Existing self-healing mechanisms are still very far from full-scale implementation, and most published work has only demonstrated damage cure at the laboratory level. Their rheological nature makes the mechanisms for damage cure difficult to implement, as the component or structure is expected to continue performing its function. In most cases, a molecular bond level chemical reaction is required for complete healing with external stimulations such as heating, light and temperature change. Such requirements of external stimulations and reactions make the existing self-healing mechanism almost impossible to implement in 3D printed products, particularly in critical applications.

- 3D printing

- self-healing mechanism

- challenges

- 3D printing structure

- crack propagation

- origami capsule

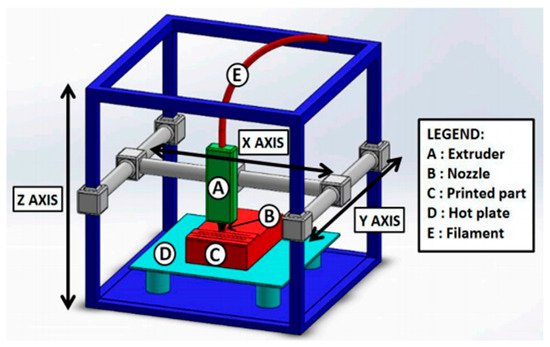

- FDM

1. Introduction

Self-healing materials, with characteristics that allow them to heal themselves when damaged by mechanical, thermal, or other causes, and to restore their original sets of properties, include metals, polymers, ceramics, and composites [1]. Self-healing can be defined as a natural process or mechanism, which enables the material to recover from the damages caused by, e.g., external phenomena through a healing process that returns the material to its original set of properties [2][3][4][5][6]. While natural mechanisms, such as the autonomous repair of bone, are lacking in traditional self-healing materials, the last decade has seen tremendous progress in the development and design of such materials [1]. Materials such as polymers and composites can exhibit characteristics of self-healing. If these materials are damaged, possibly due to fatigue, during their utilization, that damage can repair itself through self-healing mechanisms, which not only heal that material, but can also extend the working life of that material by maintaining its strength [1][1]. These properties are considered to be important in materials, which are more prone to damage, and where repair is not possible during the execution time.

The self-healing process in terms of materials started in the early 1970s, when the exploration of space (i.e., the Apollo mission) became a reality, and the shuttle was constructed of materials that included ammonium perchlorate-filled hydroxyl-terminated polybutadiene [7]. It was assumed at that time that materials could be damaged at the nanoscale, and that would lead to larger microscopic cracks, causing the catastrophic loss of not only materials, but also payloads. It became clear later that such damage could be self-healing.

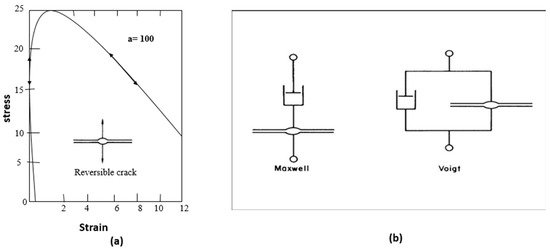

First, damage can be measured through mechanical stress-strain, to quantify the damage and effect of self-healing methods [8]. This was known as a reversible self-healing crack, which was used later to assess the basic characteristics of self-healing elements, using, for example, the Maxwell and Voigt models [7]. Figure 1 below shows the first self-healing mechanism element, which was further improved.

Since, 1970, there have been a significant number of publications on self-healing mechanisms of different materials, especially thermoplastic and cross-linked systems. However, it was 2001 when the first article on the self-healing in polymer-based materials was published in Nature [7]. This triggered research into the use of self-healing polymer materials, inspired by the tremendous advantages of self-healing materials over traditional materials in engineering applications, such as electrical, automotive, biomedical, aerospace, chemical, and civil [9].

