence of small molecules (free amino acids) which make it extremely vulnerable to bacterial and chemical spoilage.

Fish spoilage combines different processes such as enzymatic autolysis, oxidation, and microbial growth and it depends on intrinsic characteristics such as the activity of endogenous enzymes, initial bacterial composition, muscle tissue fragility and extrinsic factors related to water quality, aquaculture practices, food handling and packaging, storage, and transportation conditions, among others. These lead to changes in odor, flavor, and texture mainly because of drip loss, discoloration, protein degradation, nucleotide decomposition, accumulation of nitrogenous compounds, and lipid and protein oxidation

[2][4]. Furthermore, besides spoilage bacteria, the growth of pathogenic microorganisms is a cause of concern. Fish-associated foodborne illnesses have been linked to a variety of viruses, bacteria, and parasites

[5].

Some chemical quality indicators are used to assess the extension of fish spoilage, such as the total volatile basic-nitrogen (TVB-N) and trimethylamine-nitrogen (TMA-N), thiobarbituric acid (TBA) value, and the presence of biogenic amines (histamine, cadaverine, tyramine and putrescine) produced by the decarboxylation of specific free amino acids by the action of microorganisms

[6][7]. TVB-N includes the measurement of volatile basic nitrogenous compounds such as trimethylamine (TMA), dimethylamine (DMA), and ammonia (NH

3) which are produced by bacteria, from the action of enzymes, or from the deamination of amino acids

[8][9][10]. The proposed value of TVB-N for spoilage initiation is 30–35 mg N/100 g; however, some studies present lower levels depending on the fish species

[9][10][11]. TMA-N is produced by bacterial spoilage and enzymatic activity and the decomposition of TMA-N-oxide (major constituent of non-protein nitrogen fraction) is responsible for the fishy odor. Values of 10–15 mg TMA-N/100 g are considered the upper limit for spoilage acceptance, but lower limits are also suggested by other authors

[8][9][10]. Regarding lipid oxidation, it is the TBA value that measures the malondialdehyde (MDA) content, which is formed by the reaction with hydroperoxides. Quality values range between 2–4 mg MDA/kg, but this value might not reflect the actual rate of lipid oxidation because MDA can interact with other components

[9].

Fish is usually stored under refrigeration, presenting a very short shelf-life, or under freezing conditions, exhibiting a longer shelf-life but losing important quality properties

[12]. In fact, storage under −18 °C is the most effective and common method used, but this preservation technique leads to ice crystals formation that damages the muscle structure. In addition, thawing prior to cooking is a time-consuming process

[4].

For this reason, the development of innovative approaches for shelf-life extension became inevitable, always with the goal of achieving the best sensorial and nutritional quality and safety.

Fish can also be packaged under vacuum or under modified atmosphere, as these food packaging methodologies have been used to preserve the quality of foods, slowing down its deterioration until consumption. Packaging is used for protection from the external environment, communication, convenience for an easier handling of the product, and containment for different sized and shaped products to optimize the logistic process

[13]. Both vacuum-packaging (VP) and modified atmosphere packaging (MAP) have essentially remained unchanged since they were introduced, at the beginning of the last century, and are well-established in the food industry. Nevertheless, increasing concerns regarding food quality control and preservation have led to a new role for packages: the extension of shelf-life

[13][14].

Several preservation strategies have been evaluated, considering a minimal impact on fish texture. These strategies rely on the application of additional hurdles prior to refrigerated storage, such as natural extracts (with antimicrobial and/or antioxidant properties) or active packages, to reduce microbial loads to acceptable levels and reduce degradation reactions to increase the shelf-life of fresh fish. Chemicals such as organic acids or ozone are, by far, the most frequently used hurdles to inhibit microbial growth in foods

[15]. However, they are being replaced by alternatives perceived as more natural, such as extracts from plants and algae, or bacteriocins from bacteria.

