In today’s fast-paced world, people increasingly rely on a variety of processed foods due to their busy lifestyles. The enhanced flavors, vibrant colors, and ease of accessibility at reasonable prices have made ready-to-eat foods the easiest and simplest choice to satiate hunger, especially those that undergo thermal processing. However, these foods often contain an unsaturated amide called ‘Acrylamide’, known by its chemical name 2-propenamide, which is a contaminant formed when a carbohydrate- or protein-rich food product is thermally processed at more than 120 °C through methods like frying, baking, or roasting.

- dietary acrylamide

- Maillard’s reaction

- acrylamide toxicity

- starch

1. Introduction

2. Detection of Acrylamide in Food

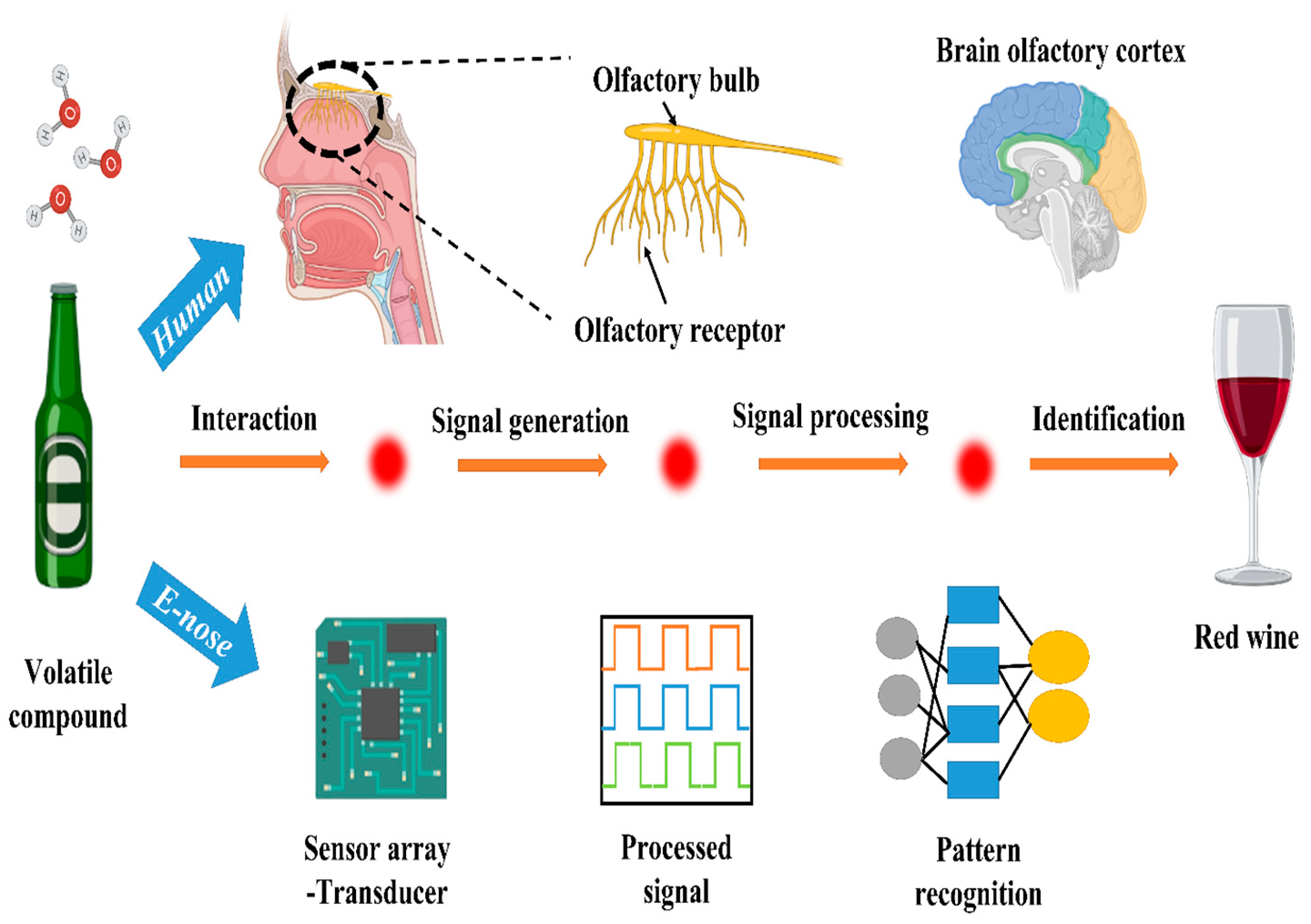

2.1. Electronic Tongue and Nose

2.2. Liquid Chromatography–Tandem Mass Spectrometry (LC–MS/MS)

2.3. Gas Chromatography–Mass Spectrometry (GC–MS)

2.4. Hemoglobin Nanoparticles (HbNPs)

2.5. Fluorescence Biosensor

2.6. Surface-Enhanced Raman Spectroscopy (SERS)

| Detection Method | Limit of Detection (LOD) | Range of Detection | Sample Model | References |

|---|---|---|---|---|

| E-tongue and nose | 2.5 × 10−3 μg kg−1 | 2.5 × 10−3–20×10−3 μg kg−1 | Olive and brine solution | [6] |

| Fluorescence biosensor | 0.5 × 10−6 nmol L−1 | 0.05 M–10−7 nmol L−1 | Potato fries | [18] |

| 2.41 × 10−2 nmol L−1 | 1 × 10−1–5 × 103 nmol L−1 | Bread crust | [19] | |

| HbNPs | 0.1 nmol L−1 | 0.05–100 nmol L−1 | Bread, nuts, potato crips, biscuits | [15] |

| 0.06 nmol L−1 | 10–171 nmol L−1 | French fries | [16] | |

