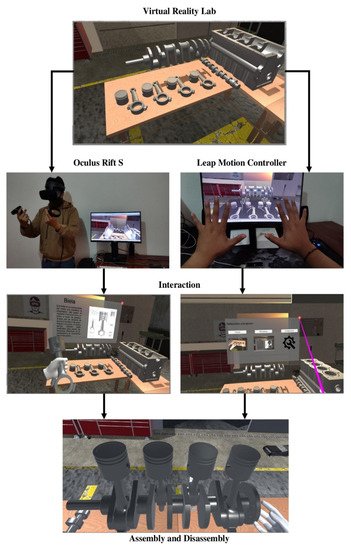

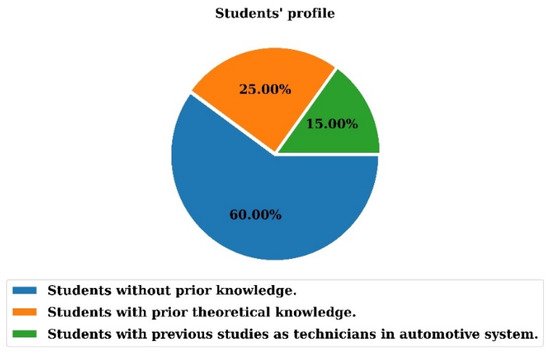

A Virtual Reality application was developed to be used as an immersive virtual learning strategy for Oculus Rift S Virtual Reality glasses and through Leap Motion Controller™ infrared sensors, focused on students of the Automotive Systems Engineering academic program, as a practical teaching-learning tool in the context of Education 4.0 and the pandemic caused by COVID-19 that has kept schools closed since March 2020. The technological pillars of Industry 4.0 were used to profile students so that they can meet the demands of their professional performance at the industrial level. Virtual Reality (VR) plays a very important role for the production-engineering sector in areas such as design and autonomous cars, as well as in training and driving courses. The VR application provides the student with a more immersive and interactive experience, supported by 3D models of both the main parts that make up the four-stroke combustion engine and the mechanical workshop scenario; it allows the student to manipulate the main parts of the four-stroke combustion engine through the Oculus Rift S controls and the Leap Motion Controller™ infrared sensors, and relate them to the operation of the engine, through the animation of its operation and the additional information shown for each part that makes it up in the application.

