Industry 4.0 is currently identified as a major factor in the future competitiveness of enterprises. However, the implementation and readiness of different technologies varies from one enterprise to another. Based on the performed factor analysis, an Industry 4.0 index (VPi4) was created, which allows the enterprises to determine their current level of Industry 4.0.

- Industry 4.0

- index

- smart

- intensity of technology

- manufacturing

- implementation

1. Introduction

The VPi4 index and its methodology allow enterprises to easily identify their own level of technology readiness within Industry 4.0. The index is a tool for managers to set strategic objectives and formulate strategies in line with the challenges of the Fourth Industrial Revolution. It can also be a criterion in deciding on investment plans in terms of selecting priorities for the further development of an enterprise. The proposed solution allows better assessment of strategic initiatives in terms of their future return. The managers can also help to decide which projects should be implemented in order to ensure greater synergies. The index includes technologies that need to be implemented in the enterprises, as well as the processes that need to be set up, changed, and reintroduced. In this sense, it can also, in addition to project management, help with the management and identification of key processes in the organization [1].

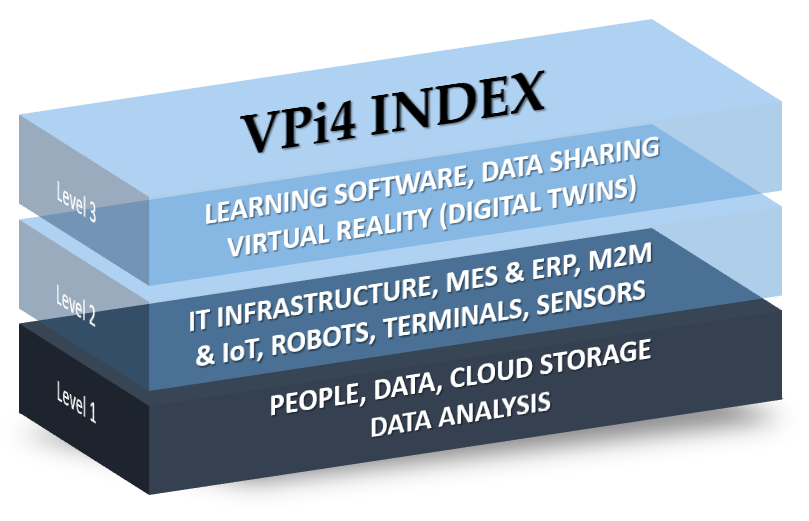

The initial level of index includes the basic requirements of Industry 4.0 such as well-qualified (the right) people [2], and processes of data collecting [3], storage in the cloud [4], and analysis of data [5]. These processes and variables are necessary for higher levels of Industry 4.0 and can be limits for the future development and introduction of Industry 4.0 implementation. The second level of the index consists of necessary infrastructure which is needed to operate with technologies. This level has more parts, such as using sensors for collecting data [4], IT infrastructure including MES [6], ERP information systems [6], linked data via M2M (or IoT), robots [7], and user-end technologies such as mobile terminals [4]. The last level is more advanced in terms of using learning software [5], virtual reality, and simulations including digital twins [8] or sharing data with other parties [9].

The cornerstone of Industry 4.0 is based on machines, equipment, logistics, and humans who are connected to each other to exchange data, process data, and make decisions, appropriately coordinating the ever-present machines [10]. Industry 4.0 is characterized primarily by digitization, robotics, and artificial intelligence.

Use o sensors. Sensors are sources of information for the control system (computer, brain) and technical devices, which measure certain physical and technical quantities and convert them into a signal that is remotely transmitted and further processed. These are various global positioning system (GPS) sensors, cameras, and microphones, forming the digital nervous system. These devices acquire information on position, distance, motion, speed, displacement, temperature, drought, humidity, sound, vibration, gases, chemicals, flow, strength, load, pressure, level, electricity, acceleration, tilt, light, etc. The use of sensors in smart factories has many facets, as discussed by many authors [11].

