Magnetic soft robots, as an innovative branch of the soft robotics discipline, are eye-catching because of their excellent controllability and high flexibility under the control of magnetic fields. Thanks to the properties of magnetic materials, this type of robot can be manufactured into extremely fine micro guide wires, making it particularly applicable in fields such as minimally invasive pipeline interventional treatment or interventional laser surgery. Although magnetic soft robots and continuum robots belong to the same category of soft robots, they show obvious differences and complementarities in design concepts, application scenarios, and technical implementation. Especially from the perspective of structural size, continuum robots have encountered certain challenges in miniaturization, and magnetic soft robots can be regarded as an important expansion and deepening of continuum robots in terms of size reduction.

- soft robots

- magnetic soft robots

- continuum robots

- interdisciplinary challenges

- medical robots

1. Continuum Robots

1.1. Principle Modeling

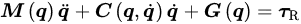

where 𝝫(𝑋) is the basis function. To capture the dynamic behavior of continuum robots in complex environments and under the influence of various forces, the kinematic model of continuum robots can be described using the Euler–Lagrange equation or Hamiltonian equation, based on the generalized coordinates 𝒒. This kinematic model can be represented as:

1.2. Data Modeling

1.3. Hybrid Modeling

2. Magnetic Soft Robots

2.1. Uniform Magnetic Field

2.2. Non-Uniform Magnetic Field

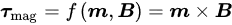

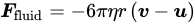

With a viscosity of 𝜂, 𝒖 is the fluid velocity and 𝒗 is the velocity of the robot in the fluid, and r is the approximate radius of the robot. Considering fluid resistance makes the multiphysics model more aligned with real-world applications and provides rich content for subsequent in-depth analysis and understanding. The net external force generated by the magnetic field and fluid resistance is reflected in the acceleration 𝑑2𝒙𝑑𝑡2 of the robot’s center of mass. The latter describes the robot’s angular acceleration 𝑑2𝜃𝑑𝑡2 around its center of mass, which is determined by the total external torque 𝜏 applied. These two equations provide us with a complete and in-depth perspective for understanding and analyzing the dynamic behavior of robots in complex multiphysics fields. Therefore, the motion equation and rotational dynamics of the robot are, respectively, given by:

2.3. Quantum Effects

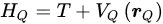

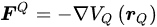

where T represents the kinetic energy term and 𝑉𝑄(𝒓𝑄) is the quantum potential energy. The system’s ground state or several low-excited states are found by solving the Schrödinger equation or other quantum equations corresponding to the Hamiltonian 𝐻𝑄. Subsequently, the quantum correction force 𝑭𝑄 is calculated, which is typically the gradient of the quantum potential energy 𝑉𝑄 concerning the coordinates 𝒓𝑄:

This entry is adapted from the peer-reviewed paper 10.3390/mi15030313

References

- Rubin, M.; Rubin, M. Cosserat Theories: Shells, Rods and Points; Springer: Berlin/Heidelberg, Germany, 2000; pp. 1–480.

- Renda, F.; Boyer, F.; Dias, J.; Seneviratne, L. Discrete cosserat approach for multisection soft manipulator dynamics. IEEE Trans. Robot. 2018, 34, 1518–1533.

- Zhang, X.; Naughton, N.; Parthasarathy, T.; Gazzola, M. Friction modulation in limbless, three-dimensional gaits and heterogeneous terrains. Nat. Commun. 2021, 12, 6076.

- Zhang, X.; Chan, F.K.; Parthasarathy, T.; Gazzola, M. Modeling and simulation of complex dynamic musculoskeletal architectures. Nat. Commun. 2019, 10, 4825.

- Webster, R.J., III; Jones, B.A. Design and kinematic modeling of constant curvature continuum robots: A review. Int. J. Robot. Res. 2010, 29, 1661–1683.

- Hasanzadeh, S.; Janabi-Sharifi, F. An efficient static analysis of continuum robots. J. Mech. Robot. 2014, 6, 031011.

- Li, X.; Yu, W.; Baghaee, M.; Cao, C.; Chen, D.; Liu, J.; Yuan, H. Geometrically exact finite element formulation for tendon-driven continuum robots. Acta Mech. Solida Sin. 2022, 35, 552–570.

- Godage, I.S.; Branson, D.T.; Guglielmino, E.; Medrano-Cerda, G.A.; Caldwell, D.G. Dynamics for biomimetic continuum arms: A modal approach. In Proceedings of the 2011 IEEE International Conference on Robotics and Biomimetics, Karon Beach, Thailand, 7–11 December 2011; pp. 104–109.

