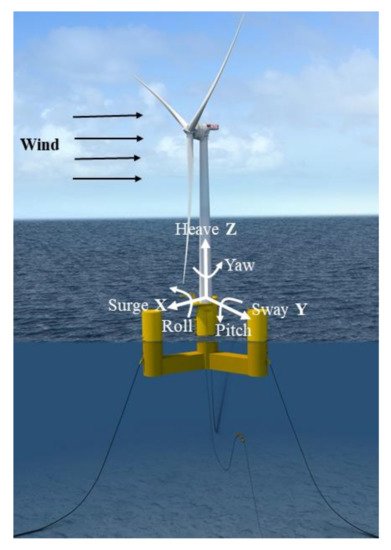

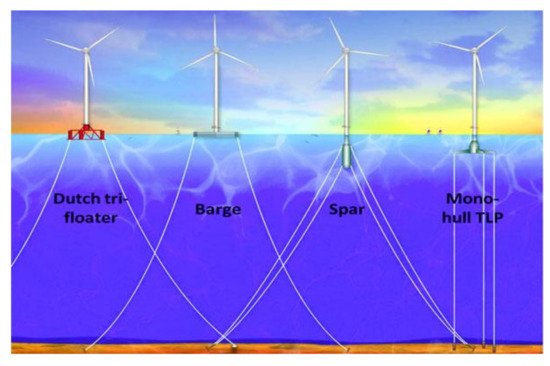

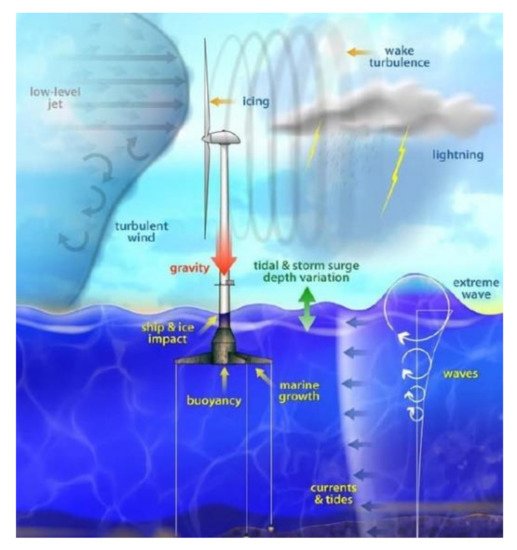

Globally, the wind resource in deep water (depths > 60 m) is very abundant. Due to the abundance of potential at these depths, the wind turbines will need the design of a floating platform because the wind turbines that are currently in operation are mostly fixed at the bottom and are dependent upon conventional concrete with a gravity base that is not feasible at these depths. A balance among the two varying principles (i.e., the requirement for a stable foundation for the wind turbine’s control and operation and the nature of the substructure being innate, to respond to environmental forces) is required for the design of the floating platform for wind energy. The absence of rigid foundations results in an additional six degrees of freedom (DOFs) for the platform of floating turbines; three translational (surge X, sway Y, and heave Z) and three rotational (roll RotX, pitch RotY, and yaw RotZ). For the platforms of onshore wind turbines and bottom-mounted offshore wind turbines, the effect of soil-structure interaction (SSI) can be modeled with six degrees of freedom; three translational (horizontal forces in X and Y and vertical force in Z) and three rotational (rocking moments in X and Y and a torsional moment in Z) respectively.