Smart polymer materials have similarities to biological self-healing phenomena, and have significantly improved the life of critical components [7][10]. The development of these kinds of systems and materials is challenging, but not impossible, and include self-healing paints and coatings, even bridges, buildings and cars [2][11]. Smart materials are often used in critical applications and components, to make sure the products have durability, flexibility, and are lightweight. Such materials are required to self-heal after damage. For example, presently, if a scratch is found on the paintwork of a car, it requires either expensive corrective work in a repair shop, or a significant and inconvenient repair by the owner. In such a situation, a self-healing process that ensures that the relevant material maintains its function is highly desirable, particularly if it retains its ability to reverse damage over a long time, and without delay. It would be doubly advantageous for the self-healing process to cure damage automatically without any peripheral intercession [4][5][12][13][14].

Most materials change their properties with age, and gradually decay. Some materials take longer than others; wood rots when insects or micro-organisms eat it away; however, plastic can take hundreds of years to break, or sooner with the help of fire or sunlight [9]. Some materials are very vulnerable and sensitive to breakage and sometimes very unexpectedly, such as when applied force (e.g., stress and strain) generates internal fractures. Such materials pose the hardest challenges in terms of the self-healing process [15]. With regular maintenance and inspection, it is easy to spot such problems as rotting or rusting; however, there can be cracks in crucial components where they are hard to detect, such as inside hot engines that operate at high speeds with spinning blades. There are technologies and techniques, which can be used to detect such faults, e.g., the well-known non-destructive testing technique of ultrasound scanning, that makes it relatively easy to find defects within materials or components during routine inspections. However, when the component is in use, it is almost impossible to detect a potential failure.

The mechanics of these challenges have become more complex with recent advancements in the design and manufacturing of polymer-based components [10][16]. For example, the mechanical behaviour of a component at microstructural level changes if it is manufactured using the additive method of manufacturing, rather than a conventional method [17]. In the past, self-healing mechanisms were devised for components made of conventional methods materials, but additive manufacturing (AM) offers important opportunities to include into the object means for self-repair [18].

However, polymer materials are considered to have highly self-healing and elastic properties, along with being a challenging task. A study from Zhao et al. found that with the use of 4-tris as a tetratopic linker to crosslink a poly(dimethylsiloxane) backbone,, one can obtain a self-healing polymer, with efficient outcomes upon stretching. It was also revealed that materials with strain at the break of material, such as polymers, recovered to their original length after being stretched [19]. The damaged material was also healed at room temperature—up to 93% within 1 h. Zhao et al. suggested that polymers can be used in different applications, like electronic sinks, biochips, matrixes in soft actuators, and others.

2. Existing Self-Healing Mechanisms in 3D Printed Structures

2.1. 3D Printing of Self-Healing Materials

2.2. General Categories of Self-Healing Mechanisms Applicable to 3D Printed Structures

2.3. Healing Mechanism for Different Material Classes

| Mechanisms | Type of Materials | Name of Materials | |

|---|---|---|---|

| Polymers & Polymer Composites | Metals | ||

| Encapsulation | ✓ | Polycarbonates, cement, ABS, poly(urea-formaldehyde) and polystyrene | |

| Increase of temperature | ✓ | ✓ | Glass, aluminium |

| Expanding phases | ✓ | ✓ | powder or slurry |

| Separation phases | ✓ | Ionomers, epoxy | |

| Reversible crosslinks | ✓ | × | Diels-Alder reactions, polycyclopendiene |

| Channel transport | ✓ | PLA (Polylactic Acid) | |

| Biological processes | × | Polyurethane (PU) | |

| Electro-chemical process | × | ✓ | Polycarbonates, polyethylene, plastic |

2.4. Focused Efforts Made for Developing Self-Healing in 3D Printed Structures

This section discusses, in detail, the effort made for developing self-healing in a 3D printed structure, including working principles and advantages, with visual evidence.