| SERS | 2 µg kg−1 | 5–100 µg kg−1 | Fried food | [20] |

| 0.02 nmol L−1 | 0.1–5 × 104 nmol L−1 | Cookies, chips, and bread | [21] | |

| LC-MS/MS | 3 ng mL−1 | 16.8–72.8 ng mL−1 | Coffee | [8] |

| 6 µg kg−1 | 197–639 µg kg−1 | Breakfast cereals | [9] | |

| 2 μg kg−1 | 95.8–9826 μg kg−1 | Medicine homologous foods (Atractylodis Macrocephalae Rhizoma) | [11] | |

| GC-MS | 0.6 µg kg−1 | 1–500 µg kg−1 | Bread, biscuits, wafers, cakes, cookies, and crackers | [13] |

| 0.6 µg kg−1 | 33.36–250.90 µg kg−1 | Roasted nuts and seeds | [14] |

3. Mitigation Strategies of Dietary Acrylamide

3.1. Air and Vacuum-Frying

3.2. Blanching

3.3. Addition of Additives

3.4. pH and Water Content

3.5. Fermentation

3.6. Hydrocolloid-Based Coating

3.7. Inhibitory and Inert Baking Atmosphere

| Mitigation Strategies |

Reduction Percentage (%) | Sample Model | Reference |

|---|---|---|---|

| Air- and vacuum-frying | 72–98% | Potato chips | [24] |

| Blanching | 65% and 96% | French fries and potato crisps | [27] |

| Additives | 30–60% | Amino acid/sugar chemical model | [32] |

| Fermentation | 70% | Roasted coffee | [38] |

| Hydrocolloid coating | 48% | French fries | [40] |

| Inhibitory and inert baking atmosphere | 50–99% | Bread | [43] |

This entry is adapted from the peer-reviewed paper 10.3390/foods13040556

References

- Rifai, L.; Saleh, F.A. A Review on Acrylamide in Food: Occurrence, Toxicity, and Mitigation Strategies. Int. J. Toxicol. 2020, 39, 93–102.

- Semla, M.; Goc, Z.; Martiniaková, M.; Omelka, R.; Formicki, G. Acrylamide: A Common Food Toxin Related to Physiological Functions and Health. Physiol. Res. 2017, 66, 205–217.