- offshore wind

- floating platform

- aerodynamics

- wake loss model

- hydrodynamics

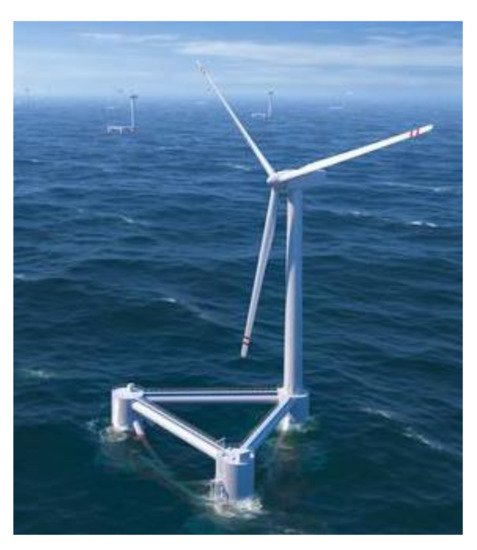

1. Floating Wind Turbines

2. Previous Work on Single Wind Turbine Floating Platforms

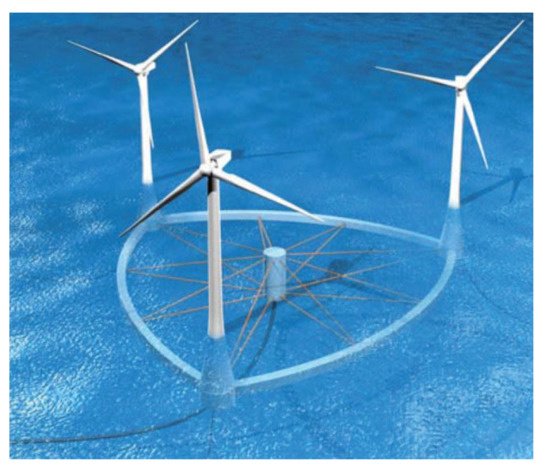

3. Previous Work on Multi-Wind-Turbine Floating Platforms

- ➢ The requirement for the evaluation of barge platforms

- ➢ Heave and roll were explained by simple equations of motion

- ➢ The analysis did not explain the impact of waves and mooring lines

| Advantages | Disadvantages | |

|---|---|---|

| Single wind turbine floating platform |

|

|

| Multi-Wind-Turbine floating platform |

|

|

This entry is adapted from the peer-reviewed paper 10.3390/en14196026

References

- Butterfield, S. Engineering Challenges for Floating Offshore Wind Turbines. In Proceedings of the 2005 Copenhagen Offshore Wind Conference, Copenhagen, Denmark, 26–28 October 2005; p. 13. Available online: https://www.nrel.gov/docs/fy07osti/38776.pdf (accessed on 18 May 2020).

- Offshore Wind Energy, Naval Energies. Available online: https://www.naval-group.com/en/saipem-and-naval-energies-sign-agreement-acquisition-naval-energies-floating-wind-business-967 (accessed on 2 November 2019).

- Harte, M.; Basu, B.; Nielsen, S. Dynamic analysis of wind turbines including soil-structure interaction. Eng. Struct. 2012, 45, 509–518.

- Namik, H. Individual Blade Pitch and Disturbance Accommodating Control of Floating Offshore Wind Turbines. Ph.D. Thesis, University of Auckland, Auckland, New Zealand, 2012. Available online: https://researchspace.auckland.ac.nz/handle/2292/11198 (accessed on 4 May 2020).

- DNV, G.L. Launches Revised Design & Certification Standards for Floating Wind Turbines, Windpower Engineering & Development. Available online: https://www.windpowerengineering.com/dnv-gl-launches-revised-design-certification-standards-for-floating-wind-turbines/ (accessed on 26 October 2019).

- Jonkman, J.M.; Buhl, M.L. Loads Analysis of a Floating Offshore Wind Turbine Using Fully Coupled Simulation. In Proceedings of the WindPower 2007 Conference and Exhibition, Los Angeles, CA, USA, 3–6 June 2007; p. 35. Available online: https://www.nrel.gov/docs/fy07osti/41714.pdf (accessed on 20 May 2020).

- Liu, Y.; Li, S.; Yi, Q.; Chen, D. Developments in semi-submersible floating foundations supporting wind turbines: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 60, 433–449.

- Kausche, M.; Adam, F.; Dahlhaus, F.; Großmann, J. Floating offshore wind—Economic and ecological challenges of a TLP solution. Renew. Energy 2018, 126, 270–280.

- Tong, K. Technical and economic aspects of a floating offshore wind farm. J. Wind Eng. Ind. Aerodyn. 1998, 74, 399–410.

- Cordle, A.; Jonkman, J. State of the Art in Floating Wind Turbine Design Tools. In Proceedings of the Twenty-First International Offshore and Polar Engineering Conference, Maui, HI, USA, 19–24 June 2011; Available online: https://www.onepetro.org/conference-paper/ISOPE-I-11-112 (accessed on 3 May 2020).

- Dinh, V.-N.; Basu, B. On the Modeling of Spar-Type Floating Offshore Wind Turbines. Key Eng. Mater. 2013, 569, 636–643.

