Flavours and fragrances are volatile compounds of large interest for different applications. Due to their high tendency of evaporation and, in most cases, poor chemical stability, these compounds need to be encapsulated for handling and industrial processing. Encapsulation, indeed, resulted in being effective at overcoming the main concerns related to volatile compound manipulation, and several industrial products contain flavours and fragrances in an encapsulated form for the final usage of customers. Several organic or inorganic materials have been investigated for the production of coated micro- or nanosystems intended for the encapsulation of fragrances and flavours, among them, polymeric coating, leading to the formation of micro- or nanocapsules with a core-shell architecture, as well as a molecular inclusion complexation with cyclodextrins, are still the most used.

1. Introduction

Flavours and fragrances are a large class of compounds widely employed as additives in different technological fields, including food, cosmetics, textiles and others, mainly to ameliorate the olfactory and gustatory sensations of the product [1,2]. They comprise both synthetic and naturally occurring molecules, such as essential oils (EO) and aroma compounds [3,4]. Especially those of natural origin, which are mostly derived from plants, possess, in addition to sensory properties, also various biological activities (e.g., antibacterial, antiviral, antifungal, antiprotozoal, insect-repellent, anticancer, antidiabetic, anti-inflammatory and antioxidant) that raise the interest around this class of compounds [5,6]. Besides the large potential of exploitation, the major drawbacks regarding their use are related to the volatility and chemical instability [7]. Indeed, most of these compounds are sensitive to light, heat or oxygen; therefore, they can be deteriorated during the manufacturing process and reduce or lose their shelf-life activity during storage and consumer manipulation [8].

2. Applications of Micro-/Nanoencapsulated Fragrances and Flavours

Micro- and nanocapsules/spheres, as well as molecular inclusion complexes with CDs, have been largely employed as protective carriers for aroma compounds (fragrances, aromas and flavours) in different technological fields [25,103]. The following paragraphs summarise the main experimental studies recently conducted on the design and application of micro- and nanocapsules/spheres in the textile, food, cosmetic and paper production fields.

2.1. Textile Applications

Textiles represent one of the most investigated applications for micro- and nanospheres/capsules encapsulating fragrances and aromas. These encapsulated volatile compounds have been employed for several years in textile-finishing processes, such as fabric conditioners to impart freshness and odour control [

104,

105,

106,

107]. Through encapsulation, fragrances are retained and released for a long time [

108]. Moreover, the sensation of the added encapsulated fragrances can be preserved also after several washing-drying cycles (up to 25); therefore, the attractiveness of the product to the consumers is improved [

109,

110]. Encapsulated perfumes and EOs have been added in scarves, ties, lingerie and other garments, as well for home textiles, such as sofa coverings, curtains and cushions for aromatherapy [

106,

111]. Perfumes and aromas can be directly applied on textiles; however, their scarce affinity to fabric fibres and their chemical volatility limit their permanence. Thus, encapsulation promotes a prolonged duration of aroma sensations due to the controlled release of the fragrance. For this purpose, several types of fabrics can be processed with encapsulated fragrances and aromas, such as cotton, silk and synthetic fibres (polyamide or polyester). These micro- and nanocapsules/spheres can be added to textiles using different techniques, such as impregnation, spraying, coating or stamping [

103,

112]. The encapsulation of fragrances and aromas is still achieved through traditional methods such as simple or complex coacervation, as well as the inclusion encapsulation method or interfacial polymerisation. However, other “innovative” encapsulation processes for fragrances and aromas have been recently explored in textile applications. Ye et al. proposed an electro-spraying method using aqueous media to prepare composite nanospheres made up of silk fibroin and β-CD encapsulating rose oxide or D-limonene (). The nanospheres have an aroma encapsulation higher than 90% and were deposited directly on silk fabric. The fragrances were released with zero-order kinetics, guaranteeing a low rate and constant release profile. Noticeably, the composite nanospheres were retained at a higher percentage (more than 80%) after 10 runs of washing with water, demonstrating its applicability in the textile field [

113].

Figure 2. Direct deposition of fragrance-loaded nanoparticles onto fabric surfaces by electro-spraying (reproduced from [

113]). CD: cyclodextrins.

