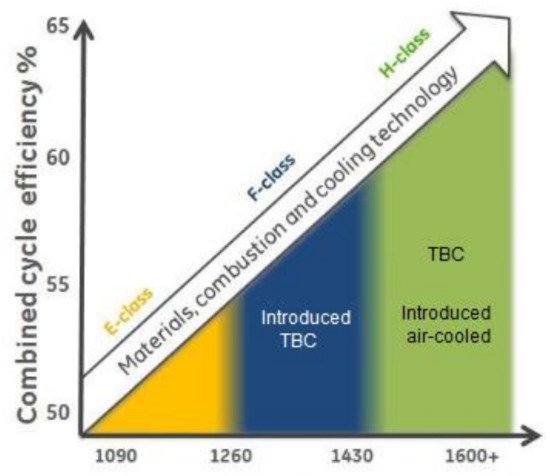

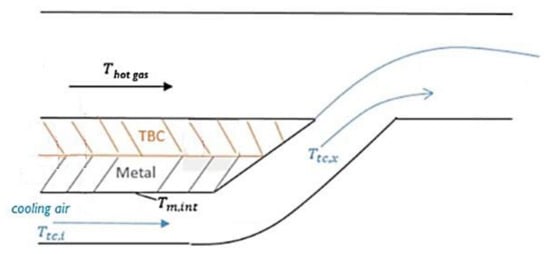

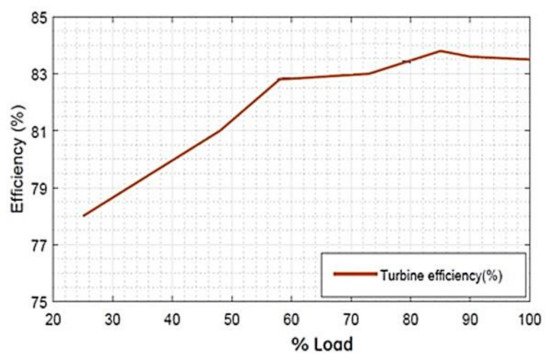

Thermal barrier coating (TBC) and cooling air systems are among the technologies that have been introduced and applied in pursuing the extensive development of advanced gas turbine. TBC is used to protect the gas turbine components from the higher operating temperature of advanced gas turbine, whereas cooling air systems are applied to assist TBC in lowering the temperature exposure of protected surfaces. Generally, a gas turbine operates in three main operational modes, which are base load, peak load, and part peak load. TBC performance under these three operational modes has become essential to be studied, as it will provide the gas turbine owners not only with the behaviors and damage mechanism of TBC but also a TBC life prediction in a particular operating condition.

- thermal barrier coating

- cooling air system

- advanced gas turbine

- TBC simulation

- thermal oxidation test rig

Note: The following contents are extract from your paper. The entry will be online only after author check and submit it.

1. Introduction

2. Advanced Gas Turbines

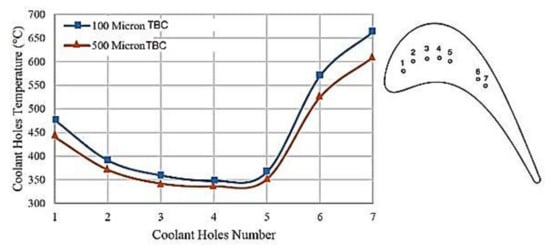

2.1. TBC in Advanced Gas Turbines

2.2. TBC-Assisted Cooling Air in Advanced Gas Turbine

3. TBC Life

- i.

-

Peak load: operation for 3 to 4 h with two startups. One typical cycle of gas turbine consists of a startup and a shutdown.

- ii.

-

Part peak load: operation for 19 h, followed by stopping for 5 h with one startup.

- iii.

-

Base load: operation for 24 h, generally 8000 equivalent operating hours (EOH) per year.

