Flexible Electronic System (FES,) known as flex circuits, have been growing rapidly in industries and organisations such as medical healthcare, energy and power, aerospace, industrial automation, military and defence, sports and entertainment are now the array of various devices are generally comprised of organic substances as a substrate.

- polymers substrates

- flexible electronics

- flexible antennas

1. Introduction

Over the last few decades, Flexible Electronic System (FES,) known as flex circuits, have been growing rapidly in industries and organisations such as medical healthcare, energy and power, aerospace, industrial automation, military and defence, sports and entertainment are now the array of various devices are generally comprised of organic substances as a substrate. These substrates create flexible devices which are not only usually characterized by their flexibility, but also their lightweightedness, durability and energy efficiency and are, resultantly, becoming recognized for their huge relevance to healthcare and medical products as well as for defence and wearable electronics. According to a market survey by Research Nester, published in “Global Flexible Electronic Market Overview”, the flexible electronic market annual growth rate is anticipated to expand 19.7% over the period 2017–2024 [1] and is estimated to reach over 30 billion USD in 2028 [2]. For certain electronic and communication applications, the flexibility of different materials is of great importance with extensive use demonstrated in flexible displays, smart tags, wearable products and flexible antennas [3][4]. Accordingly, researchers have incorporated a variety of materials for providing improved flexibility in electronic systems, including the application of polymers, plastics, paper, textiles and fabrics as substrates of these systems. Each of these materials has its own characteristics in terms of how efficiently they can be safely bent, twisted and/or crumpled.

Flexible electronics have become essential for applications requiring flexible displays and biomedical applications with complex curvilinear structures [5][6]. Correspondingly, researchers have experimented on many materials to provide increased flexibility in electronic systems, including polymers, plastic, paper, textiles and fabrics as a substrate of these systems. Each of these materials has its own individual characteristics in terms of how efficiently they can be bent, twisted and/or crumpled [7]. The bendability and flexibility characteristics of these materials make them advantageous for incorporation in designs for future smart electronics systems including application in the Internet of Things (IoTs).

For certain electronic and communication applications, the flexible characteristic of different materials is of great importance, with extensive use spreading into flexible displays, smart tags and wearable products as well as the flexible antenna developments [3][4]. Indeed, the flexible displays and antenna systems are now considered an essential part of personal communication, industry, military, and telemedicine. These flexible devices have many utilizations in health monitoring systems, aeronautics and RFID tagging applications [8][9][10][11][12][13][14][15][16]. Flexible circuits, such as carbon-nanotube thin films on plastic substrates, provide a conformal and lightweight construction. These flexible integrated circuits have many potential areas of application in embedded systems and other areas of electronics [17] with various types of flexible RFID tags are already in widespread use [18][19]. Recent examples of flexible electronics include stretchable organic solar cells which can be used as biological sensors, active-matrix displays and stretchable power sources [20]. Some other novel applications more recently on the market include flexible displays and touch screens [21], electronic paper [22] and skin-like sensing robotic systems [4][23][24], just to name a few.

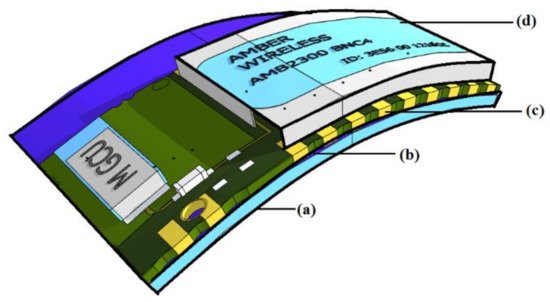

While flexible electronic devices are constructed with flexible materials such as polymers, plastic, laminates, conductive foils and fabrics, their systems, the FES, can be categorized into four main constructive parts: substrate, backplane, front panel and encapsulation (see Figure 1) which illustrates these four major parts of the FES. The appropriate selection of the first part “substrate”, the base material upon which the whole circuit is produced, is critical. The second part is the backplane, which is a Printed Circuit Board (PCB) with slots for connecting electronic components. The third part, the front panel, is customarily a metal sheet that supports the components and allows certain alteration to system components. An encapsulation layer, which encloses circuitry with a protective covering, is the final component. All of the FES parts must have some degree of bending capability without which it would conflict with the normal function of the FES.

Figure 1. Representation of a Flexible Electronic System (FES) with four major components (a) Flexible Substrate (b) backplane (c) Front Panel (d) Encapsulation.

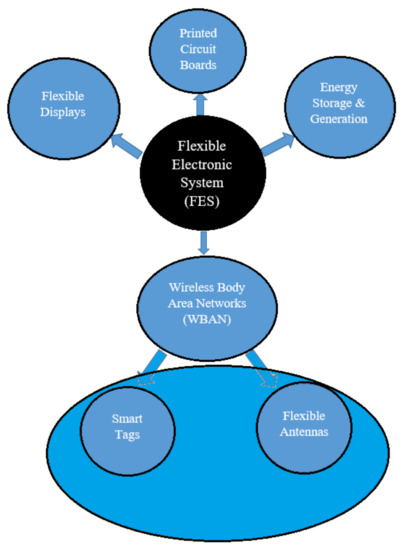

Presently, FES has become crucial for the progressive development in wearable devices which generally include flexible antennas, smart tags and sensors. The FES system covers various fields which depend on its specific applications, such as the development of Printed Circuit Boards (PCB), flexible displays, energy storage and generation, devices applicable for Wireless Body Area Networks (WBAN), see Figure 2. The flexible PCBs, displays and energy storage devices are used extensively in healthcare, entertainment, business, military and space applications.

