1. Introduction

Increasing truck transport demand [

1] and greenhouse gas emissions [

2] have garnered the interest of many to research alternative powertrain technologies for heavy-duty vehicles (HDVs). Objectives to reduce and mitigate emissions across all sectors have been set by many governments regarding the transportation sector. Conventional HDVs disproportionately represent the on-road carbon dioxide (CO

2), nitrogen oxide (NO

x), and particulate matter (PM) [

3]. Medium and heavy-duty vehicles account for approximately 23% of the greenhouse gas (GHG) emissions in the United States [

4]. HDVs also account for approximately 40–60% of the NO

x and PM emissions [

3]. Climate change, pollution, and the resulting health impacts are some of the major concerns with the rise of these combustion emissions [

5]. Therefore, the proposal for lower emission and zero-emission HDVs has been made.

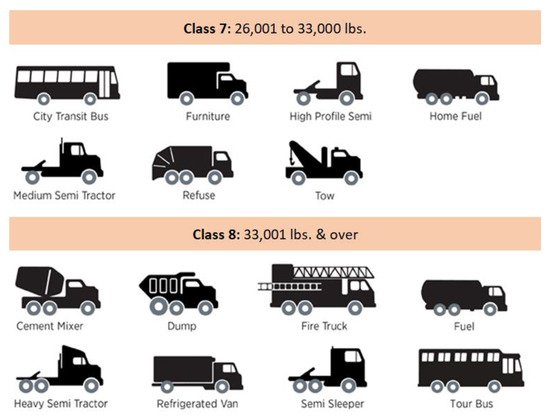

A vehicle is classified as heavy-duty if it has a gross vehicle weight rating (GVWR) greater than 26,000 lbs [

6]. The GVWR is the maximum loaded weight of the vehicle, which is the weight of the vehicle in addition to its payload. HDVs can be further classified into two classes, as seen in . Class 7 vehicles include transit buses, tow trucks, and furniture trucks. Class 8 vehicles include semi-tractors, fire trucks, and dump trucks. Class 7 vehicles have a GVWR of 26,000 lbs to 33,000 lbs, and Class 8 vehicles have a GVWR of greater than 33,000 lbs.

Figure 1. Classes and applications of heavy-duty vehicles.

Conventional HDVs use fossil fuels and an internal combustion engine (ICE) which produce energy to power their movement [

7]. Most HDVs today use an ICE that utilizes diesel called a compression-ignition engine due to its greater energy efficiency than gasoline. However, many kinds of emissions are released during diesel combustion, such as CO

2, NO

x, and PM. Lower emission strategies in HDV technology consist of increasing the efficiency or reducing the pollution of the conventional diesel truck [

8], using alternative fuels which produce fewer emissions [

9], or using a hybrid-electric powertrain that stores some of the energy it uses within batteries [

10]. These strategies work by reducing fuel consumption or by reducing their tailpipe emissions. Examples of lower emission strategies include reducing the rolling resistance of the tires, which increases the fuel savings of the vehicle and using alternative fuels such as compressed natural gas or biodiesel, which produce fewer emissions [

11]. However, zero-emission vehicles require a different powertrain as any vehicle with an ICE will result in tailpipe emissions.

The two types of zero-emission vehicles that will be discussed in this review are battery electric vehicles (BEVs) and hydrogen fuel cell vehicles (HFCVs). These vehicles propel themselves using electricity and do not require the use of an ICE. BEVs and HFCVs both convert the chemical energy stored in active materials into electrical energy within the electrochemical cells. Batteries differ from fuel cells because batteries have the active material stored within the system, while fuel cells have the active materials continuously fed into the system. BEV batteries are often composed of lithium-ion cells due to their high energy and power density [

12,

13,

14]. On the other hand, HFCVs often use proton exchange membrane fuel cells (PEMFC) due to their high-power density and cold-start capabilities [

15].