Nowadays, there are more advanced food packaging techniques available such as active and interactive and smart/intelligent packaging, characterized by the interaction between the packaging system and the food product, which react to biochemical changes in food andcan monitor the quality of products, proving visual information to the consumer about the products quality state, for example through a color system

[16][17]. Therefore, the new food packaging is characterized by the interaction between the food and the internal packaging environment

[16], while traditional packaging is characterized by an inert physical barrier between the food and the external environment.

2. Chemical Methodologies for Shelf-Life Extension

Nowadays, the shelf-life, food safety, quality, and nutritional composition of foods are the most important parameters for consumers, who are looking for increasingly natural, sustainable, fresh, and tasty foods

[18]. VP and MAP technologies are two of the most well-established preservation technologies for fishery products and are characterized by the removal of oxygen in order to slowdown microbial proliferation and oxidative reactions

[12][18][19]. Active packaging (AP) is also a packaging technology, but it interacts directly with food, such as fresh fish, in order to preserve the quality and extend its shelf-life, instead of being just an inert barrier that separates it from the external environment. Additionally, it is important to note that these preservation methodologies still need chilled storage.

2.1. Conventional Packaging: Vacuum-Packaging and Modified Atmosphere Packaging

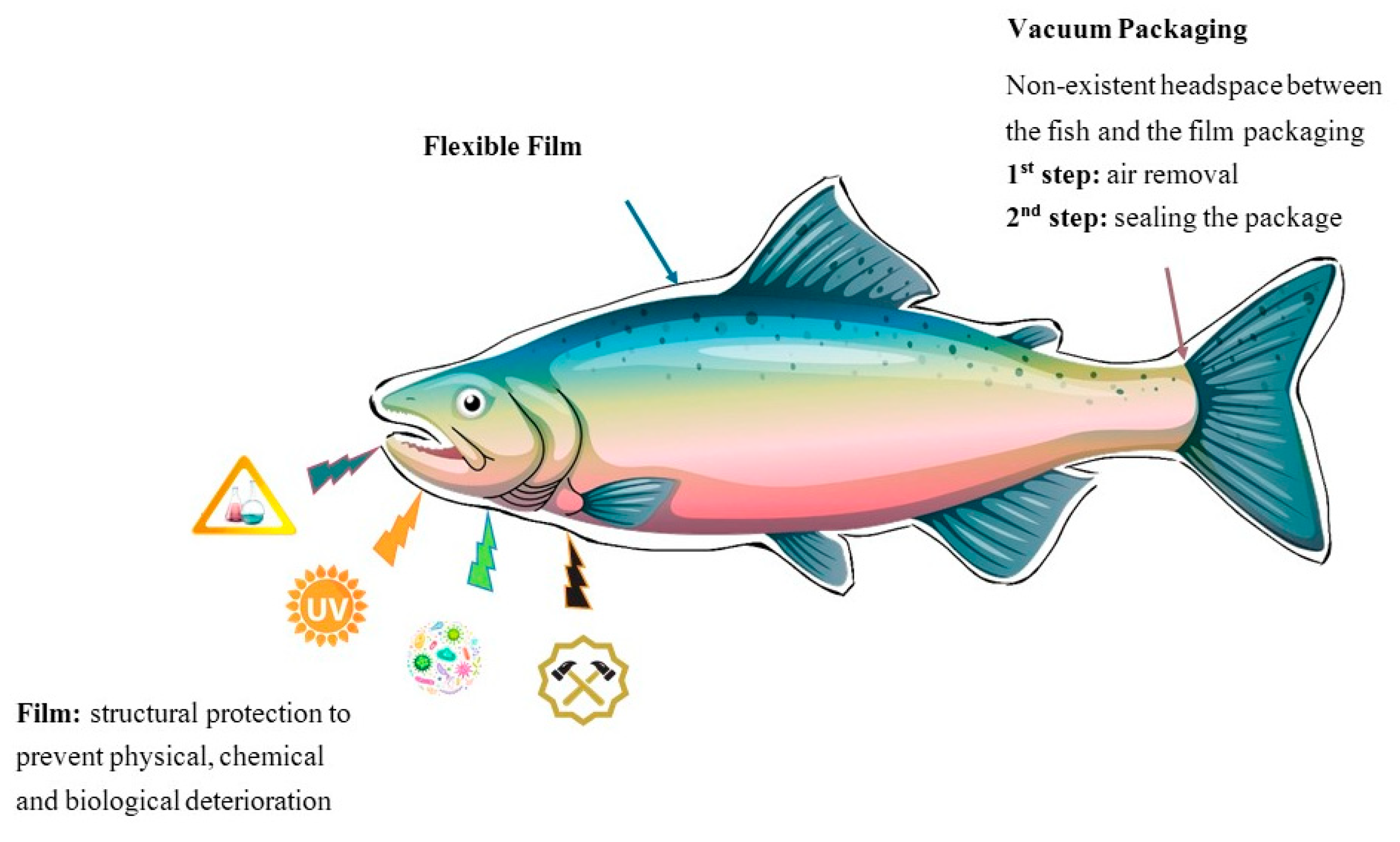

The concept of VP consists of removing the air from a package containing the product and sealing it immediately. It separates the product from the external environment, limits the package volume and prevents oxidative spoilage if the films used have oxygen (O

2) barriers

[19]. For these reasons, this low-cost technique is commonly used in the food industry

[20].