Figure 2. The next-generation flexible electronic system (FES).

The Wireless Body Area Network (WBAN) provides communications between body-worn devices and devices in the surroundings. These wearable devices include smart tags such as Radio Frequency Identification (RFID) tags and flexible wearable antennas. The emergence of the WBAN is coming out to combine FES and body-worn devices that can easily be mounted on the human body to allow humans to wear antennas and smart tags instead of carrying them. Research on the development of flexible wearable devices such as antennas and smart tags on a flexible substrate is, therefore, a fascinating area in need of further investigation.

Presently, with the exponential development of these wearable sensors and devices and the high demand of the flexible communication systems, various new challenges have arisen because of the unconventional performance requirements. The typical example, and the relevance to this paper, includes wearable electronics with flexible antennas [25], so it is very important for the flexible antennas to be lightweight, small, durable, moist and heat resistant and most importantly highly flexible without distorting radiation characteristics. For this reason, this investigation focuses on the flexibility and seamless integrity of the flexible antennas.

Traditional antennas are customarily made of conductive wires or by etching metal patterns on rigid substrates. When subjected to stretching or are folded or twisted, these types of antennas become permanently deformed, if not broken, which renders them incompatible for applications that require high bendability and are subject to continuous deformation. Flexible antennas have gained much attention in recent years with their advantage of directly addressing this problem with their high flexibility, but also for their convenient integration with other microwave components [26], lightweightedness, energy efficiency, reduced fabrication complexity, easy mount-ability on conformal surfaces, their low cost and for the abundant availability in the form of substrate films [27]. The concept of flexible wearable antennas has emerged from the progressive evolution of the Flexible Electronic System (FES).

To achieve the aforementioned characteristics for flexible antennas, conventional conductors and substrate materials such as metals and ceramics are not essentially appropriate. This is because these materials are usually rigid, costly, and lack flexibility and mechanical resilience. A lot of research has already explored numerous materials which exhibit suitable properties as a substrate for conductive materials for antennas are conductive polymers [28][29][30][31][32][33][34], conductive threads [35][36][37] and conductive textile [38][39][40][41][42][43][44][45][46][47][48][49][50][51][52]. For dielectric materials, Polyimide (PI) [7][11][26][29][53][54][55][56][57][58][59], Polyethylene Terephthalate (PET) [60][61][62][63][64][65][66][67], Polydimethylsiloxane (PDMS) [68][69][70][71][72][73][74][75][76], Polytetrafluoroethylene (PTFE) [15][77][78][79][80], Liquid Crystal polymers (LCP) [10][81][82][83][84][85][86][87][88] have been explored.

2. Advancement of Flexible Electronics

The history of materials used to provide flexibility in devices dates back more than half a century (see Table 1). Six decades ago, flexible single-crystalline silicon solar cells were implemented on satellites. These materials were bendable, non-breakable and shaped conformably [36][37]. A Thin Film Transistor (TFT) made of Tellurium was developed in 1968 on a piece of paper. In the same year, T.P Brody presented Mylar, Polyethylene and anodized Aluminum wrapping foils substrates [38]. In the mid-1980s, researchers achieved the highest ever curvature of any flexible electronic circuits.

Table 1. Chronological advancement in flexible electronics.

| Advancement in Flexible Materials | Year/Era |

|---|---|

| Early use of flexible material as straw with slurry for strengthening houses | BC |

| Discovery of electric conduction in organic materials | 1862 |

| Polymers conceptualized—rapid development followed | 1920 |

| Invention of flexible solar panels | 1967 |

| Implementation of flexible single silicon solar cells on satellites | 1968 |

| Development of Thin Film Transistor (TFT) by Radio Corporation America (RCA) | 1968 |

| Development of the first Liquid Crystal Display (LCD) | 1973 |

| Implementation of Hydrogenated Amorphous Silicon (a-Si:H) cells on flexible polymers | 1976 |

| Development of the conjugated polymer “Polyacetylene” | 1977 |

| Development of a-Si:H/ITO cells on organic polymer | Early 1980’s |

| Invention of Active Matrix Liquid Crystal Displays (AMLCD) in Japan | Mid 1980’s |

| Organic Light-Emitting Diodes (OLED) display on the flexible substrate | 1992 |

| Development of a-Si:H/TFT circuit on flexible polyimide | 1994 |

| Integration of OLED with a-Si TFT on a metal foil | 1996 |

| Development of a-Si:H TFT on the flexible stainless steel foil | 1996 |

| Development of Polycrystalline Silicon (Poly-Si) TFT on a plastic substrate | 1997 |

| Implementation of a multilayer inorganic and polymer substrates | 2003 |

| Phillips produced rollable electrophoretic displays | 2005 |

| Samsung developed a 7” flexible LCD | 2006 |

| Universal Display Centre and Palo Alto Research Centre presented OLED displays with full colour | 2006 |

| Development of polymer hybrid material for permeation barriers | 2008 |

| Development of White Organic Light Emitting Diode (WOLED) displays | 2008 |

| The development of the first flexible smartphone called paper phone | 2011 |

| Development of flexible displays on plastic for smartphones | 2012 |

| Curved OLED Display for 55-inch television and smartphones | 2013 |

| Flexible paper display for eBooks | 2013 |

| Flexible erasable writeable paperless tablet using LCPs | 2013 |

| AMOLED flexible display technology | 2013 |

| Flexible smartwatches, flexible heartbeat and blood pressure measuring sensors, RFID tags, flexible reconfigurable antennas, flexible energy harvesting circuits, | 2013–2020 |

