As the situation of severe acute respiratory syndrome coronavirus type 2 (SARS-CoV-2) is still de-teriorating, there has been a huge increase in the demand and use of disinfectants. Electrolyzed water (EW), as a novel broad-spectrum disinfectant and cleaner, has been widely used for several years.

- electrolyzed water

- clinical application

- antimicr

1. Introduction

The Center for Disease Control and Prevention (CDC) has recently reported that there is at least one person who has a healthcare-associated infection in every 31 hospital patients in any given day [1]. Such healthcare-associated infections (HAI) include central line-associated bloodstream infection, catheter-associated urinary tract infections, surgical site infection and ventilator-associated pneumonia [2]. HAIs are a major cause of morbidity and even mortality in the United States [3]. The healthcare environment is a primary source of pathogenic microorganisms [4]. Molds may be present on wet or damp surfaces or materials [5]. Bacteria may also be present in bathroom installations, including sink drains and ice machines. Furthermore, surgical site infections can sometimes be superficial infections involving the skin [6][7]. At the same time, infections in other surgical sites could be more serious, which may involve tissues under the skin, organs, or even implanted materials [8][9]. Infections also increase the length of stay, readmission rates, costs, and even mortality [10][11]. Biofilms are responsible for causing 80% of human infections. The National Institutes of Health (NIH) reported that biofilms are responsible for up to 80% of human bacterial infection [12].

Therefore, developing effective disinfectants and antiseptics for killing pathogens and destroying the biofilm formation in the environment and human healthcare is one of the most significant steps for infection prevention and control. The medical industry has employed a number of decontamination techniques throughout the hospital and healthcare clinical field [13][14][15]. However, some of these techniques have disadvantages such as high cost, low efficacy, remaining chemical residues, and adverse effects irritation on the human skin [16][17]. As an important premise for practical application, it should have high antimicrobial efficacy and no toxicity to the human body [18].

Electrolyzed water (EW) is a novel disinfectant and cleaner which has been widely used in the food industry for several years to ensure the sterilization of surfaces and safety of food [19][20][21][22]. EW is produced in an electrolysis chamber which contains dilute salt and tap water without any harmful chemical addition [23]. EW has antimicrobial effects against a variety of microorganisms including common biofilm, viruses, bacteria, spores and fungi in chronic wounds and environmental surfaces [24][25][26][27][28][29]. Currently, due to its beneficial properties (anti-infection and cell proliferative), researchers pay more attention to the application of electrolyzed water in clinical treatments including medical sterilization. The US Environmental Protection Agency (EPA) recommended the use of disinfectants with hypochlorite acid as active ingredients for the disinfection of surfaces against COVID-19 [30]. Furthermore, various studies have been carried out on the antimicrobial activity of EW against different illments, including diabetic foot ulcers [31][32], venous ulcers in the legs [33][34] or feminine hygiene [35][36].

However, some studies have reported that the application of EW is limited by factors such as the corrosion of equipment which is in contact with acidic or basic EW and the ability of organics materials (proteins, lipids and so on) to shorten its shelf life [37][38]. To overcome these defects, hurdle technology, which is a combination of two or more low-dose disinfection and preservatives techniques could be applied [39]. Therefore, EW combined with other disinfection methods could be an effective way to obtain a desirable result [40][41].

The aim of this review was to introduce recent developments and provide a new perspective with EW in the clinical field. Many characteristics of electrolyzed water in this review article were introduced including the physiochemical properties, history, limitation principle, generation methodologies, and the impact of these characteristics on the sanitizing efficacy of EW. In addition, applications of EW for microbial control in the clinical field are also discussed.

