Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The high-temperature heat pump, as a low-carbonization technology, has broad application prospects in replacing boiler heating, reducing carbon dioxide emissions, and improving the energy utilization efficiency.

- high-temperature heat pump

- working fluid

- cycle process

- hybrid heat pump

1. Introduction

At present, the large-scale use of fossil fuels in the industrial development of the world leads to the excessive emission of greenhouse gases, which continuously enhances the greenhouse effect, thus triggering the increasingly serious problem of global climate change. It has become a global consensus to control carbon dioxide emissions to slow down global warming. In 2021, China’s total energy consumption was 5.24 billion tons of standard coal, of which coal consumption accounted for 56%, oil consumption accounted for 18.5%, and natural gas consumption accounted for 8.9% [1]. In order to deal with the problem of global warming, China has put forward the goals of “achieving carbon peak before 2030 and carbon neutrality before 2060” [2].

The heat pump is an efficient energy conversion device driven by electricity or heat energy, which has great application potential in the context of low-carbon electricity in the future [3]. With the vigorous development of renewable electricity, carbon dioxide emissions in the power industry are decreasing year by year, and heat pumps for heating are more environmentally friendly and efficient than traditional coal or gas heating. In addition, heat pump technology, especially high-temperature heat pumps (>100 °C), has been widely used in central heating, industrial waste heat recovery, energy storage, and other related fields. In order to meet the requirements of carbon-neutral heating, it is particularly important to study the performance of high-temperature heat pumps in the high-temperature field above 100 °C.

2. Compression Heat Pump

The compression heat pump has become a widely used heat pump because of its simple structure and stable performance. Compression heat pumps consume electric energy to produce high-temperature heat, which is mainly divided into single-stage compression, double-stage compression, and cascade compression. COP is a key parameter to evaluate cycle performance. In the compression cycle, COP is defined as the ratio of heat production to compressor power consumption.

2.1. Single-Stage Compression Heat Pump

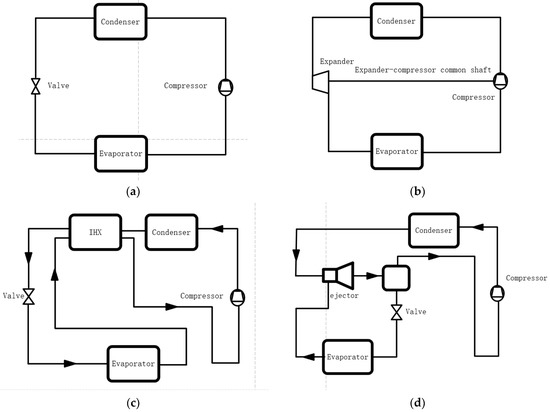

The single-stage compression heat pump system is simple in form, as shown in Figure 1a. Many scholars have studied the selection of a working fluid and the optimization of the circulation structure.

Yan [4] proposed a clean and flexible steam generation system using an air source heat pump and steam compressor. The key design parameters and simulation performance of the system were evaluated and optimized through MATLAB simulation, and a prototype was built for experimental performance evaluation. When the steam temperature at the outlet of the heat pump was above 110 °C, the average boiler efficiency of the system was above 170%, and the economy was best when the operation cycle was more than 3 years. The flow chart of different forms of single-stage compression cycles is shown in Figure 1. Luo [5] studied single-stage high-temperature heat pumps using expanders (EXs), ejectors (EEs), internal heat exchangers (IHXs), and various refrigerants (R245fa, R600, R600a, and R1234ze(z)) for higher performance and lower cost. The results showed that the COP of heat pumps with EXs, EEs, and IHXs improved by 10–18%, 8–14%, and 3–5%, respectively. Malyshev [6] revealed the relationship between individual component parameters and the overall characteristics of the heat pump (HP), which depends on the effect of condensing temperature and ambient temperature on the efficiency of each individual component. During the operation, the maneuverability, efficiency, and losses of the compressor, condenser, evaporator, and thermal expansion valve (TEV) were calculated. The data characterizing the performance of the heat pump unit (HPI) and its components under different climatic conditions were obtained.

