Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The fused deposition modeling (FDM) process, an extrusion-based 3D printing technology, enables the manufacture of complex geometrical elements. This technology employs diverse materials, including thermoplastic polymers and composites as well as recycled resins to encourage sustainable growth. FDM is used in a variety of industrial fields, including automotive, biomedical, and textiles, as a rapid prototyping method to reduce costs and shorten production time, or to develop items with detailed designs and high precision.

- fused deposition modelling (FDM)

- thermoplastics

1. Introduction

Additive manufacturing (AM) is an emerging technology for processing material and creating an object from a three-dimensional (3D) model, usually via layer-to-layer deposition. The AM process can be constituted by two phases: the first is a virtual phase during which a computer-aided design (CAD) model is prepared using CAD software packages, the second is a physical phase to develop the physical object [1].

According to the standard ISO/ASTM 52900 [2], the additive manufacturing (AM) is defined: “process of joining materials to make parts from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing and formative manufacturing methodologies” [3]. Historical terms are “additive fabrication, additive processes, additive techniques, additive layer manufacturing, layer manufacturing, solid freeform fabrication and freeform fabrication”.

Additive manufacturing (AM) is changing the aviation industry, space applications, and missile defense systems [4]. It opens up new opportunities for designing fine jewelry models or developing new artistic works [1], for the creation of adaptive and sophisticated buildings, or for smooth ready textures to paint surfaces [5]. The most common AM uses in biomedical applications involve the fabrication of body parts, anatomical models, implants for orthopedics, scaffolding, and drug delivery systems [6]. AM technologies are also becoming increasingly common in the automotive sector, where they are used to develop newer models and to modify existing ones in response to new design trends and technological breakthroughs [7].

The earliest patents on additive manufacturing processes were granted in 1984 to three French engineers from Cilas Alcatel (Orléans, France) (“French Patent FR2567668(B1)”) [8] and to C. Hull from 3D Systems, Inc. (Rock Hill, SC, USA) (“US Patent 4,575,330”) [9]. In the years since then, the AM sector has expanded to include a wide range of fast prototyping technologies, leading to the so-called “3rd Industrial Revolution” [10].

Controlling the rheological properties of molten/suspended polymers is critical to the efficiency of polymer processing. Controlling shear flow behavior requires the modification of many polymer properties (molecular weight, chain branching), as well as the application of modifiers (fillers, plasticizers, polymers) and adjusting processing factors (temperature, shear, pressure) [11].

Accordingly, the proper processing of polymeric materials requires a comprehensive understanding of their rheological properties; the characterization of polymer melt/suspended properties using relevant rheometers is very important for polymer processing management.

2. Fused Deposition Modelling (FDM) Technology of Thermoplastic-Based Filaments

Fused deposition modeling (FDM) is an AM technique that is commonly used to create models, prototypes, and products. FDM is a fast and simple method to make personalized items at a low cost. S. Scott Crump, cofounder of Stratasys, invented this technology in the late 1980s that became commercially available in 1990. Fast forward to today, FDM, also known as extrusion-based additive manufacturing or FFF (fused filament fabrication), is the most widely used 3D printing technology.

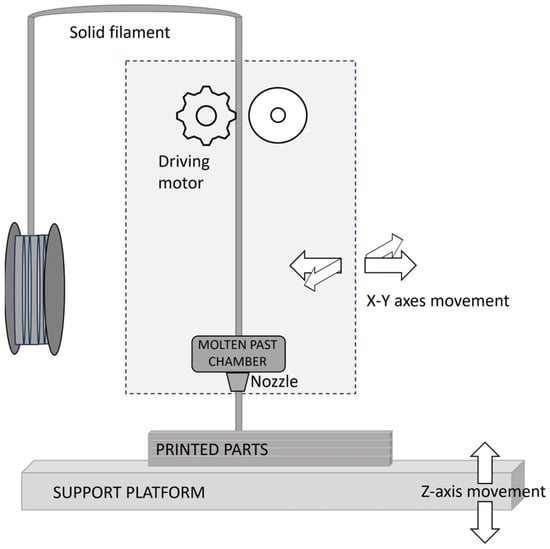

An STL (STereo Lithography interface format or acronyms of “Standard Triangle Language” or “Standard Tessellation Language”) file is processed by software, which mathematically slices and orients the model for the build process. Unwound from a coil, a solid filament (usually thermoplastic in nature) is heated past the glass transition/melting point and delivers material to an extrusion nozzle, which controls the flow. A worm-drive directs the filament into the nozzle at a predetermined rate. At the exit of the nozzle, the melted material is selectively deposited on a heated support platform to produce 3D parts directly from a CAD model in a layer-by-layer manner. This implies that after printing the first layer, the platform lowers and another layer is printed on top of the first one, and the procedure is repeated. The mechanism is frequently an X-Y-Z rectilinear design. A numerically controlled system can move the nozzle in both horizontal and vertical directions (along the X and Y axes), whereas the platform operates in the Z axis [12].