- Yang, J.; Peng, H.; Zhou, W.; Zhang, J.; Wu, Z. A modular approach for dynamic modeling of multisegment continuum robots. Mech. Mach. Theory 2021, 165, 104429.

- Dickson, L.E. Modern Algebraic Theories; BH Sanborn & Company: Denver, CO, USA, 1926.

- Robinson, D.J. A Course in the Theory of Groups; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 80.

- Armstrong, M.A. Groups and Symmetry; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1997.

- Dai, J. Geometrical Foundations and Screw Algebra for Mechanisms and Robotics; Springer: Berlin/Heidelberg, Germany, 2014.

- Siciliano, B.; Khatib, O.; Kröger, T. Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2008; Volume 200.

- Murray, R.M.; Li, Z.; Sastry, S.S. A Mathematical Introduction to Robotic Manipulation; CRC Press: Boca Raton, FL, USA, 1994.

- Lynch, K.M.; Park, F.C. Modern Robotics; Cambridge University Press: Cambridge, UK, 2017.

- Poincaré, H. Sur une forme nouvelle des équations de la mécanique. CR Acad. Sci. 1901, 132, 369–371.

- Dym, C.L.; Shames, I.H. Solid Mechanics; Springer: Berlin/Heidelberg, Germany, 1973.

- Till, J.; Aloi, V.; Rucker, C. Real-time dynamics of soft and continuum robots based on Cosserat rod models. Int. J. Robot. Res. 2019, 38, 723–746.

- Wu, G.; Shi, G. Design, modeling, and workspace analysis of an extensible rod-driven parallel continuum robot. Mech. Mach. Theory 2022, 172, 104798.

- Edelmann, J.; Petruska, A.J.; Nelson, B.J. Magnetic control of continuum devices. Int. J. Robot. Res. 2017, 36, 68–85.

- Hesch, C.; Glas, S.; Schuß, S. Space-time multibody dynamics. Multibody Syst. Dyn. 2023, 1–20.

- Chen, P.; Liu, Y.; Yuan, T.; Shi, W. Modeling of continuum robots with environmental constraints. In Engineering with Computers; Springer: Berlin/Heidelberg, Germany, 2023; pp. 1–14.

- McCulloch, W.S.; Pitts, W. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biophys. 1943, 5, 115–133.

- Kelley, H.J. Gradient theory of optimal flight paths. Ars J. 1960, 30, 947–954.

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 2012, 25, 1–9.

- Littman, M.L.; Ajunwa, I.; Berger, G.; Boutilier, C.; Currie, M.; Doshi-Velez, F.; Hadfield, G.; Horowitz, M.C.; Isbell, C.; Kitano, H.; et al. Gathering strength, gathering storms: The one hundred year study on artificial intelligence (AI100) 2021 study panel report. arXiv 2022, arXiv:2210.15767.

- Soori, M.; Arezoo, B.; Dastres, R. Artificial intelligence, machine learning and deep learning in advanced robotics, A review. Cogn. Robot. 2023, 3, 54–70.

- Morales, E.F.; Murrieta-Cid, R.; Becerra, I.; Esquivel-Basaldua, M.A. A survey on deep learning and deep reinforcement learning in robotics with a tutorial on deep reinforcement learning. Intell. Serv. Robot. 2021, 14, 773–805.

- Jumper, J.; Evans, R.; Pritzel, A.; Green, T.; Figurnov, M.; Ronneberger, O.; Tunyasuvunakool, K.; Bates, R.; Žídek, A.; Potapenko, A.; et al. Highly accurate protein structure prediction with AlphaFold. Nature 2021, 596, 583–589.

- Jumet, B.; Bell, M.D.; Sanchez, V.; Preston, D.J. A data-driven review of soft robotics. Adv. Intell. Syst. 2022, 4, 2100163.

- Bhagat, S.; Banerjee, H.; Ho Tse, Z.T.; Ren, H. Deep reinforcement learning for soft, flexible robots: Brief review with impending challenges. Robotics 2019, 8, 4.

- Kim, D.; Kim, S.H.; Kim, T.; Kang, B.B.; Lee, M.; Park, W.; Ku, S.; Kim, D.; Kwon, J.; Lee, H.; et al. Review of machine learning methods in soft robotics. PLoS ONE 2021, 16, e0246102.