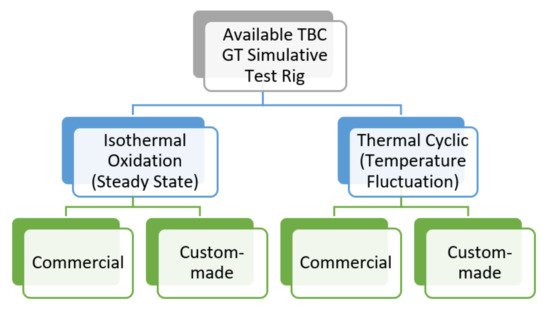

4. TBC Simulation Test Rig

4.1. Thermal Cyclic Test Rig

4.2. Isothermal Oxidation Test Rig

This entry is adapted from the peer-reviewed paper 10.3390/coatings11050560

References

- Redko, A.; Redko, O.; DiPippo, R. Industrial waste heat resources. In Low-Temperature Energy Systems with Applications of Renewable Energy; Academic Press: Cambridge, MA, USA, 2020; pp. 329–362.

- Langston, L.S. Aspects of Gas Turbine Thermal Efficiency. Mech. Eng. 2020, 142, 54–55.

- Winterbone, D.E.; Turan, A. Gas Turbines. Adv. Thermodyn. Eng. 2015, 381–422.

- Anand, V.G.K.; Parammasivam, K.M. Thermal barrier coated surface modifications for gas turbine film cooling: A review. J. Therm. Anal. Calorim. 2020.

- Nagabandi, K.; Pujari, A.K.; Iyer, D.S. Thermo-mechanical assessment of gas turbine combustor tile using locally varying thermal barrier coating thickness. Appl. Therm. Eng. 2020, 179, 115657.

- Shi, L.; Long, Y.; Wang, Y.; Chen, X.; Zhao, Q. On-line detection of porosity change of high temperature blade coating for gas turbine. Infrared Phys. Technol. 2020, 110, 103415.

- Kwon, H.M.; Moon, S.W.; Kim, T.S.; Kang, D.W. Performance enhancement of the gas turbine combined cycle by simultaneous reheating, recuperation, and coolant inter-cooling. Energy 2020, 207.

- Ziaei-Asl, A.; Ramezanlou, M.T. Thermo-mechanical behavior of gas turbine blade equipped with cooling ducts and protective coating with different thicknesses. Int. J. Mech. Sci. 2019, 150, 656–664.

- Moon, S.W.; Kwon, H.M.; Kim, T.S.; Kang, D.W.; Sohn, J.L. A novel coolant cooling method for enhancing the performance of the gas turbine combined cycle. Energy 2018, 160, 625–634.

- Prapamonthon, P.; Yooyen, S.; Sleesongsom, S.; Dipasquale, D.; Xu, H.; Wang, J.; Ke, Z. Investigation of Cooling Performances of a Non-Film-Cooled Turbine Vane Coated with a Thermal Barrier Coating Using Conjugate Heat Transfer. Energies 2018, 11, 1000.

- Ziaei-Asl, A.; Ramezanlou, M.T. Effects of Thermal Barrier Coating (TBC) Thickness on Temperature Distribution of Gas Turbine Blade. In Proceedings of the 3rd Conference on Advances in Mechanical Engineering (ICAME), Istanbul, Turkey, 19–21 December 2017.

- Luabi, A.; Hamza, N. Cooling Process of Gas Turbine Blade: A Comparison Study. Al Qadasiyah J. Eng. Sci. 2020, 13, 215–222.

- Zhang, F.; Liu, Z.; Liu, Z.; Diao, W. Experimental Study of Sand Particle Deposition on a Film-Cooled Turbine Blade at Different Gas Temperatures and Angles of Attack. Energies 2020, 13, 811.

- Daulay, M.S.H.; Sinurat, M.S.; Sinisuka, N.I.; Dinata, I.S.; Pujiatmoko, H.; Leilan, F.; Revina, T. Gas Turbine Upgrades at Muara Karang Block I Power Plant to Improve Performance and Availability. In Proceedings of the 2018 International Conference on Electrical Engineering and Computer Science (ICEECS), Bali, Indonesia, 13 November 2018.

- Torkaman, A.; Vogel, G.; Fiebiger, S.; Dietrich, D.; Washburn, R. Gas Turbine Cycle Upgrade and Validation for Heavy Duty Industrial Machines. In Proceedings of the ASME Turbomachinery Technical Conference and Exposition Volume 3: Coal, Biomass and Alternative Fuels; Cycle Innovations; Electric Power; Industrial and Cogeneration Applications; Organic Rankine Cycle Power Systems, Charlotte, NC, USA, 26–30 June 2017.