A schematic diagram of the FDM extrusion process is shown in Figure 1.

Figure 1. Schematic of FDM process.

Slicing parameters are layer thickness, flow rate, infill percentage, raster angle, raster pattern, air gap, nozzle diameter, and top and bottom width. Build orientation refers to the position of the part within the build platform in relation to the X, Y, and Z axes (horizontal, flat, or vertical alignment) [13]. Slicing parameters, building orientation, and temperature conditions are all considered critical parameters in the printing process [14].

The 3D printing process has some disadvantages, such as the low strength of the parts, rough surface finish, and slow production time [15]. For example, the layers may be too thick, leading to poor surface quality. An additional support may be needed to stabilize the 3D structure. The main cause of mechanical deficiency is deformation between layers. There is a weakness in the vertical strength of the parts due to warping and temperature fluctuations; these cause structure delamination and poor mechanical strength [14].

The maximum operating temperature of a commercially available FDM machine is commonly around 300 °C. This means that materials with exceptionally high melting points are usually inappropriate for use with this machine, and only certain types of plastics and materials that melt at moderate temperatures are suitable. ABS and PLA are the most often used thermoplastic polymers in FDM. Alternative polymers include polyamide or nylon (PA), polycarbonate (PC), polymethyl methylacrylate (PMMA), polyethylene (PE), and polypropylene (PP) [16].

Polymer-based composites and nanocomposites made with metal particles [17] (such as aluminium and iron powder), ceramics [18] (such as titanium dioxide, zirconium oxide, and aluminium oxide), nanomaterials [19] (such as carbon nanotubes, graphene, and clay), glass [20] and carbon fibres [21] (either continuous rovings or chopped fibres), and natural fibres [22] (such as wood, bamboo, flax, coir, jute, sisal, vegetable fibres, and oil palm) are commonly used in the FDM process [23].

One of the notable benefits of this growing technology is the reuse of discarded thermoplastic materials to produce quality products [24].

On one hand, convenient materials for extrusion-based printing are amorphous thermoplastic polymers. For amorphous polymers, internal tensions that occur after cooling (e.g., warpage) are limited by their low thermal expansion coefficients and extrusion temperatures [25]. On the other hand, semi-crystalline thermoplastics such as polylactic acid (PLA) [26] and thermoplastic polyurethanes [27] and polyamides (PA) [28] are employed to increase performance (increased toughness and wear resistance, as well as stiffness and strength) [29]. For example, semicrystalline printed parts are expected to exhibit a higher degree of anisotropy than amorphous ones. Semicrystalline polymers are also more challenging to work with when investigating interdiffusion across the contact, because incipient crystallization can be one of the limiting factors of the layer adhesion [25]. A high crystallization rate prevents interfacial adhesion, since the crystallized segment cannot weld to the prior layer; furthermore, high crystallinity causes internal stress and volume shrinkage [30].

The durability of FDM parts made from waste thermoplastics is lower than that of printed products made from virgin plastics [31]. Accordingly, it is important to understand the significant changes in recycled thermoplastic materials under repeated extrusions, such as chain fragmentation and changes in viscosity and strength at break [32]. It was discovered that the printing process has a strong impact on the pristine properties of extruded materials. This technique may induce a polymer decomposition reaction, resulting in a decrease in rheological properties over time. If the systems are kept at high temperatures, the destructive activity of the printing process can continue over time, further degrading the macromolecules. In composites, the damage caused by printing extrusion can be limited to the process duration [33].

Recently, new-type FDM filaments with excellent thermophysical properties have been investigated in order to improve the mechanical properties of printed parts by utilizing special engineering plastics such as polyetheretherketone (PEEK) [34], polyetherimide (PEI) [35], polyaryletherketone (PAEK) [36], and polyetherketoneketone (PEKK) [37] with excellent thermophysical properties and high melting points. This has been made possible by pushing the filament extrusion process’ technological limitations and boosting the maximum operating temperatures to 400–500 °C.