During the 1980s, it was observed that the resulting circuit performance was not affected with as much as 1.6 mm in the curvature of the flexible substrate [89][90]. Polymers were deemed materials for insulating before the discovery of conductive polymers. After the discovery of Poly-acetylene in 1977, interest in conductive polymer materials in industries increased dramatically [91]. The development of Hydrogenated Amorphous Silicon Indium Tin Oxide (a-Si: H/ITO) cells on an organic polymer was another milestone in the advancement of flexible materials [92][93]. Japan developed Plasma Enhanced Chemical Vapor Deposition (PECVD) machines in the mid-1980s that provided a base for Si–H solar cell fabrication and led to the active-matrix liquid crystal display (AMLCD) industry in Japan. Moreover, in the 1990s, flexible polyimide was of interest because of its flexibility, low cost and thermal endurance. Constant et al. [53] fabricated a Si–H TFT circuit on a flexible polyimide substrate in 1995 which was significant because this was the first time photolithography was used to affix Si–H TFT on rigid silicon to form a polyimide film [94][95].

In 1996, a hydrogenated silicon Si: H/TFT was made on a flexible stainless-steel foil [94]. In 1997, a Polycrystalline silicon (Poly–Si) TFT was successfully applied to a plastic substrate using laser annealing technology. In 2005, a rollable electrophoretic display was presented by Philips and in 2006, Samsung announced a 7-inch flexible liquid crystal panel [96][97]. Furthermore, in 2006, Universal Display Corporation and the Palo Alto Research Centre presented a prototype flexible organic light-emitting diode (OLED) display which exhibited full colour and high resolution. It was constructed using a Poly–Si TFT backplane made on steel foil [98]. In 2008, Franky et al. [22] developed a White OLED (WOLED) on a 55-inch flat panel display using a vacuum deposition process. Then, in 2012, Indium Gallium Zinc Oxide (IGZO) was used as a backplane material which, advantageously, was compatible with flexible LCDs. Poor et al. [99] presented flexible displays on a plastic substrate in 2012 for smart Televisions.

Over the last seven years, there has been a boom in the world of flexible electronic and wearable devices. From 2013–2020, flexible electronic devices such as flexible smart sensors, RFID tags, flexible reconfigurable antennas, flexible energy harvesting circuits and wearable technology brought a remarkable change in the healthcare, medical, industrial and entertainment sector. According to a report published by IDTech, forecasts from 2020–2030, indicated that the decade would be a great challenge for all companies producing wearable electronic devices including smartwatches, hearable aids, smart clothing, skin patches, Virtual Reality (VR) devices for general IoT applications [100]. Indeed, although IoT aims to connect everything to everything, the interface to this communication (the antenna) demands to be as flexible and easy to use as much as possible. A class of materials that allow flexibility and hence enable cheap and flexible deployment of antenna designs for faster and more practical IoT applications is further investigated here.

This entry is adapted from the peer-reviewed paper 10.3390/polym13030357

References

- Research Nester. Flexible Electronics Market: Global Demand Analysis & Opportunity Outlook 2024. Available online: (accessed on 26 June 2020).

- Hu, J. Overview of flexible electronics from ITRI’s viewpoint. In Proceedings of the 2010 28th VLSI Test Symposium (VTS), Santa Cruz, CA, USA, 19–21 April 2010; IEEE: New York, NY, USA, 2010; p. 84.

- Lin, C.-P.; Chang, C.-H.; Cheng, Y.T.; Jou, C.F. Development of a Flexible SU-8/PDMS-Based Antenna. IEEE Antennas Wirel. Propag. Lett. 2011, 10, 1108–1111.

- Sun, Y.; Rogers, J.A. Inorganic Semiconductors for Flexible Electronics. Adv. Mater. 2007, 19, 1897–1916.

- Ko, H.C.; Shin, G.; Wang, S.; Stoykovich, M.P.; Lee, J.W.; Kim, D.-H.; Ha, J.S.; Huang, J.; Hwang, K.-C.; Rogers, J.A. Curvilinear Electronics Formed Using Silicon Membrane Circuits and Elastomeric Transfer Elements. Small 2009, 5, 2703–2709.

- Choi, M.-C.; Kim, Y.; Ha, C.-S. Polymers for flexible displays: From material selection to device applications. Prog. Polym. Sci. 2008, 33, 581–630.

- Ahmed, S.; Tahir, F.A.; Shamim, A.; Cheema, H.M. A Compact Kapton-Based Inkjet-Printed Multiband Antenna for Flexible Wireless Devices. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 1802–1805.