- Fujimoto, K.; Fukunaga, Y.; Hada, S.; Ai, T.; Yuri, M.; Masada, J. Technology Application to MHPS Large Flame F Series Gas Turbine. In Proceedings of the ASME Turbomachinery Technical Conference and Exposition Volume 3: Coal, Biomass, and Alternative Fuels; Cycle Innovations; Electric Power; Industrial and Cogeneration; Organic Rankine Cycle Power Systems, Oslo, Norway, 11–15 June 2018.

- Goldmeer, J.; York, W.; Glaser, P. Fuel and Combustion System Capabilities of GE’s F and HA Class Gas Turbines. In Proceedings of the ASME Turbomachinery Technical Conference and Exposition Volume 4B: Combustion, Fuels and Emissions, Charlotte, NC, USA, 26–30 June 2017.

- York, W.D.; Simons, D.W.; Fu, Y. Operational Flexibility of GE’s F-Class Gas Turbines with the DLN2.6+ Combustion System. In Proceedings of the ASME Turbomachinery Technical Conference and Exposition Volume 4B: Combustion, Fuels, and Emissions, Oslo, Norway, 11–15 June 2018.

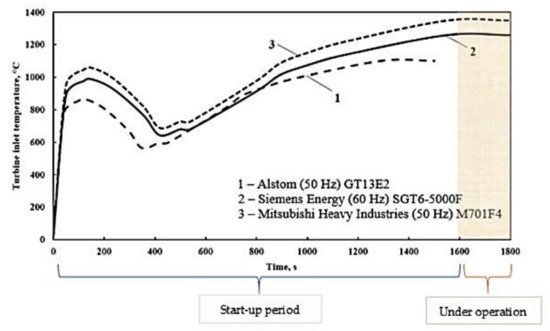

- Aminov, R.Z.; Moskalenko, A.B.; Kozhevnikov, A.I. Optimal gas turbine inlet temperature for cyclic operation. J. Phys. Conf. Ser. 2018, 1111.

- Takamura, K.; Iijima, T.; Wakazono, S.; Hada, S.; Yuri, M.; Kataoka, M. Development of 1650 °C Class Next Generation JAC Gas Turbine based on J Experience. Mitsubishi Heavy Ind. Tech. Rev. 2019, 56, 1–9.

- Kotowicz, J.; Brzęczek, M.; Job, M. The thermodynamic and economic characteristics of the modern combined cycle power plant with gas turbine steam cooling. Energy 2018, 164, 359–376.

- Suzuki, K.; Matsumura, Y.; Takata, K.; Hada, S.; Yuri, M.; Masada, J. Evolution of mhps large frame gas turbines: J to air-cooled JAC. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018; Volume 3, pp. 1–8.

- Chellaganesh, D.; Khan, M.A.; Jappes, J.T.W. Hot corrosion behaviour of nickel—Iron based superalloy in gas turbine application. Int. J. Ambient Energy 2018, 41, 1–14.

- Rakoczy, L.; Grudzień, M.; Tuz, L.; Pańcikiewicz, K.; Zielińska-Lipiec, A. Microstructure and Properties of a Repair Weld in a Nickel Based Superalloy Gas Turbine Component. Adv. Mater. Sci. 2017, 17.

- Avila-Davila, E.O.; Lopez-Hirata, V.M.; Saucedo-Muñoz, M.L.; Palacios-Pineda, L.M.; Ramirez-Vargas, I.; Cueto-Rodriguez, M.M.; Trapaga-Martinez, L.G.; Alvarado-Orozco, J.M. Study of Mechanical Degradation and Microstructural Characterization in a Ni-Based Superalloy Component of a Gas Turbine. Mater. Sci. Forum 2018, 941, 1248–1253.

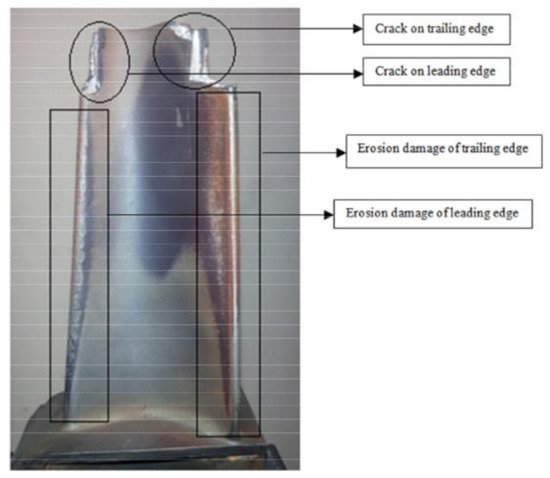

- Rani, S.; Agrawal, A.K.; Rastogi, V. Failure investigations of a first stage Ni based super alloy gas turbine blade. Mater. Today Proc. 2018, 5, 477–486.

