1. Microalgal Cultivation Systems

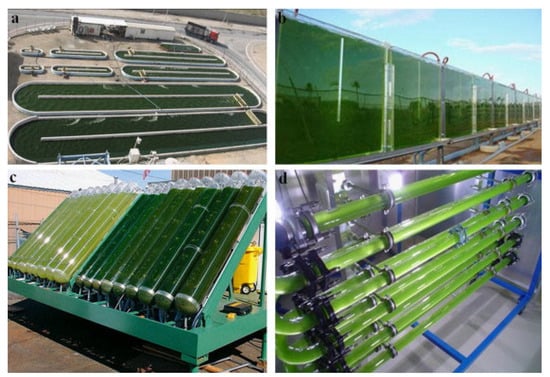

Conventional cultivation systems may be classified according to their design into three broad categories: open, closed, and hybrid, which combine the best features of open and closed photobioreactor cultivation systems. Open ponds, raceways or inclined thin-layer systems are the most used open cultivation systems. In closed photobioreactors, the culture medium is isolated from the surrounding environment by transparent surfaces, which, compared to open systems, allows for easier control of operating conditions and elimination of contamination of the processed culture medium. The most used closed systems are tubular and flat panel photobioreactors. An illustration of conventional open and closed culture system designs is shown in Figure 5.

Cultivation of microalgae involves several factors that influence the growth and production of such microorganisms. Light (solar, artificial), carbon dioxide, nutrients (especially nitrogen, phosphorus, potassium, and magnesium), and the appropriate temperature of the culture medium are critical parameters for the proper growth of photosynthetic microalgae. Different microalgae species have other requirements for the intensity and spectrum of light radiation [

30]. The growth rate of microalgae in photobioreactors can be significantly influenced by the concentration of carbon dioxide and nutrients in the culture batch. Common microalgae species can withstand a relatively wide range of culture medium temperatures. For the most widely used conventional microalgae, such as

Chlorella, a range of culture temperatures from 15 to 40 °C is most reported as optimal for proper growth. Some microalgae species (

Phaeodactylum) can only grow in a narrow temperature range of 20 to 25 °C [

31]. The optimum temperature for cultivating most freshwater microalgae species significantly limits the operating time of cultivation systems. Lower or higher temperatures may cause growth inhibition and subsequent degradation of the cultured microalgae culture due to rotting [

32]. Considering the average daily temperatures in Central or Eastern European countries (Czechia, Poland, Slovakia, and Hungary), which exceed 15 °C only in the summer months from approximately June to August [

33], microalgae cultivation in outdoor environments is significantly limited. At temperatures below 15 °C, the cultivation process works inefficiently, and the overall yields of microalgae are meager [

34]. Cultivation is often limited to the short summer period when temperatures and solar radiation intensities are sufficient for efficient microalgae growth. Failure to do so may result in the need for heat exchanging to maintain the desired temperature of the media. In some cases, artificial lighting may be used [

35]. The requirement to heat the culture medium or provide artificial lighting during escalating energy costs leads to substantial operational expenses, ultimately preventing the further commercialization of cultivation systems [

34].

Figure 5. Conventional microalgal cultivation systems. Source: grouped figure adapted from Bitog et al. [

36]: (

a) raceway system, (

b) flat panel, (

c) column, and (

d) horizontal tubular.

Current research indicates the existence of microalgae adapted to low operating temperatures [

37]. These microorganisms are primarily found in cold regions, such as the Arctic and Northern European countries, and can grow even in extremely low temperatures. These microorganisms’ adaptation includes higher concentrations of microalgal lipids’ polyunsaturated fatty acid profile [

38]. These polar microalgae can generate valuable substances, including antioxidants, carotenoids, and phenolic compounds [

39], which can be used not only as food supplements or feed but also for wastewater treatment in a similar way to conventional freshwater microalgae [