This entry is adapted from the peer-reviewed paper 10.3390/ma16247664

References

- Negi, S.; Kumar Sharma, R.; Dhiman, S. Basics, applications and future of additive manufacturing technologies: A review. J. Manuf. Technol. Res. 2013, 5, 75–96.

- ISO/ASTM 52900; Additive Manufacturing—General Principles—Terminology. ASTM International: West Conshohocken, PA, USA, 2022.

- Bikas, H.; Koutsoukos, S.; Stavropoulos, P. A decision support method for evaluation and process selection of Additive Manufacturing. Procedia CIRP 2019, 81, 1107–1112.

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. In Additive Manufacturing for the Aerospace Industry; Froes, F.H., Boyer, R., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 7–31. ISBN 9780128140635.

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive manufacturing: Technology, applications, markets, and opportunities for the built environment. Autom. Constr. 2020, 118, 103268.

- Kumar, R.; Kumar, M.; Chohan, J.S. The role of additive manufacturing for biomedical applications: A critical review. J. Manuf. Process. 2021, 64, 828–850.

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676.

- Andre, J.-C.; Le Mehaute, A.; Witte, O. De Device for Producing a Model of an Industrial Part. FR2567668A1, 17 January 1986. Available online: https://patents.google.com/patent/FR2567668A1/en (accessed on 10 December 2023).

- Charles, W. Hull Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent US4575330A, 19 December 1989.

- Ryder, M.A.; Lados, D.A.; Iannacchione, G.S.; Peterson, A.M. Fabrication and properties of novel polymer-metal composites using fused deposition modeling. Compos. Sci. Technol. 2018, 158, 43–50.

- Zhang, W.; Chen, J.; Zeng, H. Polymer processing and rheology. In Polymer Science and Nanotechnology: Fundamentals and Applications; Narain, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 149–178. ISBN 9780128168066.

- Mohd Pu’ad, N.A.S.; Abdul Haq, R.H.; Mohd Noh, H.; Abdullah, H.Z.; Idris, M.I.; Lee, T.C. Review on the fabrication of fused deposition modelling (FDM) composite filament for biomedical applications. Mater. Today Proc. 2020, 29, 228–232.

- Solomon, I.J.; Sevvel, P.; Gunasekaran, J. A review on the various processing parameters in FDM. Mater. Today Proc. 2021, 37, 509–514.

- Rajan, K.; Samykano, M.; Kadirgama, K.; Harun, W.S.W.; Rahman, M.M. Fused deposition modeling: Process, materials, parameters, properties, and applications. Int. J. Adv. Manuf. Technol. 2022, 120, 1531–1570.

- Kumar, R.; Kumar, M.; Chohan, J.S. Material-specific properties and applications of additive manufacturing techniques: A comprehensive review. Bull. Mater. Sci. 2021, 44, 1–19.

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys. Prototyp. 2017, 12, 47–59.

- Nurhudan, A.I.; Supriadi, S.; Whulanza, Y.; Saragih, A.S. Additive manufacturing of metallic based on extrusion process: A review. J. Manuf. Process. 2021, 66, 228–237.

- Dadkhah, M.; Tulliani, J.M.; Saboori, A.; Iuliano, L. Additive manufacturing of ceramics: Advances, challenges, and outlook. J. Eur. Ceram. Soc. 2023, 43, 6635–6664.

- Wu, H.; Fahy, W.P.; Kim, S.; Kim, H.; Zhao, N.; Pilato, L.; Kafi, A.; Bateman, S.; Koo, J.H. Recent developments in polymers/polymer nanocomposites for additive manufacturing. Prog. Mater. Sci. 2020, 111, 100638.

- Sodeifian, G.; Ghaseminejad, S.; Yousefi, A.A. Preparation of polypropylene/short glass fiber composite as Fused Deposition Modeling (FDM) filament. Results Phys. 2019, 12, 205–222.

- Le, A.D.; Akué Asséko, A.C.; Cosson, B.; Krawczak, P. Investigating the Effect of Interface Temperature on Molecular Interdiffusion during Laser Transmission Welding of 3D-Printed Composite Parts. Materials 2023, 16, 6121.