2.4.1. Working Principle

-

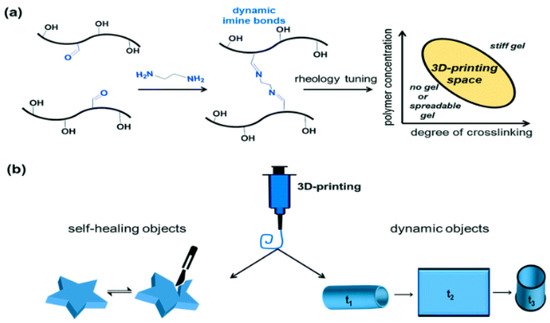

The first step comprises the synthesis and functionalization of PHEMA (benzaldehyde-functionalized poly-2 hydroxyethyl methacrylate) with the pendant benzaldehyde group; next, cross-linking with diamine takes place. A delicate rheological tuning of ink formulations and the mapping of printable space is required to prepare printable inks [59].

2.4.2. Self-Healing Mechanism Advantages and Limitations

The self-healing mechanism, as obtained in 3D printed structures, has the advantages associated with 3D printing: reduced time to production, cost-effectiveness, environmentally friendly, and versatile, as almost anything that can be imagined can be produced [18]. Nevertheless, self-healing in a 3D printing structure can lead to strain release that subsequently initiates cracks that can propagate and damage the material [68][27][32][37][69][70]. However, the self-healing properties are capable of overcoming potential damage at the sub-surface level, thus allowing cracks to be healed rapidly, with no impact on the workability of the component, thereby significantly reducing vulnerability. However, because of its high customizability and capability to print complex geometries, researchers commonly use 3D-printing [71]. Additionally, a recent development in CAD software [10] and novel materials [72] further extends their 3D printing capabilities, especially for self-healing mechanisms.

There are significant limitations that exist on both the self-healing mechanism and the exploration of the study domain. Evidence shows that most of the investigations have been conducted on how could different materials can be made more damage tolerant; less research has been conducted on how materials heal the damage within the perspective of 3D printing [18]. There are many materials, such as polymers and polymer-based composite materials, that can suffer from different types of cracks, and which can lead to more severe or catastrophic damage: these are both external (e.g., environmental attacks, etc.) and internal (e.g., quality of materials, etc.) [65]. This omission is considered as a gap in the research into self-healing as applicable to 3D printing. More research needs to be conducted in this area. The limitation, in terms of self-healing for 3D printing, is cost, because more of the catalyst is required to achieve a higher degree of healing [73][74].

This entry is adapted from the peer-reviewed paper 10.3390/polym12071534

References

- Madara, S.R.; Raj, N.S.S.; Selvan, C.P. Review of research and developments in self healing composite materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Dubai, UAE, 28–29 November 2018; Volume 346.

- Thao, T.D.P. Quasi-brittle Self-healing Materials: Numerical Modelling and Application in Civile Engineering; National University Singapore: Singapore, 2011; pp. 2–228.

- Dry, C.M. Smart multiphase composite materials that repair themselves by a release of liquids that become solids. Smart Struct. Mater. 1994, 2189, 62–70.

- Zhang, F.; Ju, P.; Pan, M.; Zhang, D.; Huang, Y.; Li, G.; Li, X. Self-healing Mechanisms in Smart Protective Coatings: A Review. Corros. Sci. 2018, 144, 74–88.

- Mihashi, H.; Nishiwaki, T. Development of engineered self-healing and self-repairing concrete-state-of-the-art report. J. Adv. Concr. Technol. 2012, 10, 170–184.

- Pelletier, M.M.; Brown, R.; Shukla, A.; Bose, A. Self-healing Concrete with a Microencapsulated Healing Agent; University of Rhode Island: Kingston, NY, USA, 2010.

- Wool, R.P. Self-healing materials: A review. R. Soc. Chem. 2008, 4, 400–418.

- Fainleib, A.M.; Purikova, O.H. Self-healing polymers: Approaches of healing and their application. Polym. J. 2019, 41, 4–18.

- Cremaldi, J.C.; Bhushan, B. Bioinspired self-healing materials: Lessons from nature. Beilstein J. Nanotechnol. 2018, 9, 907–935.

- Wu, D.Y.; Meure, S.; Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. (Oxf.) 2008, 33, 479–522.