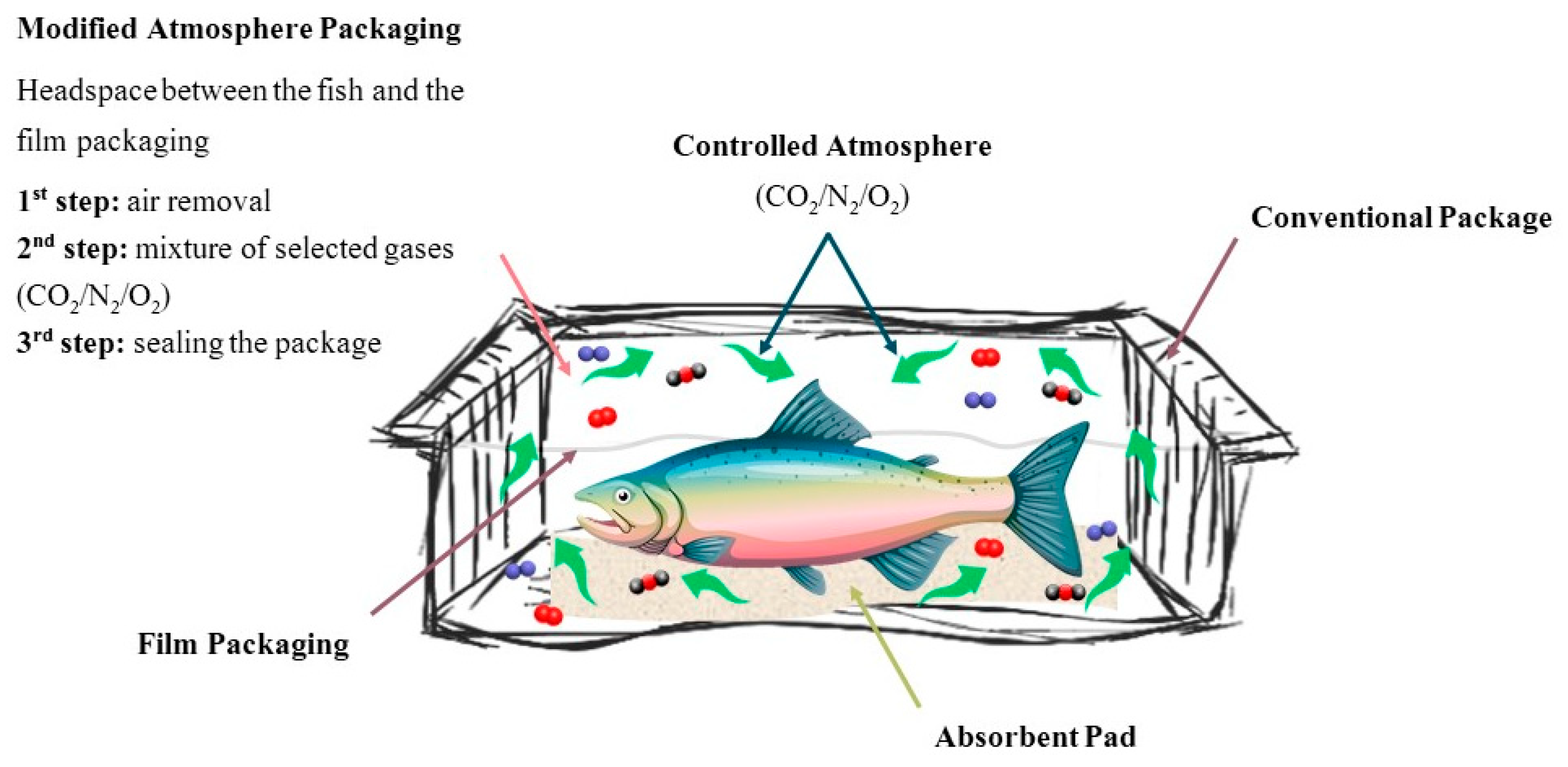

The MAP process starts with the removal of the gaseous atmosphere present in the package and then inserting a mixture of selected gases before sealing the package. Typically, this mixture of gases has high levels of carbon dioxide (CO

2), because of its antimicrobial effect inhibiting the growth of aerobic microorganisms

[19][21]. This happens because CO

2 dissolves in water and produces carbonic acid and a reduction of pH occurs. This leads to a prolongation on the lag phase and microbial growth is lowered throughout the logarithmic phase. However, the drop in pH could be minimal, and no bacteriostatic effect is noticed

[22]. Nevertheless, CO

2 can be prejudicial to sensorial acceptance, affecting cellular structures from the fish, as well all color and flavor

[23]. Oxygen (O

2) and nitrogen (N

2) are also used, since the former inhibits strictly anaerobic bacteria and the latter delays oxidative rancidity and limits aerobic microorganism’s growth when used to replace oxygen on the package

[9][21]. Ultimately, a wise combination of the abovementioned gases will result in an extension of shelf-life maintaining product quality, while it is also possible to design specific atmospheres to inhibit targeted and undesired microorganisms

[21][24].

It is important to highlight that regardless the type of packaging, fish preservation will be highly dependent on multiple factors, like type and number of microorganisms present in the water of the fish’s habitat, storage and transportation temperature, and handling during processing and distribution

[25][26]. Furthermore, different fish species and experimental designs (type of packaging, ratio of gases, storage temperature) are studied and this could explain the differences observed on the results discussed below.

Figure 1 and

Figure 2 represent the mechanism of VP and MAP technologies, respectively.

Figure 1. Schematic representation of VP technology applied to fishery products.

Figure 2. Schematic representation of MAP technology applied to fishery products.