- Ferrer-Aguirre, A.; Romero-González, R.; Vidal, J.L.M.; Frenich, A.G. Simple and Fast Determination of Acrylamide and Metabolites in Potato Chips and Grilled Asparagus by Liquid Chromatography Coupled to Mass Spectrometry. Food Anal. Methods 2016, 9, 1237–1245.

- Timmermann, C.; Mølck, S.; Kadawathagedara, M.; Bjerregaard, A.; Törnqvist, M.; Brantsæter, A.; Pedersen, M. A Review of Dietary Intake of Acrylamide in Humans. Toxics 2021, 9, 155.

- Das, J.; Mishra, H.N. Recent Advances in Sensors for Detecting Food Pathogens, Contaminants, and Toxins: A Review. Eur. Food Res. Technol. 2022, 248, 1125–1148.

- Martín-Vertedor, D.; Rodrigues, N.; Marx, Í.M.G.; Dias, L.G.; Veloso, A.C.A.; Pereira, J.A.; Peres, A.M. Assessing Acrylamide Content in Sterilized Californian-Style Black Table Olives Using HPLC-MS-QQQ and a Potentiometric Electronic Tongue. LWT 2020, 129, 109605.

- Ghalebi, M.; Hamidi, S.; Nemati, M. High-Performance Liquid Chromatography Determination of Acrylamide after Its Extraction from Potato Chips. Pharm. Sci. 2019, 25, 338–344.

- Başaran, B.; Aydın, F.; Kaban, G. The Determination of Acrylamide Content in Brewed Coffee Samples Marketed in Turkey. Food Addit. Contam. Part A 2020, 37, 280–287.

- Mesías, M.; Sáez-Escudero, L.; Morales, F.J.; Delgado-Andrade, C. Reassessment of Acrylamide Content in Breakfast Cereals. Evolution of the Spanish Market from 2006 to 2018. Food Control 2019, 105, 94–101.

- Hai, Y.D.; Tran-Lam, T.-T.; Nguyen, T.Q.; Vu, N.D.; Ma, K.H.; Le, G.T. Acrylamide in Daily Food in the Metropolitan Area of Hanoi, Vietnam. Food Addit. Contam. Part B 2019, 12, 159–166.

- Zhu, B.; Xu, X.; Ye, X.; Zhou, F.; Qian, C.; Chen, J.; Zhang, T.; Ding, Z. Determination and Risk Assessment of Acrylamide in Thermally Processed Atractylodis Macrocephalae Rhizoma. Food Chem. 2021, 352, 129438.

- Schouten, M.A.; Tappi, S.; Angeloni, S.; Cortese, M.; Caprioli, G.; Vittori, S.; Romani, S. Acrylamide Formation and Antioxidant Activity in Coffee during Roasting—A Systematic Study. Food Chem. 2021, 343, 128514.

- Nematollahi, A.; Kamankesh, M.; Hosseini, H.; Ghasemi, J.; Hosseini-Esfahani, F.; Mohammadi, A. Investigation and Determination of Acrylamide in the Main Group of Cereal Products Using Advanced Microextraction Method Coupled with Gas Chromatography-Mass Spectrometry. J. Cereal Sci. 2019, 87, 157–164.

- Nematollahi, A.; Kamankesh, M.; Hosseini, H.; Hadian, Z.; Ghasemi, J.; Mohammadi, A. Investigation and Determination of Acrylamide in 24 Types of Roasted Nuts and Seeds Using Microextraction Method Coupled with Gas Chromatography–Mass Spectrometry: Central Composite Design. J. Food Meas. Charact. 2020, 14, 1249–1260.

- Yadav, N.; Chhillar, A.K.; Pundir, C.S. Preparation, Characterization and Application of Haemoglobin Nanoparticles for Detection of Acrylamide in Processed Foods. Int. J. Biol. Macromol. 2018, 107, 1000–1013.