- Jonkman, J. Dynamics Modeling and Loads Analysis of an Offshore Floating Wind Turbine. Ph.D. Thesis, University of Colorado, Boulder, CO, USA, 2007.

- Liu, X.; Lu, C.; Li, G.; Godbole, A.; Chen, Y. Effects of aerodynamic damping on the tower load of offshore horizontal axis wind turbines. Appl. Energy 2017, 204, 1101–1114.

- Wayman, E.; Sclavounos, P.; Butterfield, S.; Jonkman, J.; Musial, W. Coupled Dynamic Modeling of Floating Wind Turbine Systems. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2006.

- Wu, C.-H.K.; Nguyen, V.-T. Aerodynamic simulations of offshore floating wind turbine in platform-induced pitching motion. Wind Energy 2016, 20, 835–858.

- Dumpleton, O. Wind energy from ship to shore. J. Wind Eng. Ind. Aerodyn. 1985, 20, 335–347.

- Henderson, A.R.; Patel, M.H.; Halliday, J.A.; Watson, G.M. Floating Offshore Wind Energy. In Proceedings of the European Wind Energy Conference (EWEC99), Nice, France, 1–5 March 1999; p. 7. Available online: https://www.researchgate.net/publication/30415925_Floating_Offshore_Wind_Energy (accessed on 9 June 2020).

- Withee, J.E. Fully Coupled Dynamic Analysis of a Floating Wind Turbine System. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2004. Available online: https://dspace.mit.edu/handle/1721.1/43619 (accessed on 4 May 2020).

- Lee, K.H. Responses of Floating Wind Turbines to Wind and Wave Excitation. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2005. Available online: https://dspace.mit.edu/handle/1721.1/33564 (accessed on 4 May 2020).

- Skaare, B.; Hanson, T.D.; Nielsen, F.G.; Yttervik, R.; Hansen, A.M.; Thomsen, K.; Larsen, T.J. Integrated dynamic analysis of floating offshore wind turbines. In Proceedings of the 2007 European Wind Energy Conference and Exhibition, Milan, Italy, 7–10 May 2007; Available online: https://orbit.dtu.dk/en/publications/integrated-dynamic-analysis-of-floating-offshore-wind-turbines (accessed on 4 May 2020).

- Suzuki, H.; Sato, A. Load on Turbine Blade Induced by Motion of Floating Platform and Design Requirement for the Platform. In Proceedings of the ASME 2007 26th International Conference on Offshore Mechanics and Arctic Engineering, San Diego, CA, USA, 10–15 June 2007; pp. 519–525.

- Matsukuma, H.; Utsunomiya, T. Motion analysis of a floating offshore wind turbine considering rotor-rotation. IES J. Part A Civ. Struct. Eng. 2008, 1, 268–279.

- Utsunomiya, T.; Sato, T.; Matsukuma, H.; Yago, K. Experimental Validation for Motion of a SPAR-Type Floating Offshore Wind Turbine Using 1/22. In 5 Scale Model. In Proceedings of the ASME 2009 28th International Conference on Ocean, Offshore and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009; pp. 951–959.

- Utsunomiya, T.; Nishida, E.; Sato, I. Wave Response Experiment on SPAR-type Floating Bodies for Offshore Wind Turbine. In Proceedings of the Nineteenth International Offshore and Polar Engineering Conference, Osaka, Japan, 21–26 July 2009; Available online: https://www.onepetro.org/conference-paper/ISOPE-I-09-129 (accessed on 4 May 2020).

- Utsunomiya, T.; Matsukuma, H.; Minoura, S.; Ko, K.; Hamamura, H.; Kobayashi, O.; Sato, I.; Nomoto, Y.; Yasui, K. On Sea Experiment of a Hybrid SPAR for Floating Offshore Wind Turbine Using 1/10 Scale Model. J. Offshore Mech. Arct. Eng. 2010, 135, 529–536.

- Sclavounos, P.; Tracy, C.; Lee, S. Floating Offshore Wind Turbines: Responses in a Seastate Pareto Optimal Designs and Economic Assessment. In Proceedings of the ASME 2008 27th International Conference on Offshore Mechanics and Arctic Engineering, Estoril, Portugal, 15–20 June 2008; pp. 31–41.