2.2. Active Packaging

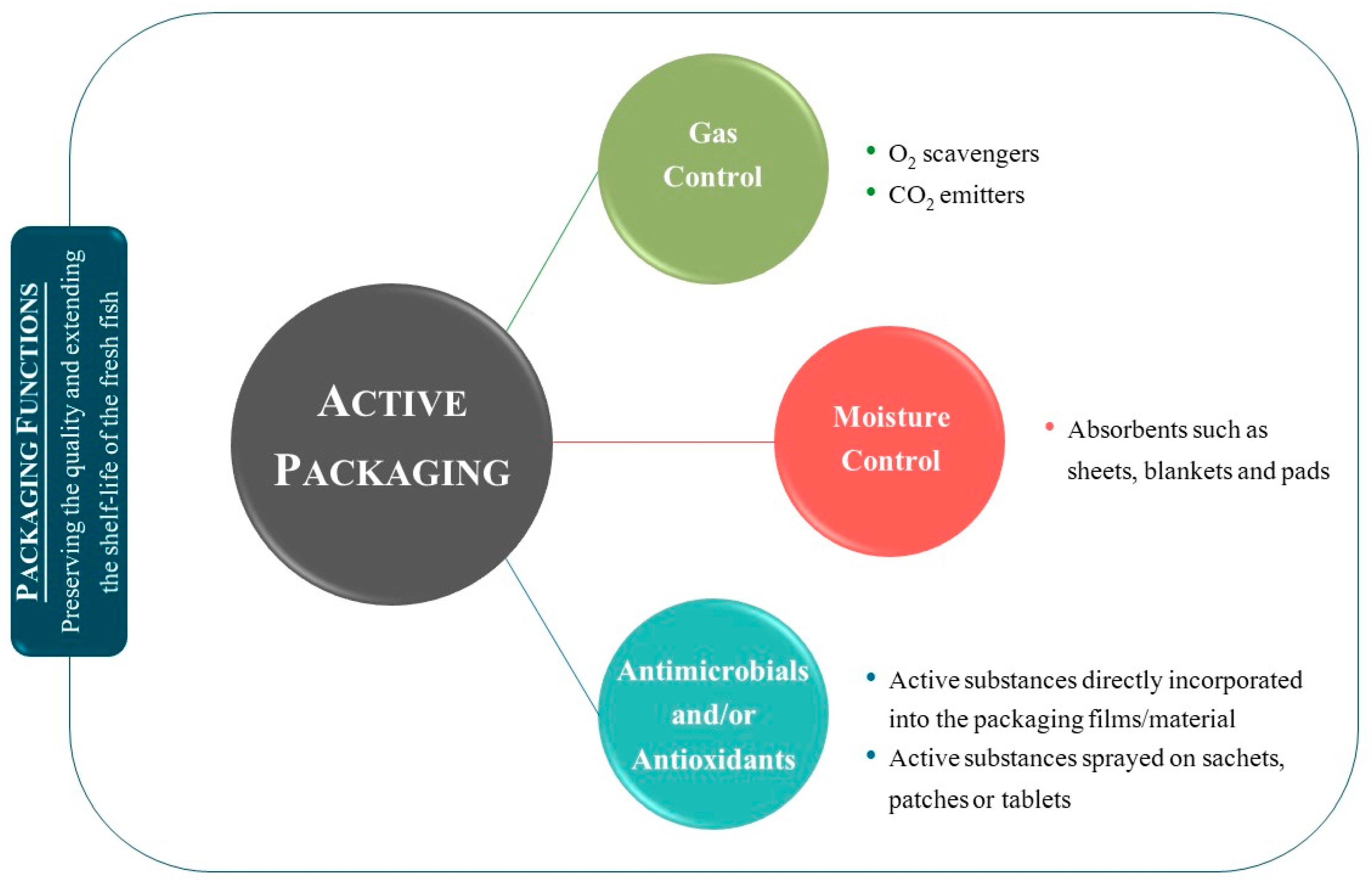

Active packaging systems are an innovative and alternative solution of high interest to food technologists. Food packaging and materials are categorized as active, according to the Regulation of the Commission of the European Union (EC No 450/2009), when their application aims to extend the shelf-life and maintain or improve safety and some physicochemical, quality, and sensorial properties of the packaged food due to the positive interaction between product, package, and environment

[16][17][27].

Therefore, active packaging is more than just an inert barrier that protects food from external detrimental factors. In fact, this technology is based on the incorporation of active substances, components, and materials into the packaging material or within the package, designed to release or absorb substances into or from packaged food or its surrounding environment

[27][28][29][30]. It is noteworthy that the main difference between active and intelligent packaging systems is the information about modifications in the quality status of the food product that is communicated to the consumer using intelligent packaging, instead of interacting with it and responding to changes in its properties, as happens with active packaging

[17]. Intelligent packaging only monitors the microbiological and physicochemical modifications (like biological reactions, pH, or temperature) of packaged foods or the surrounding environment, transmitting the information to the consumer, using devices such as sensors (including biosensors, gas sensors, printed electronics, chemical sensors, and electronic nose) and indicators (including freshness indicators, leak/integrity indicators and time and temperature indicators)

[16][17]. Intelligent packaging is not designed to interact with the packaged food or release active compounds as in active packaging, it merely helps to detect unsafe food

[16][17].