- George Thuruthel, T.; Ansari, Y.; Falotico, E.; Laschi, C. Control strategies for soft robotic manipulators: A survey. Soft Robot. 2018, 5, 149–163.

- Sahoo, A.R.; Chakraborty, P. A Study on Position Control of a Continuum Arm Using MAML (Model-Agnostic Meta-Learning) for Adapting Different Loading Conditions. IEEE Access 2022, 10, 14980–14992.

- Wei, D.; Zhou, J.; Zhu, Y.; Ma, J.; Ma, S. Axis-space framework for cable-driven soft continuum robot control via reinforcement learning. Commun. Eng. 2023, 2, 61.

- Reiter, A.; Goldman, R.E.; Bajo, A.; Iliopoulos, K.; Simaan, N.; Allen, P.K. A learning algorithm for visual pose estimation of continuum robots. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; pp. 2390–2396.

- Thuruthel, T.G.; Shih, B.; Laschi, C.; Tolley, M.T. Soft robot perception using embedded soft sensors and recurrent neural networks. Sci. Robot. 2019, 4, eaav1488.

- Schegg, P.; Duriez, C. Review on generic methods for mechanical modeling, simulation and control of soft robots. PLoS ONE 2022, 17, e0251059.

- Largilliere, F.; Verona, V.; Coevoet, E.; Sanz-Lopez, M.; Dequidt, J.; Duriez, C. Real-time control of soft-robots using asynchronous finite element modeling. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 2550–2555.

- Mathew, A.T.; Hmida, I.M.B.; Armanini, C.; Boyer, F.; Renda, F. Sorosim: A matlab toolbox for hybrid rigid-soft robots based on the geometric variable-strain approach. IEEE Robot. Autom. Mag. 2022, 30, 106–122.

- Grazioso, S.; Di Gironimo, G.; Siciliano, B. A geometrically exact model for soft continuum robots: The finite element deformation space formulation. Soft Robot. 2019, 6, 790–811.

- Wu, Q.; Gu, Y.; Li, Y.; Zhang, B.; Chepinskiy, S.A.; Wang, J.; Zhilenkov, A.A.; Krasnov, A.Y.; Chernyi, S. Position control of cable-driven robotic soft arm based on deep reinforcement learning. Information 2020, 11, 310.

- Giorelli, M.; Renda, F.; Calisti, M.; Arienti, A.; Ferri, G.; Laschi, C. Neural network and jacobian method for solving the inverse statics of a cable-driven soft arm with nonconstant curvature. IEEE Trans. Robot. 2015, 31, 823–834.

- Thuruthel, T.G.; Falotico, E.; Renda, F.; Laschi, C. Learning dynamic models for open loop predictive control of soft robotic manipulators. Bioinspiration Biomimetics 2017, 12, 066003.

- Lee, K.H.; Fu, D.K.; Leong, M.C.; Chow, M.; Fu, H.C.; Althoefer, K.; Sze, K.Y.; Yeung, C.K.; Kwok, K.W. Nonparametric online learning control for soft continuum robot: An enabling technique for effective endoscopic navigation. Soft Robot. 2017, 4, 324–337.

- Zheng, A.; Casari, A. Feature Engineering for Machine Learning: Principles and Techniques for Data Scientists; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2018.

- Felix, E.A.; Lee, S.P. Systematic literature review of preprocessing techniques for imbalanced data. IET Softw. 2019, 13, 479–496.

- Kuhn, M.; Johnson, K. Feature Engineering and Selection: A Practical Approach for Predictive Models; Chapman and Hall/CRC: Boca Raton, FL, USA, 2019.

- Khurana, U.; Samulowitz, H.; Turaga, D. Feature engineering for predictive modeling using reinforcement learning. In Proceedings of the AAAI Conference on Artificial Intelligence, New Orleans, LA, USA, 2–7 February 2018; Volume 32.

- Anderson, D.; Burnham, K. Model Selection and Multimodel Inference: A Practical Information-Theoretic Approach; Springer: Cham, Switzerland, 2004; Volume 63, pp. 1–488.

- Clarke, B. Comparing Bayes model averaging and stacking when model approximation error cannot be ignored. J. Mach. Learn. Res. 2003, 4, 683–712.

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016.

- Hastie, T.; Tibshirani, R.; Friedman, J.H.; Friedman, J.H. The Elements of Statistical Learning: Data Mining, Inference, and Prediction; Springer: Berlin/Heidelberg, Germany, 2009; Volume 2.