34]. Polar microalgae are promising for use in regions with milder climates, including Central and Eastern Europe. According to laboratory studies, polar microalgae perform productively as conventional freshwater microalgae under extreme climatic conditions when temperatures exceed 20 °C [

32]. During winter, polar microalgae strains could replace conventional microalgae species to extend the cultivation campaign. This replacement has the potential to improve the economic balance of farming systems. Cicci et al. [

40] stated that light intensity plays a significant role in microalgae growth. During winter, areas in central or Eastern Europe have relatively low intensity of photosynthetically active radiation (PAR, 400–700 nm), significantly reducing the cultivation time during the year. Microalgae that can grow in low light intensities are highly sensitive to the effects of high light intensities. This is particularly noticeable at midday when sunlight intensity is at its highest. To cultivate polar microalgae efficiently, it is crucial to design systems that effectively utilize incident light and prevent direct sunlight at high intensities that could damage the produced microalgal biomass.

Figure 6 demonstrates one of the first model rotary reactors for cultivating polar microalgae tested under extreme climatic conditions in the Arctic regions [

41].

Figure 6. A rotary photobioreactor for the cultivation of polar microalgae was installed in Longyearbyen, Svalbard. Source: own photo documentation.

The successful transfer of technical solutions and experimental results from laboratories and semi-operational facilities to operational commercial scale remains limited, mainly due to the high investment and operating costs, which are strongly influenced by the local conditions of the installation site. Most cultivation technologies are only commercially available in locations with more hours of sunlight and more favorable temperatures throughout the year (e.g., Southern or parts of Western Europe). Consequently, applying these technologies in Central and Eastern Europe is often more complex or infeasible. Unfortunately, these regions are frequently undeservedly criticized or even condemned. One possible approach to achieving efficient and economically viable microalgae production cultivation systems is to use polar microalgae strains adapted to the Arctic regions’ extreme climatic conditions. No rotary or stationary cultivation system exists that can withstand extreme operating conditions and allow scale-up of cultivation technologies to industrial scale.

2. Sustainable Renewable Energy and Green Products from Microalgae

Third-generation (3G) biorefineries use microbial cell factories to convert CO

2 into algal biomass that can produce carbon-neutral food, feed, pharmaceuticals, chemicals, and biofuels. The economic viability of 3G biofuel production is questionable due to the low biomass productivity and the biofuel’s low efficiency. As scientists and industry tend to focus on producing high-value products such as pharmaceuticals and cosmetics and their economically viable applications, the production of 3G biofuels is often overlooked. The high-value-added products may improve the economics of 3G biorefineries [

42]. One of the leading examples of value-added bioproducts is astaxanthin (the most powerful natural antioxidants, possessing hepato- and cardio-protective properties [

43]) obtained from the cultivation of the microalgae

Hematococcus pluvialis in tubular photo-bioreactors using LED lamps from AlgalifTM, Iceland [

44]. Another high-value-added bioproduct of microalgae is phycocyanin (C-PC). Phycocyanin has therapeutic properties. These include antioxidant, anti-inflammatory, and anti-cancer properties [

45]. The commercial value of phycocyanin can range from 25 EUR/mg for partially purified phycocyanin to 200 EUR/mg for phycocyanin, with a purity of 3.5 [

46].

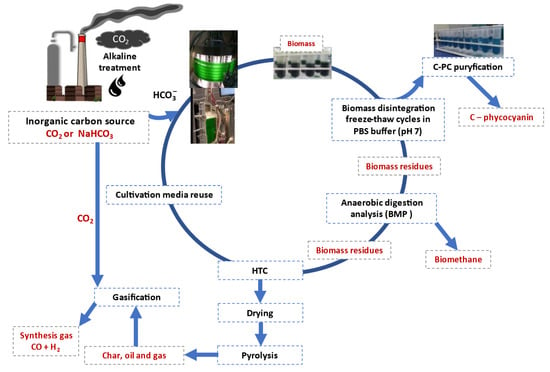

The scientific group of Prof. Ledakowicz [

47,

48] performed the research to optimize the biosynthesis process of thermostable C-PC from thermophilic cyanobacteria and to develop a series of efficient operations of down-stream processing (DSP) will allow the selection of an effective method for obtaining thermostable C-PC, combined with further biomass debris treatment by anaerobic digestion pyrolysis and gasification as presented in