- education

- virtual reality

- automotive systems

- training

- Oculus Rift S

- Leap Motion

1. Introduction

2. Virtual Reality Automotive Lab for Students

3. Discussion

4. Conclusions

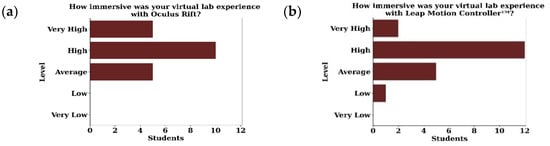

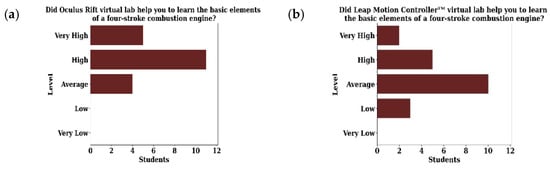

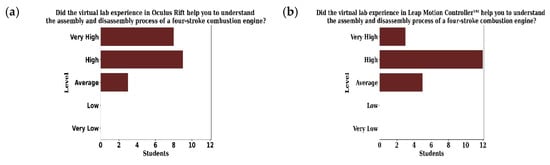

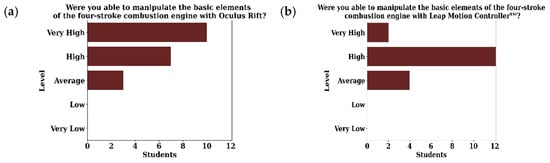

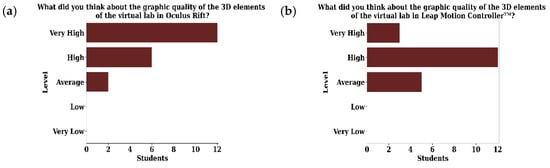

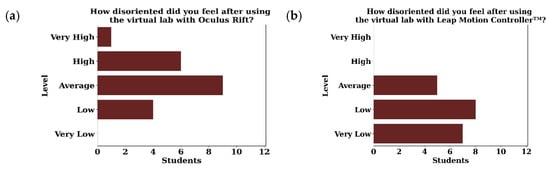

This paper shows the development and evaluation of the Virtual Reality application that presents in an interactive and immersive way, with the help of the lenses and controls of the Oculus Rift S and Leap Motion Controller™, to learn about the operation of the four-stroke engine through animation and the assembly and disassembly of its main pieces. Test results, reflected in the questionnaires applied to the students who used the Virtual Laboratory, were favorable, and the comments made when using both devices were very positive, demonstrating that the purpose for which the immersive Virtual Reality application was developed fulfills its target. Therefore, we can conclude that this application provides users with a more immersive experience, especially in the case of virtual interaction with the help of the Oculus Rift S, which allows the user to move with greater freedom within the virtual stage and the physical space, in which the way that virtual hands of the student interact through the controls of the Virtual Reality glasses with the 3D virtual models is not limited, as it is in the case of the Leap Motion Controller™, which is limited by the field of vision of the infrared sensors. This virtual application aims to familiarize the student with what the main parts of a four-stroke engine are, how they work, and how they are assembled and disassembled; it is also interactive, since, if the student wants to learn more about each engine part, they can display additional information for the selected part. This application has an interactive tutorial and allows the student to have an immersive practice in a virtual setting similar to the automotive workshop, where the practice is usually carried out in person. In the case of schools that do not have equipped workshops for each student to carry out the practice, this application allows them to experiment in a more immersive way and also allows them to have practice prior to visiting the automotive workshop to carry out a face-to-face practice with a four-stroke engine. This application can be scaled to have more modules within the Virtual Laboratory.

The advance in the development of new technologies has enormous potential in the field of education and its links with Industry 4.0. We learn more from hands-on experiences than from traditional classes and frequently referenced two-dimensional materials. Education must gradually adapt to the health conditions that we are experiencing due to the pandemic caused by COVID-19 to improve and facilitate student learning and ensure their adaptation to the work environment. The development and implementation of these virtual immersive teaching-learning tools in the academic training of automotive engineering students will allow them to be profiled towards what they will find in their professional performance at an industrial level, where Virtual Reality plays a very important role in design, autonomous cars, training, and driving.

This entry is adapted from the peer-reviewed paper 10.3390/su13179776

References

- Nubi, O.J.; Vincent, O.R. Virtual Reality: A Pedagogical Model for Simulation Based Learning. In Proceedings of the 2020 International Conference in Mathematics, Computer Engineering and Computer Science, ICMCECS 2020, Lagos, Nigeria, 18–21 March 2020.

- Saghafian, M.; Laumann, K.; Akhtar, R.S.; Skogstad, M.R. The Evaluation of Virtual Reality Fire Extinguisher Training. Front. Psychol. 2020, 11, 593466.

- Geiger, A.; Brandenburg, E.; Stark, R. Natural Virtual Reality User Interface to Define Assembly Sequences for Digital Human Models. Appl. Syst. Innov. 2020, 3, 15.

- Daineko, Y.; Ipalakova, M.; Tsoy, D.; Bolatov, Z.; Baurzhan, Z.; Yelgondy, Y. Augmented and Virtual Reality for Physics: Experience of Kazakhstan Secondary Educational Institutions. Comput. Appl. Eng. Educ. 2020, 28, 1220–1231.

- Vegara, D.; Rubio, M.P.; Prieto, F. Nueva herramienta virtual para la enseñanza de la caracterización mecánica de materiales (New tool virtual for teaching mechanics of materials characterization). Rev. Educ. Ing. 2014, 9, 98–107.