- Singh, P. Deploy Machine Learning Models to Production; Springer: Cham, Switzerland, 2021.

- Van der Loo, M.; De Jonge, E. Statistical Data Cleaning with Applications in R; John Wiley & Sons: Hoboken, NJ, USA, 2018.

- Tan, N.; Yu, P.; Zhang, X.; Wang, T. Model-free motion control of continuum robots based on a zeroing neurodynamic approach. Neural Netw. 2021, 133, 21–31.

- Tariverdi, A.; Venkiteswaran, V.K.; Richter, M.; Elle, O.J.; Tørresen, J.; Mathiassen, K.; Misra, S.; Martinsen, Ø.G. A recurrent neural-network-based real-time dynamic model for soft continuum manipulators. Front. Robot. AI 2021, 8, 631303.

- Tan, N.; Yu, P.; Zhong, Z.; Zhang, Y. Data-Driven Control for Continuum Robots Based on Discrete Zeroing Neural Networks. IEEE Trans. Ind. Inform. 2022, 19, 7088–7098.

- Youssef, S.M.; Soliman, M.; Saleh, M.A.; Elsayed, A.H.; Radwan, A.G. Design and control of soft biomimetic pangasius fish robot using fin ray effect and reinforcement learning. Sci. Rep. 2022, 12, 21861.

- Goldman, R.E.; Bajo, A.; Simaan, N. Compliant motion control for multisegment continuum robots with actuation force sensing. IEEE Trans. Robot. 2014, 30, 890–902.

- Ji, G.; Yan, J.; Du, J.; Yan, W.; Chen, J.; Lu, Y.; Rojas, J.; Cheng, S.S. Towards safe control of continuum manipulator using shielded multiagent reinforcement learning. IEEE Robot. Autom. Lett. 2021, 6, 7461–7468.

- Molnar, C. Interpretable Machine Learning; Lulu.com: Morrisville, NC, USA, 2020.

- Tsang, W.K.; Benoit, D.F. Interpretability and Explainability in Machine Learning. In Living Beyond Data: Toward Sustainable Value Creation; Springer: Berlin/Heidelberg, Germany, 2022; pp. 89–100.

- Hall, P.; Gill, N. An Introduction to Machine Learning Interpretability; O’Reilly Media, Incorporated: Sebastopol, CA, USA, 2019.

- Amann, J.; Blasimme, A.; Vayena, E.; Frey, D.; Madai, V.I.; Consortium, P. Explainability for artificial intelligence in healthcare: A multidisciplinary perspective. BMC Med. Inform. Decis. Mak. 2020, 20, 1–9.

- Dwivedi, Y.K.; Hughes, L.; Ismagilova, E.; Aarts, G.; Coombs, C.; Crick, T.; Duan, Y.; Dwivedi, R.; Edwards, J.; Eirug, A.; et al. Artificial Intelligence (AI): Multidisciplinary perspectives on emerging challenges, opportunities, and agenda for research, practice and policy. Int. J. Inf. Manag. 2021, 57, 101994.

- Xu, Q.; Xie, W.; Liao, B.; Hu, C.; Qin, L.; Yang, Z.; Xiong, H.; Lyu, Y.; Zhou, Y.; Luo, A.; et al. Interpretability of Clinical Decision Support Systems Based on Artificial Intelligence from Technological and Medical Perspective: A Systematic Review. J. Healthc. Eng. 2023, 2023, 9919269.

- Chen, P.; Dong, W.; Wang, J.; Lu, X.; Kaymak, U.; Huang, Z. Interpretable clinical prediction via attention-based neural network. BMC Med. Inform. Decis. Mak. 2020, 20, 1–9.

- Van der Velden, B.H.; Kuijf, H.J.; Gilhuijs, K.G.; Viergever, M.A. Explainable artificial intelligence (XAI) in deep learning-based medical image analysis. Med. Image Anal. 2022, 79, 102470.

- Zhang, J.; Petersen, S.D.; Radivojevic, T.; Ramirez, A.; Pérez-Manríquez, A.; Abeliuk, E.; Sánchez, B.J.; Costello, Z.; Chen, Y.; Fero, M.J.; et al. Combining mechanistic and machine learning models for predictive engineering and optimization of tryptophan metabolism. Nat. Commun. 2020, 11, 4880.

