During underground construction, the behavior of the ground is influenced by characteristics of the rock mass with situ stresses and ground water, cross section of the excavation area, excavation method, and the rate of excavation. These fundamental features are considered to ensure the support and stability of underground excavations and achieve long-term successful operation. However, the ground composition of the Himalayas hinders tunnel excavation, especially in case of mechanized tunneling; this causes time and cost overruns. This study has reviewed the recently completed Neelum–Jhelum Hydroelectric Project; the project complexities, geological environments involving significant overburden and tectonic stresses, and effects of the excavation method on tunnel stability were analyzed.

- Neelum–Jhelum Hydroelectric Project

1. Introduction

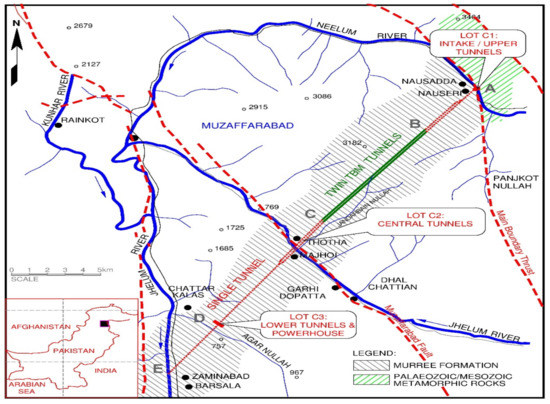

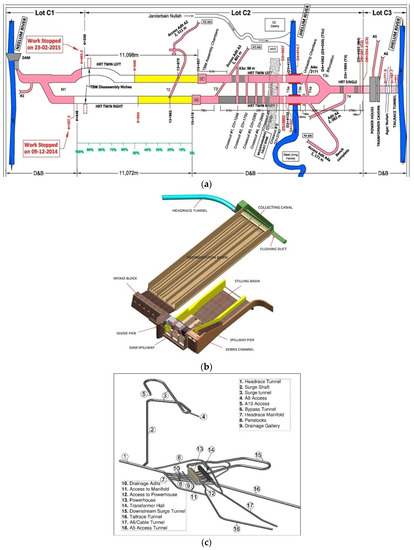

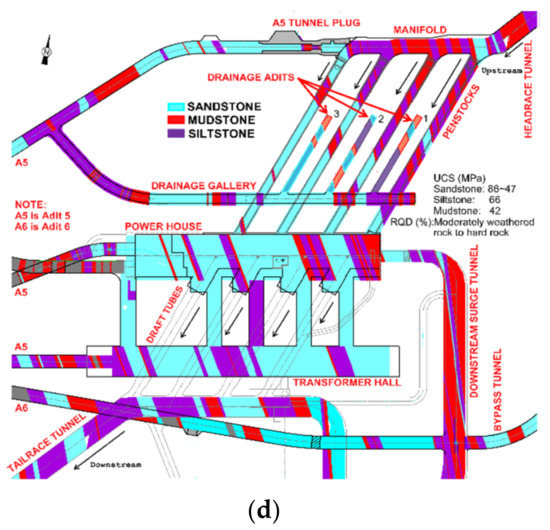

2. Project Description

General Description

| Lot | Excavation | Length (m) | Excavation Size (m) (Cross-Sectional Area (m2)) | Shape | Remarks Any |

|---|---|---|---|---|---|

| C1 | Diversion tunnel | 493 | 10.5 × 9.5 (77) | U-shaped | D&B * |

| Adit A1 | 390 | 7 × 8 (51) | U-shaped | D&B | |

| Single headrace tunnel | 874 | 9.7–11.7 (77–113) | Horse-shoe shaped | D&B with finished dia of 9.6 m | |

| Twin headrace tunnel | 4797 + 4400 (R + L) | 7.9 (51) | Horse-shoe shaped | D&B with finished dia 6.8 m | |

| C2 | Twin headrace tunnel | 9895 + 10,434 (R + L) | 8.53 (57) | Circular | TBM ** with finished dia 7.6–7.9 m |

| Twin headrace tunnel | 4950 + 4837 (R + L) | 7.9–8.5 (51–60) | Horse-shoe shaped | D&B with finished dia 6.8 m | |

| Single headrace tunnel | 4433 | 10.7–11 (94–100) | Horse-shoe shaped | D&B with finished dia 6 m | |

