Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Mee (Madhuca longifolia (Koenig) J.F. Macb. var. longifolia) is a salient economic tree spread throughout the subtropical region of the Indian subcontinent. Its seed constituents have distinctive chemical properties and thus extracted fat have distinctive nutritional and functional characteristics.

- Mee seed

- fat

- phytochemistry

1. Introduction

Mee (Madhuca longifolia (Koenig) J.F. Macb. var. longifolia) tree, also known as buttercup tree, is a forest tree distributed throughout the sub-tropical region of the Indian subcontinent. It belongs to genus Madhuca and has been represented by five species in the Indian subcontinent. They are Madhuca longifolia (Koenig) J.F. Macb. var. longifolia, Madhuca latifolia, Madhuca butyracea, Madhuca nerifolia and Madhuca bourdillonii. The most prevalent species of Madhuca are M. longifolia, M. latifolia and M. butyracea [1]. The study mainly focuses on the M. longifolia species. The tree Madhuca longifolia (Koenig) J.F. Macb. var. longifolia (synonymous with Madhuca indica Gmelin) belongs to the family Sapotaceae. People in Sri Lanka call it “Mee” in Sinhala language and “Illuppu” in Tamil language. According to Indian research studies, this tree has an important economic value in India, due to widespread uses of its seeds, fruits and flowers (Figure 1). Madhuca longifolia provides a solution for the three major “Fs”, namely as food, forage and fuel. Furthermore, Mee contains high amounts of phytochemicals and oils which can be used to develop nutritional and pharmaceutical products. Mee tree has a good potential for food and non-food applications [2]. There is a number of research studies available on the biology, phytochemical properties, and applications of Mee. According to phytochemical studies, Mee is a rich source of sugar, vitamins, protein, glycosides, alkaloids, tannins, flavonoids, steroids, terpenoids, saponins, and phenolic compounds. Thereby, it shows various pharmacological properties such as anti-inflammatory, antioxidant, analgesic, anti-hyperglycemic, hepatoprotective, anticancer, antiulcer, antitumor, neuro-pharmacological, and dermatological activities [3].

Figure 1. Mee tree (a); flowers (b); fruits (c); seeds (d).

Mee tree is a medium-to-large deciduous forest tree usually with a short trunk and a large, rounded crown. It is a large shady tree 10 m to 15 m in height. These trees are common in dry mixed deciduous forests. The tree can be grown in a wide variety of soil types and it prefers sandy soils. Mee trees can be found up to an altitude of 1200 m. It needs a mean annual temperature of 28–50 °C (maximum) and 2–12 °C (minimum), and an annual rainfall of around 550–1500 mm for proper growth [4][5]. But, Mee can also tolerate drought conditions although it is not a frost-hardy tree. This tree is a strong light demander, and its growth is suppressed under shade. The Mee tree fruits during April–May and the fruits are ovoid in shape and 2–6 cm long. They are fleshy and greenish in color, and contain 1–4 dark brown color seeds per fruit, which are rich sources of edible fat.

The seed collection was usually conducted in the months of May, June, and July. Mee seeds are comprised of quercetin, oleic, linoleic, arachidic, stearic acid, palmitic acid, aspartic acid, isoleucine, leucine, cyst cysteine alanine, proline, threonine, Mi-saponin A and B and myricetin [4]. Whole Mee seeds contain 50–61% of fat, 22% of carbohydrates, 16.9% of protein, 3.4% of ash, 3.2% of fiber, 2.5% of saponins, and 0.5% tannin [3].

Fats and oils are major constituents of a healthy diet. Hence, the consumer demand for natural and healthy edible oils is growing recently. Therefore, it is necessary to research potential edible oil seeds and their edible uses. Plant-based oils contribute to about 85% of the available oil or fat for human consumption, and there are very few plants that produce oils in commercial quantities [3]. Mee seeds produce a valuable amount of seed fat, around 50–60%, and they have the potential to be utilize in many edible and pharmaceutical products. The higher levels of linoleic acid and oleic acid content make Mee fat nutritionally valuable. The tocopherol and sterols present in Mee fat have nutritional importance. Therefore, Mee fat can be utilized to fulfill the demands for nutraceuticals and food supplements with functional, health-promoting properties. Consumers are now focusing on nontoxic plant products which have traditional medical applications [3]. Mee fat can be used for cooking and stir-frying foods and also manufacture chocolates due to its beneficial fatty acid profiles. Other than that, the emulsifying property of Mee fat makes it an emulsifying agent in producing pharmaceutical products [6]. Scientific information on the composition, functional properties, and industrial applications of Mee tree are important to enhance its utilization.