- Srifi, M.N.; Podilchak, S.K.; Essaaidi, M.; Antar, Y.M. Compact disc monopole antennas for current and future ultrawideband (UWB) applications. IEEE Trans. Antennas Propag. 2011, 59, 4470–4480.

- Myny, K.; Van Winckel, S.; Steudel, S.; Vicca, P.; De Jonge, S.; Beenhakkers, M.J.; Sele, C.W.; Van Aerle, N.A.J.M.; Gelinck, G.H.; Genoe, J.; et al. An inductively-coupled 64b organic RFID tag operating at 13.56 MHz with a data rate of 787b/s. In Proceedings of the 2008 IEEE International Solid-State Circuits Conference-Digest of Technical Papers, San Francisco, CA, USA, 3–7 February 2008; IEEE: New York, NY, USA, 2008; pp. 290–614.

- Paul, D.L.; Zhang, L.; Zheng, L. Flexible dual-band LCP antenna for RFID applications. In Proceedings of the 2013 URSI International Symposium on Electromagnetic Theory (EMTS), Hiroshima, Japan, 20–24 May 2013; IEEE: New York, NY, USA, 2013; pp. 973–976.

- Khaleel, H.R.; Al-Rizzo, H.M.; Rucker, D.G. Compact Polyimide-Based Antennas for Flexible Displays. J. Disp. Technol. 2012, 8, 91–97.

- Lee, J.-K.; Lim, Y.-S.; Park, C.-H.; Park, Y.-I.; Kim, C.-D.; Hwang, Y.-K. a-Si:H Thin-Film Transistor-Driven Flexible Color E-Paper Display on Flexible Substrates. IEEE Electron Device Lett. 2010, 31, 833–835.

- Kim, S.H.; Jang, C.; Kim, K.; Ahn, S.I.; Choi, K.C. Improvement of Reliability of a Flexible Photoluminescent Display Using Organic-Based Materials. IEEE Trans. Electron Devices 2010, 57, 3370–3376.

- Raad, H.R.; Abbosh, A.I.; Al-Rizzo, H.; Rucker, D.G. Flexible and Compact AMC Based Antenna for Telemedicine Applications. IEEE Trans. Antennas Propag. 2013, 61, 524–531.

- Sallam, M.O.; Kandil, S.M.; Volski, V.; VandenBosch, G.A.E.; Soliman, E.A. Wideband CPW-Fed Flexible Bow-Tie Slot Antenna for WLAN/WiMax Systems. IEEE Trans. Antennas Propag. 2017, 65, 4274–4277.

- Khaleel, H.R.; Al-Rizzo, H.M.; Rucker, D.G.; Al-Naiemy, Y. Flexible printed monopole antennas for WLAN applications. In Proceedings of the 2011 IEEE International Symposium on Antennas and Propagation (APSURSI), Spokane, WA, USA, 3–8 July 2011; IEEE: New York, NY, USA, 2011; pp. 1334–1337.

- Cao, Q.; Kim, H.-S.; Pimparkar, N.; Kulkarni, J.P.; Wang, C.; Shim, M.; Roy, K.; Alam, M.A.; Rogers, J.A. Medium-scale carbon nanotube thin-film integrated circuits on flexible plastic substrates. Nat. Cell Biol. 2008, 454, 495–500.

- Jung, M.; Kim, J.; Noh, J.; Lim, N.; Lim, C.; Lee, G.; Kim, J.; Kang, H.; Jung, K.; Leonard, A.D.; et al. All-Printed and Roll-to-Roll-Printable 13.56-MHz-Operated 1-bit RF Tag on Plastic Foils. IEEE Trans. Electron Devices 2010, 57, 571–580.

- Khan, M.U.A.; Raad, R.; Foroughi, J. Transient Response & Electromagnetic Behaviour of Flexible Bow-Tie Shaped Chip-less RFID Tag for General IoT Applications. Adv. Sci. Technol. Eng. Syst. J. 2020, 5, 757–764.

- Lipomi, D.J.; Tee, B.C.-K.; Vosgueritchian, M.; Bao, Z. Stretchable Organic Solar Cells. Adv. Mater. 2011, 23, 1771–1775.

- Bae, S.; Kim, H.K.; Lee, Y.; Xu, X.; Park, J.-S.; Zheng, Y.; Balakrishnan, J.; Lei, T.; Kim, H.R.; Song, Y.I.; et al. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 2010, 5, 574–578.

- Rogers, J.A.; Bao, Z.; Baldwin, K.; Dodabalapur, A.; Crone, B.; Raju, V.R.; Kuck, V.; Katz, H.; Amundson, K.; Ewing, J.; et al. Paper-like electronic displays: Large-area rubber-stamped plastic sheets of electronics and microencapsulated electrophoretic inks. Proc. Natl. Acad. Sci. USA 2001, 98, 4835–4840.

- Ilievski, F.; Mazzeo, A.D.; Shepherd, R.F.; Chen, X.; Whitesides, G.M. Soft Robotics for Chemists. Angew. Chem. Int. Ed. 2011, 50, 1890–1895.