- Gettelman, A.; Geer, A.J.; Forbes, R.M.; Carmichael, G.R.; Feingold, G.; Posselt, D.J.; Stephens, G.L.; van den Heever, S.C.; Varble, A.C.; Zuidema, P. The future of Earth system prediction: Advances in model-data fusion. Sci. Adv. 2022, 8, eabn3488.

- Yang, S.; Navarathna, P.; Ghosh, S.; Bequette, B.W. Hybrid modeling in the era of smart manufacturing. Comput. Chem. Eng. 2020, 140, 106874.

- Zhou, T.; Gani, R.; Sundmacher, K. Hybrid data-driven and mechanistic modeling approaches for multiscale material and process design. Engineering 2021, 7, 1231–1238.

- Zhang, H.; Qi, Q.; Ji, W.; Tao, F. An update method for digital twin multi-dimension models. Robot. Comput. Integr. Manuf. 2023, 80, 102481.

- Xiang, L.; Xunbo, L.; Liang, C. Multi-disciplinary modeling and collaborative simulation of multi-robot systems based on HLA. In Proceedings of the 2007 IEEE International Conference on Robotics and Biomimetics (ROBIO), Sanya, China, 15–18 December 2007; pp. 553–558.

- Braganza, D.; Dawson, D.M.; Walker, I.D.; Nath, N. A neural network controller for continuum robots. IEEE Trans. Robot. 2007, 23, 1270–1277.

- Thuruthel, T.G.; Falotico, E.; Renda, F.; Laschi, C. Model-based reinforcement learning for closed-loop dynamic control of soft robotic manipulators. IEEE Trans. Robot. 2018, 35, 124–134.

- Lu, Y.; Yang, B.; Mo, Y. Two-timescale mechanism-and-data-driven control for aggressive driving of autonomous cars. In Proceedings of the 2021 China Automation Congress (CAC), Beijing, China, 22–24 October 2021; pp. 7874–7879.

- Tsopanoglou, A.; del Val, I.J. Moving towards an era of hybrid modelling: Advantages and challenges of coupling mechanistic and data-driven models for upstream pharmaceutical bioprocesses. Curr. Opin. Chem. Eng. 2021, 32, 100691.

- Arcomano, T.; Szunyogh, I.; Wikner, A.; Pathak, J.; Hunt, B.R.; Ott, E. A hybrid approach to atmospheric modeling that combines machine learning with a physics-based numerical model. J. Adv. Model. Earth Syst. 2022, 14, e2021MS002712.

- Lee, D.; Jayaraman, A.; Kwon, J.S.I. A Hybrid Mechanistic Data-Driven Approach for Modeling Uncertain Intracellular Signaling Pathways. In Proceedings of the 2021 American Control Conference (ACC), New Orleans, LA, USA, 25–28 May 2021; pp. 1903–1908.

- Hammes-Schiffer, S.; Galli, G. Integration of theory and experiment in the modelling of heterogeneous electrocatalysis. Nat. Energy 2021, 6, 700–705.

- Ellis, J.; Jacobs, M.; Dijkstra, J.; van Laar, H.; Cant, J.; Tulpan, D.; Ferguson, N. Synergy between mechanistic modelling and data-driven models for modern animal production systems in the era of big data. Animal 2020, 14, s223–s237.

- Sansana, J.; Joswiak, M.N.; Castillo, I.; Wang, Z.; Rendall, R.; Chiang, L.H.; Reis, M.S. Recent trends on hybrid modeling for Industry 4.0. Comput. Chem. Eng. 2021, 151, 107365.

- Kurz, S.; De Gersem, H.; Galetzka, A.; Klaedtke, A.; Liebsch, M.; Loukrezis, D.; Russenschuck, S.; Schmidt, M. Hybrid modeling: Towards the next level of scientific computing in engineering. J. Math. Ind. 2022, 12, 1–12.

- Mahanty, B. Hybrid modeling in bioprocess dynamics: Structural variabilities, implementation strategies, and practical challenges. Biotechnol. Bioeng. 2023, 120, 2072–2091.

- Wang, J.; Li, Y.; Gao, R.X.; Zhang, F. Hybrid physics-based and data-driven models for smart manufacturing: Modelling, simulation, and explainability. J. Manuf. Syst. 2022, 63, 381–391.

- Kratchman, L.B.; Bruns, T.L.; Abbott, J.J.; Webster, R.J. Guiding elastic rods with a robot-manipulated magnet for medical applications. IEEE Trans. Robot. 2016, 33, 227–233.