2. Value-Added Products from Mee Fruits and Seeds

2.1. Mee Seed Fat

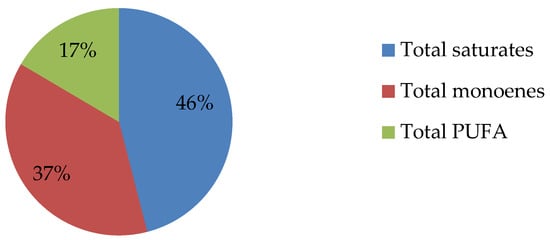

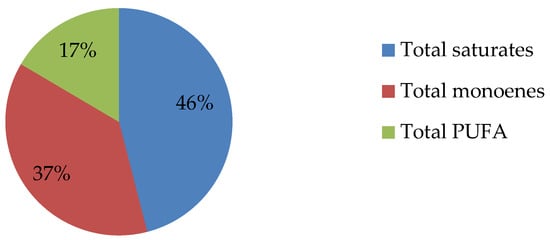

M. longifolia seeds are a novel commercial source of edible fat. Their fat is like a cocoa-like butter. Mee seeds are mechanically crushed to extract the fat and what remains is called the seed cake (Figure 2). Mee fat is light yellow in color and is retained as a semi–solid in tropical temperatures. Based on the iodine value (80 g I2/100 g Mee fat), Mee fat is considered a non-drying fat [3]. In long-term storage, its quality characteristics were deteriorated due to free fatty acid formation during the fat-extraction process. The rancidity of free fatty acids is a serious inhibiting factor for the utilization of Mee fat. The essence of toxic saponins and other lipid associates also leads Mee fat to be treated as a non-edible fat. If the extracted Mee fat was properly purified, it could use for edible purposes. Mee fat has a beneficial fatty acid profile with low saturated fatty acid content [7]. Approximately 250 mL of fat can be extracted from 1 kg of Mee seeds [4]. The seed fat contains 46% saturated fat, 37.4% monounsaturated fat, and 16.5% polyunsaturated fatty acids [3].

Figure 2. Madhuca longifolia seeds (a); seed oil (b); seed cake (c).

Mee’s fat fatty acid profile consists of 21–25% of palmitic acid (16:0), 22–25% of stearic acid (18:0), 36–37% of oleic acid (18:1), 14–16% of linoleic acid (18:2) and 1.3% of arachidic acid (20:0). Sterol fraction consists 0.97% of campesterol, 7.47% of stigmasterol, 64.78% of Β—sitosterol, 9.53% of ∆5—avenasterol, 4.08% of ∆7—stigmasterol and 9.67% ∆7—avenasterol [4]. The use of Mee fat in the food industry has been carried out on a limited scale. According to past reports, applications of this seed fat are limited mostly due to the lack of technical information regarding its properties and potential uses [7]. Semi-solid Mee fat is used in cooking, adulteration of ghee, and manufacturing chocolate. Mee fat could be used to replace hydrogenated fats, because they are free from trans fatty acids [8].

2.2. Defatted Mee Seed Cake

After extracting fat from Mee seeds, the remaining seed portion is called seed cake. It is a rich source of carbohydrates and vegetable proteins. Defatting increased the protein level in seed cake by a low percentage (16.9% to 19.68%). But, it increased the saponin level by a high percentage (2.5% to 16.7%) [3][9]. High saponin content is a limitation for food applications of seed cake. Researchers report that saponin content can be reduced by isopropanol treatment [3]. Saponin-detoxified Mee seed flour can be considered as a potential source of vegetable protein for human food and animal feed products. The defatted seed cake also showed good oil absorption and emulsification traits [3].

3. Physical, Biological, and Chemical Properties of Mee Seed Fat

3.1. Physico-Chemical Properties of Mee Seed Fat

Mee oil was extracted from dried kernel powder of Mee seeds using a Soxhlet apparatus and the extracted oil was used to determine the fatty acids as well as elements of Mee seeds [10]. The saponification value, iodine value, peroxide value, acid value, melting point, smoke point, specific gravity, and refractive index are some physicochemical parameters which were studied using AOCS (1999) and AOAC (1999) methods [10]. As coconut oil is the most cooking fat in Asian countries, it is vital to compare the physiochemical properties of Mee fat with coconut oil when popularizing Mee fat for edible uses (Table 1) [10][11].