- Fathi, S.; Zangeneh, S.H.; Pahlavani, M. A Comprehensive Analysis of Premature Failure in a Cobalt-Based Superalloy X-45 Gas Turbine Vane. J. Fail. Anal. Prev. 2019, 19, 1337–1347.

- Al-Jibory, M.W.; Rashid, F.L.; Talib, S.M. Review on Cooling Enhancement of Different Shape Gas Turbine Ribbed Blade with Thermal Barrier Coating. Int. J. Sci. Res. Eng. Dev. 2020, 3, 313–329.

- Chen, S.; Zhou, X.; Song, W.; Sun, J.; Zhang, H.; Jiang, J.; Deng, L.; Dong, S.; Cao, X. Mg2SiO4 as a novel thermal barrier coating material for gas turbine applications. J. Eur. Ceram. Soc. 2019, 39, 2397–2408.

- Sahith, M.S.; Giridhara, G.; Kumar, R.S. Development and analysis of thermal barrier coatings on gas turbine blades—A Review. Mater. Today Proc. 2018, 5, 2746–2751.

- Taniguchi, T.; Tamai, R.; Muto, Y.; Takami, S.; Tanaka, R.; Ryu, M. Performance Improvement Program for Kawasaki Gas Turbine. In Proceedings of the ASME Turbomachinery Technical Conference and Exposition Volume 3: Coal, Biomass and Alternative Fuels; Cycle Innovations; Electric Power; Industrial and Cogeneration Applications; Organic Rankine Cycle Power Systems, Charlotte, NC, USA, 26–30 June 2017.

- Sankar, V.; Ramkumar, P.B.; Sebastian, D.; Joseph, D.; Jose, J.; Kurian, A. Optimized Thermal Barrier Coating for Gas Turbine Blades. Mater. Today Proc. 2019, 11, 912–919.

- Mahalingam, S.; Yunus, S.M.; Manap, A.; Afandi, N.M.; Zainuddin, R.A.; Kadir, N.F. Crack Propagation and Effect of Mixed Oxides on TGO Growth in Thick La–Gd–YSZ Thermal Barrier Coating. Coatings 2019, 9, 719.

- Yunus, S.M.; Johari, A.D.; Husin, S. Comparison on thermal resistance performance of YSZ and rare-earth GZ multilayer thermal barrier coating at 1250 °C Gas turbine combustor liner. J. Adv. Res. Fluid Mech. Therm. Sci. 2018, 52, 123–128.

- Mehta, A.; Vasudev, H.; Singh, S. Recent developments in the designing of deposition of thermal barrier coatings—A review. Mater. Today Proc. 2020, 26, 1336–1342.

- Lashmi, P.G.; Ananthapadmanabhan, P.V.; Unnikrishnan, G.; Aruna, S.T. Present status and future prospects of plasma sprayed multilayered thermal barrier coating systems. J. Eur. Ceram. Soc. 2020, 40, 2731–2745.

- Martins, J.P.; Chen, Y.; Brewster, G.; McIntyre, R.; Xiao, P. Investigation of the bond coat interface topography effect on lifetime, microstructure and mechanical properties of air-plasma sprayed thermal barrier coatings. J. Eur. Ceram. Soc. 2020, 40, 5719–5730.

- Lakiza, S.M.; Grechanyuk, M.I.; Ruban, O.K.; Redko, V.P.; Glabay, M.S.; Myloserdov, O.B.; Dudnik, O.V.; Prokhorenko, S.V. Thermal Barrier Coatings: Current Status, Search, and Analysis. Powder Met. Met. Ceram. 2018, 57, 82–113.

- Ganvir, A.; Gupta, M.; Kumar, N.; Markocsan, N. Effect of suspension characteristics on the performance of thermal barrier coatings deposited by suspension plasma spray. Ceram. Int. 2020, 47, 272–283.

- Gupta, M.; Musalek, R.; Tesar, T. Microstructure and failure analysis of suspension plasma sprayed thermal barrier coatings. Surf. Coat. Technol. 2020, 382.