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and Mechanics for Stretchable Electronics. Science 2010, 327, 1603–1607.

- Hall, P.S.; Hao, Y. Antennas and Propagation for Body-Centric Wireless Communications; Artech House: London, UK, 2012.

- Khaleel, H.R.; Al-Rizzo, H.M.; Rucker, D.G.; Mohan, S. A compact polyimide-based UWB antenna for flexible electronics. IEEE Antennas Wirel. Propag. Lett. 2012, 11, 564–567.

- Nathan, A.; Ahnood, A.; Cole, M.T.; Lee, S.; Suzuki, Y.; Hiralal, P.; Bonaccorso, F.; Hasan, T.; Garcia-Gancedo, L.; Dyadyusha, A.; et al. Flexible Electronics: The Next Ubiquitous Platform. Proc. IEEE 2012, 100, 1486–1517.

- Sayem, A.S.M.; Simorangkir, R.B.V.B.; Esselle, K.P.; Hashmi, R.M. Development of Robust Transparent Conformal Antennas Based on Conductive Mesh-Polymer Composite for Unobtrusive Wearable Applications. IEEE Trans. Antennas Propag. 2019, 67, 7216–7224.

- Hamouda, Z.; Wojkiewicz, J.-L.; Pud, A.A.; Kone, L.; Belaabed, B.; Bergheul, S.; Lasri, T. Dual-Band Elliptical Planar Conductive Polymer Antenna Printed on a Flexible Substrate. IEEE Trans. Antennas Propag. 2015, 63, 5864–5867.

- Kirsch, N.J.; Vacirca, N.A.; Plowman, E.E.; Kurzweg, T.P.; Fontecchio, A.K.; Dandekar, K.R. Optically transparent conductive polymer RFID meandering dipole antenna. In Proceedings of the 2009 IEEE International Conference on RFID, Orlando, FL, USA, 27–28 April 2009; IEEE: New York, NY, USA, 2009; pp. 278–282.

- Salonen, P.; Rahmat-Samii, Y.; Hurme, H.; Kivikoski, M. Effect of conductive material on wearable antenna performance: A case study of WLAN antennas. In Proceedings of the IEEE Antennas and Propagation Society Symposium, Monterey, CA, USA, USA, 20–25 June 2004; IEEE: New York, NY, USA, 2004; pp. 455–458.

- Verma, A.; Weng, B.; Shepherd, R.; Fumeaux, C.; Truong, V.-T.; Wallace, G.G.; Bates, B.D. 6 GHz microstrip patch antennas with PEDOT and polypyrrole conducting polymers. In Proceedings of the 2010 International Conference on Electromagnetics in Advanced Applications, Sydney, Australia, 20–24 September 2010; IEEE: New York, NY, USA, 2010; pp. 329–332.

- Kaufmann, T.; Verma, A.; Truong, V.-T.; Weng, B.; Shepherd, R.; Fumeaux, C. Efficiency of a Compact Elliptical Planar Ultra-Wideband Antenna Based on Conductive Polymers. Int. J. Antennas Propag. 2012, 2012, 972696.

- Chen, S.J.; Kaufmann, T.; Shepherd, R.; Chivers, B.; Weng, B.; Vassallo, A.; Minett, A.I.; Fumeaux, C. A Compact, Highly Efficient and Flexible Polymer Ultra-Wideband Antenna. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 1207–1210.

- Tsolis, A.; Whittow, W.G.; Alexandridis, A.A.; Vardaxoglou, J.C. Embroidery and Related Manufacturing Techniques for Wearable Antennas: Challenges and Opportunities. Electronics 2014, 3, 314–338.

- Huang, X.; Leng, T.; Zhang, X.; Chen, J.C.; Chang, K.H.; Geim, A.K.; Novoselov, K.S.; Hu, Z. Binder-free highly conductive graphene laminate for low cost printed radio frequency applications. Appl. Phys. Lett. 2015, 106, 203105.

- Akbari, M.; Khan, M.W.A.; Hasani, M.; Björninen, T.; Sydanheimo, L.; Ukkonen, L. Fabrication and Characterization of Graphene Antenna for Low-Cost and Environmentally Friendly RFID Tags. IEEE Antennas Wirel. Propag. Lett. 2015, 15, 1569–1572.

- Corchia, L.; Monti, G.; Tarricone, L. Durability of wearable antennas based on nonwoven conductive fabrics: Experimental study on resistance to washing and ironing. Int. J. Antennas Propag. 2018, 2018, 2340293.

- Wang, Z.; Zhang, L.; Bayram, Y.; Volakis, J.L. Embroidered conductive fibers on polymer composite for conformal antennas. IEEE Trans. Antennas Propag. 2012, 60, 4141–4147.

- Locher, I.; Troster, G. Fundamental Building Blocks for Circuits on Textiles. IEEE Trans. Adv. Packag. 2007, 30, 541–550.

- Koski, K.; Vena, A.; Sydanheimo, L.; Ukkonen, L.; Rahmat-Samii, Y. Design and Implementation of Electro-Textile Ground Planes for Wearable UHF RFID Patch Tag Antennas. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 964–967.