2. Principles and History of EW

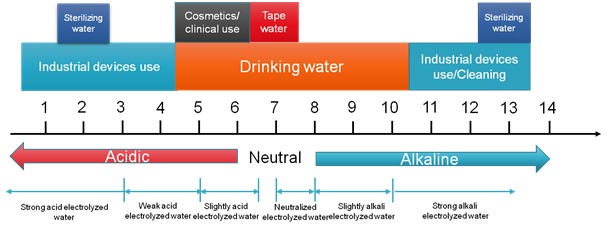

The development history of electrolyzed water can be traced back for more than a century [42]. The concept of electrolyzed water was first proposed in Russia [43]. However, it has been widely used for various purposes including disinfection, water regeneration and water decontamination in Japan since 1980. As time went by, its application has extended to other fields such as the food industry, agriculture, livestock management and clinical application [44][45][46][47]. Figure 1 illustrates the application of EW in different areas at different pH values.

Figure 1. Application of electrolyzed water (EW) at different pH values in various fields.

Electrolyzed reduced water was invented in the early 19th century [48]. Research on electrolyzed water started in Japan around 1931 and its application and popularity to agriculture in the 1950s. In 1960, the water was applied to medical care and in 1966, electrolyzed reduced water was touted as having “healing effects” including indigestion, chronic diarrhea, antacid, abnormal gastrointestinal fermentation, and hyperacidity [49]. A device for the preparation of ERW was authorized for home-use by the Ministry of Health, Labor, and Welfare of Japan [50].

In 1994, with the support of the Ministry of Health, Labor, and Welfare of Japan, the functional water foundation was established to promote the use of electrolyzed water in society. Based on considerable scientific evidence related to the risk assessment of EW, in 2005, the Drugs, Cosmetics and Medical Instruments Act of Japan was revised and re-authorized an ERW-producing device as a home-managed medical device. In 2002, the Ministry authorized the use of hypochlorous acid water on designated food additives. Recently, in 2017, the US Food and Drug Administration (USFDA) also authorized hypochlorous acid (electrolytically generated on-site) for use on food contact surfaces (FCS) [51]. In addition, Chinese standardization administration published a series of criteria in 2020, related to hypochlorous acid water, which can be used for human skin, hand and mucous membrane. Table 1 illustrates the criteria of application of EW in different countries.

3. Systems for Generation of Electrolyzed Water

Electrolyzed water (EW) is produced in an electrolysis chamber which contains hydrogen chloride (HCl) solution or dilute salt (NaCl) [52]. According to the different devices, electrolyte and electrolysis conditions, EW can be classified into the following categories: acidic electrolyzed water, neutral electrolyzed water and alkali electrolyzed water [53]. The characteristic of EW is shown in Table 2. The application of EW can be roughly divided into alkali water for drinking and electrolytic water for cleaning, sterilization, and disinfection [54][55][56].

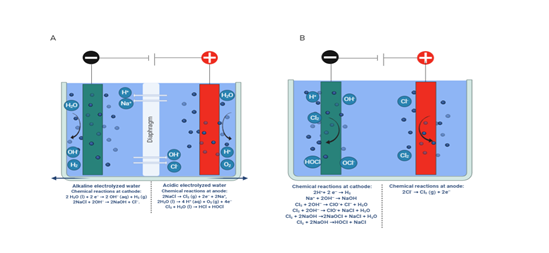

These solutions are produced by the electrolysis of dilute salt (NaCl) passing through two or three cell electrolyzers with the anode and cathode separated by a diaphragm. It can produce two types of water simultaneously. Acidic electrolyzed water (AEW), with a pH of 2 to 3, available chlorine concentration (ACC) of 10 to 90, and oxidation–reduction potential (ORP) >1100 Mv, is produced at the anode side . At the same time, basic electrolyzed water (BEW) with a pH of 10 to 13, and ORP from −800 to −900 Mv is generated at the cathode side. Nowadays, there are some novel forms of electrolyzed water such as slightly acid electrolyzed water (SAEW), weak acid electrolyzed water (WAEW) and neutral electrolyzed water (NEW) [57][58][59]. SAEW is very popular in Japan, China and Korea [60][61][62]. SAEW (pH of 5.5-6.5, ACC of 10–80 ppm and ORP of 800–900 Mv), and NEW (pH of 7–8 and ORP of 750–900 Mv) are produced by using single-cell chambers. SAEW is produced by the electrolysis of HCl alone or combined with NaCl in a single-cell unit (without diaphragm) [63]. It is expected that the SAEW will not lose its superior features after mixing due to the unipolar reaction in the process of electrolysis. In addition to the above method, NEW can also be produced by a mixture of the anodic solution with OH− ions [64]. The details are shown in Figure 2. EW can also be stored in containers of special materials or converted into ice cubes for future use [65].