Figure 7, proposing a circular approach according to the principles of sustainable development. The thermophilic strain

Synechococcus sp. PCC6715 was grown at 45 °C in an unsterile BG11 medium in two photobioreactors [

47,

48]. Centrifugation was used for the microalgal biomass harvesting. The thawed, thickened biomass was suspended in a PBS buffer. It was disrupted by 6 cycles of alternating freeze–thaw. The PBS buffer was extracted four times. The techniques used to purify thermostable C-PC from

Synechococcus sp. PCC6715 included foam fractionation (F.F.): recovery 49%, purification factor PF = 1.472; two-phase aqueous extraction (ATPE) PEG 6000–phosphate salt: recovery 97%, PF = 1.466; ultrafiltration (Hydrosart 10 kDa membrane): recovery 92%, PF = 1.472; and fast protein liquid chromatography (FPLC) gave PF = 3.4 pharmaceutical quality [

49]. Biomass debris was washed out with distilled water and frozen for further processing.

Figure 7. The idea of technology to produce thermostable C-PC—circular approach. Source: adapted from [

49,

50,

51].

2.1. Anaerobic Fermentation of Microalgal Residues

Wet waste biomass can be used as a substrate for an anaerobic process in which it is converted to biogas. Anaerobic digestion is a well-established technology for producing biogas that has been extensively researched and applied for over 60 years. Physical, chemical, and biological substrate pretreatment can increase biogas production yield [

52]. The cell wall of algae contains poorly degradable compounds such as cellulose. The extraction of compounds from algae destroys the cell wall, increasing biogas production yield. Various microorganisms undergo anaerobic digestion, so providing an active inoculum is essential. Biogas production yield from algae is in a wide range (from 20 to 600 mL/gVS) [

53]. The process has a low speed due to the limited hydrolysis step and the use of anaerobic microorganisms [

54]. Fermentation of algae can generate some problems related to low algal concentration, low C/N ratio or short storage time. Because algae can contain levels of protein from 8 to 70%, in the fermentation process, ammonia can be produced, which inhibits the anaerobic digestion process [

55]. Free ammonia is a toxic chemical for microalgae and nitrifying bacteria; the ammonia in the reactor must also controlled according to the free ammonia/inlet biomass ratio. The uninfluenced ammonia/biomass ratio (mg-NH3/mg-TSS or VSS) should be kept below 0.06 for high removal [

56]. Carbon-rich biomass is added to the feedstock as a substrate for the anaerobic digestion process. Co-digestion of two or more substrates has a beneficial effect on increasing biogas production yield by up to 200% and improving the stability of the anaerobic digestion process [

57]. Ferreira et al. [

58] achieved the highest methane yield using a mixture of 75% food waste and 25% microalgae. This resulted in a methane yield of 514 mL/gVS and a synergy between the substrates that was 28% higher than the theoretical value. Anaerobic digestion of algae is mainly carried out under mesophilic conditions, i.e., at 35–40 °C. Approximately 50% of the organic matter is degraded in this process [

59]. The remainder of the organic matter consists of compounds not degraded in anaerobic digestion, such as lignin. Anaerobic digestion of microalgae is carried out in the same design of microbial bioreactors as those used for anaerobic digestion of other biomass resources [

57]. The effective geometrical set-up of the digester and impeller should be a prime focus during the scaleup of the lab-scale digesters, and mixing in real-scale digesters should be optimized.

