1. Introduction

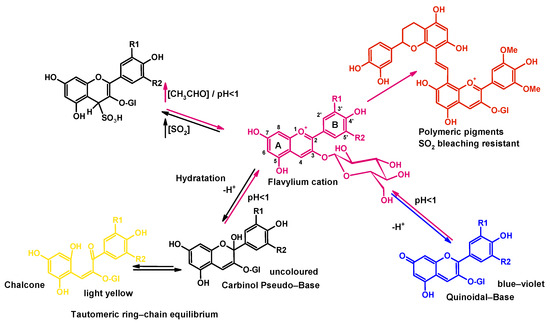

Anthocyanins are flavonoid pigments with variable colors from yellow-orange (490 nm) to red-blue (540 nm), with healthy nutritional properties widely distributed in fruits and flowers and with useful properties as food pigments [

1,

2,

3,

4,

5]. Anthocyanins can act as antioxidants, phytoalexins, or antimicrobial compounds [

6,

7]. Anthocyanins behave as weak acids, hard and soft electrophiles, nucleophiles, and metal ion binders [

8]. The main degradation effects that can affect anthocyanins are oxidative yield processes, which can be accelerated by temperature [

9]. Anthocyanins can also be affected by light (photooxidation) [

10] and oxidized by oxygen directly or via enzymes such as polyphenol oxidases and peroxidases [

9,

10]. Stability and color are also affected by pH, SO

2 bleaching, copigmentation, or the formation of polymers with other flavonoids, such as catechins or proanthocyanidins (

Figure 1). Non-thermal emerging technologies such as high-pressure processing by High Hydrostatic Pressure (HHP) or Ultra-High Pressure Homogenization (UHPH) can be used to gently extract and preserve juice anthocyanins, increasing extraction rates and stability [

11,

12].

Figure 1. Reactions that can affect anthocyanins as a function of pH, hydration, SO2 concentration, and flavonoid content.

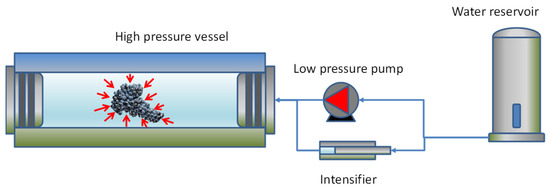

High Hydrostatic Pressure (HHP) is the application of pressure to food by a pressurizing fluid, usually water, inside a highly resistant steel vessel (

Figure 2). Initially, the vessel is filled with water using a high-flow, low-pressure pump, and later, the water is pressurized to a typical range of 500–600 MPa using a special pump called a pressure intensifier (

Figure 2). Under these pressure conditions, the water and the food inside are compressed by about 4%. The pressurization is produced with some temperature increase due to adiabatic heat compression, which is typically lower than 4 °C/100 MPa (<3.4 °C water, <3.8 °C orange juice, [

13]), producing a global heating of up to 24 °C at 600 MPa. The temperature increase also depends on the composition, which is higher for oil components. HHP is a technique that can be considered a non-thermal technology because of this soft heating, without any degradative effect on thermally sensitive molecules such as pigments or aromatic compounds [

14,

15]. Low adiabatic heating can be additionally controlled by cooling the vessel with heat exchangers.

Figure 2. HHP system scheme with steel vessel, low-pressure pump, and high-pressure intensifier. Arrows around the grape cluster simulate the hydrostatic effect of the pressure.

HHP, unlike thermal treatments, does not have enough energy to affect covalent bonds; therefore, small molecules with sensory impact are protected, and HHP can be considered a gentle technology. The formation of unexpected molecules has not been observed during HHP processing [

16]. Furthermore, HHP is a pressure process produced in a closed vessel where aeration and oxidative processes are minimized, thus reducing damage to anthocyanins.

Many studies have shown that using HHP at room temperature preserves nutritional value and has a very low effect on the levels of anthocyanins in fruits and vegetables [

17]. The HHP-treated juices show good color stability, better phenolic content, and higher antioxidant activity [

18].

