The ionizing radiations are particles or waves containing enough energy to ionize the matter when coming in contact. Their mode of action in living cells involves either the direct destruction of nucleic acid or by creating free radicals that can attack the cellular components. This cellular destruction and inactivation can be used to reduce the microbial burden in food items to increase the shelf life and safety of food, meanwhile maintaining the quality of the product. Although this technology is accepted by more than 60 countries, some consumers are reluctant to buy such products thinking that radiations might have modified their food which can also induce changes in their body after consumption. The proper scientific communication regarding the safety of ionization irradiations can change consumer behavior, and it requires the collaboration of all stakeholders in the food production chain.

- Ionizing radiations

- e-beams

- Gamma rays

- food safety

- shelf life

- Biological hazards

- Food quality

1. Definition

The ionizing irradiation is the process of applying ionizing energy to a material, such as food, to sterilize or preserve them by destroying microorganisms, parasites, insects, and other pests [1].

2. Introduction

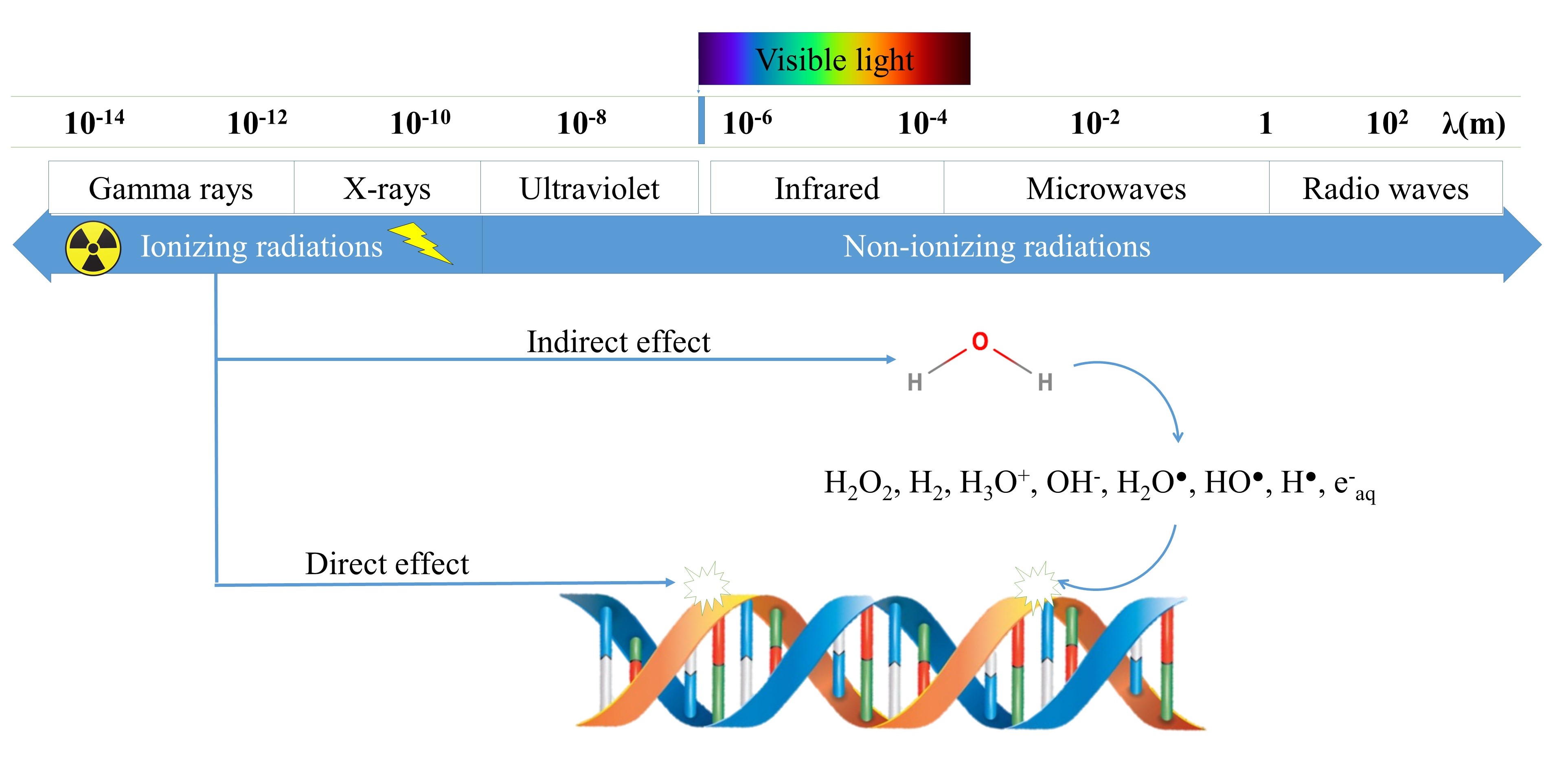

Ionizing radiations can remove bound electrons from an atomic or molecular structure, leaving the structure to become electrically charged or ionized[2]. When these radiations are bombarded on living cells at specific doses, they can denature cellular components, either by direct destruction of nucleic acid or by breaking water molecules and generating reactive oxygen species and free radicals which can subsequently damage the cellular components (Figure 1).

Figure 1. Electromagnetic spectrum and mode of action of ionizing radiations on nucleic acid in living cells

The major ionizing radiations used in food industries are: electromagnetic gamma (γ) rays obtained from radioactive forms of the elements cobalt (60Co) or cesium (137Cs), and the corpuscular beta rays (β) that are the electrically formed electrons in a cathodic tube, which are taken by an electron accelerator to form a stream of high-speed electrons propelled to foods [3].

3. Regulatory and Enforcement Status of Application of Ionizing Irradiation

3.1. Regulatory Aspects

The ionization of food products is a process subject to regulatory control. Authorized products are either part of an approved list or the authorization has been given by the competent authority based on an application for authorization. The implementation of treatments requires sophisticated installations and/or equipment in a perfectly controlled environment [4]. Therefore, ionization treatment is not as simple and globally developed as heat treatments. Several texts provide a framework for their use. At the global level, the texts of the Codex Alimentarius (2003a and 2003b) are references, they concern the general code of use 2003a and the practices of use 2003b and have been adopted by more than 60 countries. This general framework is often supplemented by national and/or community regulations; for example, European directive 1999/3/EC provides a list of authorized products and their respective radiation doses [5].