- Fu, S.; Chen, B.; Li, D.; Han, J.; Xu, S.; Wang, S.; Huang, C.; Qiu, M.; Cheng, S.; Wu, X.; et al. A Magnetically Controlled Guidewire Robot System with Steering and Propulsion Capabilities for Vascular Interventional Surgery. Adv. Intell. Syst. 2023, 5, 2300267.

- Wang, L.; Kim, Y.; Guo, C.F.; Zhao, X. Hard-magnetic elastica. J. Mech. Phys. Solids 2020, 142, 104045.

- Sano, T.G.; Pezzulla, M.; Reis, P.M. A Kirchhoff-like theory for hard magnetic rods under geometrically nonlinear deformation in three dimensions. J. Mech. Phys. Solids 2022, 160, 104739.

- Huang, W.; Liu, M.; Hsia, K.J. A discrete model for the geometrically nonlinear mechanics of hard-magnetic slender structures. Extrem. Mech. Lett. 2023, 59, 101977.

- Li, X.; Yu, W.; Liu, J.; Zhu, X.; Wang, H.; Sun, X.; Liu, J.; Yuan, H. A mechanics model of hard-magnetic soft rod with deformable cross-section under three-dimensional large deformation. Int. J. Solids Struct. 2023, 279, 112344.

- Kim, Y.; Parada, G.A.; Liu, S.; Zhao, X. Ferromagnetic soft continuum robots. Sci. Robot. 2019, 4, eaax7329.

- Richter, M.; Kaya, M.; Sikorski, J.; Abelmann, L.; Venkiteswaran, V.K.; Misra, S. Magnetic Soft Helical Manipulators with Local Dipole Interactions for Flexibility and Forces. Soft Robot. 2023, 10, 647–659.

- Gavilán, H.; Avugadda, S.K.; Fernández-Cabada, T.; Soni, N.; Cassani, M.; Mai, B.T.; Chantrell, R.; Pellegrino, T. Magnetic nanoparticles and clusters for magnetic hyperthermia: Optimizing their heat performance and developing combinatorial therapies to tackle cancer. Chem. Soc. Rev. 2021, 50, 11614–11667.

- Gavilán, H.; Rizzo, G.M.; Silvestri, N.; Mai, B.T.; Pellegrino, T. Scale-up approach for the preparation of magnetic ferrite nanocubes and other shapes with benchmark performance for magnetic hyperthermia applications. Nat. Protoc. 2023, 18, 783–809.

- Lee, J.H.; Jang, J.t.; Choi, J.s.; Moon, S.H.; Noh, S.h.; Kim, J.w.; Kim, J.G.; Kim, I.S.; Park, K.I.; Cheon, J. Exchange-coupled magnetic nanoparticles for efficient heat induction. Nat. Nanotechnol. 2011, 6, 418–422.

- Kim, Y.; Genevriere, E.; Harker, P.; Choe, J.; Balicki, M.; Patel, A.B.; Zhao, X. Telerobotically Controlled Magnetic Soft Continuum Robots for Neurovascular Interventions. In Proceedings of the 2022 International Conference on Robotics and Automation (ICRA), Philadelphia, PA, USA, 23–27 May 2022; pp. 9600–9606.

- Liu, Y.; Mohanraj, T.G.; Rajebi, M.R.; Zhou, L.; Alambeigi, F. Multiphysical analytical modeling and design of a magnetically steerable robotic catheter for treatment of peripheral artery disease. IEEE/ASME Trans. Mechatronics 2022, 27, 1873–1881.

- Lu, K.; Zhou, C.; Li, Z.; Liu, Y.; Wang, F.; Xuan, L.; Wang, X. Multi-level magnetic microrobot delivery strategy within a hierarchical vascularized organ-on-a-chip. Lab Chip 2024, 24, 446–459.

- Pittiglio, G.; Lloyd, P.; da Veiga, T.; Onaizah, O.; Pompili, C.; Chandler, J.H.; Valdastri, P. Patient-specific magnetic catheters for atraumatic autonomous endoscopy. Soft Robot. 2022, 9, 1120–1133.

- Thomas, T.L.; Sikorski, J.; Ananthasuresh, G.; Venkiteswaran, V.K.; Misra, S. Design, sensing, and control of a magnetic compliant continuum manipulator. IEEE Trans. Med. Robot. Bionics 2022, 4, 910–921.