Table 1. Comparison between Mee seed fat and coconut oil.

| Type of Oil/Fat | Saponification Value (mg KOH/g) | Iodine Value (gI2/100 g) |

Acid Value (mg KOH/g) | Peroxide Value (meq/kg) | Melting Point °C | Smoke Point °C | Specific Gravity (at 25 °C) |

Refractive Index (at 40 °C) |

|---|---|---|---|---|---|---|---|---|

| Mee | 181–184 | 56–57 | 4 | 3 | 33–34 | 168–171 | 0.9272 | 1.4672 |

| Coconut | 250–268 | 6–11 | 0.2 | 3 | 24 | 177 | 0.918 | 1.4486 |

3.2. Fat Content and Fatty Acid Profile of Mee Seed Fat

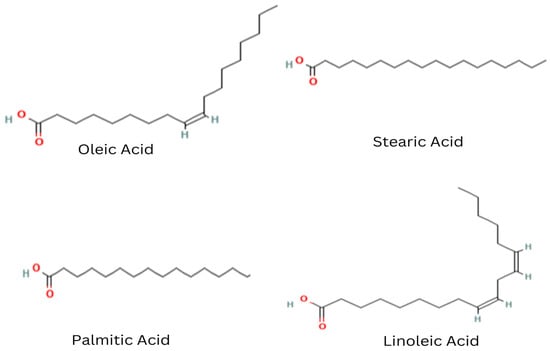

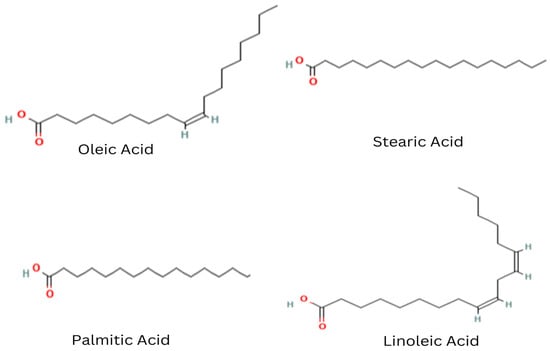

Most of the available research studies are on fatty acid profiles of Indian Mee varieties [7]. There is little research available on the chemical compositions of Sri Lankan Mee varieties [7][12]. There were similar results obtained for the fatty acid profile among the studies. Researchers report on 13 fatty acids which were identified in Mee seed extract [3]. Fatty acid methyl ester (FAME) analysis of fat shows oleic, stearic, palmitic, and linoleic as the major fatty acids, which together comprised more than 98.5% of the total identified FAMEs of Mee fat (Figure 3) [13][14][15][16]. Oleic acid was the main fatty acid (37.3%) followed by stearic acid (25.9%). According to the study Mee fat contains 46% saturated fatty acids, 37.4% monounsaturated FA, and 16.5% polyunsaturated FA (PUFA). Therefore, Mee contains a considerable amount of essential fatty acids (Figure 4) [3].

Figure 3. Major fatty acids present in Mee fat.

Figure 4. Total fatty acid profile (%) of Mee fat.

3.3. Unsaponifiable Matters Composition of Mee Seed Fat

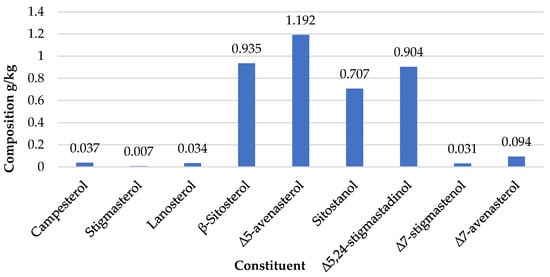

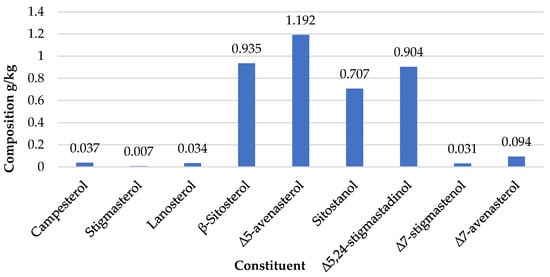

The high unsaponifiable matter (UM) content (ca. 8 g/kg fat) in Mee is one of its distinct features. It is a limitation for Mee fat use in the manufacturing industry. Mee fat contains a higher amount of phytosterols (3.94 g/kg TL). Phytosterol (ST) levels in vegetable fats are used to identify fats, and fat derivatives, and also to determine fat quality. Nine compounds were claimed as phytosterols (Figure 5) [3]. The 5-avenasterols consist of ca. 30.2% of the total ST content. An amount of 46% of the total ST consists of β-sitosterol and 5,24-stigmastadinol. Sitostanol, campesterol, stigmasterol, lanosterol, 7-avenasterol, and 7-stigmastenol were present in low quantities in Mee fat [3].

Figure 5. Sterol composition of Mee fat.