- Lim, S.; Buswell, R.; Le, T.; Wackrow, R.; Austin, S.; Gibb, A.; Thorpe, A. Development of a viable concrete printing process. In Proceedings of the 28th International Symposium on Automation and Robotics in Construction (ISARC 2011), Seoul, South Korea, 29 June–2 July 2011; pp. 665–670.

- van Tittelboom, K.; de Belie, N. Self-healing in cementitious materials-a review. Materials 2013, 2182–2217.

- Yang, Z.; Hollar, J.; He, X.; Shi, X. A self-healing cementitious composite using oil core/silica gel shell microcapsules. Cem. Concr. Compos. 2011, 33, 506–512.

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770.

- Yang, Y.; Davydovich, D.; Hornat, C.C.; Liu, X.; Urban, M.W. Leaf-Inspired Self-Healing Polymers; Chem. Elsevier Inc.: Amsterdam, The Netherlands, 2018; Volume 4, pp. 1928–1936.

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018.

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67.

- Aïssa, B.; Therriault, D.; Haddad, E.; Jamroz, W. Self-healing materials systems: Overview of major approaches and recent developed technologies. Adv. Mater. Sci. Eng. 2012.

- Zhao, P.C.; Li, W.; Huang, W.; Li, C.H. A self-healing polymer with fast elastic recovery upon stretching. Molecules 2020, 25, 597.

- Gross, B.C.; Erkal, J.L.; Lockwood, S.Y.; Chen, C.; Spence, D.M. Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences. Anal. Chem. 2014, 86, 3240–3253.

- Pati, B.P.S.S. SRD self-healing polymer composites based on graphene and carbon nanotubes. In Smart Polymer Nanocomposites: Energy Harvesting, Self-Healing and Shape Memory Applications; Springer: Berlin, Germany, 2017; pp. 119–152.

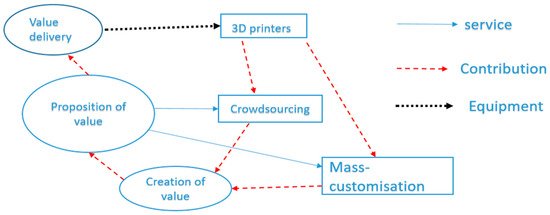

- Rayna, T.; Striukova, L. From rapid prototyping to home fabrication: How 3D printing is changing business model innovation. Technol. Forecast. Soc. Chang. 2016, 102, 214–224.

- Xin, A.D.H. 3-D Printed Tires and Shoes that Self-Repair. PHYS ORG. 2019. Available online: (accessed on 25 November 2019).

- Xu, Y.; Wu, X.; Guo, X.; Kong, B.; Zhang, M.; Qian, X.; Mi, S.; Sun, W. The boom in 3D-printed sensor technology. Sensors 2017, 17, 1166.

- Wang, L.; Sanders, J.E.; Gardner, D.J.; Han, Y. Effect of fused deposition modeling process parameters on the mechanical properties of a filled polypropylene. Prog. Addit. Manuf. 2018, 3, 205–214.

- Du, Y.; Li, D.; Liu, L.; Gai, G. Recent achievements of self-healing graphene/polymer composites. Polymers 2018, 10, 114.

- Nadgorny, M.; Xiao, Z.; Connal, L.A. 2D and 3D-printing of self-healing gels: Design and extrusion of self-rolling objects. Mol. Syst. Des. Eng. 2017, 2, 283–292.

- Jo, Y.; Jeong, D.W.; Lee, J.O.; Choi, Y.; Jeong, S. 3D-printed origami electronics using percolative conductors. RSC Adv. 2018, 8, 22755–22762.

- Zheng, X.; Lee, H.; Weisgraber, T.H.; Shusteff, M.; DeOtte, J.; Duoss, E.B.; Kuntz, J.D.; Biener, M.M.; Ge, Q.; Jackson, J.A.; et al. Ultralight, ultrastiff mechanical metamaterials. Science 2014, 344, 1373–1377.