| Adit A2 | 2475 | 7 × 8 (51) | U-shaped | D&B | |

| Adit A3 | 1890 | 7 × 8 (51) | U-shaped | D&B | |

| Adit A4 | 2090 | 7 × 8 (51) | U-shaped | D&B | |

| Adit A4a | 2175 | 9 × 9.3 (100) | Horse-shoe shaped | D&B | |

| TBM assembly chambers | L = 100 m R = 60 m |

20 × 15 | Horse-shoe shaped | D&B | |

| C3 | Headrace tunnel | 3622 | 10.7–11.7 (94–113) | Horse-shoe shaped | D&B with finished dia 6 m |

| Tailrace tunnel | 3550 | 10.7–11.7 (94–113) | Horse-shoe shaped | D&B with finished dia 6 m | |

| Powerhouse | 130 | 23 × 50 (varies) | U-shaped | D&B | |

| Transformer cavern | 170 | 16 × 20 | U-shaped | D&B | |

| Adit A5 | 660 | 7 × 8 (51) | U-shaped | D&B | |

| Adit A6 (cable tunnel) | 680 | 7 × 8 (51) | U-shaped | D&B | |

| Adit A7 | 370 | 5 × 7.5 | U-shaped | D&B | |

| Adit A8 | 62 | 6 × 7 | U-shaped | D&B | |

| Adit A10 | 50 | varies | Varies | D&B | |

| Surge shaft and surge tunnel | 350 (shaft), 743 (HST) | 11, 10.7–11.7 | Circular shaft and horse-shoe-shaped tunnel | D&B with finished dia 9.6 m | |

| Drainage gallery and drainage adits | 212, 60 | 5 × 5 (DG), 3 × 3 (DA) | U-shaped | D&B | |

| Penstocks and draft tubes | 118 (P), 98 (D) | 6.6 × 6, 6.6 x 8 | Varies | D&B | |

| Tailrace manifold and tailrace surge tunnel | 880 | 11.7 (113) | Horse-shoe shaped (varies) | D&B | |

| Bypass tunnel | 300 | 7 × 8 (51) | U-shaped | D&B |

This entry is adapted from the peer-reviewed paper 10.3390/app11041655

References

- Panthi, K.K. Evaluation of rock bursting phenomena in a tunnel in the Himalayas. Bull. Eng. Geol. Environ. 2012, 71, 761–769.

- Palmstrom, A.; Stille, H. Ground behaviour and rock engineering tools for underground excavations. Tunn. Undergr. Space Technol. 2007, 22, 363–376.

- Stille, H.; Palmström, A. Ground behaviour and rock mass composition in underground excavations. Tunn. Undergr. Space Technol. 2008, 23, 46–64.

- Sharma, H.; Tiwari, A. Tunnelling in the Himalayan Region: Geological problems and solutions. Int. Water Power Dam Constr. 2012, 64, 14–19.

- Carter, T. Himalayan ground conditions challenge innovation for successful TBM Tunnelling. In Proceedings of the Invited Paper in Proc. Hydrovision India 2011 Conference, SESSION 5c:(Risk Management in Tunnelling); Golder Associates: Toronto, ON, Canada; 2011; p. 20.

- Celada, B.; Tardáguila, I.; Varona, P.; Rodríguez, A.; Bieniawski, Z. Innovating tunnel design by an improved experience-based RMR system. In Proceedings of the World Tunnel Congress, Foz do Iguaçu, Brazil, 9–15 May 2014; p. 9.

- Verman, M.; Carter, T.; Babendererde, L. TBM vs D&B—A difficult choice in mountain terrain–some geotechnical guidelines. In 12th ISRM Congress; International Society for Rock Mechanics: Lisbon, Portugal, 2011.

- Rehman, H.; Ali, W.; Naji, A.; Kim, J.-J.; Abdullah, R.; Yoo, H.-K. Review of rock-mass rating and tunneling quality index systems for tunnel design: Development, refinement, application and limitation. Appl. Sci. 2018, 8, 1250.

- Mazaira, A.; Konicek, P. Intense rockburst impacts in deep underground construction and their prevention. Can. Geotech. J. 2015, 52, 1426–1439.

- Hanif, H.; Khurshid, M.B.; Lindhard, S.M.; Aslam, Z. Impact of variation orders on time and cost in mega hydropower projects of Pakistan. J. Constr. Dev. Ctries. 2016, 21, 37.

- Kizilbash, M.H.; Dickson, P.A.; Jaffery, N.A. Neelum Jhelum hydroelectric project: Pre-excavation grouting in twin headrace tunnels. Grouting 2017, 2017, 238–248.