Both solutions offer zero tailpipe emissions, however, their well-to-wheels (WTW) emissions are still high in many countries because of fossil fuel energy generation. WTW emissions are the emissions released from two main stages: well-to-pump, and pump-to-wheels [

16]. Well-to-pump emissions are the emissions released from the production of energy and the transport of it to the consumer. Pump-to-wheels are the refueling and tailpipe emissions generated when the vehicle is being refueled and used, respectively. Therefore, if the energy to generate the electricity or hydrogen to power the vehicle was utilized fossil fuels, the well-to-pump emissions would be significant. However, if the sources of energy used to generate the energy in these zero-emission vehicles were renewable and not fossil-fuel related, they would theoretically have zero emissions [

17].

In recent years, many researchers have been working to either improve the traditional diesel powertrain or develop battery and fuel cell electric powertrains for HDVs. With that, there have also been some works that provided a comparison between different powertrains or analysis of their impacts based on economic, environmental, and social aspects. Zhao et al. [

18] proposed several non-electrification efficiency-improving technologies as well as hybrid powertrain technologies to reduce heavy-duty truck fuel consumption. It was found that improvements in engine efficiency, aerodynamic drag, and rolling resistance would result in 6–13% in fuel savings, while hybridization was found to achieve 16% fuel saving. Sen et al. [

19] compared traditional diesel, biodiesel, compressed natural gas, hybrid, and battery electric HDVs based on life-cycle emissions, costs, and externalities, to gain insights on how alternative fuel technologies could be employed in HDVs. The results showed that overall, battery-electric HDVs outperformed all other types of trucks. Assuming that electricity could be produced from renewable energy sources in the future, the use of a battery-electric powertrain would significantly improve the life cycle cost of trucks as well as the air quality through emissions reduction. Shin et al. [

17] conducted a case study using a conjoint survey with 1049 people and a mixed multiple discrete-continuous extreme value model to analyze consumer preferences between battery electric vehicles and fuel cell vehicles. The results indicated that consumers preferred battery-electric vehicles over fuel cell vehicles. In [

9], the authors presented a summary of market diffusion studies for alternative fuels and powertrains in HDVs. The methods, main findings, and policy recommendations in each study were compared and synthesized to identify the strengths and weaknesses of each type of powertrains. It was found that there was a high degree of uncertainty regarding which HDV powertrain was superior compared to the rest. Smallbone et al. [

20] evaluated the potential impact of several HDV powertrain technologies, including conventional diesel engines, hybrid, battery-electric, hydrogen fuel cells, and free-piston engine generators.

2. Diesel Internal Combustion Engine in Heavy-Duty Vehicles

Internal combustion engines use transport fuel and combustion to propel their movement. There are two major types of internal combustion engines: compression-ignition (CI) and spark-ignition (SI) [

21]. Most conventional heavy-duty vehicles use CI engines while passenger vehicles use SI engines. Both use the four-stroke combustion cycle of intake, compression, combustion, and exhaust. However, their difference lies in the way they ignite their fuel and the type of fuel they use, which results in differences in efficiencies. CI engines use the heat from the compression stroke to ignite the fuel, while the SI engine uses spark plugs [

22]. As well, CI engines use diesel fuel which has 10–15% more energy content than gasoline [

23] which is used in SI engines. Compression values of diesel engines are higher, which leads to higher efficiencies as the likelihood that air molecules will react with the molecules in the fuel is greater. The greater energy density and the higher efficiencies make it the most popular fuel engine to date for HDVs.

A simplified conventional diesel powertrain configuration involves the engine, clutch, and transmission. The transmission converts the torque output from the engine to rotations in the axles. This is a result of engines running at higher rotations per minute than the average vehicle’s wheels. The clutch allows for the disconnection between the transmission and the engine. The engine is also connected to an alternator which transfers energy to a battery. The battery is then connected to electrical accessories and is used to start the engine alongside the starter.

Conventional HDV ranges can vary depending on the existing payload and fuel in the truck. The average mileage per gallon of fuel for each truck is around 6.5 mpg [

24]. As well, a truck can typically carry around 150–300 gallons of fuel. The range that this allows for is around 975–1950 miles without any stops to refuel. However, this range is highly dependent on the topology, the traffic, and the fact that truckers would not consume 100% of the fuel at each run. The average flow rates are 20–30 gallons per minute for a diesel pump results in a refueling time of a 300-gallon capacity truck of around 10–15 min [

25].