Biogas production has increased twofold in Europe between 2010 and 2020, so new biomass sources such as algae will be increasingly used [

52]. The anaerobic digestion process generates biogas, mainly made up of CO

2 and CH

4. This biogas can be utilized to generate electricity and heat through cogeneration systems. Upgrading biogas to biomethane is one of the most active topics in the scientific literature. It is of great interest to the bioenergy industry due to renewable energy targets. The biomethane can be used as advanced biofuel or injected directly into the gas grid. At present, the most used technologies for this purpose are water washing, chemical or physical absorption, andsorption dominantly in pressure swing configuration [

60] or innovative membrane permeation [

61]. A commercial hollow polyimide membrane is often applied for CO

2 removal from biogas for further effective reuse [

62]. Carbon dioxide is removed from the gas using a separation technique such as a membrane to increase the calorific value of biogas. CO

2 can be removed from biogas by cultivation of microalgae (methane is not toxic to microalgae) [

48] or conversion of H

2 and CO

2 by lithoautotroph microorganisms into CH

4 [

63]. The performance evaluation by Ighalo et al. [

64] has shown that microalgae can capture and sequester CO

2 with an efficiency of 40% to 93.7%.

Research is required to identify alternatives to artificial nutrients to reduce the environmental impact and cost of nutrient supply. One promising strategy to increase sustainability and obtain valuable products is the cultivation of microalgae, especially digestate, in anaerobic wastewater [

65]. Microalgae can also be grown on nutrient-rich digestate from anaerobic digestion, thereby providing simultaneous biogas upgrading and digestate bioremediation [

66]. High nutrient levels, turbid digestate, biological contaminants, ammonia, and metal toxicity can also inhibit microalgal growth. Keeping nutrient levels adequate and reducing the occurrence of contaminants is a critical issue [

67]. Another product of anaerobic digestion is digested sludge, which can be recycled as fertilizer.

2.2. Hydrothermal Carbonization of Microalgal Residues

Unfortunately, digested sludge cannot always be used as fertilizer. One method of processing digested sludge is hydrothermal carbonization (HTC), which produces hydrochar and liquid phases. One significant advantage of this hydrothermal process is that substrate containing water (more than 60%) can be utilized. It is carried out in the 180 to 250 °C temperature range under autogenous pressure (in subcritical water). The char production yield is a broad range between 20 and 70%. The hydrochar produced has hydrophobic properties, making it easy to de-water. It can potentially be used as fertilizer, an adsorbent or fuel. The char created by the HTC technology has a much lower specific surface area than that obtained by the pyrolysis process. It has a much higher adsorption capacity due to its capacity for ion exchange and complexation [

68]. Both the H:C and O:C transmission ratios in hydrochar are lowered when the processing temperature is raised [

69]. The liquid from the HTC process contains easily degradable substances that can be recycled as a medium for algae cultivation or as a substrate for anaerobic digestion. It has been observed that liquid can be produced after HTC for biochemical processes when the process temperature is around 180 °C [

70]. On the contrary, liquid after the HTC process at 250 °C contains toxic substances, including cyclic oxygen-containing compounds. After the HTC process, the liquid phase can contain up to 80% of the nitrogen in the substrate before the process [

71]. The acids produced by the HTC process have autocatalytic properties that increase the reaction rate and improve char properties (e.g., pore structure) [

72]. The HTC process also produces CO

2 with a yield of less than 5%.

2.3. Pyrolysis of Microalgal Residues

Drying is required for the further treatment of biomass residues. This process uses a lot of energy to evaporate the water. The hydrochar from the HTC is quickly separated in the sedimentation process, reducing the drying costs. After drying, the waste biomass can be pyrolyzed. Pyrolyzing algae is highly complex because algae contain lipids, proteins, and carbohydrates. The process is carried out under anaerobic conditions at temperatures between 300 and 800 °C, forming char, oil, and gas. Thermogravimetric analysis indicates that the most vigorous degradation of macro and microalgae occurs at 250–400 °C [

73]. Raising the pyrolysis temperature increases the effectiveness of gas production and lowers the efficiency of char production. The pyrolysis process can take place in an N

