Unconventional feed, which is abundant in China, contains anti-nutritional factors and toxins; however, these can be greatly reduced with microbial fermentation, thus improving the nutrient content of the feed, enhancing animal appetites, and ultimately significantly improving the intestinal health and growth performance of animals. When oxidative stress occurs, fermented feed can effectively reduce the damage caused by stress to the gastrointestinal tract, accelerate the removal of gastrointestinal abnormalities, improve the ability to resist intestinal stress, and ensure the efficient production of animals.

- unconventional feed

- fermented probiotics

- feed quality

1. Introduction

2. Types and Applications of Unconventional Feed

| Unconventional Fermented Feed Feeding | |||||

|---|---|---|---|---|---|

| Animal | Raw Materials | Probiotics | Regulated Items | Antioxidant Substance |

References |

| Boer goats | Pennisetum giganteum | Bacillus coagulans preparation | Abundance of Lactobacillus and unidentified Clostridiales ↑ Anaerovibrio and Methanobrevibacter ↓ |

CAT, GSH-Px activities and glutathione ↑ | Qiu et al. [26] |

| Laying hens | Corn–soybean meal wheat bran |

Bacillus subtilis and Saccharomyces cerevisiae | In relative Lactobacillus, Megasphaera, and Peptococcus abundance ↑ Campylobacter abundance ↓ |

Immunoglobulin A, immunoglobulin M, and immunoglobulin G ↑ | Guo et al. [27] |

| Broilers | Corn, soybean meal, corn–gluten meal, and corn dried distillers’ grains | Lactobacillus plantarum, Bacillus subtilis, and Saccharomyces cerevisiae | Abundance of Ruminococcaceae, Lactobacillaceae, and unclassified Clostridiales ↑ Abundance of Rikenellaceae, Lachnospiraceae, and Bacteroidaceae ↓ |

Acetic acid, propionic acid, butyric acid, and lactic acid ↑ | Zhu et al. [28] |

| Laying hens | Astragalus | Lactobacillus plantarum | CAT, GSH-Px, superoxide dismutase and total antioxidant capacity in serum ↑ | CAT ↑ | Hong et al. [29] |

| Cobb male broilers | Corn–soybean meal | Lactobacillus acidophilus | Body weight, ADG, average daily feed intake, and jejunum and ileum V:C ratio at 14 d and 21 d ↑ | The mRNA expression of inducible nitric oxide synthase, interleukin-8, and interleukin-1β in the jejunum ↓ | Wu et al. [30] |

| Nursery pig | Corn–soybean meal | Lactobacillus plantarum and Pediococcus acidilactici | ADG and significantly increased fecal acetate, butyrate, and total short-chain fatty acid concentrations ↑ | Short-chain fatty acid ↑ | Yang et al. [31] |

| Berkshire pigs | Rubus coreanus | Lactobacillus plantarum | The mRNA expression of transcription factors and cytokines in Th1 and Treg cells ↑ The mRNA expression of T helper cell 2 and Th17 transcription factors and cytokines ↓ |

The mRNA expression of transcription factors and cytokines in Th1 and Treg cells ↑ | Yu et al. [32] |

| Cyprinus carpio | Wheat, soybean meal, corn–gluten meal, chicken meal | C. somerae XMX-1, S. cerevisiae GCC−1, L. rhamnosus GCC-3, and B. subtilis HGcc-1 | Health and production ↑ | Liver anti-inflammatory factors transforming growth Factor-β↑ | Zhang et al. [33] |

| Juvenile olive flounder | Garlic husks, Tuna | Bacillus licheniformis and Bacillus subtilis | Weight gain, specific growth rate, and feed efficiency ↑ | Sucrose reductase↑ | Fatma et al. [34] |

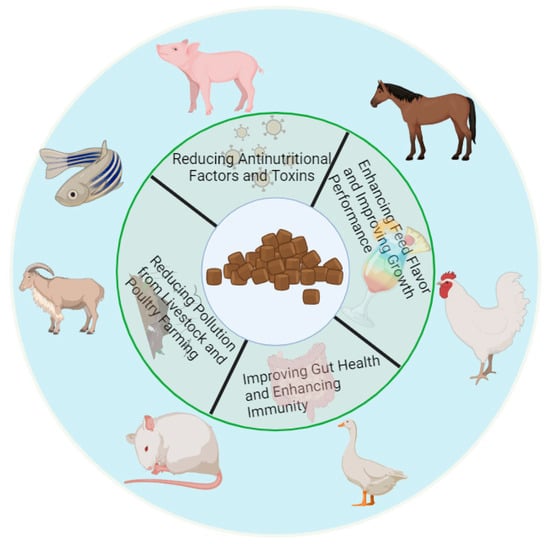

3. The Effects and Mechanism of Fermentation on the Improvement of Unconventional Feed Quality

3.1. Reductions in Anti-Nutritional Factors and Toxins

3.2. Increases Feed Flavor and Improves Growth Performance

3.3. Improves Intestinal Health and Strengthens Immunity

3.4. Reduces Pollution from Livestock and Poultry Farming

This entry is adapted from the peer-reviewed paper 10.3390/antiox13030305