Data collection and analysis. The process of data collection process includes retrieving, searching, selecting, and generating. As more and more business activities are digitized, new data sources arise, and the equipment to process these data becomes increasingly cheaper; we are entering a new era [12]. The volume of stored data is growing four times faster than the world economy, and computing power is increasing nine times faster.

Information Technology (IT) Infrastructure and Mobile Terminals. In particular, Industry 4.0 includes a radical shift in how IT infrastructure works, defined as the overall transformation of the manufacturing industry through the introduction of digitization and the internet. These transformations mean a revolutionary improvement in the design and manufacturing processes, operations, and services of manufacturing products and systems. Tjahjono [13] defines Industry 4.0 requirements for IT infrastructure in terms of device automation, auto-driving, increased need for reality, an extremely large number of monitored and managed devices, and process automation. The enterprises using the Internet of things (IoT) cannot rely solely on wireless networks such as WiFi, ZigBee, and low-power wide-area network (LPWAN) for their future critical related systems [14].

Cloud storage and Big Data. Data storage includes recording, transportation, replication, compression, cleaning, indexing, stream processing, integration, and transformation of data. Given the increase in data volume (big data), the main question is how to store all data and where. Data warehouses and centers are the most often used. A data warehouse (DW) is an integrated collection of subject-oriented decision support data [15]. Clouds are hardware services offering computing, networking, and storage capacity [16].

Information Systems and Learning Software. The implementation of Industry 4.0 uses the concept of an automation pyramid in connection with information technology. The pyramid is closely related to the vertical integration of information systems in an enterprise. Typical solutions and technologies in this vertical integration include data acquisition sensors: programmable logic controllers (PLC) that control production processes and take control levels, supervisory control and data acquisition (SCADA), which allows managing different levels of support processes and supervision, manufacturing execution systems (MES) controlling production processes, and intelligent enterprise resource planning (ERP) management for the enterprise level, the highest level in this hierarchical image [17]. Learning software includes pattern and machine learning (ML), which embodies some of the aspects of the human mind that allow us to deal with an extremely complex solution to the problem with the speed overcoming even the fastest computers [18].

Robots. Production process automation began in the 1960s with the introduction of industrial robots into the automotive manufacturing process. The automation of production systems by the introduction of industrial robots is an ongoing process and is now in line with the evolution of information technology [19]. The area of collaborative robots was extensively explored, but it is necessary to define precisely what type of robot can be specified as cooperative.

M2M Communication. Digital production includes a wide range of applied sciences. Studies in these fields attract a lot of effort both in academia and in industry, especially in connection with machine connectivity and communication (M2M), vitally important for machine collaboration and process optimization [20]. M2M communication will be provided both between physical objects and between their cloud-based digital counterparts [21].

Sharing and using data with suppliers and customers. Enterprises face a precarious environment and strive to achieve greater cooperation in the supply chain to leverage the resources and knowledge of their suppliers and customers [22]. In such a chain, this cooperation takes place through electronic data interchange (EDI) [23].

Use of virtual reality, simulation, and digital twins. Simulation is defined as an imitation of a real thing, a state, or a process. Generally, it implies displaying or modeling some key features and behavior of some physical or abstract systems for testing, optimization, and education. Product and process simulations are used extensively in production, especially processes of visualization, representation, simulation, modeling, and interpretation. Enriching digital simulations with sensor data brings reality closer and improves the accuracy of simulation results [24]. Virtual reality (VR) is broadly defined as a computer-generated three-dimensional (3D) world [25], and an environment that simulates complex situations and contexts in real life and allows people to immerse, navigate, and communicate [26]. Digital twins are a mirror image of a real-time physical process [27]. The concept of using "twins" comes from the Apollo NASA (National Aeronautics and Space Administration) program; later, it was used also in aviation, such as the "Iron Bird" [8].

