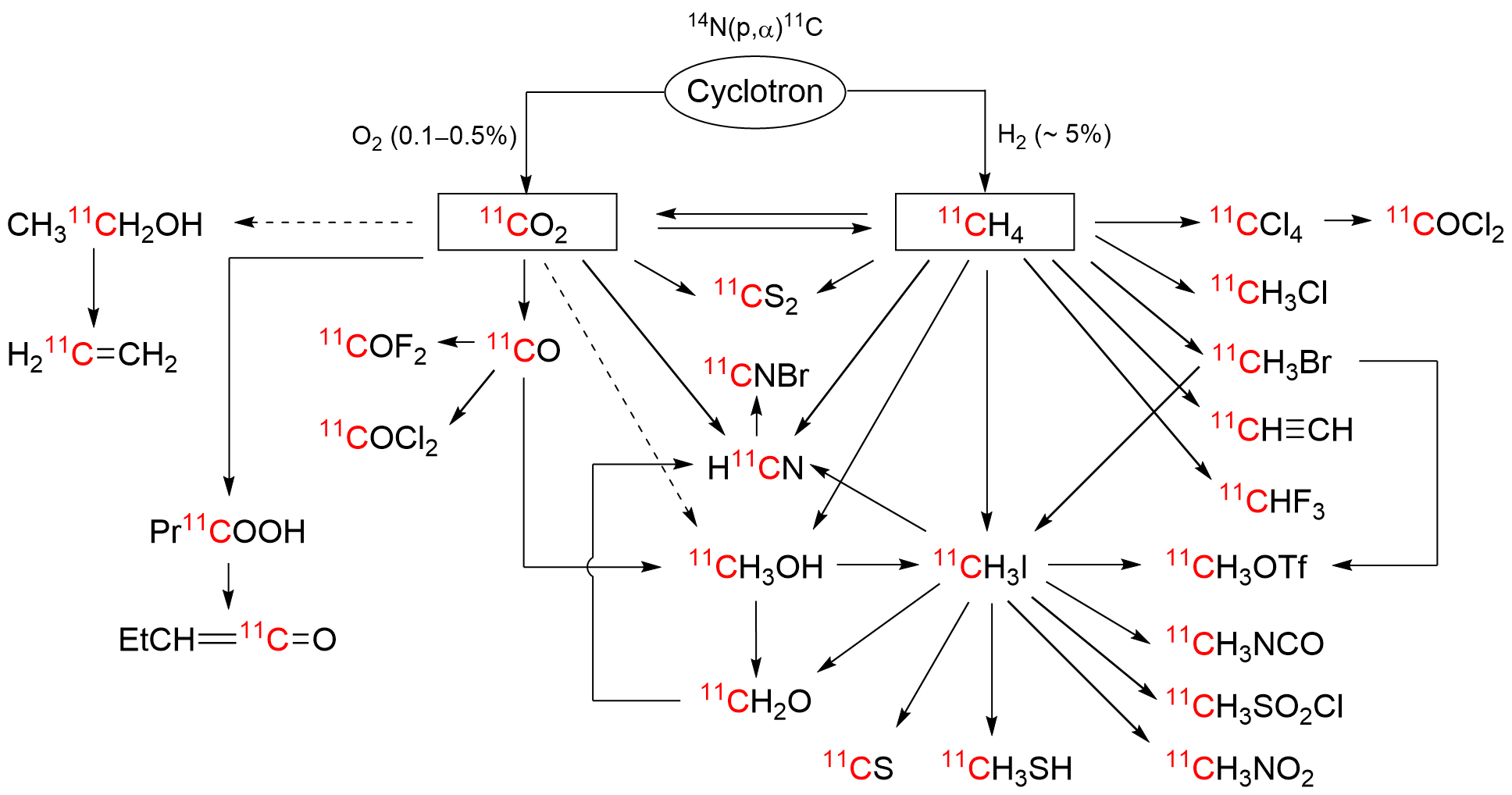

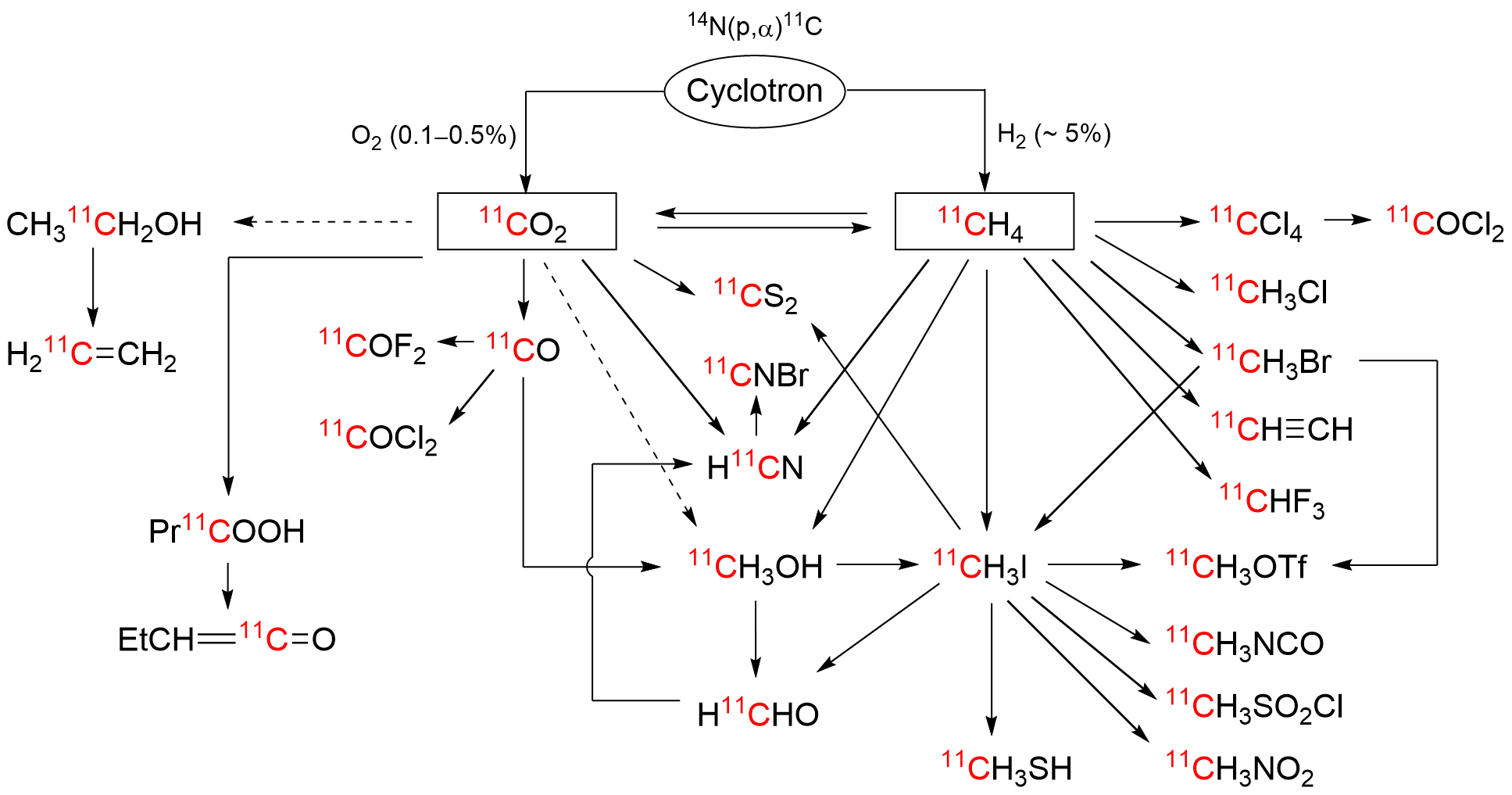

The short-lived positron-emitter carbon-11 (t1/2 = 20.4 min; β+, 99.8%) is prominent for labeling tracers for use in biomedical research with positron emission tomography (PET). Carbon-11 is produced for this purpose with a cyclotron, by the 14N(p,α)11C nuclear reaction, either on nitrogen containing a low concentration of oxygen (0.1–0.5%) or hydrogen (~5%) to produce [11C]carbon dioxide or [11C]methane, respectively. These primary radioactive products can be produced in high yields and with high molar activities. However, only [11C]carbon dioxide has some utility for directly labeling PET tracers. Primary products are required to be converted rapidly and efficiently into secondary labeling synthons to provide versatile radiochemistry for labeling diverse tracer chemotypes at molecular positions of choice. Because of their simplicity, reliability, re-usability, and amenability for automation, gas phase transformations play a major part in carbon-11 chemistry and in PET tracer development.

