Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Food Science & Technology

In an increasingly resource-constrained era, using waste and by-products from grain processing has a wide appeal. This is due to the nutritive value and economic aspects of this process and due to its compatibility with the trend towards more sustainable food systems.

- grain waste

- grain by-products

- food industry

- product quality assurance

1. Introduction

In the era of anthropogenic waste generation, an exponential increase in the need to fulfill the nutritional basics of humans has prompted the scientific community to study emerging themes and hot issues regarding this global challenge [1,2,3,4,5,6].

Worldwide, the human diet is supported by staple cereals obtained from seeds of the Gramineae family, such as wheat (Triticum spp.), corn or maize (Zea spp.), barley (Hordeum spp.), rice (Oryza spp.), rye (Secale spp.), oat (Avena spp.), millet (Pennisetum spp.), sorghum (Sorghum spp.), and a hybrid of wheat and rye, namely, triticale (Triti-cosecale Wittmack). Cereal grains contribute significantly to the global food pool in terms of global food security and nutrition. Most cereals are a staple source for various amounts of proteins, fats, minerals, and vitamins and are an important provider of dietary energy [7]. In total, the percentage of dietary energy provided by cereals appears to have remained relatively the same over time, representing about 50% of dietary energy supply [8,9]. Worldwide, for over one billion people, maize is a staple, and its grain energy contribution to the diet can exceed 50% [7]. In second place, in terms of cultivated area and human consumption, wheat represents almost 20% of the total dietary calories and proteins globally [10]. Rice contributes 20% of global calories and is an important source of minerals and vitamins. Bran contains bioactive phytochemicals and essential food components [11].

Worldwide, corn is the most cultivated and used plant, constituting a basic ingredient in many gastronomic cultures in addition to being important in animal feed, the production of biofuel, and many other industrial uses. As a staple food, it is estimated that its production is over 1136.3 million metric tons (from September 2020 to August 2021), which is much more than wheat production (776.8 million metric tons) or rice production (504.4 million metric tons) [12]. In the latest revised global forecast, according to the FAO, the total production of cereals in 2022 was 2774 million tons, 1.3% less than the previous year [13].

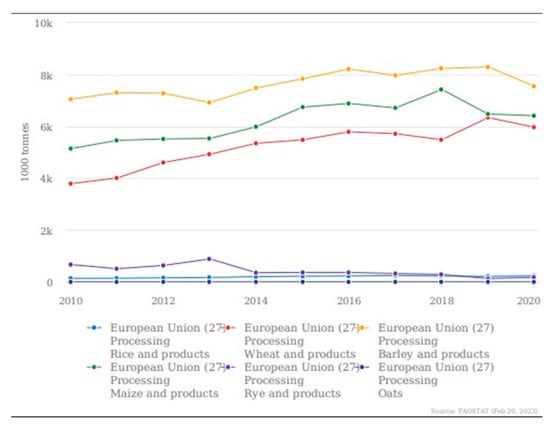

The forecast for global cereal utilization in 2022/23 is 2780 million tons. This indicates a decline of 0.6% from the 2021/22 level but is greater than the total cereal production of 2022 [13]. One of the reasons that triggered the bibliographic research is the fact that, according to the latest data published by the FAO in March 2023, this excess of cereal consumption—more than the quantity produced, the demand, and the reserve—was predicted. Therefore, under the conditions of an increased demand for resources to feed a continuously growing population, solutions must be sought for the use of all natural sources, making the most of their potential. With this desire, the United Nations established, in 2015, the Sustainable Development Goal (SDG) 12, to “Ensure sustainable consumption and production patterns”. Target 12.3, which refers to food waste, stipulates that by 2030, per capita global food waste at the retail and consumer levels will be halved, and food losses from the production flow will be reduced along with those from the supply chains, including post-harvest losses. The European Commission considers food waste as a priority area in order to achieve the Sustainable Development Goal target in agreement with the European Circular Economy Action Plan [14]. In addition, the European Commission amended the Waste Framework Directive 2008/98/EC, establishing as mandatory the monitoring and reporting of food waste by member states to create a baseline for monitoring the achievement of food waste reduction objectives and help identify relevant food waste streams to be utilized in a circular economy perspective [14,15,16,17]. In the European Union, the main grains processed from 2010 to 2020 were wheat, maize, rice, rye, barley, oats, and their related products. Figure 1 shows the quantity of each.

Figure 1. Processing of wheat, maize, rice, rye, barley, oats, and related products in the European Union (27 member states). Source: compiled by authors, based on FAOSTAT online database, 20 February 2023.

Grain processing must and can be a sustainable option to convert waste and by-products into value-added resources for the food industry and for their valorization under the circular economy (CE) concept. Innovative methods, on an industrial scale, for the recovery of food waste—instead of its disposal—must be developed in agreement with CE concepts. Currently, only conventional methods are applied on an industrial scale, providing animal feed, biofuel production, or aerobic/anaerobic treatments, which represents only a partial utilization of cereal processing waste [18,19,20,21,22].