The three main types and the most common and promising of active packaging systems of foods are: (i) gas control, including O

2 scavengers and CO

2 emitters, (ii) moisture control, and (iii) antimicrobials and/or antioxidants, which are active substances directly incorporated into the packaging material/films or sprayed on sachets, patches, or tablets

[17][30]. To reduce, inhibit, or delay the microbial growth and enzymatic/oxidative reactions of food is the primary and common goal of all three methodologies

[4].

Figure 3 summarizes the three main types of active packaging systems described above.

Figure 3. Active packaging technology applied to fishery products. Based on information available in

[17].

2.3. Chemical Additives

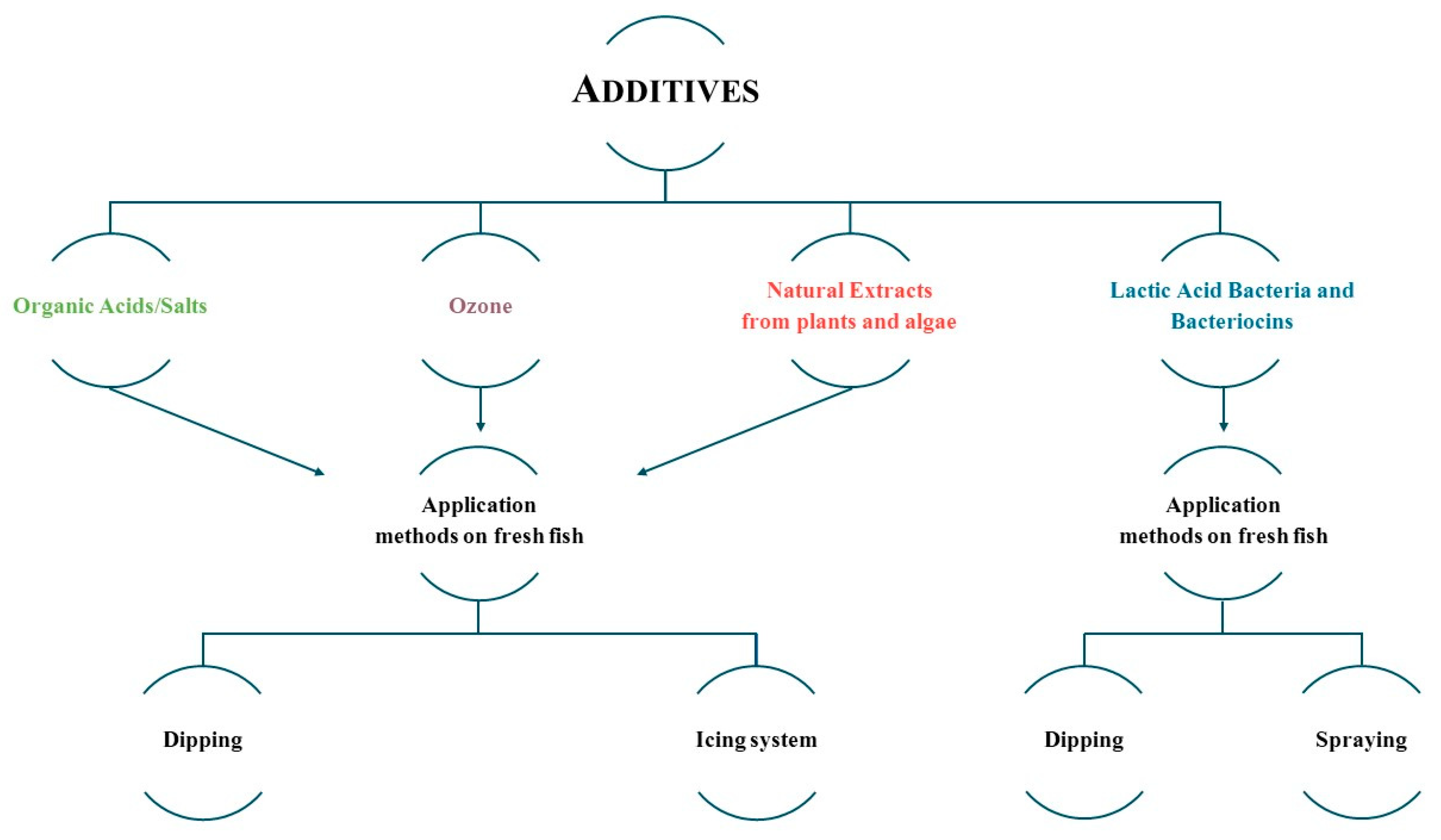

The aforementioned preservation strategies relied on either changing the natural atmosphere wherein fresh fish was packaged or by the impregnation of packaging materials with chemicals that slowly migrate to fresh fish, exerting an antioxidant and/or antimicrobial effect. Nevertheless, such chemicals can be applied directly to fresh fish, either by dipping or spraying prior to packaging, providing an additional hurdle to the refrigeration processes.

This section will focus on the main chemicals (single or in combination with icing systems) to preserve fresh fish, as well as natural extracts, bacteriocins, among others, which have different effects on fish quality and shelf-life. Figure 4 summarizes the main chemicals and application methods used to preserve fresh fish.

Figure 4. Chemical additives used to preserve fishery products and their application methods.

2.4. Natural Extracts

The application of natural preservatives in foods has caught the attention of the general public. Foods containing natural preservatives will be chosen over those containing synthetic preservatives

[2]. According to Gyawali & Ibrahim (2014)

[31], natural preservatives should have a broad action against bacteria and fungi, be non-toxic, and be active in low concentrations, not change the color and flavor of foods, have no pharmaceutical applications, be clean-label, and cost-effective. Most natural preservatives are derived from microorganisms, animals, and plants

[32].

3. Conclusions