- Bi, X.; Huang, R. 3D printing of natural fiber and composites: A state-of-the-art review. Mater. Des. 2022, 222, 111065.

- Angelopoulos, P.M.; Samouhos, M.; Taxiarchou, M. Functional fillers in composite filaments for fused filament fabrication; a review. Mater. Today Proc. 2021, 37, 4031–4043.

- Patti, A.; Acierno, S.; Cicala, G.; Zarrelli, M.; Acierno, D. Recovery of Waste Material from Biobags: 3D Printing Process and Thermo-Mechanical Characteristics in Comparison to Virgin and Composite Matrices. Polymers 2022, 14, 1943.

- Candal, M.V.; Calafel, I.; Fernández, M.; Aranburu, N.; Aguirresarobe, R.H.; Gerrica-Echevarria, G.; Santamaría, A.; Müller, A.J. Study of the interlayer adhesion and warping during material extrusion-based additive manufacturing of a carbon nanotube/biobased thermoplastic polyurethane nanocomposite. Polymer 2021, 224, 123734.

- Srinivas, V.; van Hooy-Corstjens, C.S.J.; Rastogi, S.; Harings, J.A.W. Promotion of molecular diffusion and/or crystallization in fused deposition modeled poly(lactide) welds. Polymer 2020, 202, 122637.

- Gao, J.; Hao, M.; Wang, Y.; Kong, X.; Yang, B.; Wang, R.; Lu, Y.; Zhang, L.; Gong, M.; Zhang, L.; et al. 3D printing boron nitride nanosheets filled thermoplastic polyurethane composites with enhanced mechanical and thermal conductive properties. Addit. Manuf. 2022, 56, 102897.

- Das, A.; Etemadi, M.; Davis, B.A.; McKnight, S.H.; Williams, C.B.; Case, S.W.; Bortner, M.J. Rheological investigation of nylon-carbon fiber composites fabricated using material extrusion-based additive manufacturing. Polym. Compos. 2021, 42, 6010–6024.

- Vaes, D.; Van Puyvelde, P. Semi-crystalline feedstock for filament-based 3D printing of polymers. Prog. Polym. Sci. 2021, 118, 101411.

- Ho, Q.B.; Kontopoulou, M. Improving the adhesion and properties in the material extrusion of polypropylene by blending with a polyolefin elastomer. Addit. Manuf. 2022, 55, 102818.

- Gomes, T.E.; Cadete, M.S.; Dias-de-Oliveira, J.; Neto, V. Controlling the properties of parts 3D printed from recycled thermoplastics: A review of current practices. Polym. Degrad. Stab. 2022, 196, 109850.

- Mishra, V.; Negi, S.; Kar, S. FDM-based additive manufacturing of recycled thermoplastics and associated composites. J. Mater. Cycles Waste Manag. 2023, 25, 758–784.

- Patti, A.; Acierno, S.; Cicala, G.; Acierno, D. Changes in Chemical and Physical Properties of Bio-based Thermoplastics During Fused Deposition Modelling (FDM) Process. Chem. Eng. Trans. 2023, 100, 439–444.

- Wang, P.; Zou, B.; Ding, S.; Li, L.; Huang, C. Effects of FDM-3D printing parameters on mechanical properties and microstructure of CF/PEEK and GF/PEEK. Chin. J. Aeronaut. 2021, 34, 236–246.

- Wang, P.; Zou, B.; Xiao, H.; Ding, S.; Huang, C. Effects of printing parameters of fused deposition modeling on mechanical properties, surface quality, and microstructure of PEEK. J. Mater. Process. Technol. 2019, 271, 62–74.

- Garcia-Leiner, M.; Streifel, B.; Başgül, C.; MacDonald, D.W.; Kurtz, S.M. Characterization of polyaryletherketone (PAEK) filaments and printed parts produced by extrusion-based additive manufacturing. Polym. Int. 2021, 70, 1128–1136.

- Kennedy, Z.C.; Christ, J.F.; Fenn, M.D.; Zhong, L.; Chouyyok, W.; Arnold, A.M.; Denny, A.C.; Albrecht, A.M.; Silverstein, J.A.; Erikson, R.L.; et al. Mica filled polyetherketoneketones for material extrusion 3D printing. Addit. Manuf. 2022, 49, 102492.

This entry is offline, you can click here to edit this entry!