- Truby, R.L.; Lewis, J.A. Printing soft matter in three dimensions. Nature 2016, 540, 371–378.

- Raj, S.A.; Muthukumaran, E.; Jayakrishna, K. A case study of 3D printed PLA and its mechanical properties. Mater. Today Proc. 2018, 5, 11219–11226.

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257.

- Thomas, J.P.; Renaud, J.E. Mechanical behavior of acrylonitrile butadiene styrene (ABS) fused deposition materials. Exp. Investig. Âguez 2006, 7, 148–158.

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural fillers: A review of their mechanical properties. Polymers 2019, 11, 1094.

- Bhardwaj, A.; Zou, N.; Pei, Z.J. Additive manufacturing for civil infrastructure design and construction: Current state and gaps. In Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, College Station, TX, USA, 18–22 June 2018; Volume 1, pp. 1–9.

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797.

- Sanders, P.; Young, A.J.; Qin, Y.; Fancey, K.S.; Reithofer, M.R.; Guillet-Nicolas, R.; Kleatz, F.; Pamme, N.; Chin, J.M. Stereolithographic 3D printing of extrinsically self-healing composites. Sci. Rep. 2019, 9, 1–6.

- Terryn, S.; Mathijssen, G.; Brancart, J.; Lefeber, D.; Assche, G.; van Vanderborght, B. Development of a self-healing soft pneumatic actuator: A first concept. Bioinspiration Biomim. 2015, 10.

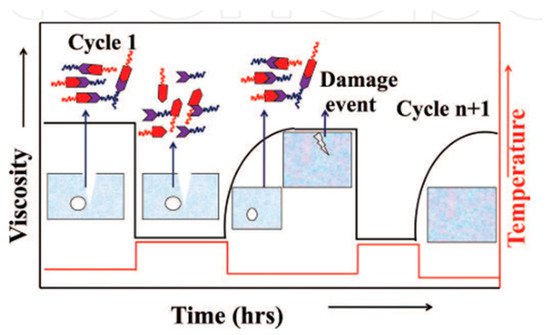

- Park, J.S.; Darlington, T.; Starr, A.F.; Takahashi, K.; Riendeau, J.; Hahn, H.T. Multiple healing effect of thermally activated self-healing composites based on Diels-Alder reaction. Compos. Sci. Technol. 2010, 70, 2154–2159.

- Toohey, K.S.; Sottos, N.R.; Lewis, J.A.; Moore, J.S.; White, S.R. Self-healing materials with microvascular networks. Nat. Mater. 2007, 6, 581–585.

- Banshiwal, J.K.; Tripathi, D.N. Self-healing polymer composites for structural application. Funct. Mater. 2019, 10, 1–13.

- Deng, G.; Li, F.; Yu, H.; Liu, F.; Liu, C.; Sun, W.; Jiang, H.; Chen, Y. Dynamic hydrogels with an environmental adaptive self-healing ability and dual responsive Sol-Gel transitions. ACS Macro Lett. 2012, 1, 275–279.

- Du, P.; Wu, M.; Liu, X.; Zheng, Z.; Wang, X.; Sun, P.; Joncheray, T.; Zhang, Y. Synthesis of linear polyurethane bearing pendant furan and cross-linked healable polyurethane containing Diels-Alder bonds. New J. Chem. 2014, 38, 770–776.

- Zhang, Z.P.; Rong, M.Z.; Zhang, M.Q. Mechanically Robust, self-healable, and highly stretchable “living” crosslinked polyurethane based on a reversible C-C bond. Adv. Funct. Mater. 2018, 28, 1–8.

