Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Additive manufacturing is evolving in the direction of carbon fiber 3D printing, a technology that combines the versatility of three-dimensional printing with the exceptional properties of carbon fiber.

- additive manufacturing (AM)

- carbon fiber 3D printing

- versatility

- continuous fiber printing

- short fiber printing

- polymer matrix

1. Introduction

Three-dimensional (3D) printing, also known as additive manufacturing (AM) or rapid prototyping (RP), is an innovative production technology that enables the fabrication of solid objects layer by layer using three-dimensional model data [1]. Unlike traditional subtractive manufacturing methods, 3D printing allows on-demand production of finished products from computer-aided design (CAD) models. This technology originated in the 1980s and has evolved as a versatile technology for accomplishing complex structures using a wide range of materials [2], including carbon-based materials, metals [3], biological materials, ceramics, and even food. 3D printing has multiple applications in various sectors, such as construction, aerospace, medicine, and many others [4], both for academic research and industrial production. Carbonaceous materials, thanks to their excellent chemical properties, versatile nanostructure, and special mechanical [5][6], electrochemical, thermal, and electrical properties, have been widely used in 3D printing. In recent years, there has been a growing interest in using 3D printing to manufacture complex systems containing carbon fibers, whether short or long. Various 3D printable carbonaceous materials have been developed, including carbon-filled composites, carbon precursors, and other variants. These materials offer significant opportunities for achieving advanced functional systems. Despite current challenges, such as optimizing the properties of printed materials, increasing carbon content, and achieving high-carbon structures, progress in 3D printing of carbon continues to push the boundaries of additive manufacturing. Research and development in this field are ongoing to fully harness the potential of 3D printing of carbon and explore new emerging applications.

2. 3D-Printed Continuous Carbon Fiber-Reinforced Composites

Considering the effectiveness demonstrated in various studies regarding the integration of carbon fiber for enhancing the mechanical performance of polymers commonly used in additive manufacturing, there has been a growing fascination with producing 3D-printed components utilizing continuous carbon fiber. In the field of additive manufacturing, the integration of continuous fibers into the plastic resin of 3D printed models represents a recent and promising innovation with the potential to define the next generation of composite materials. This technology has demonstrated a significant contribution to enhancing the mechanical properties of composites, including tensile strength, flexural strength, compression resistance, and impact resistance. Its widespread acceptance stems from its ability to generate intricate designs with a reduced number of process steps and the freedom to fabricate reinforcements as needed. Moreover, it has led to substantial improvements, often several times greater, compared to unreinforced composites, paving the way for the potential use of continuous fiber fabrication (CFF) composites in high-load-bearing applications. However, despite the advantages, the commercial application of this technology remains somewhat limited. This is primarily due to the anisotropic behavior of CFF composites, poor interfacial bonding, high porosity, and the restricted range of materials (matrix and reinforcement) available for customizing composite properties according to specific needs. Additionally, CFF composites exhibit lower mechanical performance, as evidenced by meso- and microstructural studies, in comparison to traditionally prepared composites. Other significant hurdles include challenges related to time, cost, and scalability. It is, therefore, possible to state that research into CFF composites is still in an exploratory phase, with a predominant focus on varying printing parameters, processes, and reinforcement configurations, rather than the discovery of new applications or suitable alternatives to currently used materials. Despite the challenges, the industrial potential of this technology remains considerable, but further research and development are necessary to overcome current limitations and fully unlock the opportunities offered by 3D printing of continuous fiber-reinforced composites [7][8][9][10].