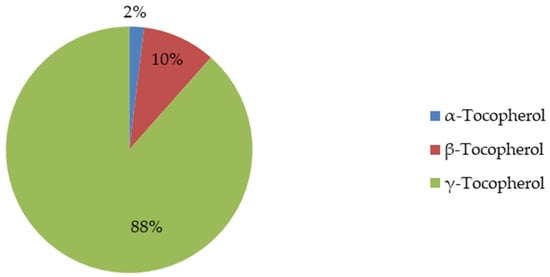

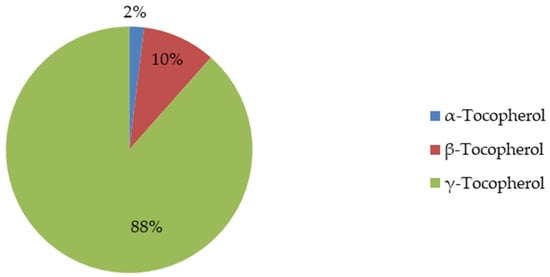

Other than phytosterols, tocopherols also play an important role as an unsaponifiable matter in Mee fat. There are four types of tocopherol isomers and three of them are present in Mee fat (Figure 6) [3]. An amount of 88.8% of total tocopherols present in Mee fat are γ-tocopherols. An amount of 9.6% of total tocopherols are β-tocopherols and the remaining 1.9% of total tocopherols are α-tocopherols. Among them, α-Tocopherol is the most efficient antioxidant of tocopherol isomers. β-tocopherol has 25–50% of the antioxidant activity of α-tocopherol, and γ-tocopherol has 10–35% of the antioxidant activity of α-tocopherol. Tocopherols add great value to Mee fat because of their nutritional value and strong stability toward oxidation [8].

Figure 6. Tocopherol composition of Mee fat.

3.4. Antioxidant Potential of Mee Seed Fat

Phytonutrients present in Mee fat have antioxidant properties and thereby contribute to the oxidative stability and improved shelf life of the fat. The natural antioxidants extracted from Mee fat can be used as a replacer for hazardous artificial antioxidants applied in the food-manufacturing industry [17][18]. Tocopherols and carotene present in Mee seed fat have significant antioxidant potential. The antiradical properties of Mee fat were compared with extra virgin olive oil [3]. 2,2-diphenyl-1-picrylhydrazyl (DPPH) radicals’ quenching activity was assessed by the above researchers. After one hour of incubation, Mee fat has shown a higher antiradical potential than extra virgin olive oil. Mee fat has been reduced by approximately 25% of DPPH radicals whereas olive oil has been reduced by 9.40%. Compositional differences between fatty acids and lipid-soluble bioactive compounds such as phenolic acids, tocopherols, tocotrienols, and carotenoids present in Mee fat affect the antioxidant potential. The total phenolic content and antioxidant capacity of the methanolic extract of Mee seed oil was evaluated by measuring the absorbance through a spectrophotometer (Uviline 9400, SECOMAM) [17].

The antioxidant potential of Mee fat was measured using DPPH and 3-ethylbenzothiazoline-6-sulphonic acid (ABTS) radical scavenging assays and β-carotene/linoleate model system using α-tocopherol as the reference antioxidant. The Mee fat extract has shown a dose-dependent activity towards DPPH and ABTS radicals [19]. The IC50 value is the way of expressing the DPPH radical scavenging activity [19]. This value is 0.078 mg/mL for Mee fat extract and 0.031 mg/mL for α-tocopherol. High antioxidant potential compounds have an IC50 value of less than 1 mg/mL. A comparison was performed between the antiradical properties of Madhuca fat and extra virgin olive oil using DPPH free radicals [1]. M. longifolia fat had higher antiradical potential than olive oil.

3.5. Mee Seed Fat Content and Quality upon Storage

Mee seed fat content and its quality depend on the storage conditions of the extracted fat [20]. Changes in Mee seed fat content and quality upon storage at different durations and conditions were studied by researchers [21]. In their study, researchers have investigated the effect of storage medium and storage condition on the fat content and other fat parameters of Mee seeds. Researchers also proved that the fat content and its composition can be changed by storage conditions, duration, exposure to light, and other environmental factors. According to them, the fatty acid oxidation of seed fats can be seen during long-term storage. Postharvest handling and storage of Mee fruits and seeds affect the final composition and the quality of processed fat. Especially, Penicillium and Aspergillus fungi genera induce seed deterioration and degradation by forming toxic materials on poor storage conditions [22].

4. Processing of Mee Seed Fat

4.1. Mechanical Press Fat Extraction

Mechanical press fat extraction uses a manual ram press or an engine-driven screw press to extract the fat. Mee seed fat extraction was conducted through a traditional screw-type fat expeller [12]. Researchers have analyzed the fat-expelling efficiency of the machine. The seeds can be subjected to a different number of extractions through the expeller and thereby produce seed fat and seed cake mixture continuously during the process. The researchers had modified the screw-type expeller to improve the fat-extraction efficiency. The optimum fat yield and quality of the fat were determined by evaluating the refractive index, saponification value, iodine value, unsaponifiable matter, free fatty acid content, and specific gravity to assess the quality of the refined fat [12]. Modified machine performances were evaluated. The crude fat yield of seeds, machine capacity, and energy consumption at different screw shaft speeds were calculated in the study. For the crude fat yield, the highest yield was obtained at a screw speed of 90 rpm. The maximum fat yield of 35% was also achieved under this condition. There can be observed a correlation between the fat yield and the speed levels. The energy consumption is lowest at speeds of 90 and 120 rpm.