- Navarro, K.M.; Silva, J.C.; Ossick, M.V.; Nogueira, A.B.; Etchegaray, A.; Mendes, R.K. Low-Cost Electrochemical Determination of Acrylamide in Processed Food Using a Hemoglobin-Iron Magnetic Nanoparticle-Chitosan Modified Carbon Paste Electrode. Anal. Lett. 2021, 54, 1180–1192.

- Li, N.; Liu, X.; Zhu, J.; Zhou, B.; Jing, J.; Wang, A.; Xu, R.; Wen, Z.; Shi, X.; Guo, S. Simple and Sensitive Detection of Acrylamide Based on Hemoglobin Immobilization in Carbon Ionic Liquid Paste Electrode. Food Control 2020, 109, 106764.

- Asnaashari, M.; Esmaeilzadeh Kenari, R.; Farahmandfar, R.; Taghdisi, S.M.; Abnous, K. Fluorescence Quenching Biosensor for Acrylamide Detection in Food Products Based on Double-Stranded DNA and Gold Nanoparticles. Sens. Actuators B Chem. 2018, 265, 339–345.

- Wei, Q.; Zhang, P.; Liu, T.; Pu, H.; Sun, D.-W. A Fluorescence Biosensor Based on Single-Stranded DNA and Carbon Quantum Dots for Acrylamide Detection. Food Chem. 2021, 356, 129668.

- Cheng, J.; Zhang, S.; Wang, S.; Wang, P.; Su, X.-O.; Xie, J. Rapid and Sensitive Detection of Acrylamide in Fried Food Using Dispersive Solid-Phase Extraction Combined with Surface-Enhanced Raman Spectroscopy. Food Chem. 2019, 276, 157–163.

- Wu, L.; Zhang, W.; Liu, C.; Foda, M.F.; Zhu, Y. Strawberry-like SiO2/Ag Nanocomposites Immersed Filter Paper as SERS Substrate for Acrylamide Detection. Food Chem. 2020, 328, 127106.

- Zhang, X.; Zhang, M.; Adhikari, B. Recent Developments in Frying Technologies Applied to Fresh Foods. Trends Food Sci. Technol. 2020, 98, 68–81.

- Belkova, B.; Hradecky, J.; Hurkova, K.; Forstova, V.; Vaclavik, L.; Hajslova, J. Impact of Vacuum Frying on Quality of Potato Crisps and Frying Oil. Food Chem. 2018, 241, 51–59.

- Akkurt, K.; Mogol, B.A.; Gökmen, V. Mitigation of Acrylamide in Baked Potato Chips by Vacuum Baking and Combined Conventional and Vacuum Baking Processes. LWT 2021, 144, 111211.

- Maan, A.A.; Anjum, M.A.; Khan, M.K.I.; Nazir, A.; Saeed, F.; Afzaal, M.; Aadil, R.M. Acrylamide Formation and Different Mitigation Strategies during Food Processing—A Review. Food Rev. Int. 2022, 38, 70–87.

- Sansano, M.; Heredia, A.; Peinado, I.; Andrés, A. Dietary Acrylamide: What Happens during Digestion. Food Chem. 2017, 237, 58–64.

- Ofosu, I.W.; Ankar-Brewoo, G.M.; Lutterodt, H.E.; Benefo, E.O.; Menyah, C.A. Estimated Daily Intake and Risk of Prevailing Acrylamide Content of Alkalized Roasted Cocoa Beans. Sci. Afr. 2019, 6, e00176.

- Hu, H.; Liu, X.; Jiang, L.; Zhang, Q.; Zhang, H. The Relationship between Acrylamide and Various Components during Coffee Roasting and Effect of Amino Acids on Acrylamide Formation. J. Food Process. Preserv. 2021, 45, e15421.

- Sharif, R.; Shahar, S.; Rajab, N.F.; Fenech, M. Dietary Pattern, Genomic Stability and Relative Cancer Risk in Asian Food Landscape. Nutr. Cancer 2022, 74, 1171–1187.

- Jia, R.; Wan, X.; Geng, X.; Xue, D.; Xie, Z.; Chen, C. Microbial L-Asparaginase for Application in Acrylamide Mitigation from Food: Current Research Status and Future Perspectives. Microorganisms 2021, 9, 1659.