1. Introduction

The short-lived positron-emitter carbon-11 (

t1/2 = 20.4 min) has prominent applications for labeling organic tracers that are used in biomedical research, drug development, and disease diagnosis with the molecular imaging technique of positron emission tomography (PET) [

1]. Carbon-11 decays almost purely by positron emission (β

+, 99.8%) with the remainder by electron capture. In dense tissue, the emitted positron travels a short path before being annihilated by combining with an electron. Positron annihilation results in emission of a pair of antiparallel photons, each with an energy of 511 keV. The photons can readily escape from deep tissue. Their coincident detection provides the basis for locating the administered tracer (or any arising radiometabolite) responsible for the positron emission within a living subject, whether animal or human. Nowadays, there are highly sophisticated ‘PET cameras’ that can record the distribution of radioactivity with time in the whole animal or human body or in major organs such as brain or heart. PET scans with a physical resolution of about a millimeter can be achieved every few seconds or minutes [

2]. The biomedical information gained depends on the design of the tracer. Most tracers are designed to provide information on the distributions of a particular low-density protein (e.g., a neuroreceptor, transporter, enzyme, or pathological plaque), or on the protein interaction with either an endogenous compound (e.g., neurotransmitter) or a known or experimental drug. PET is highly sensitive, being able to detect proteins at sub-nanomolar concentrations. Because of its short half-life, carbon-11 must be rapidly produced and transformed into a PET tracer for time of need. This requires carbon-11 production and usually rapid conversion of simple primary one-carbon

11C-labeled entities into reactive labeling synthons.

2. Carbon-11 Production and Gas Phase Transformation

Carbon-11 is produced almost exclusively by the higher yielding [

7,

8] and easily manageable

14N(p,α)

11C nuclear reaction on high pressure nitrogen gas [

9]. Typically, the nitrogen has an initial pressure of about 225 psi, and irradiations are performed with moderate to high beam currents (typically 40–150 μA) of moderate energy protons (~16.5 MeV). Many compact biomedical cyclotrons are commercially available for this purpose [

10,

11]. For example, in the authors' laboratory, over 3 curies of carbon-11 can be produced from a 40-minute irradiation of a nitrogen–oxygen mixture with a 45 μA beam of 16.5 MeV protons by a PETtrace cyclotron. By contrast, with this scale of carbon-11 production, only 10 to 20 mCi of a tracer is typically required to be administered to a human subject for a PET experiment.

The chemical form of the retrieved carbon-11 depends on both cyclotron target gas composition and irradiation dose [

9,

12]. Normally, oxygen (0.1–0.5%

v/

v) is added to the nitrogen target gas to ensure reliably high recovery of [

11C]carbon dioxide (

Scheme 1). The recovered [

11C]carbon dioxide can be concentrated in a trap composed of a small coil of stainless steel tube immersed in a cryogen, either liquid nitrogen or liquid argon. Alternatively, [

11C]carbon dioxide can be trapped without any of the added oxygen on molecular sieves at room temperature and then released in the concentrated form with an inert gas at higher temperature [

14]. This method is overall efficient and reliable, and therefore widely used. If hydrogen (~5%

v/

v) is present in the irradiated nitrogen target gas, [

11C]methane (

Scheme 1) is produced. [

11C]Methane is readily recovered and concentrated from irradiated target gas by passage into a Porapak N trap at room temperature or a Porapak Q trap at −186 °C [

15]. [

11C]Methane can then be released at a higher temperature.