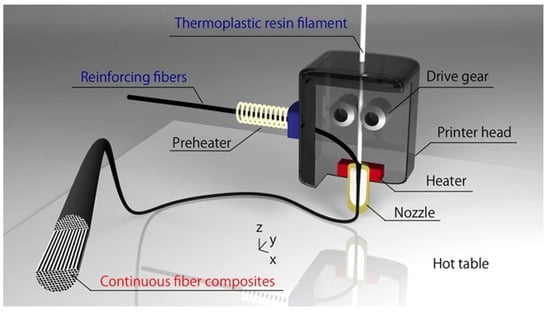

Li et al., 2016 [11] explores the use of 3D printing technology to manufacture continuous carbon fiber-reinforced polylactic acid (PLA) composites. It involves a specialized nozzle design to ensure uniform mixing of carbon fibers and PLA resin during printing and addresses the weak bond between carbon fibers and PLA through fiber preprocessing. Experimental results show substantial improvements in mechanical and thermal properties. Tensile and flexural strengths of preprocessed carbon fiber-reinforced composites are 13.8% and 164% higher than untreated samples, respectively. The storage modulus also surpasses pure PLA and untreated samples, with increases of 166% and 351%, respectively. Scanning electron microscope (SEM) analyses confirm enhanced fiber-resin bonding. This rapid 3D printing technology has promising applications in creating complex, high-performance components, especially in aerospace. Other studies have developed similar methodologies; specifically, Matsuzaki et al., 2016 [12] have developed an innovative technique for 3D printing of continuous fiber-reinforced thermoplastic composites, based on fused deposition modeling (see Figure 1).

Figure 1. Schematic of the 3D printer head used to produce continuous FRTPs using an in-nozzle ([12], reproduced under a CC BY 4.0 license).

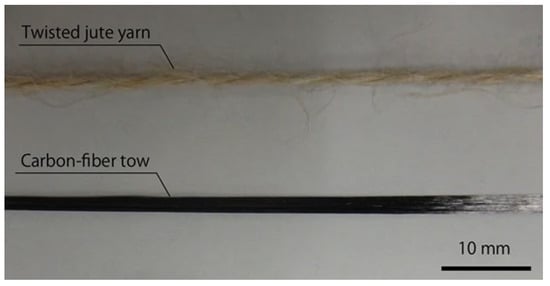

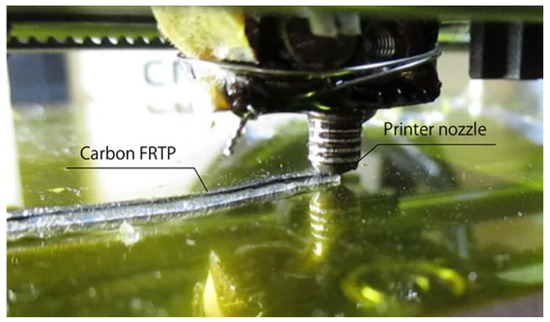

This technique allows the direct production of 3D components without the use of molds and is considered a possible future standard methodology for the fabrication of advanced composites. In the process, a thermoplastic filament and continuous fibers are supplied to the 3D printer separately. The fibers are impregnated with thermoplastic resin inside the heated nozzle just before printing. Polylactic acid (PLA) was used as the thermoplastic matrix, while reinforcement options include both carbon fibers and natural jute fibers (see Figure 2). The results obtained demonstrate that carbon fiber-reinforced composites exhibit superior mechanical properties compared to jute-reinforced composites and non-reinforced polymers. This method (Figure 3) represents a notable advancement in the production of 3D-printed composites, with significant potential for future applications.

Figure 2. Continuous fiber reinforcements used for 3D printing ([12], reproduced under a CC BY 4.0 license).

Figure 3. Photograph of the 3D printing of a CFRTP ([12], reproduced under a CC BY 4.0 license).

Processes have also been developed for the recycling of components produced with continuous carbon fiber and PLA. In this innovative process, continuous carbon fibers are recycled from 3D printed continuous fiber-reinforced thermoplastic composites (CFRTPC) to produce PLA-impregnated carbon filaments. These recycled filaments perform better than the original ones. Pure PLA and recycled carbon filaments are then used to remanufacture composites with significantly improved mechanical properties. This approach reduces waste and promotes sustainability in CFRTPC production, despite a slight increase in energy consumption. Overall, it represents a significant step toward eco-friendly CFRTPC production [13].

Compared to other 3D printing techniques, like FDM, SLA, SLS, inkjet, and extrusion, the mechanical properties of these 3D-printed CFRTP composites are superior, whether with continuous or short carbon fiber reinforcement. This methodology enables the creation of highly customized CFRTP geometries with complex designs, optimizing costs and flexibility when compared to conventional production methods. Furthermore, the technology is easily scalable for large-scale manufacturing. In the study, a finite element analysis (FE) model was developed to predict temperature distribution in the CFRTP structure during the laser-assisted 3D printing process. This model proves valuable in optimizing the technique for various structural composites. To summarize, this technology offers the capability to produce components of varying sizes, ranging from small to large, making it highly advantageous for large-scale commercial production. With its process flexibility and the ability to construct strong and lightweight structures, this technology holds significant potential across diverse industries, including aerospace, automotive, marine, and civil engineering, where automation can effectively reduce costs and waste.