Diesel HDVs release three major types of emissions: carbon oxides, nitrogen oxides, and particulate matter [

26]. There are other components, such as sulfur oxides and organic compounds that are released, but they are not analyzed in this report. Emissions from HDVs tend to vary widely depending on the weight, driving cycle, age, terrain, injection timing, and after-treatment of the vehicle and its engine [

27]. According to a study by Seo et al., an HDV with a GVWR from 26,000 lbs to 88,000 lbs can emit CO

2 from 29 g/km-ton to 119 g/km-ton, respectively [

28]. The Canadian National Railway, on average, estimates that a heavy-duty truck will emit around 63.8 g/km-ton of CO

2 with an average shipment of 16 tons (35,200 lbs) [

29]. Regarding NO

x emissions, the average truck will emit around 7 g/mile, which, compared to a conventional gasoline car, is greater by a factor of 10 [

30]. To combat emissions, after-treatment system technology can be installed, which processes some of the exhaust gases into non-harmful substances. For example, selective catalytic reduction technology uses the reactions between ammonia and NO

x through a catalyst to form nitrogen and water vapor [

11]. This aids in reducing the amount of NO

x that is released into the environment.

The current infrastructure for diesel HDVs is highly prevalent and it is available in most, if not all, countries. As of 2019, nearly all the HDV market runs on conventional diesel fuel [

9,

31]. The demand for alternative fuels is increasing for HDVs, but the alternative fuels markets are still in the very early stages. Regarding energy efficiency, diesel engines, from tank-to-wheel, on average, are around 23% energy efficient [

32]. This means that out of the available energy at the fuel tank, only 23% of it is used as actual work, with the rest being lost due to heat and friction. The specific energy of diesel fuel is around 42.9 MJ/kg [

33].

3. Battery Electric Powertrain in Heavy-Duty Vehicles

BEVs use battery packs to power electric motors for their propulsion. The most common type of battery proposed for battery power packs in battery HDVs is lithium-ion due to its high energy density, high energy efficiency, and long lifespan [

43,

44]. At its most basic level, a lithium-ion battery cell consists of a cathode and lithium anode along with a separator and electrolyte solution. During discharge and charge, lithium ions are carried by the electrolyte from the cathode to the anode and vice-versa, respectively, through the separator, which generates an electron current. All battery power packs must come with a battery management system. This system monitors the battery’s state of charge (SOC), state of health (SOH), state of energy (SOE), and more [

45]. This component is vital to ensure safe and reliable vehicle operation.

The powertrain of a BEV consists of the battery pack, the DC/AC inverter, and the electric motors. This powertrain is much simpler than that of a conventional diesel truck as there are not as many mechanically moving parts as there is no engine. This simplicity is part of the reason why BEVs have 20–30% lower maintenance costs when compared to conventional gas or diesel-powered vehicles [

14]. Additionally, most BEVs also have regenerative braking capabilities. This system works by capturing the kinetic energy that would usually be lost when braking in a conventional vehicle [

46]. In most other vehicles, braking works by pressing brake pads onto rotors attached to the axle. This creates friction that decelerates the vehicle, but the kinetic energy of the car gets converted into thermal energy at the brake pads and is lost to the environment. The practice of regenerative braking serves to extend the driving range and reduce wear on conventional brake pads.

The range for a battery HDV depends on the type of battery and weight of the vehicle. The battery range for a typical battery freight vehicle is around 100–200 km on a single charge [

47,

48]. However, Tesla’s semi-truck claims to be able to travel 800 km on a full charge [

49]. The major concerns are the weight of the battery in relation to the capacity required with freight vehicles. A heavier battery is required for longer ranges which would require greater energy and power output. For an 800 km range, the battery capacity required would be around 1000 kWh of energy which would require at least 5500 kg (12,000 lbs) dedicated to the battery with current energy densities [

50].