2. Added-Value Compounds for Food Industry

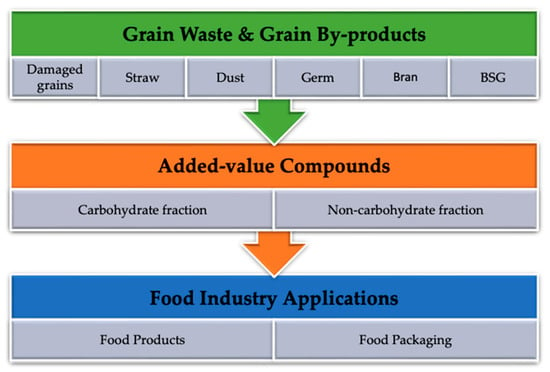

Grain processing wastes and by-products can not only be directly incorporated into food products but can also be used for the extraction of value-added compounds that can be introduced into the food industry production process as functional food ingredients, as shown in Figure 2.

Figure 2. Schematic diagram showing food industry applications of added-value compounds from grain waste and grain by-products (original source).

The treatment of cereal industrial wastes uses physicochemical and biological methods at high conversion costs [20,94,95]. Therefore, the extraction and use of these valuable compounds are less frequent on an industrial scale in the food industry and more frequent in biorefineries for conversion into fuel as a renewable source of energy. Currently, cereal by-products have been linked to health promotion due to their rich content of fiber, minerals, vitamins, phenolic compounds, phytosterols, policosanols, and other phytochemicals responsible for reducing oxidative stress and mediating the inflammatory process and excretion and absorption of lipids [42]. For this reason, researches related to the recovery of the biological compounds from grain processing waste and by-products also address to the benefits brought to the improvement of products in the food industry.

2.1. Carbohydrate Fraction

The grain processing chain generates significant amounts of waste known as lignocellulosic biomass [14,96]. Grain wastes that include carbohydrate fractions, especially hemicelluloses, are bran, straw, and hulls/husks.

Of total agricultural waste, 20–35% is hemicellulose, a dietary fiber that represents the most promising source for valuable applications [97]. Industrial-scale applications of hemicelluloses are still underutilized at this point [98]. Hemicellulose demonstrates excellent properties, including biodegradability, biocompatibility, and bioactivity, which also enable it to be applied in the food industry [99], as presented in Table 1.

Beta-glucans and arabinoxylans from cereals make them valuable components of dietary fibers. Because of high processing costs, there is a limited use of pure preparations of beta-glucans as a food ingredient; instead, the use of bulk fractions and the use of novel separation and purification processes may bring effective solutions [29]. The extraction of hemicelluloses (such as arabinoxylans and β-glucans) from the cell walls and from fractionation and purification can be used in various food applications. The extraction process is possible through four main types of methods: water extraction, which can be carried out at low or high temperatures, chemical extraction (with acids, alkalis, or organic solvents), specific enzymes’ extraction, or mechanical treatments (microwave, ultrasound, extrusion) [97,100]. Herrera-Balandrano et al. demonstrated that it is possible to add impure hemicellulose fractions to food products to improve sensory and chemical properties; for example, according to a study, the addition of 0.15% and 0.30% nixtamalized corn bran can increase the antioxidant capacity, phenolic content, and physicochemical properties of Frankfurter sausages [101].

Table 1. Applications of carbohydrate fractions from grain by-products and waste in the food industry.

| Grain By-Product/Waste |

Carbohydrate Fraction | Food Industry Applications | Source |

|---|---|---|---|

| Wheat bran Rye bran BSG * |

Cellulose | Improving sensory and chemical properties of food products | [26,101,102,103,104,105,106] |

| Cereal bran | Arabinoxylans | Packaging materials (films) Thickening and stabilizing agent in the food industry |

[102,106,107,108,109] |

| Wheat bran Corn bran BSG * |

Lignin | Emulsifying stability; dispersing and binding agent | [26,102,103,106,109,110,111] |

| Oat bran BSG * |

Beta-glucans | Wheat flour substitutes Improve beverage satiety Food hydrocolloids |

[26,102,112,113] |

| BSG * | Residual undigested starch | Prebiotic ingredients for the meat industry | [26,112,114,115] |

| Wheat bran | Lactic and succinic acids | Acidulant, flavoring, preservative agent in the food industry | [116] |

| Wheat germ | Linoleic acid, | Food ingredient with potential health benefits | [117,118,119] |

| Corn germ | palmitic acid, | Commercial shortening replacement in food industries | |

| Rye bran | oleic acid | Food-grade ingredient | |

| Wheat germ Rye bran |

Linolenic acid | Food-grade ingredient | [117,119] |

| Corn germ | Stearic acid | Commercial shortening replacement in food industries | [118] |

Organic acid (linoleic, linolenic, palmitic, oleic, stearic, lactic, and succinic acids), another carbohydrate fraction, is obtained by fermentative production and is used as an acidulant, flavoring agent, or preservative in the food industry, as depicted in Table 1.