Consumer information on food treatments is extremely important, especially for treatments that are not always universally accepted. For ionizing radiation, information concerning its application to the food and/or one of the ingredients of the food is mandatory. This may be in the form of label statements such as “product treated by ionizing radiation”, “product treated by ionizing energy”, “product treated by irradiation” or the affixing of the international symbol “radura”, which indicates the existence of such treatments (Figure 2). However, the use of the radura symbol is voluntary [6].

Figure 2. Radura symbol.

3.2. Applications of Authorized Ionizing Treatments

There are several ways to describe the agri-food applications of ionizing treatments; the most common is based on the dose applied [7]. Different levels of ionizing radiations are authorized for different food materials (Table 1).

Table 1. Use of different levels of irradiation dose for food preservation.

|

Dose (kGy) |

Usage for Food Products |

|

0.05–0.15 |

Anti-germination for potatoes, onions, garlic, shallots, etc. |

|

0.15–3 |

Pesticide and insecticide properties (by the destruction of embryos and larvae, and sterilization of adults) for cereals, fruits, and pulses. In this dose range, some meat parasitic worms, e.g., Trichinella in pork, can be eliminated, and also the ripening of fresh fruits and vegetables is delayed. |

|

2–10 |

Treatment of meat and meat products, ready meals, fish products (fish, shellfish, frog’s legs), fresh fruit and vegetables, spices and herbs, and various ingredients (gums, additives) to improve and guarantee a hygienic quality by eliminating pathogenic microorganisms and/or extend their shelf life by reducing the microbial population of spoilage. |

|

10–60 |

Food is sterilized and then can be stored for up to 2 years at room temperature in sealed plastic packaging |

The terms radicidation and radurization are used to refer to these applications of less than 10 kGy doses [8]. Radicidation (from Latin: radiare—radiate and ocsidere—kill) is the application to the food of a dose of ionization sufficient to reduce the specific number of viable pathogenic bacteria to a level such that they are not detectable by any known method. This term also applies to the destruction of specific parasites. Radurization (from Latin: radiare—radiate and durare—prolong) is the application of an ionization dose sufficient to preserve the quality of food by ensuring a substantial reduction in the number of spoilage bacteria.