The recharging time for a battery HDV depends on the type of charger and the capacity of each truck. A truck would need a level 3 charger, which can output power greater than 25 kW. At this power output, the recharging time would be around 20 h for a 1000 kWh battery. However, with power outputs at a speculated 1 MW, the recharging time could theoretically be reduced to 1 h. However, fast charging has had negative implications in concern with degradation as faster charging can result in shorter overall battery life [

51]. Current technology has the capability of charging at 50 kW [

52]. The tailpipe emissions of a battery HDV, as with any zero-emission vehicle, are zero; however, the current infrastructure for battery HDVs is limited. Tesla announced in 2017 that they plan to implement a network of “megachargers” for their upcoming Tesla Semi. The “megacharger” would deliver over 1 MW of power so that Semi could be charged in a relatively short period of time [

53]. However, as of 2020, none of these megachargers have been deployed publicly. Gallo estimates that one charger installation would cost between $17 000 and $32,000 for a low-powered 16.5 kW charger, with prices increasing up to between $150,000 and $200,000 for a more powerful, 450 kW charger [

54]. Due to the lack of current battery HDVs on the market, there has been little heavy-duty BEV infrastructure deployment so far. However, there is a growing number of regular electric vehicle charging stations that have been installed across North America [

55] that can potentially be fitted for HDVs. This will simply just take much more time and consume a lot more power in recharging due to the higher battery capacities required in HDVs.

The tank-to-wheel efficiency for a BEV is averaged to be around 68%, with a range of 64.4% to 86% [

32]. The losses would be due to the friction in the powertrain, and the electrical resistances in the transport of electricity. This varies depending on the battery type and the electrical resistances involved. The specific energy of a Li-ion battery depends on the design and characteristics, but they range from 120–220 Wh/kg [

56]. The lifespan of a battery in freight BEVs is around 6 years—1000 to 2000 deep cycle life—due to battery degradation [

48]. This is often categorized as the time that it takes for the capacity of the battery to reach 70–80% of the original capacity [

57]. However, this lifespan is dependent on temperature, type of application, and the state of charge [

58]. To compete with conventional diesel engines, the goal for electric drive vehicles is to reach a lifespan of around 10–15 years.

4. Hydrogen Fuel Cell Electric Powertrain in Heavy-Duty Vehicles

FCEVs operate similarly to BEVs because they are both driven by electric motors. However, unlike BEVs, FCEVs rely on a hydrogen fuel cell to provide the electric motor’s power. Hydrogen fuel cells are electrochemical devices that convert the chemical energy of hydrogen into electricity, heat, and water. Since there is no combustion required to generate usable energy, FCEVs have the benefit of having zero tailpipe emissions. A typical PEMFC is used by ionizing hydrogen atoms from the fuel tank at the anode [

66]. Then, the hydrogen protons pass through the proton exchange membrane, where they react with oxygen and form water as a by-product. Meanwhile, the electrons stripped from the hydrogen fuel can be used to power the electric motors of the vehicle or charge the vehicle’s battery. In addition to the PEMFC, there are various other types, including alkaline (AFC), phosphoric acid (PAFC), solid oxide (SOFC), molten carbonate (MCFC), and more [

67].

The fuel cell HDV powertrain is like the battery HDV. They both contain batteries and have their energy sources connected to electric motors that power their propulsion. As well, they both would have regenerative braking capabilities, which recharge batteries in the deceleration of the system [

68]. The difference is the main energy source itself. FCEVs use fuel cell stacks and hydrogen as their main energy source, while BEVs would use batteries. FCEVs would use a battery for fuel cell start-up, capture regenerative braking energy, provide extra power during accelerations, and aid in low-speed propulsion as fuel cells would be at a low-efficiency region [

69]. There has also been work done in vehicle powertrains that contain ultracapacitors instead of batteries, or ultracapacitors and batteries together alongside the fuel cell to aid in additional energy storage and distribution [

70]. The energy from the fuel cell stack would be transferred to a DC/AC inverter which adjusts the voltage levels [

71]. Then, once the voltage levels are adjusted, the energy is transferred to the electric motor. The electric motor then transfers that energy into the transmission and the resulting axles that power its propulsion.