- Suzuki, H.; Kurimoto, M.; Kitahara, Y.; Fukumoto, Y. Progressive Drifting of Floating Wind Turbines in a Wind Farm. In Proceedings of the ASME 2009 28th International Conference on Ocean, Offshore and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009; pp. 1403–1409.

- Weinzettel, J.; Reenaas, M.; Solli, C.; Hertwich, E.G. Life cycle assessment of a floating offshore wind turbine. Renew. Energy 2009, 34, 742–747.

- Principle Power Inc. Globalizing Offshore Wind. Available online: http://www.principlepowerinc.com/en/windfloat (accessed on 27 October 2019).

- Roddier, D.; Cermelli, C.; Weinstein, A. WindFloat: A Floating Foundation for Offshore Wind Turbines—Part I: Design Basis and Qualification Process. In Proceedings of the ASME 2009 28th International Conference on Ocean, Offshore and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009; pp. 845–853.

- Cermelli, C.; Roddier, D.; Aubault, A. WindFloat: A Floating Foundation for Offshore Wind Turbines—Part II: Hydrodynamics Analysis. In Proceedings of the ASME 2009 28th International Conference on Ocean, Offshore and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009; pp. 135–143.

- Aubault, A.; Cermelli, C.; Roddier, D. WindFloat: A Floating Foundation for Offshore Wind Turbines—Part III: Structural Analysis. In Proceedings of the ASME 2009 28th International Conference on Ocean, Offshore and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009; pp. 213–220.

- Henderson, A.R.; Zaaijer, M.B.; Bulder, B.; Pierik, J.; Huijsmans, R.; van Hees, M.; Snijders, E.; Wijnants, G.H.; Wolf, M.J. Floating Windfarms for Shallow Offshore Sites. In Proceedings of the Fourteenth International Offshore and Polar Engineering Conference, Toulon, France, 23–28 May 2004; Available online: https://www.onepetro.org/conference-paper/ISOPE-I-04-003?sort=&start=0&q=Floating+Windfarms+for+Shallow+Offshore+Sites&from_year=&peer_reviewed=&published_between=&fromSearchResults=true&to_year=&rows=10# (accessed on 4 May 2020).

- Henderson, A.R.; Bulder, B.; Huijsmans, R.; Peeringa, J.; Pierik, J.; Snijders, E.; Van Hees, M.; Wijnants, G.H.; Wolf, M.J. Feasibility Study of Floating Windfarms in Shallow Offshore Sites. Wind Eng. 2003, 27, 405–418.

- Musial, W.; Butterfield, S.; Boone, A. Feasibility of Floating Platform Systems for Wind Turbines. In Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exibit, Reno, NV, USA, 5–8 January 2004.

- Zambrano, T.; MacCready, T.; Kiceniuk, T.; Roddier, D.G.; Cermelli, C.A. Dynamic Modeling of Deepwater Offshore Wind Turbine Structures in Gulf of Mexico Storm Conditions. In Proceedings of the 25th International Conference on Offshore Mechanics and Arctic Engineering, Hamburg, Germany, 4–9 June 2006; pp. 629–634.

- Ishihara, T.; Phuc, P.V.; Sukegawa, H.; Shimada, K. A study on the dynamic response of a semi-submersible floating offshore wind turbine system Part 1: A water tank test. In Proceedings of the 12th International Conference on Wind Engineering: ICWE 12, Cairns, Australia, 1–6 July 2007; p. 4. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.505.2788&rep=rep1&type=pdf (accessed on 26 October 2019).

- Shimada, K.; Ohyama, T.; Miyakawa, M.; Ishihara, T.; Phuc, P.V.; Sukegawa, H. A Study on a Semi-Submersible Floating Offshore Wind Energy Conversion System. In Proceedings of the Seventeenth International Offshore and Polar Engineering Conference, Lisbon, Portugal, 1–6 July 2006; Available online: https://www.onepetro.org/conference-paper/ISOPE-I-07-481 (accessed on 3 May 2020).

- Manabe, H.; Uehiro, T.; Utiyama, M.; Esaki, H.; Kinoshita, T.; Takagi, K.; Okamura, H.; Satou, M. Development of the floating structure for the Sailing-type Offshore Wind Farm. In Proceedings of the OCEANS 2008—MTS/IEEE Kobe Techno-Ocean, Kobe, Japan, 8–11 April 2008; pp. 1–4.