- Öchsner, A.; Altenbach, H. State of the Art Thermal Barrier Coating (TBC) Materials and TBC Failure Mechanisms. Adv. Struct. Mater. Prop. Charact. Mod. Mater. 2017, 33, 441–452.

- Manap, A.; Seo, D.; Ogawa, K. Characterization of Thermally Grown Oxide on Cold Sprayed CoNiCrAlY Bond Coat in Thermal Barrier Coating. Mater. Sci. Forum 2011, 696, 324–329.

- Manap, A.; Nakano, A.; Ogawa, K. The Protectiveness of Thermally Grown Oxides on Cold Sprayed CoNiCrAlY Bond Coat in Thermal Barrier Coating. J. Therm. Spray Tech. 2012, 21, 586–596.

- Pankov, V.; Patnaik, P.C.; Chen, K. The Role of Thermally Grown Oxide in the Failure Thermal Barrier Coatings for Gas Turbine Engine Applications. In Proceedings of the Montreal Global Power and Propulsion Forum, Montreal, QC, Canada, 7–9 May 2018.

- Wei, Z.-Y.; Cai, H.-N.; Meng, G.-H.; Tahir, A.; Zhang, W.-W. An innovative model coupling TGO growth and crack propagation for the failure assessment of lamellar structured thermal barrier coatings. Ceram. Int. 2019, 46, 1532–1544.

- Shi, J.; Zhang, T.; Wang, B.; Zhang, X.; Song, L.; Hu, R. Temperature-Dependent Isothermal Oxidation Behavior of a Ni-20Cr-18W Superalloy in Static Air. J. Mater. Eng. Perform. 2020, 29, 2658–2666.

- Jiang, J.; Jiang, L.; Cai, Z.; Wang, W.; Zhao, X.; Liu, Y.; Cao, Z. Numerical stress analysis of the TBC-film cooling system under operating conditions considering the effects of thermal gradient and TGO growth. Surf. Coat. Technol. 2018, 357.

- Manap, A.; Okabe, T.; Ogawa, K.; Mahalingam, S.; Abdullah, H. Experimental and smoothed particle hydrodynamics analysis of interfacial bonding between aluminum powder particles and aluminum substrate by cold spray technique. Int. J. Adv. Manuf. Technol. 2019, 4519–4527.

- Mohammadi, M.; Kobayashi, A.; Javadpour, S.; Jahromi, S.A.J. Evaluation of hot corrosion behaviors of Al2O3-YSZ composite TBC on gradient MCrAlY coatings in the presence of Na2SO4-NaVO3 salt. Vacuum 2019, 167, 547–553.

- Uysal, S.C.; Liese, E.; Nix, A.C.; Black, J. A thermodynamic model to quantify the impact of cooling improvements on gas turbine efficiency. J. Turbomach. 2018, 140, 1–14.

- Vandervort, C. Advancements in H class gas turbines and combined cycle power plants. In Proceedings of the ASME Turbo Expo, Oslo, Norway, 11–15 June 2018; Volume 3, pp. 1–10.

- Sabri, K.; Gaceb, M.; Si-Chaib, M.O. Analysis of a Directionally Solidified (DS) GTD-111 Turbine Blade Failure. J. Fail. Anal. Prev. 2020, 20, 1162–1174.

- Jiang, J.; Wu, D.; Wang, W.; Zhao, X.; Ma, X.; Wang, B.; Shi, H.-J. Fracture behavior of TBCs with cooling hole structure under cyclic thermal loadings. Ceram. Int. 2019, 46, 3644–3654.

- Wang, S.; Zhang, Z. Failure Mechanism of Turbine Guide Vane and Oxide Composition Analysis on the Surface of Failure Vane Cracks. Eng. Fail. Anal. 2020, 117.

- Janawitz, J.; Masso, J.; Childs, C. GE Power & Water Heavy-Duty Gas Turbine Operating and Maintenance Considerations GER-3620M (02/15); GE Power & Water: Atlanta, GA, USA, 2015.

- Saravanamuttoo, H.I.H. Gas Turbines for Electric Power Generation. In Thermal Power Plants Vol. 3, EOLSS; University of New Brunswick: Fredericton, NB, Canada; ISBN 978-1-905839-28-5.

- Uddin, M.; Romlie, M.F.; Abdullah, M.F. Performance Assessment and Economic Analysis of a Gas-Fueled Islanded Microgrid—A Malaysian Case Study. Infrastructures 2019, 4, 61.