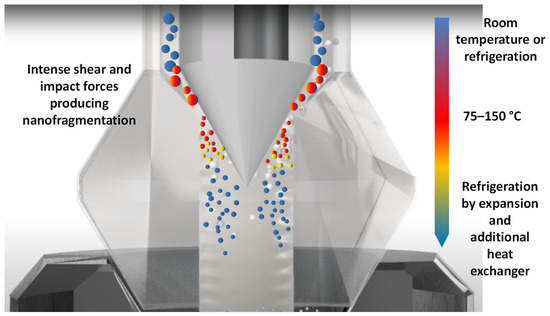

Ultra-High Pressure Homogenization (UHPH) is a high-pressure technology in which a fluid is pumped at more than 200 MPa (typically 300 MPa) through a thin, high-resistance steel pipeline and later depressurized via a special valve made of a high-resistance alloy [

19,

20]. The valve is often made of tungsten carbide and is usually coated with nanolayers of extremely resistant carbon polymers. Inside the valve, fluids are subjected to extreme shear forces and impacts, causing nanofragmentation of microorganisms, colloids, and biopolymers to 100–500 nm [

20,

21] (

Figure 3).

Figure 3. Effect of impact and shear forces on colloid nanofragmentation and temperature in a UHPH valve (adapted from

http://www.ypsicon.com/ (accessed on 15 July 2023)).

Some interesting effects of submicron nanofragmentation are the elimination of microorganisms, inactivation of enzymes (including oxidative polyphenol oxidases, PPOs), increase in antioxidant activity, and better colloidal stability [

20,

21,

22,

23]. Additionally, UHPH is very gentle with sensory quality. No degradation of terpenes [

21], anthocyanins [

22], or thermal markers such as hydroxymethyl furfural was observed during the processing of grape juices [

21].

2. Extraction of Anthocyanins by HHP

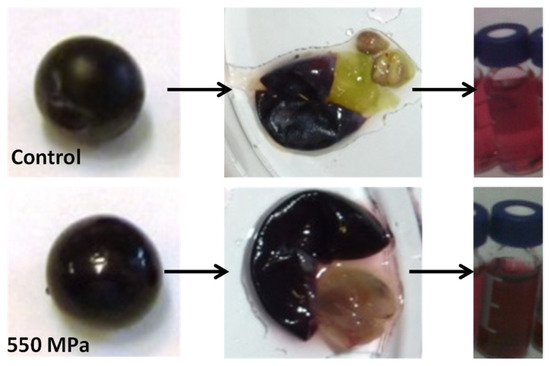

The extraction of anthocyanins by HHP is influenced by the intensity of pressure, temperature, and polarity (ethanol content) [

26]. In addition, the substitution pattern in the anthocyanin ring also affects the extraction, depending on the -OCH

3 and -OH substituents [

26]. People have observed that after HHP treatment of grapes, even if the external appearance remains unaffected, perhaps just a little more brilliant, the surface looks as if it has been pored; the migration of anthocyanins into the pulp can be observed because of the red color (

Figure 4) [

25]. The permeability of the cells increases, and the diffusion of anthocyanins is improved [

37]. The anthocyanins are released from the vacuoles in the skins and later migrate to the pulp, but also to the seeds during the HHP treatment, and the effect is pressure-dependent. The higher the pressure, the more intense the extraction, reaching higher concentrations of anthocyanins in the juice of the grapes processed at 550 MPa/10 min compared to the 200 and 400 MPa treatments [

25]. A similar effect was observed in total polyphenols but with a less pressure-dependent behavior when a comparable extraction was observed at pressures in the range of 200–550 MPa. The increase in the extraction of total polyphenols was in the range of 20–25% [

25]. The extraction of anthocyanins can range from 20 to 80%, depending on the processing parameters (pressure, time, temperature, and polarity) and the conditions of the grape (ripeness, skin thickness and resistance, and previous processes) or grape by-products [

25,

26,

34].

Figure 4. Effect of HHP on the surface and pulp of Vitis vinifera cv Tempranillo grape berries and on color extraction with a treatment of 550 MPa for 10 min.