- Ou, K. Development of a Virtual Ecological Environment for Learning the Taipei Tree Frog. Sustainability 2021, 13, 5911.

- Ramirez, J.A.; Bueno, A.M.V. Learning Organic Chemistry with Virtual Reality. In Proceedings of the 2020 IEEE International Conference on Engineering Veracruz, ICEV 2020, Veracruz, Mexico, 26–29 October 2020.

- Nainggolan, F.; Siregar, B.; Fahmi, F. User Experience in Excavator Simulator Using Leap Motion Controller in Virtual Reality Environment. J. Phys. Conf. Ser. 2020, 1566, 012093.

- Wijaya, F.; Tseng, Y.; Tsai, W.; Pan, T.; Hu, M. VR Piano Learning Platform with Leap Motion and Pressure Sensors. Comput. Sci. 2020, 585–586.

- Alvarez-Lopez, F.; Maina, M.F.; Arango, F.; Saigí-Rubió, F. Use of a Low-Cost Portable 3D Virtual Reality Simulator for Psychomotor Skill Training in Minimally Invasive Surgery: Task Metrics and Score Validity. JMIR Serious Games 2020, 8, e19723.

- Ferreira, S.C.; Chaves, R.O.; da Seruffo, M.C.R.; Pereira, A.; Azar, A.P.D.S.; Dias, Â.V.; de dos Santos, A.A.S.; Brito, M.V.H. Empirical Evaluation of a 3D Virtual Simulator of Hysteroscopy Using Leap Motion for Gestural Interfacing. J. Med. Syst. 2020, 44, 198.

- Vassigh, S.; Ortega, F.R.; Barreto, A.; Tarre, K.; Maldonado, J. Use of 3D Human-Computer Interaction for Teaching in the Architectural, Engineering and Construction Fields. In Universal Access in Human-Computer Interaction. Virtual, Augmented, and Intelligent Environments. UAHCI 2018; Lecture Notes in Computer Science Series; Antona, M., Stephanidis, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; Volume 10908, pp. 149–159.

- Vergara, D.; Rubio, M.P.; Lorenzo, M. On the Design of Virtual Reality Learning Environments in Engineering. MTI 2017, 1, 11.

- Hasan, B.; Al-Quorashy, Y.; Al-Mousa, S.; Al-Sahhaf, Y.; El-Abd, M. V-LAB—The Virtual Electric Machines Laboratory. In Proceedings of the IEEE Global Engineering Education Conference, EDUCON, Porto, Portugal, 27–30 April 2020; Volume 2020, pp. 72–77.

- Makarova, I.; Boyko, A.; Shubenkova, K.; Pashkevich, A.; Giniyatullin, I. Virtual Laboratories: Engineers’ Training for Automotive Industry. In Proceedings of the ICETA 2019—17th IEEE International Conference on Emerging Elearning Technologies and Applications, Stary Smokovec, Slovakia, 21–22 November 2019; pp. 505–511.

- Miranda, M.R.; Costa, H.; Oliveira, L.; Bernardes, T.; Aguiar, C.; Miosso, C.; Oliveira, A.B.S.; Diniz, A.C.G.C.; Domingues, D.M.G. Development of Simulation Interfaces for Evaluation Task with the Use of Physiological Data and Virtual Reality Applied to a Vehicle Simulator. Proc. SPIE 2015, 9392, 93920713.

- Salah, B.; Abidi, M.H.; Mian, S.H.; Krid, M.; Alkhalefah, H.; Abdo, A. Virtual Reality-Based Engineering Education to Enhance Manufacturing Sustainability in Industry 4.0. Sustainability 2019, 11, 1477.

- Hincapié, M.; Valdez, A.; Güemes-Castorena, D.; Ramírez, M. Use of Laboratory Scenarios as a Strategy to Develop Smart Factories for Industry 4.0. Int. J. Interact. Des. Manuf. 2020, 14, 1285–1304.