4.2. Solvent Oil Extraction (Chemical Extraction)

The fat is extracted from the solid through a leaching process using a liquid solvent. The chemical extraction using the n-hexane method gives the highest fat yield [23]. The chemical extraction method was considered an effective method because it extracts higher fat yield and due to its reliable performance. The chemical extraction of Mee fat has been conducted using different solvents and different time periods according to the AOAC method [10]. The extractions were carried out for 6 h, 5 h, and 4 h. The solvents n-Hexane (bp. 65–70 °C) and petroleum ether (bp. 40–60 °C) were tested in the study. Four hours of extraction time with n-hexane can be used as the method provides better Mee fat extract efficiency with good quality. The rate of solvent extraction depends on many factors such as particle size, the type of solvent used, temperature, and agitation speed. According to the reports, solvent extraction is only economical in large-scale fat extractions.

4.3. Ultrasonic-Assisted Bio-Oil Extraction

The effect of ultrasonic-assisted extraction for Mee seeds through optimizing conventional solvent extraction procedures was studied [24]. Ground Mee seed powder was mixed with different solvents to study the extraction process. Both single solvents and combinations of solvents were tested. There, diethyl ether/ethanol, chloroform/methanol, and isopropanol/methanol were used as solvent combinations in suitable proportions. Investigations were performed to optimize various parameters like temperature, extraction time, type of solvent, solvent ratio, potassium chloride, and hydrochloric acid concentrations of the extracted fat. Further increases in fat extraction from Mee seeds were achieved through the ultrasonic-assisted extraction method. They characterized Mee fat by gas chromatography–mass spectrometry (GC–MS) and studied the fat characteristics. Through solvent extraction, a 77.9% fat yield was obtained from Mee seeds. Their mixed solvents, diethyl ether, and ethanol were taken in a 3:1 ratio at 50 °C for 20 min. as the extraction medium. This fat yield was increased while performing the ultrasonic-assisted solvent extraction. The extracted Mee fat yield was observed as 82% in ultrasonic-assisted solvent extraction. GC–MS confirmed that the Mee fat contains octadecenoic acid.

5. Potential Industrial Applications of Mee Seed Fat

5.1. Stir Frying Application

Sensory evaluations were conducted for Mee fat and coconut fat for frying purposes. There, Mee fat and coconut fat were compared with each other for deep-fat frying and stir-frying of french fries using the above two types of fat [10]. Taste, odor, mouth feel and organoleptic acceptability were evaluated as sensory attributes. The test results show that in the stir-frying method, there was no significant difference (p > 0.05) between Mee fat and coconut oil for the evaluated sensory attributes. According to the research, Mee fat has a good potential as cooking fat. During the frying process the Δ5-avenasterol present in Mee fat helps to protect fat from oxidative polymerization [3].

5.2. An Alternative Ingredient for Halal Fats

The potential of Mee fat as an alternative ingredient for halal fats (fats which are permitted under the Islamic Law and which Muslims are allow to eat without any punishment) was tested by some researchers [25][26]. Pork fat is a common halal fat used in food processing that has an animal origin. Mee fat is a plant-based non-halal fat with good processing potential. Studies show that pork fat has more unsaturated fatty acids (USFA) than saturated fatty acids (SFA). Oleic acid (38.24%) is the major fatty acid in pork fat. Other fatty acids available in pork fat are palmitic (22.68%) and linoleic (20.39%) acids. In Mee fat, major fatty acids are oleic (44.02%), stearic (22.05%), and palmitic (20.88%) acids. But, it has a very small amount of linoleic acid (7.85%) compared to pork fat. Mee fat has a higher saturated fatty acid content (42.93%) compared to pork fat (36.62%). Fractionation results in stearin fractions (solid) and olein fractions (liquid) of the fat. In the above study, the basic physico-chemical parameters of pork fat, Mee fat, and their fractions were evaluated. Their slip melting point (SMP), cloud point (CP), and iodine value (IV) were analyzed and compared with each other. The results show that Mee fat has a higher SMP value compared to pork fat. Compared to native samples, stearin fractions had a higher SMP. The SMP of pork fat stearin (45.75 °C) was lower than Mee fat stearin (46.50 °C). CP values were used to evaluate the thermal characteristics of olein fractions. Pork fat olein has a lower CP compared to Mee fat olein. IV represents the degree of unsaturation of fats. Pork fat shows an IV of 73.80 while Mee fat shows an IV of 61.10. When considering stearin fraction, pork fat has a lower IV than Mee fat stearin. However, pork fat olein has a higher IV value compared to Mee fat olein. The study reports some common thermal characteristics of pork fat and Mee fat. Both fats have thermal transitions at low and high temperatures, and these fats yield solid stearin and liquid olein. Both pork fat and Mee fat display similar saturated fatty acid profiles between 0 °C to 25 °C. Therefore, Mee fat could be used as an alternative ingredient for halal fats.