The retention of fragrances and aromas, especially after washing or rubbing, depends on the penetration of microcapsules and nanocapsules into the spacing of textiles during the finishing process. To address this, in a work, a series of micro-/nanocapsules, with a size suitable for the pore spacing of cotton textiles and formed by citronella oil as the core material and chitosan as the wall material, was prepared through a microemulsion approach. These micro-/nanocapsules were applied on the textile through vacuum impregnation. The matching between the spacing of the pore sizes of cotton textiles and the sizes of micro-/nanocapsules was assessed via the retention of aromatic compounds in the finished cotton textiles after several washing cycles (washing durability). Indeed, the aromatic retention of cotton textiles finished by nanocapsules was much greater than the same textiles finished with microcapsules (28.84% vs. 1.55%) after 10 cycles of washing. The authors demonstrated that nanocapsules can penetrate better into the pores of the cotton textiles [

114]. To overcome the issue related to the poor combination fastness and duration in the textiles, several approaches were employed in the past, using chemical binders or crosslinking agents. Recently, Ma et al. exploited electrostatic adsorption and immobilisation to retain nanocapsules loaded with lavender essence on cotton textiles. Firstly, the textile was positively charged through quaternary ammonium cationisation to promote the adsorption of nanocapsules with a negatively charged surface. The in-situ immobilisation was achieved via the diffusion and permeation of an alkali solution, leading to a chemical bond between nanocapsules and the textile fibres at the position of absorption. The encapsulated fragrance was released continuously for 120 days, and 91.19% of the essence still remained entrapped in the textile after five washing cycles. The authors proposed this method as a simple and “green” approach for the preparation of nanocomposite textile materials for different applications.

2.2. Food Applications

Another application in which the micro- and nanoencapsulation of fragrances and flavours research has been focused on is related to food [

143]. As for the other active ingredients, the encapsulation of fragrances and flavours has been exploited in food processing and for the design of active food packaging [

40]. In the food industry, encapsulated flavours and fragrances have been widely used to ameliorate taste and/or odour, to adjust the nutritional value and to prolong the shelf-life of food [

144,

145,

146]. As such, food quality has improved, with positive implication in terms of consumer satisfaction and food consumption [

147]. For instance, fragrances and flavours are volatile compounds and are prone to evaporation during several food-processing operations or storage of the final product. Moreover, they can undergo chemical instability due to oxidation in the presence of air and light, moisture or high temperature, leading to chemical degradation and possible interactions with other food additives [

148]. In this regard, these compounds can be stabilised by encapsulation or complex formations. In addition to overcoming these concerns, encapsulation and/or complex formations improve also the manageability of these volatile food additives, guaranteeing stability and a simpler and standardised dosing. A classic example of the encapsulation of flavours in food technology is coffee aroma. Coffee aroma compounds are a mixture of pyridines, pyrazines, ketones, furans, etc. contained in the oil extracted from roasted coffee. These compounds are considered as flavouring agents to enrich the aroma, especially in instant coffee formulations. Roasted coffee oil is composed of several unsaturated fatty acids sensitive to oxidative degradation in the presence of air. Therefore, microencapsulation has been proposed as a strategy to preserve the freshly brewed coffee aroma in instant coffee products for a prolonged time after the first opening of the packaging. In addition, microencapsulation can be employed to control the release of these coffee aroma compounds over time. Specifically, roasted coffee oil was encapsulated in a modified food starch derived from waxy maize, and the resultant microcapsules were added to the formula of soluble coffee and instant cappuccino products with the aim of modulating the release of volatile organic compounds (VOC). The addition of microparticles improved the quality of the products in terms of aroma intensity, and the authors demonstrated how the composition of the product can affect the aroma release profile [

149]. Among all fragrances and aromas, EOs obtained from a large botanical variety of plants are the most encapsulated substances in food [

40,

150]. They are used to provide a pleasant smell to food or to cover the original odour, configuring the olfactory sensation as a product identity marker. Being volatile liquids, their direct incorporation in food is not straightforward. Therefore, the food industry generally employed encapsulated or complex EOs, since these technological approaches both stabilised the components of EOs and increased their manageability. Complexation with β-CDs and encapsulation by simple or complex coacervation are still the most investigated in recent scientific studies. Different EOs have been employed for their antioxidant and antimicrobial effects, exploited for fruit preservation. Syringa EO was microencapsulated by the formation of complexes with β-CDs and used as an antifungal agent against

Botrytis cinerea and

Alternaria alternata to improve the quality attributes and storage behaviours of peaches [

151]. Similarly, microcapsules of

Zingiber officinale EO were prepared using chitosan and carboxymethyl cellulose as shell materials to investigate the effects on the postharvest quality and prolonged the shelf-life of jujube fruits in terms of morphologic characteristics and some parameters as soluble solid contents, titratable acidity, the Red index and decay index and sensory quality [

152]. The EO extracted from the leaves of Eucalyptus and incorporated into carboxymethyl cellulose (CMC) was employed to control fungal growth causing soft rot on strawberries, configured as a valid alternative to synthetic fungicides for this preharvest treatment [

153].