2, Ar or CO

2 atmosphere. Using CO

2 instead of N

2 leads to lower output of char and oil, but increases the yields of gas production (especially CO) and acetic acid in the liquid phase. [

74,

75]. In addition, CO

2 in the atmosphere during pyrolysis leads to the breakdown of volatile fatty acids, increased protein degradation, and reduced fat degradation [

76]. Subject to temperature and heat-up rate, the pyrolysis procedure can be grouped into three different classes: slow, medium, and fast [

77]. Fast pyrolysis (heating rate > 100 K/min) produces mainly oil, whereas slow pyrolysis (heating rate < 1 K/min) produces mainly char [

78]. The use of microwaves as a heat source in the algae pyrolysis process significantly increases the yield of gas production, calorific value, and char properties for the gasification process [

79,

80]. The gas produced during pyrolysis contains H

2, CH

4, CO, CO

2, and low hydrocarbons (C

xH

y). This gas can be used for heat and power generation as well as for chemical production. as being upgraded for chemical production [

81]. Pyrolysis oil consists of acids, alcohols, aromatics, esters, furans, ketones, phenols, and sugars [

82]. Oil from algae contains more oxygenous and nitrogenous compounds than oil produced from lignocellulosic biomass. Oxygen in oil can cause acidity, corrosion, and low calorific value [

83], while nitrogen in oil can produce NOx in combustion [

84]. The oil properties in the pyrolysis process are improved by adding a catalyst, e.g., zeolites [

75,

83]. Used oil as fuel or chemical needs to apply rectification or extraction process [

83]. Char can be recycled as a fuel in combustion and gasification processes. It has a higher calorific value than the substrate. It also contains significant amounts of carbon and nitrogen, making it suitable for use as a fertilizer or adsorbent.

2.4. Gasification of Microalgal Residues in CO2 Atmosphere

Gasification is one way to recycle CO2, the gasifying agent in the Boudouard reaction by Equation (1). This reaction is endothermic and occurs at temperatures above 850 °C.

Other gasification agents, such as steam or oxygen, can be incorporated. Adding oxygen to the gasification agent means the gasification reaction can be exothermic [

77]. Char from, e.g., pyrolysis processes, is utilized as a carbon source in the reaction by Equation (1). The gasification process is considerably slower than pyrolysis [

85]. At temperatures above 850 °C, the gasification rate depends on the mass transfer. Raising the temperature does not significantly increase the gasification rate, as the process is controlled by diffusion [

86,

87]. The increased pressure and partial pressure of CO

2 improve the gasification process, resulting in better heat and mass transfer phenomena [

87]. Increasing the CO

2 concentration above 50% in gasification processes does not always increase the gasification rate [

85]. The average concentration of CO

2 from industry is around 14%. The gasification process is a heterogeneous reaction. Its efficiency depends on the porosity and surface area of the char. A faster exchange of reactants on the char surface is achieved by increasing the flow rate of the gasification agent. The efficiency of the gasification process is also significantly influenced by particle size. Smaller char particles offer less mass and heat movement resistance, resulting in a faster reaction. The gasification process rate is affected by the ash content in char. The rate of gasification is accelerated by the addition of Mg, Na, Fe, K, and Ca, and retarded by the inclusion of Al and Si. Charcoal properties are strongly influenced by the pyrolysis process. The reactivity of the char is dependent on the temperature, the atmosphere, the pyrolysis time, the pressure, and the particle size, with the temperature being the most critical factor. It has been observed that char reactivity in the gasification process increases with higher temperatures during the pyrolysis process [

88]. Increasing the pressure during the pyrolysis process leads to less reactivity of the char [

89]. Pyrolysis and gasification can occur in the same atmosphere (in situ) or another (ex situ). The gas produced by in situ gasification has better properties than that produced by ex situ gasification [

90]. A literature review shows that more research has been carried out on microalgae under different conditions and with other species than on macroalgae [

91]. The kinetics of the gasification process are carried out in thermobalance and fixed-bed reactors. Large-scale gasification of algae is carried out in fluidized bed reactors or high-temperature downdraft gasifiers (HTDG).