Refrigeration and freezing are common methods used to preserve fresh fish, which is perishable due to its rich nutritional composition and physicochemical characteristics. However, these low temperature-based technologies cause some detrimental quality changes, such as off-odors, off-flavors, rancidity, and loss of texture; therefore, several technologies have been introduced to improve the overall preservation of the product.

Vacuum and modified atmosphere packaging technologies are characterized by the manipulation of the atmosphere of the package, offering an additional hurdle to the physical barrier protecting the fishery products. This allows the slowdown of microbial deterioration and the rate of degradation reactions and, consequently, an increase in the shelf-life. Overall, increases in the shelf-life of fresh fish by MAP of 2/3 days and 4/5 days, when compared with VP and air packages, respectively, along with better sensorial quality have been reported.

By adding active compounds with antimicrobial and/or antioxidant capacities to synthetic or natural packaging films, active packaging technology has a positive impact on the shelf-life and quality characteristics of fresh fish. As in active packaging, chemical additives (like organic acids and ozone) and natural extracts make it possible to slow down microbial proliferation and decrease TVB-N and TMA-N values, both important parameters related to the shelf-life and sensorial quality of fresh fish.

Despite the advantages of the use of chemical-based strategies for fresh fish preservation here presented and discussed, both regulatory and consumer approval challenges must be overcome until real commercial applications can be safely used in the industry. Moreover, an intense validation procedure must be performed to fully elucidate and convince regulatory authorities on the safe use of natural extracts as food preservatives, alongside with raising consumer awareness of the advantages of such procedures in the food industry. Nevertheless, even though some of the presented preservatives exemplified here come from natural sources, their toxicity is yet to be evaluated, as well as the interactions that such compounds can have either with the fish products or packaging.

In conclusion, these chemical-based strategies are proven to successfully impact fresh fish preservation and the interest in their application will certainly warrant new developments in research in the future.

This entry is adapted from the peer-reviewed paper 10.3390/foods10102300