- Vetiska, J.; Holub, M.; Blecha, P.; Bradac, F.; Brazina, J.; Stanek, V.; Kroupa, J.; Tuma, Z. Industry 4.0 in Educational Process; Springer International Publishing: Berlin/Heidelberg, Germany, 2021.

- Hamurcu, A.; Timur, Ş.; Rızvanoğlu, K. An Overview of Virtual Reality within Industrial Design Education. J. Eng. Des. Technol. 2020, 18, 1889–1905.

- Checa, D.; Bustillo, A. Advantages and Limits of Virtual Reality in Learning Processes: Briviesca in the Fifteenth Century. Virtual Real. 2020, 24, 151–161.

- Iordache, D.D. Evaluation of Virtual Reality-Based Applications in Education. In Proceedings of the eLearning and Software for Education Conference, Bucharest, Romania, 23–24 April 2020; pp. 499–504.

- González-Ortega, D.; Díaz-Pernas, F.J.; Martínez-Zarzuela, M.; Antón-Rodríguez, M. Comparative Analysis of Kinect-Based and Oculus-Based Gaze Region Estimation Methods in a Driving Simulator. Sensors 2021, 21, 26.

- Joshi, S.; Hamilton, M.; Warren, R.; Faucett, D.; Tian, W.; Wang, Y.; Ma, J. Implementing Virtual Reality Technology for Safety Training in the Precast/ Prestressed Concrete Industry. Appl. Ergon. 2021, 90, 103286.

- Vaughan, N.; John, N.; Rees, N. CPR Virtual Reality Training Simulator for Schools. In Proceedings of the 2019 International Conference on Cyberworlds, CW 2019, Kyoto, Japan, 2–4 October 2019; pp. 25–28.

- Maltsev, A.V.; Mikhaylyuk, M.V. Visualization and Virtual Environment Technologies in the Tasks of Cosmonaut Training. Sci. Vis. 2020, 12, 16–25.

- Jou, M.; Wang, J. Computers in Human Behavior Investigation of Effects of Virtual Reality Environments on Learning Performance of Technical Skills. Comput. Human Behav. 2013, 29, 433–438.

- Schroeter, R.; Gerber, M.A. A Low-Cost VR-Based Automated Driving Simulator for Rapid Automotive UI Prototyping. In Proceedings of the Adjunct Proceedings—10th International ACM Conference on Automotive User Interfaces and Interactive Vehicular Applications, AutomotiveUI, Toronto, ON, Canada, 23–25 September 2018; pp. 248–251.

- Gerber, M.A.; Schroeter, R.; Vehns, J. A Video-Based Automated Driving Simulator for Automotive UI Prototyping, UX and Behaviour Research. In Proceedings of the 11th International Conference on Automotive User Interfaces and Interactive Vehicular Applications, AutomotiveUI ’19, Utrecht, The Netherlands, 21–25 September 2019; Association for Computing Machinery: New York, NY, USA, 2019; pp. 14–23.

- Ihemedu-Steinke, Q.C.; Sirim, D.; Erbach, R.; Halady, P.; Meixner, G. Development and Evaluation of a Virtual Reality Driving Simulator. In Mensch und Computer 2015; Oldenbourg Wissenschaftsverlag: Munich, Germany, 2015; pp. 491–498.

- Liang, J.S. Modeling an Immersive VR Driving Learning Platform in a Web-Based Collaborative. Int. J. Comput. Integr. Manuf. 2010, 23, 876–892.

- Wan, J.; Wang, N. A Method of Motion-Based Immersive Design System for Vehicle Occupant Package. In Proceedings of the ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference IDETC/CIE, Quebec, QC, Canada, 26–29 August 2018; pp. 1–6.

- Meyrueis, V. A Template Approach for Coupling Virtual Reality and CAD in an Immersive Car Interior Design Scenario Alexis Paljic, Laure Leroy and Philippe Fuchs. Int. J. Prod. Dev. 2013, 18, 395–410.