HHP has shown a protective effect on several anthocyanins with low degradation after treatment and protection of antioxidant capacity [

33,

38,

39]. The protective effect on anthocyanins is better when pre-processing is carried out at low oxygen levels [

40]. Inertization by a nitrogen atmosphere in the pre-processing of berries probably reduces the effect of residual PPO activity on anthocyanin oxidation. Color retention is usually better in HHP treatments than in conventional thermal processing (80–90 °C) [

41], probably due to the intensification of oxidation.

The protective effect on anthocyanins in preserving the antioxidant capacity and the partial inactivation of PPOs make HHP a gentle technique for extracting anthocyanins from fruits or vegetable tissues. The subsequent stability of the extracted anthocyanins under refrigeration favors the stability and valorization of these pigments to be used in the food industry, obtain wines with faster macerations, or even fermentations in the absence of skins, facilitating winemaking.

3. Extraction of Anthocyanins by UHPH

Anthocyanins are essential for the color, antioxidant properties, and sensory quality of berry juices and their fermentative products, such as wine. After juice extraction, anthocyanins can remain entrapped or adsorbed in colloidal particles of the pulp and are also more exposed to the action of PPOs than in the whole berry. Mechanical action and nanofragmentation in the UHPH valve are powerful tools to release the anthocyanins from the colloidal fragments and to avoid the effects of PPOs by inactivating them.

In the application of UHPH, the juice is pressurized by pumping with a special pump that works at >200 MPa (usually at 300 MPa); the capillary pipeline section is smaller than 1 mm so that any fluid with a colloid size higher than 500 µm cannot be processed [

20]. Grapes or raw grape skins cannot be processed directly because of the previous size limitation, but UHPH can be applied to the unsettled must obtained by pressing after cold soaking or enzyme treatments of the crushed grape [

22]. It would also be possible to mechanically process the skins with the pomace using a milling system and later apply UHPH to the puree.

A high efficiency of UHPH to disaggregate and destroy biofilms by mechanical effects has been observed [

48]. The processing of plant matrices by UHPH produces a better and more stable colloidal structure [

49], which can be measured by particle settling produced by centrifugation [

50]. In addition, higher viscosity and turbidity can be observed due to the formation of stable colloidal nanoparticles [

51]. What can be observed after the UHPH processing at pressures higher than 200 MPa is the nano-fragmentation of all the microorganisms and colloidal fragments from the plant tissues (

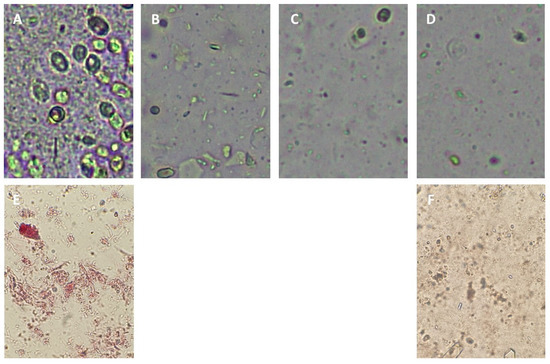

Figure 5). In the raw juice of unsettled Tempranillo grape (

Vitis vinifera L.), yeast cells and large colloidal fragments can be observed (

Figure 5A), which are nano-fragmented during UHPH by the impact and shear forces generated in the valve and a thinner and more regular colloidal structure can be observed (

Figure 5B–D). In addition, the colloids are slightly colored red by the anthocyanins (

Figure 5A (Tempranillo),

Figure 5E (Cabernet sauvignon)), which disappear from them in the UHPH-treated juice (

Figure 5B–D,F) [

22]. Using Atomic Force Microscopy (AFM), the average colloid size in Cabernet sauvignon juice before and after UHPH treatment was measured to be 1.32 ± 0.46 µm (predominantly super-micron scale) and 0.46 + 0.14 µm (nanometric scale), respectively [

22]. Previously, and in agreement with this value, a similar size range of 100–400 nm was measured in grape juice treated with UHPH using laser light scattering [

21]. Nanofragmentation at a size greater than 100 nm is relevant because lower values may have nanosafety implications due to the possibility of crossing plasmatic barriers.

Figure 5. Optical microscopy of red juices from two varieties treated with UHPH, Tempranillo (Vitis vinifera L.) (A) Control 0.1 Mpa; (B) UHPH 240 Mpa; (C) UHPH 270 Mpa; (D) UHPH 300 MPa; Cabernet Sauvignon (Vitis vinifera L.); (E) Control 0.1 Mpa; (F) UHPH 300 MPa.