Figure 2. Generation of electrolyzed water. A: alkaline electrolyzed water and acidic electrolyzed water; B: slightly acidic electrolyzed water. Created with BioRender.com.

This entry is adapted from the peer-reviewed paper 10.3390/microorganisms9010136

References

- Yeshambel, A.; Endalamaw, A.; Belay, D.M.; Mekonen, D.K.; Birhan, B.M.; Bayih, W.A. Healthcare-associated infection and its determinants in Ethiopia: A systematic review and meta-analysis. PLoS ONE 2020, 15, e0241073, doi:10.1371/journal.pone.0241073.

- Weiner-Lastinger, L.M.; Abner, S.; Edwards, J.R.; Kallen, A.J.; Karlsson, M.; Magill, S.S.; Pollock, D.; See, I.; Soe, M.M.; Wal-ters, M.S.; et al. Antimicrobial-resistant pathogens associated with adult healthcare-associated infections: Summary of data reported to the National Healthcare Safety Network, 2015–2017. Infect. Control Hosp. Epidemiol. 2019, 41, 1–18, doi:10.1017/ice.2019.296.

- Savetamal, A. Infection in Elderly Burn Patients: What Do We Know? Surg. Infect. 2020, 21, doi:10.1089/sur.2020.322.

- Chyderiotis, S.; Legeay, C.; Verjat-Trannoy, D.; Le Gallou, F.; Astagneau, P.; Lepelletier, D. New insights on antimi-crobial efficacy of copper surfaces in the healthcare environment: A systematic review. Clin. Microbiol. Infec. 2018, 24, 1130–1138.

- Habibi, A.; Safaiefarahani, B. Indoor Damp Surfaces Harbor Molds with Clinical Significance. Curr. Med. Mycol. 2018, 4, 1–9, doi:10.18502/cmm.4.3.169.

- Edmiston, C.E.; McBain, A.J.; Kiernan, M.; Leaper, D.J. A narrative review of microbial biofilm in postoperative surgical site infections: Clinical presentation and treatment. J. Wound Care 2016, 25, 693–702, doi:10.12968/jowc.2016.25.12.693.

- Iskandar, K.; Sartelli, M.; Tabbal, M.; Ansaloni, L.; Baiocchi, G.L.; Catena, F.; Coccolini, F.; Haque, M.; Labricciosa, F.M.; Moghabghab, A.; et al. Highlighting the gaps in quantifying the economic burden of surgical site infections associated with antimicrobial-resistant bacteria. World J. Emerg. Surg. 2019, 14, 1–14, doi:10.1186/s13017-019-0266-x.

- Stevens, D.L. Treatments for skin and soft-tissue and surgical site infections due to MDR Gram-positive bacteria. J. Infect. 2009, 59, S32–S39, doi:10.1016/s0163-4453(09)60006-2.

- Gomila, A.; Carratalà, J.; Badia, J.M.; Camprubí, D.; Piriz, M.; Shaw, E.; Diaz-Brito, V.; Espejo, E.; Nicolas, C.; Brugués, M. Preoperative oral antibiotic prophylaxis reduces Pseudomonas aeruginosa surgical site infections after elective colorectal sur-gery: A multicenter prospective cohort study. BMC Infect. Dis. 2018, 18, 507.

