Microseismic event identification is of great significance for enhancing our understanding of underground phenomena and ensuring geological safety. Microseismic monitoring entails the continuous surveillance of minuscule seismic events during mining activities. These imperceptible events provide valuable information about evolving geological conditions. They serve as early warning signals, offering crucial insights into potential hazards and enabling timely preventive measures. This not only safeguards the well-being of miners but also enhances the overall efficiency and sustainability of mining practices.

- microseismic events

- machine learning

- signal processing

- waveform recognition

1. Introduction

2. Microseismic Monitoring Signals

2.1. Microseismic Monitoring Data

2.2. Waveform Features

-

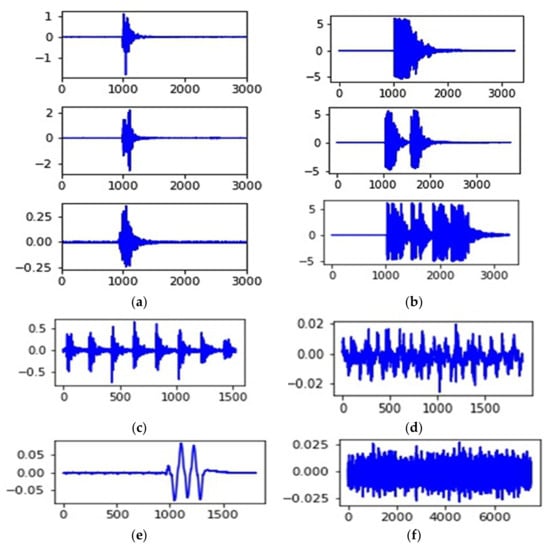

Rock microfracture microseismic events, which are usually associated with stress changes and cracks in underground rock formations. The waveform characteristics of these events show small amplitude, high frequency, short duration, and may display certain periodicity.

-

Blasting events are seismic signals generated by blasting activities in mines or underground projects. The waveform characteristics are usually high amplitude, low frequency, longer duration, and specific spectral features.

-

Rock drilling events, which originate from mechanical activities such as rock gouging and drilling in mines and other sites, produce noisy signals. Although these signals may appear in microseismic monitoring, they are unrelated to seismic activity and need to be distinguished from microseismic events. Their waveform characteristics are generally characterized by high amplitude noise, broad bandwidth, transient signals, and lack of significant periodicity.

-

Other noise events, which refer to noise sources other than rock drilling events, such as unloading, equipment operation, power interference, and groundwater flow, may interfere with the monitoring and identification of MS. The waveform characteristics of these noise events are usually random, irregular, and without obvious frequency and amplitude patterns.

This entry is adapted from the peer-reviewed paper 10.3390/app132312739

References

- Li, J.; Zhan, K. Intelligent Mining Technology for an Underground Metal Mine Based on Unmanned Equipment. Engineering 2018, 4, 381–391.

- Abdalzaher, M.S.; Soliman, M.S.; El-Hady, S.M.; Benslimane, A.; Elwekeil, M. A Deep Learning Model for Earthquake Parameters Observation in IoT System-Based Earthquake Early Warning. IEEE Internet Things J. 2022, 9, 8412–8424.

- Arrowsmith, S.J.; Trugman, D.T.; MacCarthy, J.; Bergen, K.J.; Lumley, D.; Magnani, M.B. Big Data Seismology. Rev. Geophys. 2022, 60, e2021RG000769.

- Mousavi, S.M.; Beroza, G.C. Machine Learning in Earthquake Seismology. Annu. Rev. Earth Planet. Sci. 2023, 51, 105–129.

- Du, J.; Chen, J.; Pu, Y.; Jiang, D.; Chen, L.; Zhang, Y. Risk Assessment of Dynamic Disasters in Deep Coal Mines Based on Multi-Source, Multi-Parameter Indexes, and Engineering Application. Process Saf. Environ. Prot. 2021, 155, 575–586.