The efforts made by research to advance the development of additive manufacturing technologies in the field of continuous carbon fiber composites are an example of how important this technology is for the evolution of production systems. Many studies have focused on the analysis of the mechanical properties of the structures obtained with the aforementioned technology [14][15][16][17][18][19]. The discussion proceeds by analyzing more specifically the mechanical properties of thermoplastic composites containing continuous carbon fiber. Melenka et al., 2016 [20] carried out a study with the aim of evaluating the elastic properties of fiber-reinforced 3D-printed structures and predicting these elastic properties using a stiffness averaging (VAS) method. In the study in question, the tensile properties of 3D-printed and fiber-reinforced components produced by the “MarkOne” 3D printer were evaluated. The specimens studied in this work were produced by varying the volume fraction of the fibers within the 3D-printed structures (4.04, 8.08, and 10.1%, respectively). The experimentally determined modulus of elasticity was found to be 1767.2, 6920.0, and 9001.2 MPa for fiber volume fractions of 4.04%, 8.08%, and 10.1%, respectively. The predicted elastic modules were found to be 4155.7, 7380.0, and 8992.1 MPa. The model results differed from the experiments by 57.5%, 6.2%, and 0.1% for the respective fiber volume fractions. The test results showed that an increase in the volume of fiber reinforcement leads to an increase in the stiffness and ultimate strength of the test specimens. Furthermore, there are numerous works that aim to correlate the mechanical properties with the production process [21][22][23], this objective is fundamental in the technological development of this technique, as the cause–effect relationship between production methodology and finished product is essential. An example of how printing parameters can impact performance is seen in the interlaminar behavior of print products. The adhesion between layers is fundamental in continuous 3D printing of carbon fiber as it represents the weak point of this technology. This adhesion has been analyzed in various works [24][25] and is believed to be related to certain printing parameters. Tian et al., 2016 [26] researched an innovative manufacturing process based on 3D printing of continuous fiber-reinforced thermoplastic composites (CFRTPC). In this printing process, continuous carbon fiber filaments and PLA were used as the matrix, respectively, they were simultaneously fed into the fused deposition additive manufacturing (FDM) process. It has been found that temperature and pressure are fundamental parameters for the printing process, determining the final mechanical properties of the composites. A systematic investigation was conducted into the influence of printing parameters on the interfaces and performance of printed composites. Complete impregnation of the thermoplastic materials in the fiber bundle was achieved when the polymer temperature was between 200 and 230 °C. The strength of the bond between the various layers could be guaranteed with a layer thickness of between 0.4 mm and 0.6 mm. With optimized process parameters, 3D-printed CFR PLA composites with a fiber content of 27% can achieve maximum flexural strength of 335 MPa and a flexural modulus of 30 GPa. It is also relevant to examine the behavior of thermoplastic and continuous fiber components in relation to impact resistance. The study of Caminero et al., 2018 [27] deals with continuous fiber-reinforced thermoplastic composites 3D printed using fused deposition modeling (FDM) technology. The text highlights the importance of FDM as a promising additive manufacturing technology for composites and the rise of continuous fiber-reinforced thermoplastic composites in industrial applications due to their excellent mechanical performance and recyclability characteristics. One of the main objectives of the study is to analyze the effect of impact damage on the structural integrity of 3D-printed composites compared to traditional prepreg composites. In particular, the build orientation, layer thickness, and volumetric content of the fibers are examined. The results indicate that build orientation and layer thickness affect impact resistance differently for flat and vertical specimens, with more brittle fracture in vertical specimens. The overall results reveal that, in some cases, 3D-printed composites significantly outperform traditional 3D-printed thermoplastic materials and can be compared to conventional prepreg materials in terms of impact resistance. To end this section, it is important to underline that continuous carbon fibers are not the only ones subjected to research and capable of obtaining excellent results in the additive production of long fiber composites. Continuous glass fibers constitute a valid alternative, from the point of view of mechanical properties, compared to continuous carbon fibers [28][29][30][31].