- Lim, S.L.; Ong, K.C.B.; Chan, Y.H.; Loke, W.C.; Ferguson, M.; Daniels, L. Malnutrition and its impact on cost of hos-pitalization, length of stay, readmission and 3-year mortality. Clin. Nutr. 2012, 31, 345–350.

- Lingsma, H.F.; Bottle, A.; Middleton, S.; Kievit, J.; Steyerberg, E.W.; Marang-Van De Mheen, P.J. Evaluation of hospital out-comes: The relation between length-of-stay, readmission, and mortality in a large international administrative database. BMC Health Serv. Res. 2018, 18, 116.

- Jamal, M.; Ahmad, W.; Andleeb, S.; Jalil, F.; Imran, M.; Nawaz, M.A.; Hussain, T.; Ali, M.; Rafiq, M.; Kamil, M.A. Bacterial biofilm and associated infections. J. Chin. Med. Assoc. 2018, 81, 7–11, doi:10.1016/j.jcma.2017.07.012.

- Song, X.; Vossebein, L.; Zille, A. Efficacy of disinfectant-impregnated wipes used for surface disinfection in hospitals: A re-view. Antimicrob. Resist. Infect. Control 2019, 8, 1–14, doi:10.1186/s13756-019-0595-2.

- Klemeš, J.J.; Fan, Y.V.; Jiang, P. The energy and environmental footprints of COVID-19 fighting measures-PPE, dis-infection, supply chains. Energy 2020, 211, 118701.

- Wang, J.; Shen, J.; Ye, D.; Yan, X.; Zhang, Y.; Yang, W.; Li, X.; Wang, J.; Zhang, L.; Pan, L. Disinfection technology of hospital wastes and wastewater: Suggestions for disinfection strategy during coronavirus Disease 2019 (COVID-19) pandemic in China. Environ. Pollut. 2020, 262, 114665, doi:10.1016/j.envpol.2020.114665.

- Stoica, M. Sustainable Sanitation in the Food Industry. In Sustainable Food Systems from Agriculture to Industry; Elsevier: Am-sterdam, The Netherlands, 2018; pp. 309–339.

- Sharma, A.; Das, P.; Buschmann, M.; Gilbert, J.A. The Future of Microbiome-Based Therapeutics in Clinical Applications. Clin. Pharmacol. Ther. 2020, 107, 123–128.

- Goh, C.F.; Ming, L.C.; Wong, L.C. Dermatologic reactions to disinfectant use during the COVID-19 pandemic. Clin. Dermatol. 2020, doi:10.1016/j.clindermatol.2020.09.005.

- Rahman, S.; Khan, I.; Oh, D.-H. Electrolyzed Water as a Novel Sanitizer in the Food Industry: Current Trends and Future Perspectives. Compr. Rev. Food Sci. Food Saf. 2016, 15, 471–490, doi:10.1111/1541-4337.12200.

- Arya, R.; Bryant, M.; Degala, H.L.; Mahapatra, A.K.; Kannan, G. Effectiveness of a low-cost household electrolyzed water generator in reducing the populations of Escherichia coli K12 on inoculated beef, chevon, and pork surfaces. J. Food Process. Preserv. 2018, 42, e13636, doi:10.1111/jfpp.13636.

- Veasey, S.; Muriana, P.M. Evaluation of electrolytically-generated hypochlorous acid (‘electrolyzed water’) for sanitation of meat and meat-contact surfaces. Foods 2016, 5, 42.

- Graça, A.; Santo, D.; Quintas, C.; Nunes, C. Growth of Escherichia coli, Salmonella enterica and Listeria spp., and their inac-tivation using ultraviolet energy and electrolyzed water, on ‘Rocha’ fresh-cut pears. Food Control 2017, 77, 41–49, doi:10.1016/j.foodcont.2017.01.017.

- Xuan, X.; Ling, J. Generation of Electrolyzed Water. In Electrolyzed Water in Food: Fundamentals and Applications; Springer Science and Business Media LLC: Cham, Switzerland, 2019; pp. 1–16.