- Vaben, R.; Bakan, E.; Mack, D.; Martin, T.; Sohn, Y.J.; Sebold, D.; Guillon, O. Unique performance of thermal barrier coatings made of yttria-stabilized zirconia at extreme temperatures (>1500 °C). J. Am. Ceram. Soc. 2020.

- Mahade, S.; Curry, N.; Björklund, S.; Markocsan, N.; Joshi, S. Durability of gadolinium zirconate/YSZ double-layered thermal barrier coatings under different thermal cyclic test conditions. Materials 2019, 12, 2238.

- Mahalingam, S.; Manap, A.; Yunus, S.M.; Afandi, N. Thermal Stability of Rare Earth-PYSZ Thermal Barrier Coating with High-Resolution Transmission Electron Microscopy. Coatings 2020, 10, 1206.

- Wang, T.; Shao, F.; Ni, J.; Zhao, H.; Zhuang, Y.; Sheng, J.; Zhong, X.; Yang, J.; Tao, S. Corrosion behavior of air plasma spraying zirconia-based thermal barrier coatings subject to Calcium–Magnesium–Aluminum-Silicate (CMAS) via burner rig test. Ceram. Int. 2020, 46, 18698–18706.

- Zhang, L.; Fan, W.; Wang, Y.; Liu, K.; Wang, Z.Z.; Bai, Y. Oxidation Resistance of Plasma-Sprayed Double-Layered LC/YSZ Coatings with Different Thickness Ratios at High Temperatures. Oxid. Met. 2020, 94, 397–408.

- Kolagar, A.M.; Tabrizi, N.; Cheraghzadeh, M.; Shahriari, M.S. Failure analysis of gas turbine first stage blade made of nickel-based superalloy. Case Stud. Eng. Fail. Anal. 2017, 8, 61–68.

- Ma, X.; Rivellini, K.; Ruggiero, P.; Wildridge, G. Toward Durable Thermal Barrier Coating with Composite Phases and Low Thermal Conductivity. J. Therm. Spray Tech. 2020, 29, 423–432.

- Yingsang, W.; Pei-feng, H.; Yao, W.; McCay, M.H.; Edward, C.D.; David, M.; Lei, H.; Chao, W.; Hongqi, Z. Laser Thermal Gradient Testing and Fracture Mechanics Study of a Thermal Barrier Coating. J. Therm. Spray Technol. 2019, 28, 1239–1251.

- Jiang, J.; Ma, X.; Wang, B. Stress analysis of the thermal barrier coating system near a cooling hole considering the free-edge effect. Ceram. Int. 2020, 46, 331–342.

- Abedini, S.; Dong, C.; Davies, I.J. Mechanisms and control of edge interfacial delamination in a multilayer system containing a functionally graded interlayer. Surf. Coat. Technol. 2020, 382.

- Liu, H.; Li, S.; Jiang, C.Y.; Yu, C.T.; Bao, Z.B.; Zhu, S.L.; Wang, F.H. Preparation and oxidation performance of a low-diffusion Pt-modified aluminide coating with Re-base diffusion barrier. Corros. Sci. 2020, 168.

- Xiao, B.; Huang, X.; Robertson, T.; Tang, Z.; Kearsey, R. Sintering resistance of suspension plasma sprayed 7YSZ TBC under isothermal and cyclic oxidation. J. Eur. Ceram. Soc. 2020, 40, 2030–2041.

- Negami, M.; Hibino, S.; Kawano, A.; Nomura, Y.; Tanaka, R.; Igashira, K. Development of highly durable thermal barrier coating by suppression of thermally grown oxide. J. Eng. Gas Turbines Power 2018, 140, 1–8.

- Doleker, K.M.; Ozgurluk, Y.; Karaoglanli, A.C. Isothermal oxidation and thermal cyclic behaviors of YSZ and double-layered YSZ/La2Zr2O7 thermal barrier coatings (TBCs). Surf. Coat. Technol. 2018, 351, 78–88.

- Góral, M.; Swadźba, R.; Kubaszek, T. TEM investigations of TGO formation during cyclic oxidation in two- and three-layered Thermal Barrier Coatings produced using LPPS, CVD and PS-PVD methods. Surf. Coat. Technol. 2020, 394, 1–10.