5.3. A cocoa Butter Substitute

Mee fat has a similar fatty acid profile to cocoa butter [3][27][28][29]. The high levels of oleic and stearic acids in Mee fat give it the suitability to be a cocoa butter substitute [30][31]. Therefore, Mee fat has the potential to produce chocolates, confectionery products, and shortenings.

5.4. Development of Food Packaging Material

Food packaging films made out of antimicrobial compounds are important in food safety to protect food from microbial contamination and increase its shelf life [9]. Petroleum-based polymeric substances such as polyethylene, polycarbonate, polyethylene terephthalate, polyvinylchloride, polypropylene, polystyrene, and polyamides are the most common packaging materials. Due to environmental concerns, bio-based polymer films are successful alternatives for food packaging due to their easy availability, low cost, and biodegradability. But, these polymers lack tensile strength and water absorption. These can be controlled by combining them with other polymeric substances which improve the desired characteristics of the film. Pure polysaccharides can composite with nanoparticles such as AgO, TiO2, and ZnO according to research data available. Other than that, plant extracts such as neem, papain, grape, and green tea extract also have moderate to very good antibacterial activity and could be incorporated in food-packaging developments.

5.5. Pharmaceutical Product Manufacturing

Natural products are gaining a high demand in the present in many industrial fields. Medicinal product manufacturing is one of them. The major components of a medicinal cream are the active pharmaceutical ingredient (API) and the excipient. The excipients sometimes act as “non-active agents” and also have been found to enhance the activity of the API. Agar, alginates, cellulose, gelatin, guar gum, pectin, starch, and xanthan gum are some of the natural pharmaceutical excipients used in the pharmaceutical products manufacturing industry. They are composed of therapeutic supplementary properties and also have applications such as binding agents, coating material, disintegrating agents, gelling agents, stabilizers, sustaining agents, thickening agents, etc.

5.6. Formulation of Coating Binders

The development of polyetherimide-based corrosion-protective polyurethane coating from Mee fat was carried out [32]. The Mee fat was successfully used in the preparation of polyetherimide resin (MPEA)-derived polyurethanes. There, Mee fat was converted to fatty amide (MFA) and then converted into polyetherimide (MPEA). The synthesized materials were characterized by spectroscopic methods. It possesses good coating properties such as gloss, pencil hardness, and thermal stability. Mee fat-based polyurethane resins have excellent potential properties for use in the formulation of coating binders. The prepared coatings applied on metal and particle board panels and the performance of the coatings were analyzed and found to be suitable as an anticorrosive coating material.

5.7. Biodiesel Production

Mee fat also has good potential in biodiesel production and can partially replace petroleum diesel. Due to less environmental pollution, low-cost biomass receives attention in biodiesel manufacture. Vegetable fats such as soybean, rapeseed, sunflower, and safflower are generally used to prepare biodiesel [33]. Biomass is one of the technically and economically feasible options against fossil fuels. Biofuel can also be used in any mixture with fossil fuels because of their similar characteristics. This includes common straight fatty acids such as palmitic acid (C16:0), stearic acid (C18:0), oleic acid (C18:1), linoleic acid (C18:2) and linolenic acid (C18:3) [34]. Fatty acid methyl esters (FAMEs) of seed fat are utilized as a substitute fuel in a diesel engine.

6. Therapeutic Potential and Nutritional Properties of Mee Seed Fat

Mee can be considered a medicinal plant with a good pharmacological profile. It provides potent aid for its future clinical uses in modern medicine [7]. Mee (Madhuca longifolia) seed fat has a number of medicinal and nutritional properties. Many researchers have reported on the anti-inflammatory property, anti-cancer properties, hypoglycemic properties, anti-ulcer activity, laxative properties, etc. of Mee seed fat [30][35][36]. The anti-inflammatory action of Mee on rats was also evaluated by a research group [37]. Mee fat also has demulcent properties. Therefore, it can be used to treat skin diseases, rheumatism, headache, laxative, and piles, and also as a galactagogue. The ethanol extract and saponin blend of Mee seeds was evaluated for anti-inflammatory action using acute, sub-acute, and chronic models of inflammation in rats [38]. There, ethanol extract and a saponin mixture of Mee at a different dose level was studied. The edema caused by carrageenan in the acute model of inflammation was significantly reduced by the above mixture. Both extracts had a more effective response than the reference drug in the sub-acute inflammation model. Results prove the significant anti-inflammatory activity of M. longifolia saponins. An in vitro study on the anticancer activity of different extracts of Mee seeds against human cancer cell lines was experimented with and evaluates the cell growth inhibition [39]. The study found that various extracts of Mee seeds have very good to moderate anticancer activity.