- Takeda, Y.; Uchiumi, H.; Matsuda, S.; Ogawa, H. Acidic electrolyzed water potently inactivates SARS-CoV-2 de-pending on the amount of free available chlorine contacting with the virus. Biochem. Bioph. Res. Commun. 2020, 530, 1–3.

- Izumi, H.; Inoue, A. Viability of sublethally injured coliform bacteria on fresh-cut cabbage stored in high CO2 atmospheres following rinsing with electrolyzed water. Int. J. Food Microbiol. 2018, 266, 207–212.

- Hyun-Ji, K.; Tango, C.N.; Ramachandran, C.; Deog-Hwan, O. Sanitization Efficacy of Slightly Acidic Electrolyzed Water against pure cultures of Escherichia coli, Salmonella enterica, Typhimurium, Staphylococcus aureus and Bacillus cereus spores, in Comparison with Different Water Hardness. Sci. Rep. 2019, 9, 1–14.

- Lemos, J.G.; Stefanello, A.; Bernardi, A.O.; Garcia, M.V.; Magrini, L.N.; Cichoski, A.J.; Wagner, R.; Copetti, M.V. Antifungal efficacy of sanitizers and electrolyzed waters against toxigenic Aspergillus. Food Res. Int. 2020, 137, 109451.

- Salisbury, A.-M.; Percival, S.L. The Efficacy of an Electrolysed Water Formulation on Biofilms. In Neurotransmitter Interactions and Cognitive Function; Springer Science and Business Media LLC: Cham, Switzerland, 2018; pp. 1–8.

- Eftekharizadeh, F.; Dehnavieh, R.; Hekmat, S.N.; Mehrolhassani, M.H. Health technology assessment on super oxidized wa-ter for treatment of chronic wounds. Med. J. Islamic Repub. Iran 2016, 30, 384.

- Samara, F.; Badran, R.; Dalibalta, S. Are Disinfectants for the Prevention and Control of COVID-19 Safe? Health Secur. 2020, 18, 496–498.

- Supardi, E.; Yusuf, S.; Massi, M.N.; Haeruddin, H. Evaluation of different type of electrolyzed water against bacterial colo-nization of diabetic foot ulcers: Study in vitro. Med. Clínica Práctica 2020, 3, 100090, doi:10.1016/j.mcpsp.2020.100090.

- Chittoria, R.K.; Yootla, M.; Sampatrao, L.; Raman, S.V. The role of super oxidized solution in the management of diabetic foot ulcer: Our experience. Nepal Med. Coll. J. 2007, 9, 125–128.

- Bongiovanni, C.M. Effects of Hypochlorous Acid Solutions on Venous Leg Ulcers (VLU): Experience With 1249 VLUs in 897 Patients. J. Am. Coll. Clin. Wound Spéc. 2016, 6, 32–37, doi:10.1016/j.jccw.2016.01.001.

- Thekdi, P.I.; Bathla, V.; Koradi, P.; Jhala, D.; Patel, D. A study on newer dressing materials versus conventional dressing ma-terials in ulcer healing. Int. Surg. J. 2016, 3, 108–112.

- Hopkins, J. Electrolyzed water treatment for feminine hygiene. Google Patents US20060275502A1, 7 December 2006.

- Morris, C.D.; Stone, J.K. Method for remediating mold and mildew using acidic electrolyzed water. U.S. Patent 7,445,800, 4 November 2008.

- Jo, H.-Y.; Tango, C.N.; Oh, D.-H. Influence of different organic materials on chlorine concentration and sanitization of slightly acidic electrolyzed water. LWT 2018, 92, 187–194, doi:10.1016/j.lwt.2018.02.028.