3. 3D-Printed Short Carbon Fiber-Reinforced Composites

Various studies have evaluated an innovative family of technologies for the production of short fiber-reinforced components [32][33][34][35][36], expanding the options available to designers. Fiber-reinforced AM composites are characterized by the fact that various process-related parameters, such as the amount of reinforcing fiber or the printing architecture, can predominantly influence the tensile properties of the final parts [37]. To optimize the production of components made using these new AM technologies [38], an extensive preparatory phase of studies is needed to lay the guidelines for the design of fiber-reinforced 3D-printed parts. It is precisely necessary to evaluate the effects that the different geometric parameters have on the tensile properties of 3D-printed composites produced using the filament fusion (FFF) technique. In this section, both the production technologies of short fiber composites using AM and the mechanical characteristics will be presented together. This choice lies in the fact that, unlike additive manufacturing which involves long fiber products, the additive manufacturing of short fiber composites does not present too many complexities regarding the architecture of the machine, as the operation is essentially that of a classic FDM machine that prints only polymer.

Ferreira et al., 2017 [39] characterized materials produced at a mechanical level through FDM additive manufacturing techniques, using PLA and PLA+CF or PLA reinforced with short carbon fibers with a percentage of 15%. The chosen approach considers materials as orthotropic layered structures with specific orientations. The mechanical properties examined are as follows: strength modulus (E1 and E2), Poisson’s ratios (n12 and n21), shear modulus (G12), as well as tensile strength (S1 and S2) and shear strength (S12). The testing was carried out on samples with unidirectional arrangements or specific orientations. The results highlight a significant increase in stiffness in the printing direction (E1) for PLA+CF, with an increase of approximately 2.2% compared to PLA. A 25% improvement in transverse strength modulus (E2) and 16% improvement in shear modulus (G12) was detected. Furthermore, the fibers contribute to diversifying the Poisson’s ratios (n12 is 2.5 times higher than n21) in PLA+CF, in line with the increase in stiffness in the printing direction. However, the tensile strength (S1 and S2) and the shear strength (S12) do not undergo significant changes due to the addition of fibers. Another aspect to consider is the length of the carbon fibers, estimated at 60 µm, which may be insufficient to make significant improvements in strength properties. Furthermore, the limited adhesion between PLA and carbon fibers appears to contribute to the greater fragility of the reinforced material. SEM analysis reveals how the short carbon fibers in the PLA+CF composite are mainly aligned with the printing direction, explaining the notable increase in stiffness in this direction.

In a study on the fabrication of thermoplastic matrix CFRP composites using the fused deposition modeling (FDM) technique, Ning et al., 2015 [40] studied the impact of the addition of carbon fibers on the mechanical properties of the samples. The main results are reported below. The addition of carbon fibers to plastic materials resulted in an increase in tensile strength and Young’s modulus; on the other hand there was a decrease in toughness, yield strength, and ductility. The samples with a percentage of 5% by weight of carbon fibers showed on average the highest tensile strength values, with an increase of 22.5%. At the same time, samples with 7.5 wt% carbon fibers showed the highest average values of Young’s modulus, with an increase of 30.5%. Samples with 150 µm length carbon fibers demonstrated higher tensile strength and Young’s modulus than those with 100 µm length carbon fibers. However, they showed lower toughness and ductility, without significant differences in yield strength. Compared to samples composed solely of thermoplastic polymers, CFRP composite samples with a 5% weight percentage of carbon fibers presented higher flexural strength, flexural modulus, and flexural toughness, with increases of 11.82%, 16.82%, and 21.86%, respectively. Furthermore, it was found that increasing the percentage of carbon fibers to 10 wt% led to an increase in porosity in the samples, resulting in a decrease in the average values of tensile strength, toughness, yield strength, and ductility.