This entry is adapted from the peer-reviewed paper 10.3390/agronomy13102445

References

- Ramadan, M.F.; Mörsel, J.T. Madhuca longifolia Butter. In Fruit Oils: Chemistry and Functionality; Springer: Cham, Switzerland, 2019; pp. 291–300.

- Thangamani, D.; Rajan, S.P.; Karunamoorthi, J.; Lalitha, S. Spiritually significant natural resource of Madhuca longifolia (J. Koenig ex L.) J.F. Macbr. Conservation and its value added products management. Pharma Innov. J. 2022, 11, 792–796.

- Ramadan, M.F.; Abdel-Hamed, E.M.W. Health-promoting Potential and Nutritional Value of Madhuca longifolia Seeds. In Nuts and Seeds in Health and Disease Prevention, 2nd ed.; Academic Press: Cambridge, MA, USA, 2020.

- Khare, P.; Kishore, K.; Sharma, D.K. Medicinal uses, Phytochemistry and Pharmacological profile of Madhuca longifolia. Asian J. Pharm. Pharmacol. 2018, 4, 570–581.

- Kendre, N.; Wakte, P. A review on Phytochemicals and biological attributes of Madhuca longifolia. Asian J. Pharm. Pharmacol. 2021, 7, 74–84.

- Saif, M.; Varma, R.; Kant, R.; Gupta, R. Madhuca longifolia (Mahua): A comprehensive ethno pharmacological review. Int. J. Chem. Stud. 2020, 8, 172–175.

- Munasinghe, M.; Wansapala, J. Study on variation in seed morphology, oil content and fatty acid profile of Madhuca longifolia grown in different Agro-climatic zones in Sri Lanka. Sci. Res. 2015, 3, 105–109.

- Ramadan, M.F.; Mohdaly, A.A.A.; Assiri, M.A.A.; Tadros, M.; Niemeyer, B. Functional characteristics, nutritional value and industrial applications of Madhuca longifolia seeds: An overview. J. Food Sci. Technol. 2016, 53, 2149–2157.

- Gupta, A.; Kumar, A.; Sharma, S.; Vijay, V.K. Comparative evaluation of raw and detoxified mahua seed cake for biogas production. Appl. Energy 2013, 102, 1514–1521.

- Munasinghe, M.; Wansapala, J. Oil extraction from Madhuca longifolia (J. Konig) J.F. Macbr seeds and evaluation of physico- chemical properties, fatty acid profile, antioxidant potential and sensory characteristics. Trop. Agric. 2016, 9, 29–35.

- Seneviratne, K.; Jayathilaka, N. Coconut Oil: Chemistry and Nutrition; Lakva Publishers: Battaramulla, Sri Lanka, 2016; pp. 18–34.

- Bandara, D.M.S.P.; Dissanayake, C.A.K.; Rathnayaka, H.M.A.P.; Senanayake, D.P. Performance evaluation of the screw type oil expeller for extracting Mee (Madhuca longifolia) oil. J. Biosyst. Eng. 2016, 41, 177–183.

- National Center for Biotechnology Information. PubChem Compound Summary for CID 445639, Oleic Acid. 2023. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Oleic-Acid (accessed on 10 February 2023).

- National Center for Biotechnology Information. PubChem Compound Summary for CID 985, Palmitic Acid. 2023. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Palmitic-Acid (accessed on 10 February 2023).

- National Center for Biotechnology Information. PubChem Compound Summary for CID 5281, Stearic Acid. 2023. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Stearic-Acid (accessed on 10 February 2023).

- National Center for Biotechnology Information. PubChem Compound Summary for CID 5280450, Linoleic Acid. 2023. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Linoleic-Acid (accessed on 12 February 2023).

- Thilakarathna, R.C.N.; Lee, F.S.; Tang, T.-K.; Chan, E.-S.; Lee, Y.-Y. Physicochemical and antioxidative properties of ultrasound-assisted extraction of mahua (Madhuca longifolia) seed oil in comparison with conventional Soxhlet and mechanical extractions. Ultrason. Sonochem. 2023, 92, 106280.

- Baky, M.H.; Elsaid, M.B.; Farag, M.A. Phytochemical and biological diversity of triterpenoid saponins from family Sapotaceae: A comprehensive review. Phytochemistry 2022, 202, 113345.

- Bopitiya, D.; Madhujith, T. Antioxidant Activity and Total Phenolic Content of Mee (Madhuca sp.) Oil; Book of Abstracts of the Peradeniya; University Research Sessions: Nugegoda, Sri Lanka, 2012; Volume 17.