- Hertleer, C.; Tronquo, A.; Rogier, H.; Vallozzi, L.; Van Langenhove, L. Aperture-Coupled Patch Antenna for Integration Into Wearable Textile Systems. IEEE Antennas Wirel. Propag. Lett. 2007, 6, 392–395.

- Zhang, L.; Wang, Z.; Volakis, J.L. Textile antennas and sensors for body-worn applications. IEEE Antennas Wirel. Propag. Lett. 2012, 11, 1690–1693.

- Hertleer, C.; Rogier, H.; Vallozzi, L.; Van Langenhove, L. A Textile Antenna for Off-Body Communication Integrated Into Protective Clothing for Firefighters. IEEE Trans. Antennas Propag. 2009, 57, 919–925.

- Kaivanto, K.; Berg, M.; Salonen, E.; de Maagt, P. Wearable circularly polarized antenna for personal satellite communication and navigation. IEEE Trans. Antennas Propag. 2011, 59, 4490–4496.

- Samal, P.B.; Soh, P.J.; Vandenbosch, G.A. UWB all-textile antenna with full ground plane for off-body WBAN communications. IEEE Trans. Antennas Propag. 2013, 62, 102–108.

- Kaufmann, T.; Fumeaux, C. Wearable Textile Half-Mode Substrate-Integrated Cavity Antenna Using Embroidered Vias. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 805–808.

- Corchia, L.; Monti, G.; De Benedetto, E.; Cataldo, A.; Angrisani, L.; Arpaia, P.; Tarricone, L. Fully-Textile, Wearable Chipless Tags for Identification and Tracking Applications. Sensors 2020, 20, 429.

- Mokhtari, F.; Spinks, G.M.; Fay, C.; Cheng, Z.; Raad, R.; Xi, J.; Foroughi, J. Wearable Electronic Textiles from Nanostructured Piezoelectric Fibers. Adv. Mater. Technol. 2020, 5, 1900900.

- Mokhtari, F.; Cheng, Z.; Raad, R.; Xi, J.; Foroughi, J. Piezofibers to smart textiles: A review on recent advances and future outlook for wearable technology. J. Mater. Chem. A 2020, 8, 9496–9522.

- Corchia, L.; De Benedetto, E.; Monti, G.; Cataldo, A.; Angrisani, L.; Arpaia, P.; Tarricone, L. Radio-frequency Identification Based on Textile, Wearable, Chipless Tags for IoT Applications. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd 4.0 & IoT), Naples, Italy, 4–6 June 2019; IEEE: New York, NY, USA, 2019; pp. 1–5.

- Agneessens, S.; Rogier, H. Compact Half Diamond Dual-Band Textile HMSIW On-Body Antenna. IEEE Trans. Antennas Propag. 2014, 62, 2374–2381.

- Constant, A.; Burns, S.G.; Shanks, H.; Gruber, C.; Landin, A.; Schmidt, D.; Thielen, C.; Olympie, F.; Schumacher, T.; Cobbs, J. Development of thin film transistor based circuits on flexible polyimide substrates. In Proc Electrochemical Society; Harvard University: Cambridge, MA, USA, 1995; pp. 94–135.

- Morris, S.; Chandran, A.R.; Timmons, N.; Morrison, J. The fabrication and analysis of a polyimide based loop antenna for 2.45 GHz WBAN applications. In Proceedings of the 2016 Loughborough Antennas and Propagation Conference, LAPC 2016, Loughborough, UK, 14–15 November 2016; IEEE: Loughborough, UK, 2017.

- Hong, S.; Kim, Y.; Lee, C.; Jung, C.W. A flexible and transparent antenna on a polyimide substrate for laptop computers. In Proceedings of the 2015 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting, Vancouver, BC, Canada, 17–25 July 2015; IEEE: New York, NY, USA, 2015; pp. 930–931.

- Beer, S.; Gulan, H.; Rusch, C.; Zwick, T. Integrated 122-GHz antenna on a flexible polyimide substrate with flip chip interconnect. IEEE Trans. Antennas Propag. 2013, 61, 1564–1572.

- Qiu, Y.; Jung, Y.H.; Lee, S.; Shih, T.-Y.; Lee, J.; Xu, Y.H.; Xu, R.; Lin, W.; Behdad, N.; Ma, Z. Compact parylene-c-coated flexible antenna for WLAN and upper-band UWB applications. Electron. Lett. 2014, 50, 1782–1784.

- Khaleel, R. Design and fabrication of compact inkjet printed antennas for integration within flexible and wearable electronics. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 1722–1728.

- Jung, J.; Lee, H.; Lim, Y. Broadband flexible comb-shaped monopole antenna. IET Microw. Antennas Propag. 2009, 3, 325–332.

- Boehme, M.; Charton, C. Properties of ITO on PET film in dependence on the coating conditions and thermal processing. Surf. Coat. Technol. 2005, 200, 932–935.

- Yoon, H.K.; Park, J.A.; Yoon, Y.J.; Lee, C.-H. A CPW-fed polarization diversity antenna for UWB systems. In Proceedings of the Antennas and Propagation Society International Symposium, San Diego, CA, USA, 5–11 July 2008; pp. 1–4.

- Betancourt, D.; Haase, K.; Hubler, A.; Ellinger, F. Bending and Folding Effect Study of Flexible Fully Printed and Late-Stage Codified Octagonal Chipless RFID Tags. IEEE Trans. Antennas Propag. 2016, 64, 2815–2823.