Papon et al., 2019 [41] evaluated the fracture properties (stress intensity factor and energy release rate) of materials produced by FDM 3D printing using polylactic acid (PLA) and composites reinforced with short carbon fibers (CF). The goal was to understand how CF reinforcement, nozzle conformation, and bead orientation influenced fracture characteristics, void contents, and inter-material adhesion. During the study, samples made using the filament fusion (FFF) manufacturing technique using circular and square nozzles were compared with traditional samples manufactured using compression printing (CM). Compact tension (CT) samples with different CF concentrations (0%, 3%, 5%, 7%, and 10%) were produced with two layering orientations (45 degrees/−45 degrees and 0 degrees/90 degrees) using PLA filaments and CF/PLA composites. The results demonstrated that CF/PLA composites exhibited a significant increase in fracture toughness and higher fracture energy compared to pure PLA. At 5% CF, fracture toughness increased by 42% for the 0 degree/90 degree bead orientation and by 38% for the 45 degree/−45 degree orientation. Fracture energy increased by 77% for the 0 degree/90 degree orientation and by 88% for the 45 degree/−45 degree orientation with the same fiber concentration. In addition, samples made with square-shaped nozzles exhibited higher fracture toughness with fewer bead gaps and larger bond areas compared to circular nozzles. It was also observed that the fibers were mainly aligned along the beads produced due to the FFF process. In terms of fracture mechanism, the 0 degree/90 degree orientation saw a greater contribution from the 90 degree curbs, while the 45 degree/−45 degree orientation saw contributions from both the 45 degree and −45 degrees. However, no improvement in fracture characteristics was observed with higher fiber concentrations (7% and 10%). This was attributed to void spaces within the beads, microcracks, a weak bond between the fibers and the PLA matrix, and void spaces around the surface of the fibers. To address these issues, proper surface treatment of the fibers, use of appropriate sizing agents prior to 3D printing, and annealing to reduce internal bead void spaces and improve the interface between the fibers and the matrix are recommended. In summary, the study highlighted the important role of carbon fiber reinforcement, nozzle geometry and, bead orientation on the fracture characteristics of materials produced with 3D printing, underlining the opportunity for further research to optimize these parameters and improve the performance of the materials. It can be seen from the various studies analyzed that the study of composites of thermoplastic matrix and short carbon fibers, produced using additive manufacturing techniques, is fundamental for the evolution of this technology, as the performance of the finished products is strictly correlated with a series of parameters production characteristics characteristic of 3D printing. The parameters capable of influencing the final characteristics of this type of composites are not easy to identify and numerous works have attempted to identify and study them in order to optimize the processes [42][43][44][45].

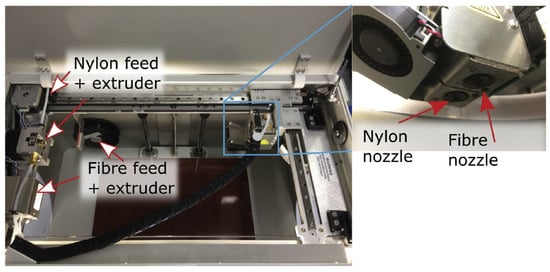

Blok et al., 2018 [46] examined 3D printing compositional blends for FFF, where carbon fibers are embedded in a thermoplastic matrix in order to increase its strength and stiffness (see Figure 4).

Figure 4. Overview of the MarkOne printer with the dual nozzle system to print nylon filament and fiber filament ([46], reproduced under a CC BY 4.0 license).

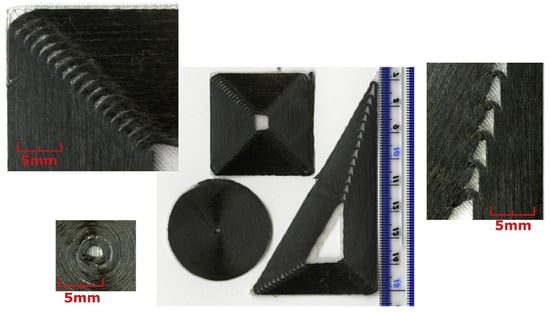

Experimental research was conducted to compare blends with short fibers and blends with continuous fibers (see Figure 5). Printing continuous carbon fibers using the “Mark One” printer was found to result in significant performance improvements over unreinforced thermoplastics, with mechanical properties of a similar magnitude to typical unidirectional epoxy matrix composites.

Figure 5. Benchmark prints for Mark One printer with detail of corner radii ([46], reproduced under a CC BY 4.0 license).