- Pu, Y.; Apel, D.B.; Liu, V.; Mitri, H. Machine Learning Methods for Rockburst Prediction-State-of-the-Art Review. Int. J. Min. Sci. Technol. 2019, 29, 565–570.

- Zhang, C.; Jin, G.; Liu, C.; Li, S.; Xue, J.; Cheng, R.; Wang, X.; Zeng, X. Prediction of Rockbursts in a Typical Island Working Face of a Coal Mine through Microseismic Monitoring Technology. Tunn. Undergr. Space Technol. 2021, 113, 103972.

- Cui, F.; Sun, J.; Lai, X.; Jia, C.; Zhang, S. Study on the Energy Release Law of Overburden Rock Breaking and Anti-Rockburst Technology in the Knife Handle Working Face of a Gently Inclined Coal Seam. Appl. Sci. 2023, 13, 11809.

- Pu, Y.; Apel, D.B.; Hall, R. Using Machine Learning Approach for Microseismic Events Recognition in Underground Excavations: Comparison of Ten Frequently-Used Models. Eng. Geol. 2020, 268, 105519.

- Jiang, R.; Dai, F.; Liu, Y.; Wei, M. An Automatic Classification Method for Microseismic Events and Blasts during Rock Excavation of Underground Caverns. Tunn. Undergr. Space Technol. 2020, 101, 103425.

- Duan, Y.; Shen, Y.; Canbulat, I.; Luo, X.; Si, G. Classification of Clustered Microseismic Events in a Coal Mine Using Machine Learning. J. Rock Mech. Geotech. Eng. 2021, 13, 1256–1273.

- Kan, J.; Dou, L.; Li, J.; Song, S.; Zhou, K.; Cao, J.; Bai, J. Discrimination of Microseismic Events in Coal Mine Using Multifractal Method and Moment Tensor Inversion. Fractal Fract. 2022, 6, 361.

- Wang, C.; Si, G.; Zhang, C.; Cao, A.; Canbulat, I. Variation of Seismicity Using Reinforced Seismic Data for Coal Burst Risk Assessment in Underground Mines. Int. J. Rock Mech. Min. Sci. 2023, 165, 105363.

- Wang, R.; Chen, S.; Li, X.; Tian, G.; Zhao, T. AdaBoost-Driven Multi-Parameter Real-Time Warning of Rock Burst Risk in Coal Mines. Eng. Appl. Artif. Intell. 2023, 125, 106591.

- Shu, L.; Liu, Z.; Wang, K.; Zhu, N.; Yang, J. Characteristics and classification of microseismic signals in heading face of coal mine: Implication for coal and gas outburst warning. Rock Mech. Rock Eng. 2022, 55, 6905–6919.

- Yin, H.; Zhang, G.; Wu, Q.; Yin, S.; Soltanian, M.R.; Thanh, H.V.; Dai, Z. A Deep Learning-Based Data-Driven Approach for Predicting Mining Water Inrush from Coal Seam Floor Using Microseismic Monitoring Data. IEEE Trans. Geosci. Remote Sens. 2023, 61, 4504815.

- Dong, L.J.; Wesseloo, J.; Potvin, Y.; Li, X.B. Discrimination of Mine Seismic Events and Blasts Using the Fisher Classifier, Naive Bayesian Classifier and Logistic Regression. Rock Mech. Rock Eng. 2016, 49, 183–211.

- Li, L.; Tan, J.; Schwarz, B.; Staněk, F.; Poiata, N.; Shi, P.; Diekmann, L.; Eisner, L.; Gajewski, D. Recent Advances and Challenges of Waveform-Based Seismic Location Methods at Multiple Scales. Rev. Geophys. 2020, 58, e2019RG000667.

- Jinqiang, W.; Basnet, P.; Mahtab, S. Review of Machine Learning and Deep Learning Application in Mine Microseismic Event Classification. Min. Miner. Depos. 2021, 15, 19–26.