Radappertization (by the name of Nicolas Appert, the inventor of thermal sterilization method of food products) is the application of high dose (10 to 60 kGy) of ionization to food in order to reduce the number and/or activity of living microorganisms so that none (except viruses) is detectable by any recognized method [8]. Such radio-sanitized products can then be stored for up to 2 years at room temperature in sealed plastic packaging. It should nevertheless be noted that the search for commercial sterility or microbiological stability remains a very marginal application of ionization (Table 2).

Table 2. Ionization dose (in kGy) to ensure the radappertization of various foods.

|

Foods |

Dose (kGy) |

Temperature |

|

Bacon |

25.2 |

Room |

|

Beef |

41.2 |

−30 °C |

|

Corned beef |

26.9 |

−30 °C |

|

Duck with orange sauce |

21 |

−40 °C |

|

Turkey |

28 |

−40 °C |

|

Ham |

31.4 |

−30 °C |

|

Pork |

43.7 |

−30 °C |

|

Pork sausages |

25.5 |

−30 °C |

|

Chicken |

42.7 |

−30 °C |

|

Mashed carrots and sweet potatoes |

28 |

−40 °C |

|

Madras rice |

28 |

−40 °C |

Adapted from Desmonts et al. [9].

This entry is adapted from the peer-reviewed paper 10.3390/foods9070878

References

- Desmonts, M.H.; Strasser, A.; Hasselmann, C.; Marchionie, E.; Hausser, F. Les traitements ionisants desaliments. In Traitement Ionisants et Hautes Pressions des Aliments; Federighi, M., Tholozan, J.L., Eds.; Economica:Paris, France, 2001; pp. 1–20, ISBN 2-7178-4162-8.

- Fabiana Regina Lima; Kássia Vieira; Miriam Santos; Poliana Mendes De Souza; Effects of Radiation Technologies on Food Nutritional Quality. Descriptive Food Science 2018, NA, 137-152, 10.5772/intechopen.80437.

- What Is Ionizing Radiation? . WHO. Retrieved 2020-7-10

- Food Irradiation: What You Need to Know . FDA. Retrieved 2020-7-10

- IAEA. Manual of Good Practice in Food Irradiation: Sanitary, Phytosanitary and Other Applications; TechnicalReports Series; International Atomic Energy Agency: Vienna, Austria, 2015; ISBN 978-92-0-105215-5.

- Codex Alimentarius. Codex Alimentarius Code of Practice for Radiation Processing of Food (CAC/RCP 19–1979,Rev.2–2003b); Editorial Correction 2011; Food Standards Program; Secretariat of the Codex AlimentariusCommission; FAO/WHO: Rome, Italy, 2011.

- Muhammad Tanveer Munir; Michel Federighi; Control of Foodborne Biological Hazards by Ionizing Radiations. Foods 2020, 9, 878, 10.3390/foods9070878.

- Obodovskiy, I. Radiation sterilization. In Radiation: Fundamentals, Applications, Risks, and Safety; Obodovskiy, I.,Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 373–378, ISBN 978-0-444-63979-0.

- Mohammad Habibur Rahman; Saiful Islam; Shahida Begum; Liaqat Ali; Bidhan Chandra Sutradhar; Vera O Neil; Anwar Hossain; Caroline Nandwa; Scientific Opinion on the Standards and Regulations of Irradiated Food. Journal of Nutrition & Food Sciences 2018, 8, 1-6, 10.4172/2155-9600.1000718.