Applying UHPH produces a highly effective nano-fragmentation of the plant tissues and cells, releasing the anthocyanins from them and facilitating high and rapid extraction (

Figure 5) [

22]. Therefore, the application of UHPH is a powerful, gentle technology not only to eliminate microorganisms but also to release pigments [

22], thus protecting the color [

51,

52] and other nutrients, antioxidants, and nutraceutical compounds [

51,

52,

53,

54,

55].

Several significant works have been carried out on the use of High-Pressure Homogenization (HPH) or UHPH for the processing of juices or plant-based beverages [

21,

23,

34,

49,

50,

51,

56,

57,

58], but not too much in the processing of red grape juice or berries rich in anthocyanins. However, there are some recent works at 150–300 MPa with important results, including the release of anthocyanins from plant cells or fragments, the protection of color and the control of browning, the specific effect on acylated anthocyanins, the inactivation of PPOs and the preservation of antioxidant activity [

22,

59,

60], together with effective control of microbial loads. Conversely, a 33–38% reduction in anthocyanins was observed in mulberry juice processed at 200 MPa with a pilot UHPH system at a flow rate of 10 L/h, which the authors associate with uncontrolled peroxidase or polyphenol oxidase, but which can be avoided with ascorbic acid [

61]. Most of the studies reporting a reduction in anthocyanin content work at lower pressures (50–200 MPa) and in multi-cycle mode (2–5 passes) [

60,

62,

63], which increases the possibilities of oxidation and damage by mechanical effects during several passes through the UHPH valve. Furthermore, at a pressure of 200 MPa or less, people are at the limit of UHPH and work more in the HPH range. In these conditions, the inactivation of PPOs is lower [

20]. An intense inactivation of PPOs (>90%, [

21]) has been observed at 300 MPa, and therefore, the oxidative damage to anthocyanins will be more intense, especially in a longer multipass process. The design shape and nanocoating of the valve and seat valve is another key aspect to enhance the mechanical effects and inactivation [

20,

31]. From our experience, working at 300 MPa in a single pass, the inactivation of PPOs, the antimicrobial effect, and the stability of anthocyanins are optimal, with strong protection of the color and better antioxidant activity [

22]. In general, several works have observed a clear effect on particle size and viscosity after (U)HPH, which affects the extraction of molecules such as anthocyanins, phenolic aroma, and other nutrients, as well as the colloidal stability of the juice [

62]. The effect on size is pressure-dependent, as observed by optical microscopy and light scattering [

62] and AFM microscopy [

22].

4. HHP vs. UHPH in the Extraction and Stability of Anthocyanins

The use of HHP has the advantage of allowing the processing of solids; therefore, it is possible to process grapes, grape pomace, or even bunches. The only limitation is that the size of the product to be treated must be smaller than the diameter and length of the vessel. Large HHP machines with a diameter of 0.38 m can be found on the market today. (

https://www.hiperbaric.com/en/ (accessed on 24 August 2023)). Therefore, treating whole destemmed grape berries or bunches is perfectly possible on an industrial scale [

25], as well as processing by-products such as pomace [

26]. The extraction of solids can be obtained from the whole raw material and can be higher than in the case of UHPH, where a previous pre-extraction is needed. However, after the pre-extraction, the intense nano-fragmentation caused by UHPH in the colloids guarantees a better release of anthocyanins from the colloidal plant fragments [

22]. In addition, the continuous nature of UHPH processing makes it more efficient from an industrial perspective.

Concerning anthocyanin oxidation, the main disadvantage of HHP is the variable effect on the inactivation of oxidative enzymes [

16,

27,

32,

33]. The protective effect of UHPH on anthocyanin color is due to its gentle action on them but also to the highly effective control of PPOs [

21,

23,

56], which can be considered more intense than in HHP treatment, where inactivation is usually variable and under stronger conditions [

64,

65,

66,

67,

68,

69,

70].

This entry is adapted from the peer-reviewed paper 10.3390/antiox12091746