The range of a fuel cell HDV depends on the payload but also the amount of hydrogen that is stored in the vehicle. A typical fuel cell HDV will be able to reach a range of 500–1000 miles with a single fueling session and two hydrogen tanks carrying 40–60 kg of hydrogen each at 350 bars [

72]. Some aggregated drive cycle data indicate that hydrogen fuel consumption for a class 8 vehicle can range from 5.5 to 9.2 miles per kg of hydrogen [

73]. The hydrogen refueling rate for heavy-duty trucks would be around 120 g/s which would result in around a 16-min refueling time [

74,

75]. The tailpipe emissions of a fuel cell HDV, as with any zero-emission vehicles, will be zero. However, the available infrastructure for HFCVs is very scarce. At the end of 2018, there were only 370 H2 refueling stations in operation globally, with most of them in Europe, Japan, and America [

76]. The lack of infrastructure has resulted in high fuel costs and high vehicle capital costs. However, it is expected to be cheaper when greater infrastructure and more vehicles emerge. A major company in the heavy-duty sector called Cummins claims to have installed over 2000 on-and-off PEMFC applications across the globe [

77].

The energy efficiency of a PEMFC stack is around 45% [

32]. The range lies around 40–60% depending on how it is built what it is composed of [

78]. Cummins claims to have PEMFC efficiencies of 51–59% [

79]. Assuming all the energy is from renewable sources and considering all the transportation and energy losses, the overall energy efficiency would be around 23% [

80]. The efficiency is greater than diesel’s but is less than battery. The specific energy of hydrogen is around 32,702 Wh/kg or approximately 118 MJ/kg [

13]. The fuel cell HDV goal is to reach a 25,000 h lifetime operating time, giving a range of about 500,000 miles or 12 years [

81]. The fuel cell’s service life is limited by the degradation mechanisms related to the catalyst and the membrane [

82]. The end of life is typically categorized when the voltage degradation drops by 10% relative to the beginning of life voltage. The light-duty transportation goal of 5000 h has yet to be met, with an average of around 2000–3000 h [

83,

84]. Experimentally, there have been buses that have been shown to run over 25,000 h operating time [

85]. There has not been much literature on fuel cell lifespan in freight applications. However, the lifetime of PEMFCs is often not reported as there is no agreement on the standard definition for durability due to differences in operating conditions.

5. Comparison and Analysis of Diesel, Battery, and Fuel Cell Heavy-Duty Vehicles

The criteria that are compared in for the three HDV technologies are the tailpipe emissions, the tank-to-wheel efficiency, the fuel consumption, the range, the refueling/recharging time, and energy density. The tailpipe emissions are the emissions released due to work in the vehicle. The emissions to generate the electricity for hydrogen fuel cells and batteries were not considered. The tank-to-wheel efficiency is the energy efficiency of the process from the energy storage system inside the vehicle until it is converted into mechanical energy in the wheels. Fuel consumption is the distance that can be traveled per unit of the energy source. The range is a calculation of the distance that can be covered by a given truck for each technology. The refueling/recharging time is the time it takes for the energy storage system to meet its capacity. Lastly, the specific energy is the energy content for each type of fuel per kg of energy source. The lifespan was discussed in some of the previous sections but is not directly compared in this section due to insufficient literature.

Table 1. Comparison between three discussed heavy-duty vehicle powertrains.

|

Criteria

|

Diesel

|

Battery

|

Hydrogen Fuel Cell

|

|

Tailpipe emissions

|

Yes

|

No

|

No

|

|

Total vehicle cost 1

|

119,000–134,000 USD

|

164,641–585,000 USD

|

135,503–249,900 USD

|

|

Well-to-tank efficiency 2

|

~86% [91]

|

~55.3% [91]

|

~76% [91]

|

|

Tank-to-wheel efficiency

|

~23% [32]

|

~68% [32]

|

~45% [32]

|

|

Fuel consumption

|

6.5 miles/gallon [24]

|

0.5 miles/kWh [50]

|

5.5–9.2 miles/kg H2 [73]

|

|

Range

|

975–1950 miles

|

62–500 miles

|

660–1104 miles

|

|

Refueling time

|

6–12 min

|

2.85–20 h

|

16.67 min

|

|

Specific Energy

|

42.9 MJ/kg [33]

|

0.432–0.792 MJ/kg [56]

|

118 MJ/kg [14]

|

1 The total vehicle costs were taken from a specific case study conducted for California. Reproduced from [92], UC Davis: National Center for Sustainable Transportation: 2020. 2 The well-to-tank efficiencies of the fuels were of the same pathway (natural gas as the source) for comparative purposes.