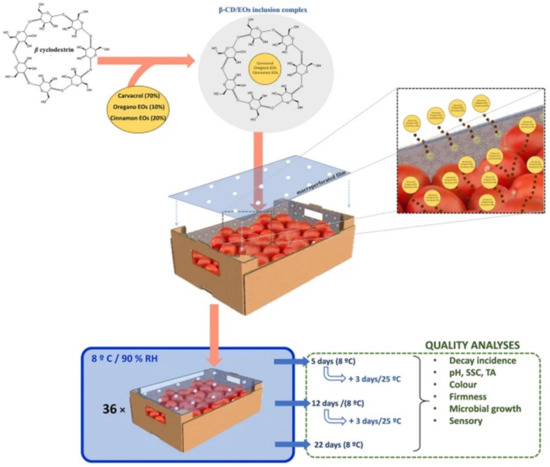

Active packaging represents a fashionable option to preserve the quality and prolong the shelf life of food products. It refers to packaging materials, which are not inert, and does not exert only a mechanical function of enclosing food, but they “actively” interact with the atmosphere inside the packaging or directly with food products [

154,

155,

156]. In most cases, active packaging results in being effective in preventing chemical–physical or microbiological degradation by maintaining, at the same time, the organoleptic and nutritional properties of the product () [

157].

Figure 3. Application of essential oil-β-CD molecular inclusion complexes for the preparation of an active cardboard packaging for food storage (Reproduced from [

174]).

summarises the recent studies reporting the microencapsulation and nanoencapsulation of fragrances and flavours for food applications.

The European Union (EU) Cosmetics Regulation defines a cosmetic product as “any substance or mixture used for external parts of the human body (epidermis, hair system, nails, lips and external genital organs), teeth and mucous membranes of the oral cavity for cleaning them, perfuming them, changing their appearance and/or correcting body odors and/or protecting them or keeping them in good condition” [

187]. In the last years, the beauty and personal care industry have become a multibillion-dollar international business with a significant growth value in emerging markets, such as Brazil, China, India, Indonesia and Argentina [

188,

189]. In general, there is an increasing interest in natural cosmetic formulations that generates the demand for new products reformulated by using botanical and bioactive ingredients, including fragrances and aromas, to contribute to health, beauty and wellness. Another goal to have success in such a competitive and demanding sector is the use emergent technologies, such as microencapsulation able to give innovation, functional properties and, thus, an additional value to a cosmetic product [

190]. In particular, microencapsulation technologies have been proposed to increase stability, to protect against degradation and, also, to direct and control the release of active ingredients [

191,

192].

3.4. Paper Applications

Another application of the aroma and fragrances encapsulation is the design of aromatic paper or scented paper. Aromatic paper is intended to provide a pleasant surrounding atmosphere on the basis of the aromatherapy principles. In this regard, research has been focused on the development of wallpaper with the aim of providing comfortable sensations and to enhance the psychological and physical well-being [

212,

213]. Scented papers are, generally, wrapping or writing papers, in which perfumes or fragrances are added for voluptuary purposes or marketing appeal. These papers can be prepared by adding the nano/microspheres containing fragrances or aromas directly into the pulp during the processing operations, or, alternatively, the encapsulated materials can be adsorbed onto the paper surface in a further production step. Moreover, the scented encapsulated compounds can be applied on paper after dispersing them into a coating varnish or ink.

Lavender oil microcapsules were prepared with ABA-type triblock copolymer (polyethylene oxide-polypropylene glycol-polyethylene oxide, PEO-b-PPG-b-PEO) and adsorbed onto the paper surface. The distribution of the microcapsules on the paper surface was homogeneous without degradation. The colour and gloss properties of the paper were also maintained in compliance with the standards [

214]. In another work, lavender EO was encapsulated by coacervation using gelatin/gum arabica as the shell material. The obtained microcapsules were dispersed into a UV-curable varnish at a selected microcapsule-to-varnish ratio. The varnish was characterised in terms of the control and protection of the encapsulated lavender EO major volatile components. Notably, the presence of the encapsulated materials does not interfere with the standard screen-printing process generally employed to produce a fragrant gift-wrapping paper [

215].

Recently, encapsulated fragrances with an antibacterial effect were applied on paper. Specifically, vanillin was encapsulated in chitosan/poly(lactic-co-glycolic acid (PLGA) nanocapsules to prepare an aromatic wallpaper with an additional antibacterial action. Thanks to the presence of chitosan, the nanospheres showed an antibacterial effect against Gram positive and Gram negative, and the adhesion on the wallpaper was also enhanced [

216]. In another work, the encapsulated EO had an antibacterial effect. Citronella EO was encapsulated in microcapsules, obtained by complex coacervation using as a coating material the mixture gelatin/carboxymethyl cellulose or gelatin/gum arabic or by the in-situ polymerisation of melamine–formaldehyde with a polyacrylic acid modifier. These nanocapsules were employed for the preparation of functional coatings intended for paper or cardboard secondary packaging. Both microencapsulation methods provided single-core microcapsules, but some differences were highlighted. Microcapsules from coacervation were more permeable and allowed a steady release of the EO, while those from in-situ polymerisation were impermeable, showing a high retention of the EO, which was released only after a mechanical pressure.

This entry is adapted from the peer-reviewed paper 10.3390/molecules25245878