- Shamsipoor, A.; Farvizi, M.; Razavi, M.; Keyvani, A.; Mousavi, B.; Pan, W. High-temperature oxidation behavior in YSZ coated Cr2AlC and CoNiCrAlY substrates. Surf. Coat. Technol. 2020, 401, 126239.

- Fritscher, K. Life and FCT Failure of Yttria- and Ceria-Stabilized EBPVD TBC Systems on Ni-Base Substrates. Oxid. Met. 2019, 91, 131–157.

- Barhanko, D.A.; Åberg, N.R.; Andersson, O.H. Development of Blade Tip Repair for SGT-700 Turbine Blade Stage 1, with Oxidation Resistant Weld Alloy. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Volume 6: Ceramics; Controls, Diagnostics, and Instrumentation; Education; Manufacturing Materials and Metallurgy, Oslo, Norway, 11–15 June 2018.

- Adam, M.; Kontermann, C.; Oechsner, M. A study on failure of double-layer thermal barrier coatings subjected to uniaxial compression tests using acoustic emission analysis and digital image correlation. Procedia Struct. Integr. 2018, 13, 1226–1231.

- Taleghani, P.R.; Valefi, Z.; Ehsani, N. Characterization and oxidation behaviour of nanostructured La2(Zr0.7Ce0.3)2O7/YSZ coatings prepared by calcined precursor precipitate plasma spraying. Surf. Eng. 2020, 1–14.

- Yang, S.; Yuan, H.; Zeng, W.; Guo, H. Chemo-thermo-mechanical modeling of EB-PVD TBC failure subjected to isothermal and cyclic thermal exposures. Int. J. Fatigue 2020, 141, 105817.

- Jing, F.; Yang, J.; Yang, Z.; Zeng, W. Critical compressive strain and interfacial damage evolution of EB-PVD thermal barrier coating. Mater. Sci. Eng. A 2020, 776, 139038.

- Fan, Y.; Fan, J.; Li, W.; Han, Y.; Lv, Y.; Cheng, H. Microstructure and ultra-high temperature isothermal oxidation behaviour of YSZ-particle-modified WSi2 coating. Surf. Coat. Technol. 2020, 397, 125982.

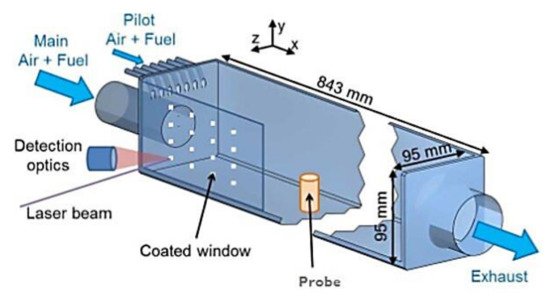

- Nau, P.; Yin, Z.; Lammel, O.; Meier, W. Wall Temperature Measurements in Gas Turbine Combustors with Thermographic Phosphors. J. Eng. Gas Turbines Power 2019, 141.

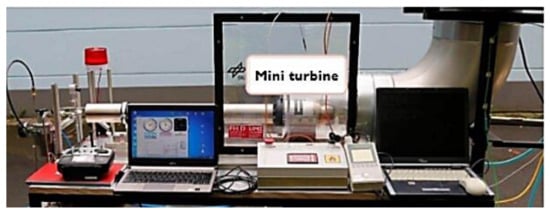

- Naraparaju, R.; Lau, H.; Lange, M.; Fischer, C.; Kramer, D.; Schulz, U.; Weber, K. Integrated testing approach using a customized micro turbine for a volcanic ash and CMAS related degradation study of thermal barrier coatings. Surf. Coat. Technol. 2018, 337, 198–208.

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C.; Yildirim, B.; Welters, M. Correlation of thermal characteristics and microstructure of multilayer electron beam physical vapor deposition thermal barrier coatings. Thin Solid Film. 2020, 707, 138081.

- Karaoglanli, A.C.; Grund, T.; Turk, A.; Lampke, T. A comparative study of oxidation kinetics and thermal cyclic performance of thermal barrier coatings (TBCs). Surf. Coat. Technol. 2019, 371, 47–67.

- Essa, S.K.; Chen, K.; Liu, R.; Wu, X.; Yao, M.X. Failure Mechanisms of APS-YSZ-CoNiCrAlY Thermal Barrier Coating under Isothermal Oxidation and Solid Particle Erosion. J. Therm. Spray Technol. 2020.