- Issaoui, M.; Delgado, A.M. Grading, labeling and standardization of edible oils. In Fruit Oils: Chemistry and Functionality; Ramadan, M., Ed.; Springer: Cham, Switzerland, 2019.

- Nayak, S.; Sahoo, U.K. Changes in Madhuca latifolia Macbride seed oil content and quality upon storage at different duration and condition. Vegetos 2021, 34, 422–431.

- Behera, S.; Swain, M.R. A survey of post-harvest spoilage of mahua (Madhuca latifolia L.) flowers. J. Agric. Technol. 2013, 9, 227–235.

- Keneni, Y.G.; Bahiru, L.A.; Marchetti, J.M. Effects of Different Extraction Solvents on Oil Extracted from Jatropha Seeds and the Potential of Seed Residues as a Heat Provider. BioEnergy Res. 2020, 14, 1207–1222.

- Baskar, G.; Naveenkumar, R.; Mohanapriya, N.; Nivetha, S.R.; Aiswarya, R. Optimization and kinetics of ultrasonic assisted bio oil extraction from Madhuca indica seeds. Ind. Crops Prod. 2018, 124, 954–959.

- Halal Research Council. What Is Halal? 2023. Available online: https://www.halalrc.org/glossary.php (accessed on 7 September 2023).

- Marikkar, J.M.N.; Yanty, N.A.M. Seed fat from Madhuca longifolia as raw material for Halal alternative fats. Borneo Sci. 2012, 31, 97–106.

- Tambun, R.; Ferani, D.G.; Afrina, A.; Tambun, J.A.A.; Tarigan, I.A.A. Fatty Acid Direct Production from Palm Kernel Oil. In Proceedings of the 1st International Conference on Industrial and Manufacturing Engineering, Medan City North Sumatera, Indonesia, 16 October 2018.

- Medeiros de Azevedo, W.; Ferreira Ribeiro de Oliveira, L.; Alves Alcântara, M.; Tribuzy de Magalhães Cordeiro, A.M.; da Silva, F.; Chaves Damasceno, K.S.; Kelly de Araújo, N. Physicochemical characterization, fatty acid profile, antioxidant activity and antibacterial potential of cacay oil, coconut oil and cacay butter. PLoS ONE 2020, 15, e0232224.

- Bisht, V.; Neeraj; Solanki, V.K.; Dalal, N. Mahua an important Indian species: A review. J. Pharmacogn. Phytochem. 2018, 7, 3414–3418.

- Dalvi, T.S.; Kumbhar, U.J.; Shah, N. Madhuca longifolia: Ethanobotanical, phytochemical studies, pharmacological aspects with future prospects. Interdiscip. J. Appl. Basic Subj. 2022, 2, 1–9.

- Naik, B.; Kumar, V. Cocoa Butter and Its Alternatives: A Review. J. Bioresour. Eng. Technol. 2014, 1, 7–17.

- Pawar, M.S.; Kadam, A.S.; Yemul, S.O. Development of polyether amide based corrosion protective polyurethane coating from mahua oil. Prog. Org. Coat. 2015, 89, 143–149.

- Gandhi, S.S.; Gogate, P.R. Process intensification of fatty acid ester production using esterification followed by transesterification of high acid value mahua (lluppai ennai) oil: Comparison of the ultrasonic reactors. Fuel 2021, 294, 120560.

- Marchetti, J.M.; Keneni, Y.G. Review Oil extraction from plant seeds for biodiesel production. AIMS Energy 2017, 5, 316–340.

- Shrirao, A.V.; Koch, N.I.; Chandewar, A.V. Madhuca longifolia (Sapotaceae): A Review of its Traditional Uses and Phyto-Pharmacological Profile. Res. Chron. Health Sci. 2017, 3, 45–50.

- Reddy, I.S. Madhuca indica: An untapped forest tree for its medicinal uses. Pharma Innov. J. 2022, 11, 1747–1751.

- Janghel, V.; Chandel, S.S.; Sahu, J.; Patel, P.K. Madhuca indica (Mahua)—Pharmaceutical, Nutraceutical and Economical Importance for Tribal People of Chhattisgarh State. Int. J. Pharm. Phytopharm. Res. 2019, 9, 16–28.

- Ramchandra, D.; Gaikwad, M.D.; Liyaqat, A.M.D.; Swamy, S.K.P. Anti-inflammatory activity of Madhuca longifolia seeds saponin mixture. Pharm. Biol. 2009, 47, 592–597.

- Bhaumik, A.; Kumar, M.U.; Khan, K.A.; Srinivas, C.H. The Bioactive Compounds Obtained from the Fruit Seeds of Madhuca longifolia (L.) act as potential anticancer agents. Sch. J. App. Med. Sci. 2014, 2, 1235–1238.

This entry is offline, you can click here to edit this entry!