However, the method has limitations in design freedom, as the fragile continuous carbon fibers cannot be deposited smoothly through small bending radii and sharp corners.

Filaments with embedded carbon microfibers of short length (approximately 100 μm) demonstrate improved printing capabilities and are suitable for use with standard printing methods but offer only a modest increase in mechanical properties compared to purely thermoplastic characteristics. The hypothesis is formulated that increasing the length of the fibers in filaments with short fibers can lead to an increase in mechanical properties, potentially approaching those of composites with continuous fibers, while maintaining the high degree of freedom in the design of the process itself (FFF). The performance of two of the currently most advanced solutions was evaluated through mechanical tests. The tensile strength and stiffness of parts printed with continuous fibers were 986 MPa and 64 GPa, respectively, more than an order of magnitude higher than parts printed with short fiber-reinforced filaments (33 MPa and 1.9 GPa). A disadvantage of the continuous fiber printer, however, is limited control over the position of the fibers and the formation of voids when printing more complex shapes.

To combine the advantages of both techniques, many studies have been carried out to optimize AM processes of composite materials capable of using both continuous fiber and short carbon fiber as reinforcement. The influence on the variation in parameters, such as infill density and infill patterns for short fiber composite material, as well as fiber volume fraction and printing architecture of continuous fiber-reinforced (CFR) composites, was investigated. The influence of the position of the initial point of deposition of the reinforcing fibers on the tensile properties of the test samples was studied. Furthermore, the influence of the fiber deposition pattern on the tensile performance was quantified [47][48][49].

This entry is adapted from the peer-reviewed paper 10.3390/ma16237311

References

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A Critical Review of Fused Deposition Modeling 3D Printing Technology in Manufacturing Polylactic Acid Parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889.

- Muflikhun, M.A.; Syahril, M.; Mamba’udin, A.; Santos, G.N.C. A Novel of Hybrid Laminates Additively Manufactured via Material Extrusion—Vat Photopolymerization. J. Eng. Res. 2023, 100146.

- Nugraha, A.D.; Ruli; Supriyanto, E.; Rasgianti; Prawara, B.; Martides, E.; Junianto, E.; Wibowo, A.; Sentanuhady, J.; Muflikhun, M.A. First-Rate Manufacturing Process of Primary Air Fan (PAF) Coal Power Plant in Indonesia Using Laser Powder Bed Fusion (LPBF) Technology. J. Mater. Res. Technol. 2022, 18, 4075–4088.

- Nugraha, A.D.; Syahril, M.; Muflikhun, M.A. Excellent Performance of Hybrid Model Manufactured via Additive Manufacturing Process Reinforced with GFRP for Sport Climbing Equipment. Heliyon 2023, 9, e14706.

- Naranjo-Lozada, J.; Ahuett-Garza, H.; Orta-Castañón, P.; Verbeeten, W.M.H.; Sáiz-González, D. Tensile Properties and Failure Behavior of Chopped and Continuous Carbon Fiber Composites Produced by Additive Manufacturing. Addit. Manuf. 2019, 26, 227–241.

- Zhang, Y.; Qiao, J.; Zhang, G.; Li, Y.; Li, L. Prediction of Deformation and Failure Behavior of Continuous Fiber Reinforced Composite Fabricated by Additive Manufacturing. Compos. Struct. 2021, 265, 113738.

- Kabir, S.M.F.; Mathur, K.; Seyam, A.F.M. A Critical Review on 3D Printed Continuous Fiber-Reinforced Composites: History, Mechanism, Materials and Properties. Compos. Struct. 2020, 232, 111476.

- Rafiei, J.; Ghasemi, A.R. A Brief Review on Three-Dimensional Printed Continuous Fiber-Reinforced Polymer Composites. Polym. Sci. Q. 2021, 11, 44–60.

- Yang, C.; Tian, X.; Liu, T.; Cao, Y.; Li, D. 3D Printing for Continuous Fiber Reinforced Thermoplastic Composites: Mechanism and Performance. Rapid Prototyp. J. 2017, 23, 209–215.

- Valvez, S.; Santos, P.; Parente, J.M.; Silva, M.P.; Reis, P.N.B. 3D Printed Continuous Carbon Fiber Reinforced PLA Composites: A Short Review. Procedia Struct. Integr. 2020, 25, 394–399.