- Chen, W.; Shan, X.; Li, J.; Guo, Y.; Guo, F.; Zhao, X.; Ni, N.; Xiao, P. Effects of iron and platinum on the isothermal oxidation of β-NiAl overlay coatings fabricated by spark plasma sintering. Surf. Coat. Technol. 2020, 382.

- Yang, H.Z.; Zou, J.P.; Shi, Q.; Wang, D.; Dai, M.J.; Lin, S.S.; Chen, X.; Wang, W.; Xia, X.P. Comprehensive study on the microstructure evolution and oxidation resistance performance of NiCoCrAlYTa coating during isothermal oxidation at High temperature. Corros. Sci. 2020, 175, 108889.

- Jonnalagadda, K.P.; Eriksson, R.; Li, X.H.; Peng, R.L. Fatigue life prediction of thermal barrier coatings using a simplified crack growth model. J. Eur. Ceram. Soc. 2019, 39, 1869–1876.

- Izadinia, M.; Soltani, R.; Sohi, M.H. Effect of segmented cracks on TGO growth and life of thick thermal barrier coating under isothermal oxidation conditions. Ceram. Int. 2020, 46, 7475–7481.

- Paraschiv, A.; Banu, A.; Doicin, C.; Ionica, I. Isothermal oxidation behavior of plasma sprayed conventional and nanostructured ysz thermal barrier coatings. UPB Sci. Bull. Ser. B Chem. Mater. Sci. 2020, 82, 163–174.

- Vorkötter, C.; Hagen, S.P.; Pintsuk, G.; Mack, D.E.; Virtanen, S.; Guillon, O.; Vaßen, R. Oxide Dispersion Strengthened Bond Coats with Higher Alumina Content: Oxidation Resistance and Influence on Thermal Barrier Coating Lifetime. Oxid. Met. 2019, 92, 167–194.

- Xiao, B.; Robertson, T.; Huang, X.; Kearsey, R. Fracture performance and crack growth prediction of SPS TBCs in isothermal experiments by crack numbering density. Ceram. Int. 2020, 46, 2682–2692.

- Chang, S.; Oh, K.-Y. Contribution of High Mechanical Fatigue to Gas Turbine Blade Lifetime during Steady-State Operation. Coatings 2019, 9, 229.

- Zulkifli, I.S.M.; Yajid, M.A.M.; Idris, M.H.; Uday, M.B.; Daroonparvar, M.; Emadzadeh, A.; Arshad, A. Microstructural evaluation and thermal oxidation behaviors of YSZ/NiCoCrAlYTa coatings deposited by different thermal techniques. Ceram. Int. 2020, 46, 22438–22451.

- Karaoglanli, A.C.; Ozgurluk, Y.; Doleker, K.M. Comparison of microstructure and oxidation behavior of CoNiCrAlY coatings produced by APS, SSAPS, D-gun, HVOF and CGDS techniques. Vacuum 2020, 180, 109609.

- Shi, J.; Zhang, T.; Sun, B.; Wang, B.; Zhang, X.; Song, L. Isothermal oxidation and TGO growth behavior of NiCoCrAlY-YSZ thermal barrier coatings on a Ni-based superalloy. J. Alloy. Compd. 2020, 844, 156093.

- Zakeri, A.; Bahmani, E.; Aghdam, A.S.R.; Saeedi, B.; Bai, M. A study on the effect of nano-CeO2 dispersion on the characteristics of thermally-grown oxide (TGO) formed on NiCoCrAlY powders and coatings during isothermal oxidation. J. Alloy. Compd. 2020, 835, 155319.

- Doleker, K.M.; Ozgurluk, Y.; Ahlatci, H.; Karaoglanli, A.C. Isothermal Oxidation Behavior of Gadolinium Zirconate (Gd2Zr2O7) Thermal Barrier Coatings (TBCs) produced by Electron Beam Physical Vapor Deposition (EB-PVD) technique. Open Chem. 2018, 16, 986–991.

- Doleker, K.M.; Karaoglanli, A.C.; Ozgurluk, Y.; Kobayashi, A. Performance of single YSZ, Gd2Zr2O7 and double-layered YSZ/Gd2Zr2O7 thermal barrier coatings in isothermal oxidation test conditions. Vacuum 2020, 177, 109401.