Additional H

2 can be obtained using the CO produced in the WGS reaction. This H

2 can synthesize CH

3OH, higher alcohols or DME [

92]. Using CO

2 as a gasification agent reduces syngas nitrogen compounds, increases calorific gas value, and lowers tar yield production [

93]. Co-gasification of biomass and coal creates a synergistic effect [

94]. The gasification process using CO

2 is also carried out through CaO looping. The catalytic properties of CaO increase the concentration of H

2 in the syngas produced by up to 10% [

95].

3. Biochemical CO2-to-X Sustainability towards LCA Analysis

Generally known, climate neutrality, decarbonization, and CO

2-to-X strategies deal with reaching low-carbon technologies, for which the upgrade of existing and development of novel technologies, infrastructure, and strong political and public support is needed [

96]. Life cycle assessment of the product (LCA) represents an effective instrumentation tool ensuring the evaluation of technological pathways’ environmental impact in decarbonization strategies. This tool assesses the environmental footprint of carbon, determines carbon-intensive steps in the product supply chain, and highlights options for minimizing carbon emissions in the complex manufacturing process [

97]. LCA analysis also helps avoid double counting, carbon leakage or greenwashing [

98].

The available literature sources bring several LCA studies regarding microalgal cultivation with subsequent microalgae treatment. The studies usually evaluate environmental impact factors for the whole CO

2 processing chain, i.e., CO

2 to microalgae, harvesting, product separation, and cleaning, all with the implementation of conventional or renewable energy sources. Schneider et al. [

99] found that microalgal cultivation in raceway ponds, centrifugal separation, and drying evinced the lowest environmental impact to fix CO

2 to microalgal biomass against filtration, electrolocation, and flocculation with NaOH. No differences in carbon footprint were found when applying the airlift or paddle wheels configuration for mixing the cultivation batch. Microalgal cultivation and freeze-drying were identified as the dominant environmental footprint factors in the CO

2 to microalgal powder pathway. These can be reduced by implementing renewable energy systems, environmentally friendly nutrients for culture medium, and cleaning solutions [

100]. The carbon footprint for microalgae-derived biofuels is presented by the study of Bradley et al. [

101], in which biodiesel was produced from

Phaeodactylum and

Nannochloropsis strains.

It has been found that microalgae-derived biofuels are not yet preferred over fossil-derived fuels. This is because fossil-derived diesel emits 8.84 × 10

−2 kg CO

2eq, while microalgae-derived biodiesel, which uses energy from solar systems, emits 1.48 × 10

−1 kg CO

2eq. The microalgal cultivation system needs to be improved regarding process efficiency and energy use because 0.99 MJ of energy for microalgal cultivation was required to produce 1 MJ of microalgae-derived biodiesel. Microalgal pigments, including chlorophylls, carotenoids, and phycobiliproteins, offer eco-friendly alternatives to synthetic pigments. Microalgae-derived pigments were found to have a higher environmental impact value than synthetic pigments [

102]. Regarding astaxanthin production, electricity production is a significant ecological impact factor. Applying sunlight instead of artificial illumination sharply decreases the environmental impact factor [

102]. López-Herrada et al. [

103] serve a life-cycle analysis to create a fungicide based on amphidinols. The calculation proved the hypothesis that photosynthetic bioprocesses are net CO

2 producers, ecotoxicity is reduced for microalgal fungicides compared to synthetic ones, and microalgal-derived fungicides evinced a lower environmental footprint than commercial ones. The environmental impact of wastewater treatment can be significantly reduced by combining it with microalgae cultivation. The advantages of this procedure are the low operational expenses, the recycling of the nutrient content of the effluent into high-value products, and the direct absorption of CO

2 emissions [

104]. Regarding microalgal fermentation processes, the microalgal heterotrophic fermentation in commercial fermenters with a volume of 60 m