Carbohydrate fractions from cereal processing by-products and waste can also be an important source for the food packaging industry due to the lignocellulosic materials that they contain, which can be utilized as low-cost substrates for the production of PHA-polyhydroxyalkanoates [94] and PHB-poly-3-hyrdroxybutyrate (Table 2). Enzymatic actions transform the lignocellulosic material in fermentable sugars and then the material is fermented by different bacteria (Enterococcus, Lactobacillus, Leuconostoc, and Streptococcus) and fungi (Rhizopus Monilina and Mucor) [94,120]. The first report of biopolymer production from mild acid-pretreated rice straw (using Bacillus firmus NII 0830) [121] emphasized the possibility of the replacement of petrochemical-derived plastics by the biopolymer poly-3-hydroxybutyrate (PHB). Maximum PHB production was 1.697 g/L from 1.9 g/L biomass; the highest value (89% of biomass) was reported from Bacillus species. And yet, the high operational cost of this PHA is a big disadvantage in industrial production and commercialization [94,122].

Table 2. Applications of carbohydrate fractions from grain by-products and waste in food packaging.

| Grain By-Product/Waste |

Carbohydrate Fraction | Food Packaging Applications | Source |

|---|---|---|---|

| Wheat bran Wheat straw Rice straw Oat husk |

Cellulose | PHA *, PHB ** Paper sheet Reinforcing agent for biocomposites in packaging Edible film |

[26,121,122,123,124] |

| Wheat bran | Lactic acid | Packaging, films, and edible coatings with PLA *** |

[26,125,126,127,128] |

2.2. Non-Carbohydrate Fraction

The food industry mainly exploits the non-carbohydrate fraction represented by proteins and phenolic compounds extracted from grain processing waste and by-products (Table 3).

Table 3. Applications of non-carbohydrate fraction from grain by-products/waste in the food industry.

| Grain By-Product/Waste |

Non-Carbohydrate Fraction | Food Industry Applications | Source |

|---|---|---|---|

| BSG * Wheat bran concentrate Wheat germ (raw, defatted, thermally treated) Defatted corn germ Defatted oat bran Defatted Rice bran Malted barley germs |

Protein | Texture improvers and food additives Enriching food products showed excellent functional properties in terms of high solubility, good water, and fat absorption capacity Good vegetable protein supplement for cereal-based diets Strong antioxidant activity in food |

[29,60,61,62,63,64,129,130,131,132,133,134,135,136,137,138,139,140] |

| Cereal (wheat, rice, oat) bran | Phenolic compounds |

Functional food ingredient Additives to extend the shelf life of food Flavoring |

[96,116,141] |

The protein extracted from corn by-products has a unique structure, molecular shape, and solubility, forming a uniform, transparent, and soft film with good oil and water retention characteristics that make it useful in food preservation [12]. One of the best potential sources of vegetable protein for the food industry is brewer’s spent grain, due to its high protein content, which represents about 20% in dry matter [142]. The food industry can benefit from the use of protein hydrolysates as texture improvers and food additives [129]. Considering the importance of these added-value compounds for the food industry, many studies have concentrated on efficient extraction techniques such as alkaline extraction [132], enzyme-assisted extraction [134], microwave-assisted enzymatic extraction [135,143], and sequential aqueous and alkaline (110 mM NaOH) extraction followed by isoelectric precipitation (pH 3.8), [136] and sodium hydroxide (110 mM) and ultrasound treatment (power 250 W, duty cycle 60%, 20 min/25 °C) [137].

Phenolic compounds can be found mainly in bran, so after its separation from the grain, an extraction process is required. The extraction of polyphenols from cereal by-products can be carried out with various techniques: acid and alkaline hydrolysis [144,145], ultrasound assisted extraction [89,146] microwave-assisted extraction [147], extraction with supercritical carbon dioxide [148], extraction by steam explosion treatment of grain by-products [149], and enzymatic hydrolysis [150]. Wheat and oat bran contain the main phenolic compounds, represented by phenolic acids (ferulic acid, caffeic acid, vanillic acid, p-coumaric acid, dihydroxybenzoic acid, and avenanthramide) and flavonoid subclasses [151]. In rye bran, the most important phenolic compounds (for antioxidant activity) include the group represented by p-hydroxybenzoic acid and its derivatives (especially vanillic and syringic acid) and the group represented by p-coumaric acid and its derivatives (ferulic and caffeic acid) [152]. Phenolic acids, as antioxidant compounds recovered from grain waste and by-products, are used in the food industry as additives to extend the shelf life of food [96]. Vanillin from ferulic acid through biotechnical processes is very often used as a flavoring in the food industry [116].

This entry is adapted from the peer-reviewed paper 10.3390/foods12203770

This entry is offline, you can click here to edit this entry!