- Kourogi, Y.; Takagi, K.; Hotta, J. Experimental Study on Maneuverability Coefficients for the Navigation Simulation of VLMOS. In Proceedings of the OCEANS 2008—MTS/IEEE Kobe Techno-Ocean, Kobe, Japan, 8–11 April 2008; pp. 1–6.

- Korogi, Y.; Hiramatsu, T.; Takagi, K. Sailing Performance of a Very Large Mobile Offshore Structure for Wind Power Plant. In Proceedings of the ASME 2009 28th International Conference on Ocean, Offshore and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009; pp. 1311–1318.

- Lefranc, M.; Torud, A. Three Wind Turbines on One Floating Unit, Feasibility, Design and Cost. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2011.

- Hu, C.; Sueyoshi, M.; Liu, C.; Liu, Y. Hydrodynamic Analysis of a Semi-Submersible-Type Floating Wind Turbine. J. Ocean Wind Energy 2014, 1, 7.

- Bae, Y.H.; Kim, M.-H. The Dynamic Coupling Effects of a MUFOWT (Multiple Unit Floating Offshore Wind Turbine) with Partially Broken Blade. J. Ocean Wind Energy 2015, 2, 89–98.

- Kim, K.; Kim, H.; Lee, J.; Kim, S.; Paek, I. Design and performance analysis of control algorithm for a floating wind turbine on a large semi-submersible platform. J. Phys. Conf. Ser. 2016, 753, 92017.

- Kim, H.C.; Kim, M.H.; Kim, K.H.; Hong, K.; Bae, Y.H. Global Performance of a Square-Type Semi-Submersible KRISO Multi-Unit Floating Wind Turbine; Numerical Simulation vs. In Model Test. In Proceedings of the 26th International Ocean and Polar Engineering Conference, Rhodes, Greece, 26 June–2 July 2016; Available online: https://www.onepetro.org/conference-paper/ISOPE-I-16-638 (accessed on 2 May 2020).

- Kang, H.; Kim, M.-H.; Kim, K.-H.; Hong, K. Hydroelastic Analysis of Multi-Unit Floating Offshore Wind Turbine Platform (MUFOWT). In Proceedings of the 27th International Ocean and Polar Engineering Conference, San Francisco, CA, USA, 25–30 June 2017; Available online: https://www.onepetro.org/conference-paper/ISOPE-I-17-637 (accessed on 4 May 2020).

- Kim, K.H.; Hong, J.P.; Park, S.; Lee, K.; Hong, K. An Experimental Study on Dynamic Performance of Large Floating Wave-Offshore Hybrid Power Generation Platform in Extreme Conditions. J. Korean Soc. Mar. Environ. Energy 2016, 19, 7–17.

- Lee, H.; Poguluri, S.K.; Bae, Y.H. Performance Analysis of Multiple Wave Energy Converters Placed on a Floating Platform in the Frequency Domain. Energies 2018, 11, 406.

- Jang, H.-K.; Park, S.; Kim, M.-H.; Kim, K.-H.; Hong, K. Effects of heave plates on the global performance of a multi-unit floating offshore wind turbine. Renew. Energy 2018, 134, 526–537.

- Bashetty, S.; Ozcelik, S. Design and Stability Analysis of an Offshore Floating Multi-Turbine Platform. In Proceedings of the 2020 IEEE Green Technologies Conference (GreenTech), Oklahoma City, OK, USA, 1–3 April 2020; pp. 184–189.

- Bashetty, S.; Ozcelik, S. Effect of Pitch Control on the Performance of an Offshore Floating Multi-Wind-Turbine Platform. J. Phys. Conf. Ser. 2021, 1828, 012055.

- Bashetty, S.; Ozcelik, S. Aero-Hydrodynamic Analysis of an Offshore Floating Multi-Wind-Turbine Platform—Part I. In Proceedings of the 2020 IEEE 3rd International Conference on Renewable Energy and Power Engineering (REPE), Edmonton, AB, Canada, 9–11 October 2020; pp. 1–6.

- Bashetty, S.; Ozcelik, S. Aero-Hydrodynamic Analysis of an Offshore Floating Multi-Wind-Turbine Platform—Part II. In Proceedings of the 2020 IEEE 3rd International Conference on Renewable Energy and Power Engineering (REPE), Edmonton, AB, Canada, 9–11 October 2020; pp. 7–11.