2. Model Description

Source: authors

The first level of introducing Industry 4.0 into an enterprise consists of the following areas (with factor biases):

- We have the right people (mechatronics, mounter, technologist)—0.61;

- We collect data—0.82;

- Data storage in the cloud—0.63;

- We analyze data—0.86.

The second level of introducing Industry 4.0 into an enterprise consists of the following areas:

- IT infrastructure (speed, stability)—0.53;

- MES, ERP—0.75;

- We use linked data (M2M)—0.58;

- Use of robots, robotic arms (in production and elsewhere)—0.54;

- Mobile terminals—0.54;

- Use of sensors—0.58.

The third level of introducing Industry 4.0 into an enterprise consists of the following areas:

- Use of learning software—0.44;

- Suppliers can use our data (response options, predictions)—0.67;

- Use of virtual reality (digital twins, simulation)—0.68.

VPi4 index aims to categorize Industry 4.0 components into a clear framework. The proposed index brings a new three-level structure of the Industry 4.0 phenomenon. The main theoretical contribution is, in particular, the determination of the content of the term and the determination of the importance of different factors in the context of the readiness of companies to implement Industry 4.0 concepts. The differences between more technologically and less technologically demanding industries confirm the specifics of different fields in the use of new technologies. This confirms the conclusions of many other researches and the fact that new technologies are largely being introduced, especially in the field of mechanical engineering. The results also indicate that the subjective perception of enterprises of their own level of Industry 4.0 corresponds more or less to the actual situation. The problem, however, is probably the lack of visibility in terms of the current challenges, priorities, and complexity of technology [28].

References

- Scremin, L.; Armellini, F.; Brun, A.; Solar-Pelletier, L.; Beaudry, C.. Towards a framework for assessing the maturity of manufacturing companies in industry 4.0 adoption In Analyzing the Impacts of Industry 4.0 in Modern Business Environments; Hershey: Derry Township, PA, USA, 2018; pp. 224–254.

- Thuy Duong Oesterreich; Frank Teuteberg; Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Computers in Industry 2016, 83, 121-139, 10.1016/j.compind.2016.09.006.

- Akdil, K.Y.; Ustundag, A.; Cevikcan, E.. Maturity and Readiness Model for Industry 4.0 Strategy. In Industry 4.0: Managing the Digital Transformation; Ustundag, A., Cevikcan, E., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 61–94.

- Gökalp, E.; Şener, U.; Eren, P.E.. Development of an Assessment Model for Industry 4.0: Industry 4.0-MM. In Software Process Improvement and Capability Determination; Mas, A., Mesquida, A., O’Connor, R.V., Rout, T., Dorling, A., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 128–142.

- Jeongcheol Lee; Sungbum Jun; Tai-Woo Chang; Jinwoo Park; A Smartness Assessment Framework for Smart Factories Using Analytic Network Process. Sustainability 2017, 9, 794, 10.3390/su9050794.

- Andreja Rojko; Industry 4.0 Concept: Background and Overview. International Journal of Interactive Mobile Technologies (iJIM) 2017, 11, 77-90, 10.3991/ijim.v11i5.7072.

- Abdulmotaleb El Saddik; Digital Twins: The Convergence of Multimedia Technologies. IEEE MultiMedia 2018, 25, 87-92, 10.1109/mmul.2018.023121167.

- Beata Slusarczyk; INDUSTRY 4.0 – ARE WE READY?. Polish Journal of Management Studies 2018, 17, 232-248, 10.17512/pjms.2018.17.1.19.

- M. Weyrich; Jan-Philipp Schmidt; Christof Ebert; Machine-to-Machine Communication. IEEE Software 2014, 31, 19-23, 10.1109/ms.2014.87.

- Jiri Tupa; Jan Simota; Frantisek Steiner; Aspects of Risk Management Implementation for Industry 4.0. Procedia Manufacturing 2017, 11, 1223-1230, 10.1016/j.promfg.2017.07.248.