In PET imaging experiments on animals and human subjects, the mass of administered tracer must be limited to avoid possible toxicity and to comply with the tracer principle, which is to avoid perturbation of the biochemical system being studied. In this regard, an extremely important consideration in the production of carbon-11 is the molar activity (

Am) of the chemical species that is produced. The molar activity is defined as the ratio of radioactivity (e.g., in Ci) to the total mass of all isotopologues (e.g., in μmol) of the chemical species in question at a specific time, such as the end of the radionuclide production (ERP). For an

11C-labeled product, the isotopologues to be considered are the corresponding natural abundance

12C and

13C isotopologues. Cyclotron irradiations typically produce carbon-11 with molar activities of 20 to 100 Ci/μmol than is theoretically possible (

9200 Ci/μmol), because traces of non-radioactive isotopologues, known as carrier, may inadvertently enter the cyclotron target or the radioactive product recovery system. For example, during [11C]carbon dioxide production, carbon dioxide may be produced from organic materials during irradiation, or a trace of atmospheric carbon dioxide may contaminate the target or product recovery apparatus. Therefore, scrupulous measures are required to minimize the ingress or production of trace carrier [20,21]. The application of careful measures to eliminate potential sources of carrier in post-irradiation chemical processing can lead to good conservation of molar activity [22,23]. The experience of many laboratories is that the recovered activities of [

11C]methane are substantially lower than the recovered yields of [

11C]carbon dioxide for the same energy and beam current in high-intensity production irradiations. However, some laboratories report appreciably higher molar activity for [

11C]methane than [

11C]carbon dioxide [

15,

17].

Scheme 1. Processes leading to [11C]carbon dioxide and [11C]methane by proton irradiation of nitrogen gas with low level oxygen or hydrogen, respectively. They are subsequently converted in gas phase to more reactive synthons for 11C-labeling of PET tracers. Dashed arrow indicates non-gas phase process.

An ability to produce tracers for PET imaging depends on being able to convert a primary cyclotron-produced product, either [

11C]carbon dioxide or [

11C]methane, into the tracer by rapid and high-yielding post-irradiation chemical means (

Scheme 1). In practice, only two or three physical half-lives can be allowed for a full tracer production, including the separation and formulation of tracer for intravenous administration. Because of its reactivity, [

11C]carbon dioxide has some direct but limited utility (e.g., for

11C-carboxylation reactions). However, [

11C]methane must be transformed into some other labeling agent to be useful. Similarly, the chemical transformations of [

11C]carbon dioxide can produce more useful labeling agents.

Whereas the preponderance of carbon-11 chemistry is carried out in solution, methods for performing 11C-chemistry in the gas phase are highly attractive. They can often be performed on-line and very rapidly in a flow of a suitable inert carrier gas (e.g., nitrogen or helium), and they allow easy product isolation, often in a solvent of choice. Catalysts and reactants can often be used repeatedly, and usually the apparatus can be readily automated for the protection of personnel from radioactivity. A broad range of 11C-labeling agents can now be produced in the gas phase from the two main cyclotron products, [11C]carbon dioxide or [11C]methane, as depicted in Scheme 1. Consequently, rapid gas phase transformations now play a major part in carbon-11 chemistry and in PET tracer utilization and development because of such simplicity, reliability, re-usability, and amenability for automation. Some notable examples are the syntheses of: i) [11C]carbon monoxide by reduction of [11C]carbon dioxide over heated (850 °C) molybdenum [38]; ii) [11C]hydrogen cyanide by platinum-catalyzed reaction with ammonia at 965 °C [46]; iii) [11C]iodomethane by high temperature (725 °C) iodination of [11C]methane [24] and conversion to [11C]methyl triflate with silver(I) triflate at 150 to 200 °C [89]; iv) [11C]fluoroform by cobalt(III) fluoride-mediated fluorination of [11C]methane at 270 °C [54]; and v) the synthesis of [11C]carbonyl difluoride by room temperature fluorination of [11C]carbon monoxide with silver(II) fluoride.[72]. In many examples, the gas phase transformations have supplanted inferior solution phase methods. Some of the methods (e.g., [11C]iodomethane synthesis) are now incorporated into commercially available automated radiosynthesis platforms and are very widely applied for regular PET tracer syntheses.

This entry is adapted from the peer-reviewed paper 10.3390/ijms25021167