- Castro, A.T.; Sharma, S.K. Inkjet-Printed Wideband Circularly Polarized Microstrip Patch Array Antenna on a PET Film Flexible Substrate Material. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 176–179.

- Khan, M.U.A.; Raad, R.; Foroughi, J.; Tubbal, F.E.; Xi, J. Novel Bow-Tie Chip-less RFID Tag for Wearable Applications. In Proceedings of the 2019 19th International Symposium on Communications and Information Technologies (ISCIT), Ho Chi Minh City, Vietnam, 25–27 September 2019; IEEE: New York, NY, USA, 2019; pp. 10–13.

- Moro, R.; Bozzi, M.; Collado, A.; Georgiadis, A.; Via, S. Plastic-based substrate integrated waveguide (SIW) components and antennas. In Proceedings of the 2012 42nd European Microwave Conference, Amsterdam, The Netherlands, 29 October–1 November 2012; IEEE: New York, NY, USA, 2012; pp. 1007–1010.

- Saeed, S.M.; Balanis, C.A.; Birtcher, C.R. Radiation characteristics of flexible reconfigurable antenna with curved cylindrical configurations. In Proceedings of the 2016 IEEE International Symposium on Antennas and Propagation (APSURSI), Fajardo, Puerto Rico, 26 June–1 July 2016; IEEE: New York, NY, USA, 2016; pp. 1433–1434.

- Kaufmann, T.; Ranasinghe, D.C.; Zhou, M.; Fumeaux, C. Wearable Quarter-Wave Folded Microstrip Antenna for Passive UHF RFID Applications. Int. J. Antennas Propag. 2013, 2013.

- So, J.-H.; Thelen, J.; Qusba, A.; Hayes, G.J.; Lazzi, G.; Dickey, M.D. Reversibly Deformable and Mechanically Tunable Fluidic Antennas. Adv. Funct. Mater. 2009, 19, 3632–3637.

- Cheng, S.; Wu, Z. A Microfluidic, Reversibly Stretchable, Large-Area Wireless Strain Sensor. Adv. Funct. Mater. 2011, 21, 2282–2290.

- Kubo, M.; Li, X.; Kim, C.; Hashimoto, M.; Wiley, B.J.; Ham, D.; Whitesides, G.M. Stretchable Microfluidic Radiofrequency Antennas. Adv. Mater. 2010, 22, 2749–2752.

- Hage-Ali, S.; Tiercelin, N.; Coquet, P.; Sauleau, R.; Fujita, H.; Preobrazhensky, V.; Pernod, P. A Millimeter-Wave Microstrip Antenna Array on Ultra-Flexible Micromachined Polydimethylsiloxane (PDMS) Polymer. IEEE Antennas Wirel. Propag. Lett. 2009, 8, 1306–1309.

- Koulouridis, S.; Kiziltas, G.; Zhou, Y.; Hansford, D.J.; Volakis, J.L. Polymer–ceramic composites for microwave applications: Fabrication and performance assessment. IEEE Trans. Microw. Theory Tech. 2006, 54, 4202–4208.

- Scarpello, M.L.; Kurup, D.; Rogier, H.; Ginste, D.V.; Axisa, F.; Vanfleteren, J.; Joseph, W.; Martens, L.; Vermeeren, G. Design of an Implantable Slot Dipole Conformal Flexible Antenna for Biomedical Applications. IEEE Trans. Antennas Propag. 2011, 59, 3556–3564.

- Cheng, S.; Rydberg, A.; Hjort, K.; Wu, Z. Liquid metal stretchable unbalanced loop antenna. Appl. Phys. Lett. 2009, 94, 144103.

- Hayes, G.J.; So, J.-H.; Qusba, A.; Dickey, M.D.; Lazzi, G. Flexible Liquid Metal Alloy (EGaIn) Microstrip Patch Antenna. IEEE Trans. Antennas Propag. 2012, 60, 2151–2156.

- Simorangkir, R.B.V.B.; Yang, Y.; Matekovits, L.; Esselle, K.P. Dual-Band Dual-Mode Textile Antenna on PDMS Substrate for Body-Centric Communications. IEEE Antennas Wirel. Propag. Lett. 2016, 16, 677–680.

- Komeya, M.; Shimasaki, H. Studies on a cavity-backed slot antenna made of a conductive textile bent along a spherical surface. In Proceedings of the 2013 URSI International Symposium on Electromagnetic Theory (EMTS), Hiroshima, Japan, 20–24 May 2013; IEEE: New York, NY, USA, 2013; pp. 561–564.

- Fujiwara, K.; Shimasaki, H.; Morimoto, K.; Kuwahara, N. Studies on a polyester fabric substrate of the feed line to a flexible slot antenna. In Proceedings of the Microwave Conference (APMC), Asia-Pacific, Sendai, Japan, 4–7 November 2014; IEEE: New York, NY, USA, 2014; pp. 456–458.

- Durgun, A.C.; Balanis, C.A.; Birtcher, C.R.; Allee, D.R. Design, simulation, fabrication and testing of flexible bow-tie antennas. IEEE Trans. Antennas Propag. 2011, 59, 4425–4435.