- Li, N.; Li, Y.; Liu, S. Rapid Prototyping of Continuous Carbon Fiber Reinforced Polylactic Acid Composites by 3D Printing. J. Mater. Process. Technol. 2016, 238, 218–225.

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-Dimensional Printing of Continuous-Fiber Composites by in-Nozzle Impregnation. Sci. Rep. 2016, 6, 23058.

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and Remanufacturing of 3D Printed Continuous Carbon Fiber Reinforced PLA Composites. J. Clean. Prod. 2017, 142, 1609–1618.

- Saeed, K.; McIlhagger, A.; Harkin-Jones, E.; McGarrigle, C.; Dixon, D.; Shar, M.A.; McMillan, A.; Archer, E. Characterization of continuous carbon fibre reinforced 3D printed polymer composites with varying fibre volume fractions. Compos. Struct. 2022, 282, 115033.

- Li, L.; Liu, W.; Sun, L. Mechanical Characterization of 3D Printed Continuous Carbon Fiber Reinforced Thermoplastic Composites. Compos. Sci. Technol. 2022, 227, 109618.

- Uşun, A.; Gümrük, R. The Mechanical Performance of the 3D Printed Composites Produced with Continuous Carbon Fiber Reinforced Filaments Obtained via Melt Impregnation. Addit. Manuf. 2021, 46, 102112.

- Araya-Calvo, M.; López-Gómez, I.; Chamberlain-Simon, N.; León-Salazar, J.L.; Guillén-Girón, T.; Corrales-Cordero, J.S.; Sánchez-Brenes, O. Evaluation of Compressive and Flexural Properties of Continuous Fiber Fabrication Additive Manufacturing Technology. Addit. Manuf. 2018, 22, 157–164.

- Justo, J.; Távara, L.; García-Guzmán, L.; París, F. Characterization of 3D Printed Long Fibre Reinforced Composites. Compos. Struct. 2018, 185, 537–548.

- Mohammadizadeh, M.; Imeri, A.; Fidan, I.; Elkelany, M. 3D Printed Fiber Reinforced Polymer Composites—Structural Analysis. Compos. B Eng. 2019, 175, 107112.

- Melenka, G.W.; Cheung, B.K.O.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation and Prediction of the Tensile Properties of Continuous Fiber-Reinforced 3D Printed Structures. Compos. Struct. 2016, 153, 866–875.

- Zhang, J.; Zhou, Z.; Zhang, F.; Tan, Y.; Tu, Y.; Yang, B. Performance of 3D-Printed Continuous-Carbon-Fiber-Reinforced Plastics with Pressure. Materials 2020, 13, 471.

- Chacón, J.M.; Caminero, M.A.; Núñez, P.J.; García-Plaza, E.; García-Moreno, I.; Reverte, J.M. Additive Manufacturing of Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling: Effect of Process Parameters on Mechanical Properties. Compos. Sci. Technol. 2019, 181, 107688.

- He, Q.; Wang, H.; Fu, K.; Ye, L. 3D Printed Continuous CF/PA6 Composites: Effect of Microscopic Voids on Mechanical Performance. Compos. Sci. Technol. 2020, 191, 108077.

- Liu, T.; Tian, X.; Zhang, M.; Abliz, D.; Li, D.; Ziegmann, G. Interfacial Performance and Fracture Patterns of 3D Printed Continuous Carbon Fiber with Sizing Reinforced PA6 Composites. Compos. Part. A Appl. Sci. Manuf. 2018, 114, 368–376.

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Reverte, J.M. Interlaminar Bonding Performance of 3D Printed Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling. Polym. Test. 2018, 68, 415–423.

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and Performance of 3D Printed Continuous Carbon Fiber Reinforced PLA Composites. Compos. Part. A Appl. Sci. Manuf. 2016, 88, 198–205.

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Rodríguez, G.P. Impact Damage Resistance of 3D Printed Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling. Compos. B Eng. 2018, 148, 93–103.

- Mosleh, N.; Dariushi, S.; Esfandeh, M. An Experimental and Numerical Investigation on Mechanical Properties of 3D Printed Continuous Glass Tow Preg-Reinforced Composites. Rapid Prototyp. J. 2022, 28, 1284–1296.