- Brown, A. Bridging the Gap from Gasoline to Hybrids: Using Systems Engineering to Deliver Advanced Powertrain Technologies (2010-01-0012). In Green Technologies and the Mobility Industry; SAE: Warrendale, PA, USA, 2011; pp. 13–19.

- Caputo, F.; Greco, A.; Amato, E.D.; Notaro, I.; Spada, S. A Preventive Ergonomic Approach Based on Virtual and Immersive Reality. In Proceedings of the AHFE 2018 International Conference on Ergonomics in Design, Orlando, FL, USA, 21–25 July 2018; Volume 1, pp. 3–15.

- Abidi, M.H.; El-tamimi, A.M.; Al-ahmari, A.M.; Darwish, S.M. Virtual Ergonomic Assessment of First Saudi Arabian Designed Car in a Semi-Immersive Environment. Procedia Eng. 2013, 64, 622–631.

- Cortés Caballero, J.M.; Pérez Martínez, Á.A.; Mejía Villegas, J.E.; Hernández Chávez, M.; Fabila Bustos, D.A.; Hernández Quintanar, L.F. La Formación de Ingenieros En Sistemas Automotrices Mediante La Realidad Aumentada. Innovación Educ. 2020, 20, 25–44.

- Homen Pavlin, M.; Sužnjevic, M. The Opinions and Attitudes of Students Future IT Teachers on the Use of VR and AR in Teaching. In Proceedings of the 2019 42nd International Convention on Information and Communication Technology, Electronics and Microelectronics, MIPRO 2019, Opatija, Croatia, 20–24 May 2019; pp. 709–714.

- Abulrub, A.; Attridge, A.; Williams, M. Virtual Reality in Engineering Education: The Future of Creative Learning. Int. J. Emerg. Technol. Learn. 2011, 6, 4–11.

- Mousavi, M.; Aziz, F.A.; Ismail, N. Opportunities and Constraints of Virtual Reality Application in International and Domestic Car Companies of Malaysia. In Proceedings of the 2012 UKSim 14th International Conference on Computer Modelling and Simulation, Cambridge, UK, 28–30 March 2012; pp. 273–277.

- Quevedo, W.; Sánchez, J.; Arteaga, O.; Alvarez, M.; Zambrano, V.; Sánchez, C.; Andaluz, V. Virtual Reality System for Training in Automotive Mechanics. In Proceedings of the International Conference on Augmented Reality, Virtual Reality and Computer Graphics, Ugento, Italy, 12–15 June 2017; pp. 185–198.

- Schwarz, S.; Regal, G.; Kempf, M.; Schatz, R. Learning Success in Immersive Virtual Reality Training Environments: Practical Evidence from Automotive Assembly. In Proceedings of the NordiCHI 20: Shaping Experiences, Shaping Society, Tallinn, Estonia, 25–29 October 2020.

- Hui, Z. Head-Mounted Display-Based Intuitive Virtual Reality Training System for the Mining Industry. Int. J. Min. Sci. Technol. 2017, 27, 717–722.

- Fernández-González, P.; Carratalá-Tejada, M.; Monge-Pereira, E.; Collado-Vázquez, S.; Baeza, P.S.; Cuesta-Gómez, A.; Oña-simbaña, E.D.; Jardón-Huete, A.; Molina-Rueda, F.; De Quirós, C.B.; et al. Leap Motion Controlled Video Game-Based Therapy for Upper Limb Rehabilitation in Patients with Parkinson ’s Disease: A Feasibility Study. J. NeuroEng. Rehabil. 2019, 16, 133.

- Boletsis, C. VR Locomotion in the New Era of Virtual Reality: An Empirical Comparison of Prevalent Techniques. Adv. Hum. Comput. Interact. 2019, 2019.

- Keil, J.; Edler, D.; Meara, D.O.; Korte, A.; Dickmann, F. Effects of Virtual Reality Locomotion Techniques on Distance Estimations. ISPRS Int. J. Geo-Inf. 2021, 10, 150.