- Khan, M.U.A.; Raad, R.; Foroughi, J.; Tubbal, F.; Theoharis, P.I.; Raheel, M.S. Effects of Bending Bow-Tie Chipless RFID Tag for Different Polymer Substrates. In Proceedings of the 2019 13th International Conference on Signal Processing and Communication Systems (ICSPCS), Surfers Paradise, Australia, 16–18 December 2019; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2019; pp. 1–4.

- Kao, H.-L.; Cho, C.-L.; Zhang, X.Y.; Chang, L.-C.; Wei, B.-H.; Dai, X.; Chiu, H.-C. Bending Effect of an Inkjet-Printed Series-Fed Two-Dipole Antenna on a Liquid Crystal Polymer Substrate. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 1172–1175.

- Ni, J.; Hong, J. Compact Varactor-Tuned Microstrip High-Pass Filter with a Quasi-Elliptic Function Response. IEEE Trans. Microw. Theory Tech. 2013, 61, 3853–3859.

- Rida, A.; Margomeno, A.; Lee, J.S.; Schmalenberg, P.; Nikolaou, S.; Tentzeris, M.M. Integrated wideband 2-D and 3-D transitions for millimeter-wave RF front-ends. IEEE Antennas Wireless Propag. Lett. 2010, 9, 1080–1083.

- Rida, A.; Nikolaou, S.; Tentzeris, M.M. Broadband UHF RFID/sensor modules for pervasive cognition applications. In Proceedings of the 2009 3rd European Conference on Antennas and Propagation, Berlin, Germany, 23–27 March 2009; IEEE: New York, NY, USA, 2009; pp. 2344–2347.

- Rao, M.V.; Madhav, B.; Anilkumar, T.; Prudhvinadh, B. Circularly polarized flexible antenna on liquid crystal polymer substrate material with metamaterial loading. Microw. Opt. Technol. Lett. 2020, 62, 866–874.

- DeJean, G.; Bairavasubramanian, R.; Thompson, D.; Ponchak, G.; Tentzeris, M.; Papapolymerou, J. Liquid crystal polymer (LCP): A new organic material for the development of multilayer dual-frequency/dual-polarization flexible antenna arrays. IEEE Antennas Wirel. Propag. Lett. 2005, 4, 22–26.

- Vyas, R.; Rida, A.; Bhattacharya, S.; Tentzeris, M.M. Liquid Crystal Polymer (LCP): The ultimate solution for low-cost RF flexible electronics and antennas. In Proceedings of the 2007 IEEE Antennas and Propagation Society International Symposium, Honolulu, HI, USA, 9–15 June 2007; IEEE: New York, NY, USA, 2007; pp. 1729–1732.

- Sagor, H.; Abbasi, Q.H.; Alomainy, A.; Hao, Y. Compact and conformal ultra wideband antenna for wearable applications. In Proceedings of the 5th European Conference on Antennas and Propagation (EUCAP), Rome, Italy, 11–15 April 2011; IEEE: New York, NY, USA, 2011; pp. 2095–2098.

- Wong, W.S.; Salleo, A. Flexible Electronics: Materials and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009.

- Theiss, S.; Wagner, S. Amorphous silicon thin-film transistors on steel foil substrates. IEEE Electron Device Lett. 1996, 17, 578–580.

- Poor, A. Reformulating displays [Tools & Toys]. IEEE Spectr. 2012, 49, 28–29.

- Peng, H.; Sun, X.; Weng, W.; Fang, X. Polymer Materials for Energy and Electronic Applications; Academic Press: Cambridge, MA, USA, 2016.

- Tjong, S.-C. Nanocrystalline Materials: Their Synthesis-Structure-Property Relationships and Applications; Newnes: Oxford, UK, 2013.

- Crabb, R.L.; Treble, F.C. Thin Silicon Solar Cells for Large Flexible Arrays. Nat. Cell Biol. 1967, 213, 1223–1224.

- Raghu Das, J.H.; Harrop, P. IDTechEx Reports: 5G, RFID & The Internet of Things-IDTechEx Reports and Subscriptions. 2020. Available online: (accessed on 17 September 2020).

- Gustafsson, G.; Cao, Y.; Treacy, G.; Klavetter, F.; Colaneri, N.; Heeger, A. Flexible light-emitting diodes made from soluble conducting polymers. Nature 1992, 357, 477–479.

- Young, N.D.; Harkin, G.; Bunn, R.; McCulloch, D.; Wilks, R.; Knapp, A. Novel fingerprint scanning arrays using polysilicon TFT’s on glass and polymer substrates. IEEE Electron Device Lett. 1997, 18, 19–20.

- Smith, P.M.; Carey, P.G.; Sigmon, T.W. Excimer laser crystallization and doping of silicon films on plastic substrates. Appl. Phys. Lett. 1997, 70, 342–344.

- So, F.; Kido, J.; Burrows, P. Organic Light-Emitting Devices for Solid-State Lighting. MRS Bull. 2008, 33, 663–669.

- Hayward, J. IDTechEx: Wearable Technology Forecasts: 2020–2030. IDtechEX. 2020. Available online: (accessed on 17 September 2020).