- Chabaud, G.; Castro, M.; Denoual, C.; Le Duigou, A. Hygromechanical Properties of 3D Printed Continuous Carbon and Glass Fibre Reinforced Polyamide Composite for Outdoor Structural Applications. Addit. Manuf. 2019, 26, 94–105.

- Wang, Y.; Lyu, C.; Zhang, Q.; Li, W.; Liu, J. Preparation and Performance Index Test of Continuous Glass Fiber Reinforced Filament- Polylactic Acid for 3D Printer. J. Phys. Conf. Ser. 2021, 1906, 012053.

- Fernandes, R.R.; Tamijani, A.Y.; Al-Haik, M. Mechanical Characterization of Additively Manufactured Fiber-Reinforced Conposites. Aeosp. Sci. Tecnol. 2021, 113, 106653.

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. B Eng. 2017, 110, 442–458.

- Yavas, D.; Zhang, Z.; Liu, Q.; Wu, D. Fracture Behavior of 3D Printed Carbon Fiber-Reinforced Polymer Composites. Compos. Sci. Technol. 2021, 208, 108741.

- Parandoush, P.; Lin, D. A Review on Additive Manufacturing of Polymer-Fiber Composites. Compos. Struct. 2017, 182, 36–53.

- Ismail, K.I.; Yap, T.C.; Ahmed, R. 3D-Printed Fiber-Reinforced Polymer Composites by Fused Deposition Modelling (FDM): Fiber Length and Fiber Implementation Techniques. Polymers. 2022, 14, 4659.

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused Filament Fabrication of Fiber-Reinforced Polymers: A Review. Addit. Manuf. 2018, 21, 1–16.

- van de Werken, N.; Tekinalp, H.; Khanbolouki, P.; Ozcan, S.; Williams, A.; Tehrani, M. Additively Manufactured Carbon Fiber-Reinforced Composites: State of the Art and Perspective. Addit. Manuf. 2020, 31, 100962.

- Nawafleh, N.; Celik, E. Additive Manufacturing of Short Fiber Reinforced Thermoset Composites with Unprecedented Mechanical Performance. Addit. Manuf. 2020, 33, 101109.

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental Characterization and Micrography of 3D Printed PLA and PLA Reinforced with Short Carbon Fibers. Compos. B Eng. 2017, 124, 88–100.

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive Manufacturing of Carbon Fiber Reinforced Thermoplastic Composites Using Fused Deposition Modeling. Compos. B Eng. 2015, 80, 369–378.

- Papon, E.A.; Haque, A. Fracture Toughness of Additively Manufactured Carbon Fiber Reinforced Composites. Addit. Manuf. 2019, 26, 41–52.

- Goh, G.D.; Yap, Y.L.; Agarwala, S.; Yeong, W.Y. Recent Progress in Additive Manufacturing of Fiber Reinforced Polymer Composite. Adv. Mater. Technol. 2019, 4, 1800271.

- Kabir, S.M.F.; Mathur, K.; Seyam, A.F.M. The Road to Improved Fiber-Reinforced 3D Printing Technology. Technologies 2020, 8, 51.

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly Oriented Carbon Fiber-Polymer Composites via Additive Manufacturing. Compos. Sci. Technol. 2014, 105, 144–150.

- Al Abadi, H.; Thai, H.T.; Paton-Cole, V.; Patel, V.I. Elastic Properties of 3D Printed Fibre-Reinforced Structures. Compos. Struct. 2018, 193, 8–18.

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K.S. An Investigation into 3D Printing of Fibre Reinforced Thermoplastic Composites. Addit. Manuf. 2018, 22, 176–186.

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529.

- Peng, Y.; Wu, Y.; Wang, K.; Gao, G.; Ahzi, S. Synergistic Reinforcement of Polyamide-Based Composites by Combination of Short and Continuous Carbon Fibers via Fused Filament Fabrication. Compos. Struct. 2019, 207, 232–239.

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D Printing of Fibre-Reinforced Thermoplastic Composites Using Fused Filament Fabrication-A Review. Polymers 2020, 12, 2188.

This entry is offline, you can click here to edit this entry!