- McAfee, A.; Brynjolfsson, E.; Big Data: The Management Revolution. Harv. Bus. Rev. 2012, 90, 60–68, .

- Benny Tjahjono; C. Esplugues; J.E. Ares; G. Pelaez; What does Industry 4.0 mean to Supply Chain?. Procedia Manufacturing 2017, 13, 1175-1182, 10.1016/j.promfg.2017.09.191.

- Mehmet Ali Erturk; Muhammed Ali Aydın; Muhammet Talha Büyükakkaşlar; Hayrettin Evirgen; A Survey on LoRaWAN Architecture, Protocol and Technologies. Future Internet 2019, 11, 216, 10.3390/fi11100216.

- Fuertes, W.; Reyes, F.; Valladares, P.; Tapia, F.; Toulkeridis, T.; Pérez, E.; An Integral Model to Provide Reactive and Proactive Services in an Academic CSIRT Based on Business Intelligence. Systems 2017, 5, 52, 10.3390/systems5040052.

- McKinsey and Co.. Clearing the Air on Cloud Computing; McKinsey and Co.: New York, NY, USA, 2009; pp. 1-33.

- Ismael Abad; Carlos Cerrada; J. A. Cerrada; Ruben Heradio; Enrique Valero; Managing RFID Sensors Networks with a General Purpose RFID Middleware. Sensors 2012, 12, 7717-7737, 10.3390/s120607719.

- Schlank, R.. Dynamic Memory: A Theory of Reminding and Learning in Computers and People; Cambridge University Press: Cambridge, UK, 1982; pp. 272.

- Ray Zhong; Xun Xu; Eberhard Klotz; Stephen T Newman; Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616-630, 10.1016/j.eng.2017.05.015.

- Zhaozong Meng; Zhipeng Wu; John Gray; A Collaboration-Oriented M2M Messaging Mechanism for the Collaborative Automation between Machines in Future Industrial Networks. Sensors 2017, 17, 2694, 10.3390/s17112694.

- Dongbum Seo; You-Boo Jeon; Song-Hee Lee; Keun-Ho Lee; Cloud computing for ubiquitous computing on M2M and IoT environment mobile application. Cluster Computing 2016, 19, 1001-1013, 10.1007/s10586-016-0573-x.

- Mei Cao; Qingyu Zhang; Supply chain collaboration: Impact on collaborative advantage and firm performance. Journal of Operations Management 2010, 29, 163-180, 10.1016/j.jom.2010.12.008.

- Wenzhi Zeng; Ngying Zhang; Yuan-Hao Fang; Jingwei Wu; Jiesheng Huang; Comparison of partial least square regression, support vector machine, and deep-learning techniques for estimating soil salinity from hyperspectral data. Journal of Applied Remote Sensing 2018, 12, 1, 10.1117/1.jrs.12.022204.

- Nikolaos Nikolakis; Vasilis Maratos; Sotiris Makris; A cyber physical system (CPS) approach for safe human-robot collaboration in a shared workplace. Robotics and Computer-Integrated Manufacturing 2019, 56, 233-243, 10.1016/j.rcim.2018.10.003.

- Ralf Blossey; Self-cleaning surfaces — virtual realities. Nature Materials 2003, 2, 301-306, 10.1038/nmat856.

- Diemer, J.. Sichere Industrie-4.0-Plattformen auf Basis von Community-Clouds. In Handbuch Industrie 4.0: Produktion, Automatisierung und Logistik; Vogel-Heuser, B., Bauernhansl, T., ten Hompel, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–28.

- Eric Lutters; PILOT PRODUCTION ENVIRONMENTS DRIVEN BY DIGITAL TWINS. The South African Journal of Industrial Engineering 2018, 29, 40-53, 10.7166/29-3-2047.

- Jaroslav Vrchota; Martin Pech; Readiness of Enterprises in Czech Republic to Implement Industry 4.0: Index of Industry 4.0. Applied Sciences 2019, 9, 5405, 10.3390/app9245405.