Figure 1. Different styles of single compression heat pump cycles [5]. (a) Single compression cycle, (b) Single compression cycle with expander, (c) Single compression cycle with IHX, (d) Single compression cycle with ejector.

2.2. Two-Stage Compression Heat Pump

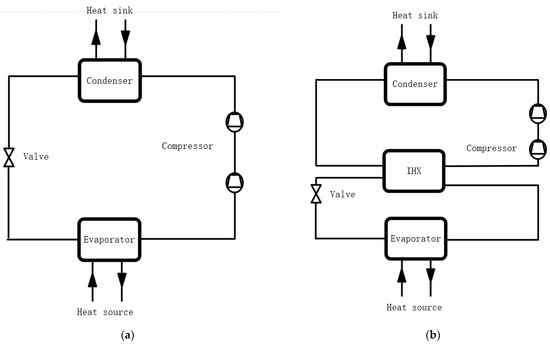

The two-stage compression heat pump uses two compressors to obtain a higher-temperature lift, as shown in Figure 2a, and IHX is added to the cycle to improve cycle efficiency and reduce discharging temperature, as shown in Figure 2b [7].

Figure 2. Two-stage compression heat pump cycles. (a) Two-stage compression cycle, (b) Two-stage compression cycle with IHX.

Wang [8] analyzed the effects of evaporation temperature, condensing temperature, and intermediate pressure on the cycle performance of a two-stage compression heat pump with a heat exchanger. The thermal performance of the high-temperature heat pump steam (HTHPS) system was mainly determined by its different cycle configurations. The improvement of the thermal performance of the quasi-two-stage steam-compression high-temperature heat pump based on the pre-IHX cycle and the post-IHX cycle was studied, and the influence of the IHX cycle on the thermal performance of the heat pump was analyzed [9]. Two-stage steam compression technology can effectively improve the system performance, and the influence of two thermal effects on the COP based on mathematical analysis and a numerical method was analyzed [10]. Jiang [11] built a general model of two-stage vapor compression technology for performance comparison among different cycles, refrigerant selection, and operational analysis. The model was verified by the experiment and then the sub-cooling parameter and the evaporating and condensing pressure were calculated and analyzed among eight different inter-stage configurations.

2.3. Cascade Heat Pump

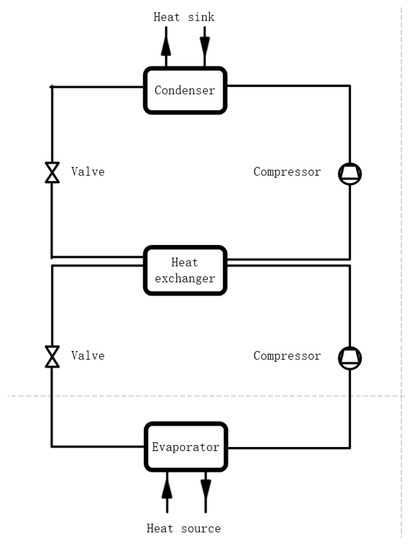

Compared with two-stage compression, the high-pressure stage and the low-pressure stage of the cascade heat pump are connected through a heat exchanger, as shown in Figure 3. The COP of the cascade cycle can be higher by selecting a suitable working fluid in different temperature intervals.

Figure 3. Cascade compression heat pump cycle.

Ma [12] proposed a high-temperature cascade heat pump (HTCHP), which took the near-azeotropic mixing medium BY-3 as the low-level circulating medium and R245fa as the high-level circulating medium. The temperature lift of HTCHP could reach 100 °C and the outlet temperature of the condensing unit could reach 142 °C. Kim [13] conducted experimental research and numerical simulation on the optimal intermediate temperature of a cascade heat pump system. When the inlet temperature is higher and the ambient temperature is lower, the system performance decreases and the corresponding optimal intermediate temperature increases. The numerical optimization of the intermediate temperature can better predict the experimental data. Kim [14] took the cascade cycle used by a water heater heat pump as the research object to verify the influence of rising water temperature on pressure and performance changes, studied the optimal intermediate temperature of the cascade cycle relative to temperature lift, and used this temperature for the transient operation of the heat pump.