- Liyanage, D.W.K.; Yevtushenko, D.P.; Konschuh, M.; Bizimungu, B.; Lu, Z.-X. Processing Strategies to Decrease Acrylamide Formation, Reducing Sugars and Free Asparagine Content in Potato Chips from Three Commercial Cultivars. Food Control 2021, 119, 107452.

- Wang, X.; Xu, L. Influence Factors on the Formation of Acrylamide in the Amino Acid/Sugar Chemical Model System. J. Food Nutr. Res. 2014, 2, 344–348.

- Aarabi, F.; Seyedain Ardebili, M. The Effect of Sugar Type and Baking Condition on Formation of Acrylamide in Industrial Rotary Moulded Biscuit. J. Food Meas. Charact. 2020, 14, 2230–2239.

- Shakeri, F.; Shakeri, S.; Ghasemi, S.; Troise, A.D.; Fiore, A. Effects of Formulation and Baking Process on Acrylamide Formation in Kolompeh, a Traditional Cookie in Iran. J. Chem. 2019, 2019, 1425098.

- Wang, Y.; Hu, H.; McClements, D.J.; Nie, S.; Shen, M.; Li, C.; Huang, Y.; Zhong, Y.; Chen, J.; Zeng, M.; et al. PH and Lipid Unsaturation Impact the Formation of Acrylamide and 5-Hydroxymethylfurfural in Model System at Frying Temperature. Food Res. Int. 2019, 123, 403–413.

- Albedwawi, A.; Al Sakkaf, R.; Yusuf, A.; Osaili, T.; Al-Nabulsi, A.; Liu, S.-Q.; Palmisano, G.; Ayyash, M. Acrylamide Elimination by Lactic Acid Bacteria: Screening, Optimization, In Vitro Digestion, and Mechanism. Microorganisms 2022, 10, 557.

- Nachi, I.; Fhoula, I.; Smida, I.; Ben Taher, I.; Chouaibi, M.; Jaunbergs, J.; Bartkevics, V.; Hassouna, M. Assessment of Lactic Acid Bacteria Application for the Reduction of Acrylamide Formation in Bread. LWT 2018, 92, 435–441.

- Akıllıoglu, H.G.; Gökmen, V. Mitigation of Acrylamide and Hydroxymethyl Furfural in Instant Coffee by Yeast Fermentation. Food Res. Int. 2014, 61, 252–256.

- Zhang, N.; Zhou, Q.; Fan, D.; Xiao, J.; Zhao, Y.; Cheng, K.-W.; Wang, M. Novel Roles of Hydrocolloids in Foods: Inhibition of Toxic Maillard Reaction Products Formation and Attenuation of Their Harmful Effects. Trends Food Sci. Technol. 2021, 111, 706–715.

- Aiswarya, R.; Baskar, G. Enzymatic Mitigation of Acrylamide in Fried Potato Chips Using Asparaginase from Aspergillus Terreus. Int. J. Food Sci. Technol. 2018, 53, 491–498.

- Zokaei, M.; Kamankesh, M.; Abedi, A.-S.; Moosavi, M.H.; Mohammadi, A.; Rezvani, M.; Shojaee-Aliabadi, S.; Khaneghah, A.M. Reduction in Acrylamide Formation in Potato Crisps: Application of Extract and Hydrocolloid-Based Coatings. J. Food Prot. 2020, 83, 754–761.

- Jiang, Y.; Qin, R.; Jia, C.; Rong, J.; Hu, Y.; Liu, R. Hydrocolloid Effects on Nε-Carboxymethyllysine and Acrylamide of Deep-Fried Fish Nuggets. Food Biosci. 2021, 39, 100797.

- Gülcan, Ü.; Candal Uslu, C.; Mutlu, C.; Arslan-Tontul, S.; Erbaş, M. Impact of Inert and Inhibitor Baking Atmosphere on HMF and Acrylamide Formation in Bread. Food Chem. 2020, 332, 127434.