3 to produce bio-oils displayed 86% of the environmental impacts by the nutrient need and electricity requirement for fermentation. The CO

2 emissions increased with the length of the fermentation time. At a residence time of 131 h, the daily GHG emissions were 1.92 × 10

3 CO

2eq per day, producing one kilogram of bio-oil [

105]. Climate change, fossil resource scarcity, human toxicity, freshwater, and marine ecotoxicity have been identified as phototrophic cascade fermenters’ most significant environmental impact [

106]. Huang et al. [

107] demonstrate a consolidated bioprocessing system in which pigment-extracted microalgal residues are co-fermented with biomass to produce ethanol. Life cycle assessments have revealed that such co-fermentation has a 2.7 to 10.7 times lower environmental impact than alternative ethanol production pathways using microalgal biomass. The environmental impact has been assessed to quantify the energy conversion characteristics and environmental effects of biohydrogen and biomethane industrial production two-stage fermentation from microalgae and food waste [

108]. With 53.8% and 16.6% of the total energy input, the dominant energetic processes were biomass pretreatment and microalgae cultivation. The total greenhouse gas emissions were 124 g CO

2eq per MJ. Microalgae photosynthesis absorbed 49 g CO

2eq per MJ of carbon sources. The primary sources of emissions were electricity production (41.6%), CO

2 release in pressurized water (27.8%), and energy recovery (19.8%).

Microalgal biomass and residues can also undergo thermochemical conversion via hydrothermal liquefaction, pyrolysis or gasification. LCA studies on microalgal thermochemical treatment concluded that sustainability and less impact on the environment can be reached only if energy-intensive drying processes are excluded [

109]. Hydrothermal liquefaction (HTL) was found to be a promising transformation pathway to produce renewable or jet fuels. A significant decrease in GHG emission was observed for the microalgal-based jet fuel of 35.2 kg CO

2eq per GJ compared to the fossil-based fuel of 86.5 kgCO

2eq per GJ [

110]. Hydrothermal liquefaction of wastewater-based microalgal biomass was more sustainable in most impact categories. The GHG emissions were reported for the HTL-based bio-oil production of 0.233 kg CO

2eq MJ

−1 from microalgal cultivation in wastewater compared to 21 times higher HTL-based bio-oil production of 4.7 kg CO

2eq MJ

−1 from microalgal cultivation applying synthetic nutrients [

111]. Chen and Quinn [

112] pointed out that biofuel from algal hydrothermal liquefaction performs worse than conventional fuels regarding ecotoxicity and eutrophication potential.

Unfortunately, some papers focus on LCA analysis of pyrolysis or gasification of microalgal residues. Catalytic pyrolysis offers the opportunity to transform microalgae into biofuels and fine chemicals. Microalgal biomass productivity makes pyrolysis less common than cellulosic biomass [

113]. Life cycle assessment of microalgae cultivation, bio-oil extraction, and slow pyrolysis processing of microalgae residues show a net increase of up to 50% in the less impact on the environment and total life cycle impact [

114]. Drying of microalgal biomass before pyrolysis has a significant effect on environmental impact factors. The carbon footprint can be improved using nutrients from waste streams, integrating renewable energy and heat recovery systems. Wang et al. [

115] performed LCA analysis for pyrolysis treating microalgae and microalgal residues after bio-oil extraction. The microalgal pre-treatment and bio-oil produced resulted in an 11% reduction in energy use plus a 25% increase in greenhouse gas emissions compared to no oil extraction. Azadi et al. [

116] analyzed algal syngas using a fluidized bed gasifier for LCA. A cradle-to-grave assessment determined that the carbon footprint ranged from 0.07 to 0.195 kg CO

2eq MJ

−1. In comparison, the carbon footprint of syngas produced by steam reforming of natural gas is around 0.1 kg CO

2eq MJ

−1. A solar system can reduce the carbon footprint to less than 0.04 g CO

2eq MJ

−1.

This entry is adapted from the peer-reviewed paper 10.3390/su16031201