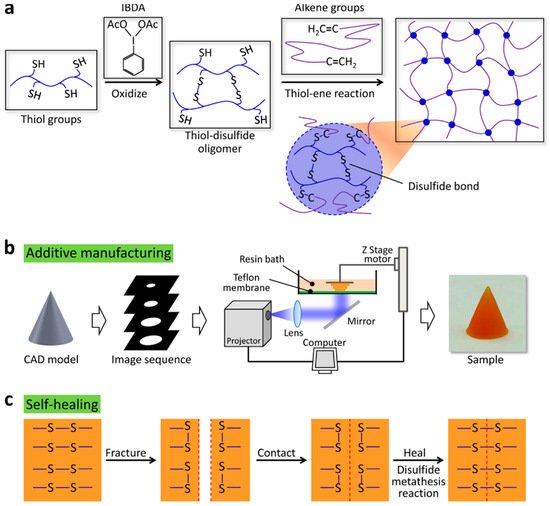

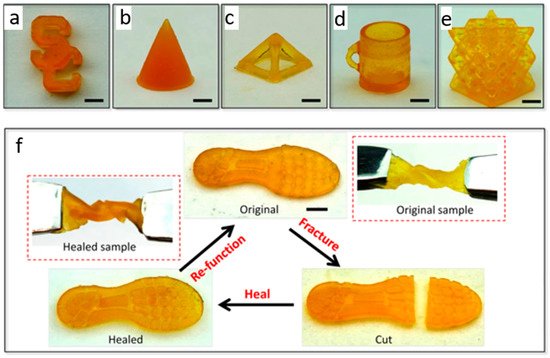

- Li, X.; Yu, R.; He, Y.; Zhang, Y.; Yang, X.; Zhao, X.; Huang, W. Self-healing polyurethane elastomers based on a disulfide bond by digital light processing 3D printing. ACS Macro Lett. 2019, 8, 1511–1516.

- Yang, Y.; Urban, M.W. Self-healing polymeric materials. Chem. Soc. Rev. 2013, 42, 7446–7467.

- Zhang, M.Q.; Rong, M.Z. Intrinsic self-healing of covalent polymers through bond reconnection towards strength restoration. Polym. Chem. 2013, 4, 4878–4884.

- Darabi, M.A.; Khosrozadeh, A.; Mbeleck, R.; Liu, Y.; Chang, Q.; Jiang, J.; Cai, J.; Wang, Q.; Luo, G.; Xing, M. Skin-inspired multifunctional autonomic-intrinsic conductive self-healing hydrogels with pressure sensitivity, stretchability, and 3D printability. Adv. Mater. 2017, 29, 1–8.

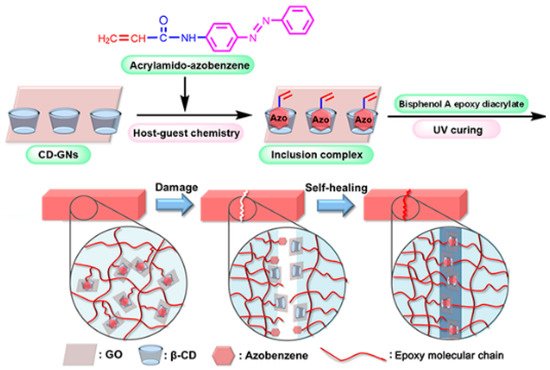

- Hu, Z.; Zhang, D.; Lu, F.; Yuan, W.; Xu, X.; Zhang, Q.; Liu, H.; Shao, Q.; Guo, Z.; Huang, Y. Multistimuli-responsive intrinsic self-healing epoxy resin constructed by host-guest interactions. Am. Chem. Soc. 2018, 51, 5294–5303.

- Deng, G.; Tang, C.; Li, F.; Jiang, H.; Chen, Y. Covalent cross-linked polymer gels with reversible sol-gel transition and self-healing properties. Macromol. Am. Chem. Soc. 2010, 43, 1191–1194.

- Scott, T.F.; Schneider, A.D.; Cook, W.D.; Bowman, C.N. Chemistry: Photoinduced plasticity in cross-linked polymers. Science 2005, 308, 1615–1617.

- Hager, B.M.D.; Greil, P.; Leyens, C.; van der Zwaag, S.; Schubert, U.S. Self-healing materials. Adv. Mater. 2010, 22, 5424–5430.