- Flemming, H.C.; Wingender, J. The biofilm matrix. Nat. Rev. Microbiol. 2010, 8, 623–633.

- Faustino, C.M.; Lemos, S.M.; Monge, N.; Ribeiro, I.A. A scope at antifouling strategies to prevent catheter-associated infections. Adv. Colloid Interface Sci. 2020, 284, 102230.

- Rajaramon, S.; Shanmugam, K.; Dandela, R.; Solomon, A.P. Emerging evidence-based innovative approaches to control catheter-associated urinary tract infection: A review. Front. Cell. Infect. Microbiol. 2023, 13, 1134433.

- Baburova, P.I.; Kladko, D.V.; Lokteva, A.; Pozhitkova, A.; Rumyantceva, V.; Rumyantceva, V.; Pankov, I.V.; Taskaev, S.; Vinogradov, V.V. Magnetic Soft Robot for Minimally Invasive Urethral Catheter Biofilm Eradication. ACS Nano 2023, 17, 20925–20938.

- Koo, H.; Allan, R.N.; Howlin, R.P.; Stoodley, P.; Hall-Stoodley, L. Targeting microbial biofilms: Current and prospective therapeutic strategies. Nat. Rev. Microbiol. 2017, 15, 740–755.

- Cava, R.; de Leon, N.; Xie, W. Introduction: Quantum Materials. Chem. Rev. 2021, 121, 2777–2779.

- Tokura, Y.; Kawasaki, M.; Nagaosa, N. Emergent functions of quantum materials. Nat. Phys. 2017, 13, 1056–1068.

- Shulga, K.; Il’ichev, E.; Fistul, M.V.; Besedin, I.; Butz, S.; Astafiev, O.; Hübner, U.; Ustinov, A.V. Magnetically induced transparency of a quantum metamaterial composed of twin flux qubits. Nat. Commun. 2018, 9, 150.

- Zunger, A. Bridging the gap between density functional theory and quantum materials. Nat. Comput. Sci. 2022, 2, 529–532.

- Thomas, L.H. The calculation of atomic fields. Mathematical Proceedings of the Cambridge Philosophical Society; Cambridge University Press: Cambridge, UK, 1927; Volume 23, pp. 542–548.

- Hartree, D.R. The wave mechanics of an atom with a non-Coulomb central field. Part I. Theory and methods. In Proceedings of the Mathematical Proceedings of the Cambridge Philosophical Society; Cambridge University Press: Cambridge, UK, 1928; Volume 24, pp. 89–110.

- Jones, M.A.; Vallury, H.J.; Hill, C.D.; Hollenberg, L.C. Chemistry beyond the Hartree–Fock energy via quantum computed moments. Sci. Rep. 2022, 12, 8985.

- Sauceda, H.E.; Gálvez-González, L.E.; Chmiela, S.; Paz-Borbón, L.O.; Müller, K.R.; Tkatchenko, A. BIGDML—Towards accurate quantum machine learning force fields for materials. Nat. Commun. 2022, 13, 3733.

- Bocus, M.; Goeminne, R.; Lamaire, A.; Cools-Ceuppens, M.; Verstraelen, T.; Van Speybroeck, V. Nuclear quantum effects on zeolite proton hopping kinetics explored with machine learning potentials and path integral molecular dynamics. Nat. Commun. 2023, 14, 1008.

- Wang, X.; Mao, G.; Ge, J.; Drack, M.; Cañón Bermúdez, G.S.; Wirthl, D.; Illing, R.; Kosub, T.; Bischoff, L.; Wang, C.; et al. Untethered and ultrafast soft-bodied robots. Commun. Mater. 2020, 1, 67.

- Ni, Y.; Sun, Y.; Zhang, H.; Li, X.; Zhang, S.; Li, M. Data-Driven Navigation of Ferromagnetic Soft Continuum Robots Based on Machine Learning. Adv. Intell. Syst. 2023, 5, 2200167.

- Liu, Z.; Wang, S.; Feng, F.; Xie, L. A magnetorheological fluid based force feedback master robot for vascular interventional surgery. J. Intell. Robot. Syst. 2022, 106, 20.

- Yao, J.; Cao, Q.; Ju, Y.; Sun, Y.; Liu, R.; Han, X.; Li, L. Adaptive actuation of magnetic soft robots using deep reinforcement learning. Adv. Intell. Syst. 2023, 5, 2200339.