- Xuan, X.; Wang, M.; Ahn, J.; Ma, Y.; Chen, S.; Ye, X.; Liu, D.; Ding, T. Storage Stability of Slightly Acidic Electrolyzed Water and Circulating Electrolyzed Water and Their Property Changes after Application. J. Food Sci. 2016, 81, E610–E617, doi:10.1111/1750-3841.13230.

- Khan, I.; Tango, C.N.; Miskeen, S.; Lee, B.H.; Oh, D.-H. Hurdle technology: A novel approach for enhanced food quality and safety-A review. Food Control 2017, 73, 1426–1444.

- Almås, G.H. Acetic acid and hypochlorous acid compositions for treatment of skin trauma. U.S. Pat. Appl. 15/852,603, 2018.

- Almås, G.H. Compositions and methods for treating biofilms without inducing antimicrobial resistance. U.S. Pat. Appl. 16/672,393, 2020.

- Oh, D.-H.; Khan, I.; Tango, C.N. Hurdle Enhancement of Electrolyzed Water with Other Techniques. In Electrolyzed Water in Food: Fundamentals and Applications; Springer Science and Business Media LLC: Cham, Switzerland, 2019; pp. 231–260.

- Zhiznin, S.; Timokhov, V.; Gusev, A. Economic aspects of nuclear and hydrogen energy in the world and Russia. Int. J. Hy-drog. Energy 2020, 45, 31353–31366, doi:10.1016/j.ijhydene.2020.08.260.

- Forghani, F. Application of Electrolyzed Water in Agriculture. In Electrolyzed Water in Food: Fundamentals and Applications; Springer Science and Business Media LLC: Cham, Switzerland, 2019; pp. 223–230.

- Zheng, W.; Li, Z.; Shah, S.B.; Li, B. Removal of ammonia and airborne culturable bacteria by proof-of-concept wind-break wall with slightly acidic electrolyzed water spray for a layer breeding house. Appl. Eng. Agric. 2016, 32, 393–399.

- Graça, A.; Santo, D.; Pires-Cabral, P.; Quintas, C. The effect of UV-C and electrolyzed water on yeasts on fresh-cut apple at 4 °C. J. Food Eng. 2020, 282, 110034, doi:10.1016/j.jfoodeng.2020.110034.

- Hakim, H.; Alam, S.; Sangsriratanakul, N.; Nakajima, K.; Kitazawa, M.; Ota, M.; Toyofuku, C.; Yamada, M.; Thammakarn, C.; Shoham, D.; et al. Inactivation of bacteria on surfaces by sprayed slightly acidic hypochlorous acid water: In vitro exper-iments. J. Vet. Med. Sci. 2016, 78, 1123–1128, doi:10.1292/jvms.16-0075.

- Al-Haq, M.I.; Sugiyama, J.; Isobe, S. Applications of Electrolyzed Water in Agriculture & Food Industries. Food Sci. Technol. Res. 2005, 11, 135–150, doi:10.3136/fstr.11.135.

- Shiroodi, S.G.; Ovissipour, M. Electrolyzed Water Application in Fresh Produce Sanitation. In Postharvest Disinfection of Fruits and Vegetables; Elsevier: Amsterdam, The Netherlands, 2018; pp. 67–89.

- Shirahata, S.; Hamasaki, T.; Teruya, K. Advanced research on the health benefit of reduced water. Trends Food Sci. Technol. 2012, 23, 124–131, doi:10.1016/j.tifs.2011.10.009.

- U.S. Food & Drug Administration. Environmental Assessment for Food Contact Notification FCN 1811; U.S. Food & Drug Ad-ministration, the United States, https://www.fda.gov/food/environmental-decisions/environmental-decision-memo-food-contact-notification-no-1811, ac-cessed on 1 October 2017.

- Rahman, S.; Ding, T.; Oh, D.-H. Effectiveness of low concentration electrolyzed water to inactivate foodborne pathogens under different environmental conditions. Int. J. Food Microbiol. 2010, 139, 147–153.