- Ramesh, M.; Arun Ramnath, R.; Khan, A.; Khan, A.A.P.; Asiri, A.M. Electrically Conductive Self-Healing Materials: Preparation, Properties, and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 1–13.

- Balazs, A.C. Modeling self-healing materials. Mater. Today 2007, 10, 18–23.

- van Dijk, N.; van der Zwaag, S. Self-healing phenomena in metals. Adv. Mater. Interfaces 2018, 5, 1–13.

- Buha, J.; Lumley, R.N.; Crosky, A.G. Microstructural development and mechanical properties of interrupted aged Al-Mg-Si-Cu alloy. Metall. Mater. Trans. A 2006, 37, 3119–3130.

- van der Zwaag, S.; van Dijk, N.H.; Jonkers, H.M.; Mookhoek, S.D.; Sloof, W.G. Self-healing behaviour in Man-made engineering materials: Bioinspired but taking into account their intrinsic character. Philos. Trans. R. Soc. A 2009, 367, 1689–1704.

- Yuan, Y.C.; Yin, T.; Rong, M.Z.; Zhang, M.Q. Self healing in polymers and polymer composites. Concepts, realization and outlook: A review. Express Polym. Lett. 2008, 2, 238–250.

- Belowich, M.E.; Stoddart, J.F. Dynamic imine chemistry. Chem. Soc. Rev. 2012, 41, 2003–2024.

- Brisson, E.R.L.; Xiao, Z.; Levin, L.; Franks, G.V.; Connal, L.A. Facile synthesis of histidine functional poly (N-isopropylacrylamide): Zwitterionic and temperature responsive materials. Polym. Chem. 2016, 7, 1945–1952.

- Brisson, E.R.L.; Xiao, Z.; Franks, G.V.; Connal, L.A. versatile synthesis of amino acid functional polymers without protection group chemistry. Biomacromolecules 2017, 18, 272–280.

- Kamarudin, A.F. Self-Healing Polymer. Polymer Reviews. 2017. Available online: (accessed on 20 March 2020).

- Yu, K.; Xin, A.; Du, H.; Li, Y.; Wang, Q. Additive manufacturing of self-healing elastomers. NPG Asia Mater. 2019, 11.

- Centre, I.; Materials, A. Innovations in Self—Healing Materials. 2018, pp. 1–10. Available online: (accessed on 21 March 2020).

- Pang, J.W.C.; Bond, I.P. A hollow fibre reinforced polymer composite encompassing self-healing and enhanced damage visibility. Compos. Sci. Technol. 2005, 65, 1791–1799.

- The Engineer. 3D-Printed Rubber Materials Self-Heal When Fractured or Punctured. Tech Trends 2020. 2019. Available online: (accessed on 2 April 2020).

- Saunders, S. 3D Printed Self-Healing Materials Can Fix Sole of Shoe in Two Hours. 3D Print. 2019. Available online: (accessed on 30 March 2020).

- Hia, I.L.; Vahedi, V.; Pasbakhsh, P. Self-healing polymer composites: Prospects, challenges, and applications. Polym. Rev. 2016, 56, 225–261.

- Marta., I.; Turri, S.; Levi, M.; Suriano, R. 4D printed thermally activated self-healing and shape memory polycaprolactone-based polymers. Eur. Polym. J. 2018, 101, 169–176.

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B 2017, 110, 442–458.

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 2017, 117, 10212–10290.

- Zhang, Z.; Demir, K.G.; Gu, G.X. Developments in 4D-printing: A review on current smart materials, technologies, and applications. Int. J. Smart Nano Mater. 2019, 10, 205–224.

- Wu, Q.; Zou, S.; Gosselin, F.P.; Therriault, D.; Heuzey, M.C. 3D printing of a self-healing nanocomposite for stretchable sensors. J. Mater. Chem. C 2018, 6, 12180–12186.

- Donaldson, L. Breakthrough in 3D-printed Self-Healing Materials. Materials Today. 2019. Available online: (accessed on 25 March 2020).