- Ding, T.; Oh, D.-H.; Liu, D. Electrolyzed Water in Food: Fundamentals and Applications; Springer: Berlin/Heidelberg, Germany, 2019.

- Naito, Y.; Higashimura, Y.; Baba, Y.; Inoue, R.; Takagi, T.; Uchiyama, K.; Mizushima, K.; Hirai, Y.; Ushiroda, C.; Tanaka, Y. Effects of molecular hydrogen-dissolved alkaline electrolyzed water on intestinal environment in mice. Med. Gas. Res. 2018, 8, 6–11, doi:10.4103/2045-9912.229597.

- Kitaori, N.; Uno, M.; Nishiki, Y.; Furuta, T. Method of sterilization and electrolytic water ejecting apparatus. U.S. Patent 7,887,679. 15 February 2011.

- Kim, E.S. Electrolysis apparatus capable of producing disinfectant or cleaning agent, and electrolysis method therefor. U.S. Pat. Appl. 16/569,153, 2020.

- Liang, D.; Wang, Q.; Zhao, D.; Han, X.; Hao, J. Systematic application of slightly acidic electrolyzed water (SAEW) for natu-ral microbial reduction of buckwheat sprouts. LWT 2019, 108, 14–20, doi:10.1016/j.lwt.2019.03.021.

- Zheng, W.; Xie, C.; Liang, J.; Yu, Q.-D.; Bai, D.; Huang, J. Effects of weak acidic electrolytic water ice and modified packaging on shrimp quality of Litopenaeus vannamei. Sci. Technol. Food Ind. 2018, 34 http://en.cnki.com.cn/Article_en/CJFDTotal-REEF201704010.htm.

- Rivera‐Garcia, A.; Santos‐Ferro, L.; Ramirez‐Orejel, J.C.; Agredano‐Moreno, L.T.; Jimenez‐Garcia, L.F.; Pa-ez‐Esquiliano, D.; Andrade‐Esquivel, E.; Cano‐Buendia, J.A. The effect of neutral electrolyzed water as a disinfectant of eggshells artificially contaminated with Listeria monocytogenes. Food Sci. Nutr. 2019, 7, 2252–2260.

- Naka, A.; Yakubo, M.; Nakamura, K.; Kurahashi, M. Effectiveness of slightly acidic electrolyzed water on bacteria reduction: In vitro and spray evaluation. PeerJ 2020, 8, e8593, doi:10.7717/peerj.8593.

- Zhang, C.; Zhang, Y.; Zhao, Z.; Liu, W.; Chen, Y.; Yang, G.; Xia, X.; Cao, Y. The application of slightly acidic electrolyzed water in pea sprout production to ensure food safety, biological and nutritional quality of the sprout. Food Control 2019, 104, 83–90.

- Mansur, A.R.; Oh, D.-H. Modeling the Growth of Epiphytic Bacteria on Kale Treated by Thermosonication Combined with Slightly Acidic Electrolyzed Water and Stored under Dynamic Temperature Conditions. J. Food Sci. 2016, 81, M2021–M2030, doi:10.1111/1750-3841.13388.

- Bansal, V.; Prasad, P.; Mehta, D.; Siddiqui, M.W. Ultrasound Techniques in Postharvest Disinfection of Fruits and Vegetables; Elsevier: Amsterdam, The Netherlands, 2018; pp. 159–177.

- Zhang, J.; Yang, H.; Chan, J.Z.Y. Development of Portable Flow-Through Electrochemical Sanitizing Unit to Generate Near Neutral Electrolyzed Water. J. Food Sci. 2018, 83, 780–790, doi:10.1111/1750-3841.14080.

- Xuan, X.T.; Fan, Y.F.; Ling, J.G.; Hu, Y.; Liu, D.H.; Chen, S.G.; Ye, X.Q.; Ding, T. Preservation of squid by slightly acidic elec-trolyzed water ice. Food Control 2017, 73, 1483–1489, doi:10.1016/j.foodcont.2016.11.013.