3. Absorption Heat Pump

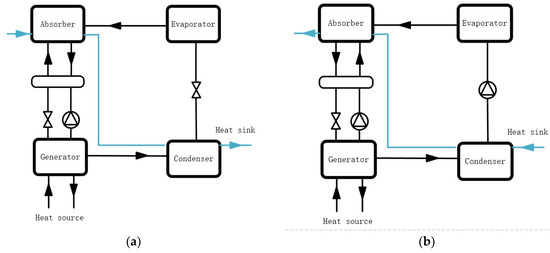

The absorption heat pump is divided into the first absorption heat pump type and the second absorption heat pump type according to the purpose of heating, as shown in Figure 4. The first absorption heat pump type is used to produce a large amount of medium-temperature heat, which is used for civil refrigeration and heating with a COP (defined as the ratio of heat production to heat absorbed by the heat source) of 1.6~1.8. The second type of absorption heat pump is mainly used to improve the heating temperature, whose COP is about 0.4~0.6. Driven by a medium-temperature heat source, the heat from the medium-temperature heat source is transferred to the high-temperature heat source.

Figure 4. Absorption heat pump cycle. (a) First type absorption cycle, (b) Second type absorption cycle.

Wu [15] modeled single-stage and two-stage air source heat pumps (ASAHPs) and ground source heat pumps (GSAHPs) in order to explore the working fluid alignment and circulation mode suitable for heating and domestic hot water in cold areas. Based on these models, the performance of absorption heat pumps under different generation, evaporation, and condensation temperatures was simulated, respectively, when NH3-H2O, NH3-LiNO3, and NH3-NaSCN were used as working fluids. Xu [16] conducted theoretical and experimental research on the waste heat recovery system of a lithium bromide aqueous absorption heat pump. The new heat pump system could heat hot water to 81.34 °C. Yang [17] introduced life cycle cost (LCC) to study the influence of internal parameters of a two-stage absorption heat pump on economy, and the study revealed that the evaporator temperature T0 had the greatest influence on LCC. Balderas-Sanchez [18] compared the double-stage double-effect absorption heat pump with the double-effect absorption heat pump, and found that the double-stage double-effect heat pump had lower performance, but the temperature lift was significantly increased, which could reach 82 °C.

4. Hybrid Heat Pump

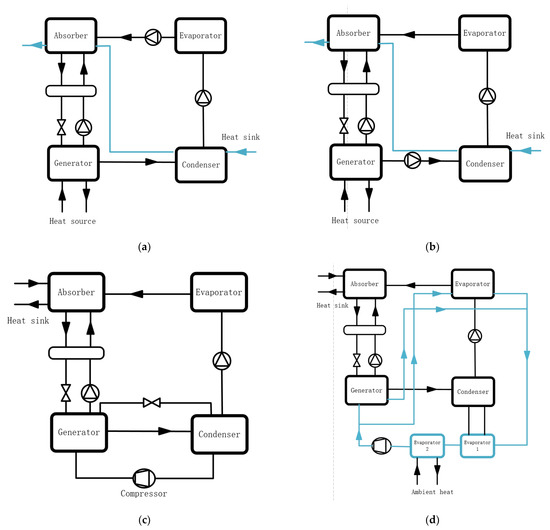

In order to make full use of the advantages of absorption and compression, some scholars organically combine the two types of heat pumps to increase the heating temperature and expand the operating range. At present, the hybrid cycle can be divided into two types. One is to embed the compressor in the absorption cycle to reduce the heat source temperature or increase the heating temperature. The other is to achieve greater temperature lift of the heat pump through the coupling between the circulating components.

Zhang [19] combined compressors with absorption heat pumps and found that compression-assisted absorption heat pumps can save 50% operating costs and reduce 60% carbon dioxide emissions. Feng [20] studied the influence of compressors on the cycle performance at different positions of the system, and found that adding compressors into the cycle could reduce the heat source temperature and increase the heating temperature, as shown in Figure 5a,b. Schweigler [21] directly integrated the high-speed turbo-compressor into the single-stage water/lithium bromide absorption heat pump cycle, and studied the cycle characteristics of three different operating modes through detailed steady-state thermal process simulation. A compression ratio of 3 allows a rise in the cooling water inlet temperature by 10 K, and enables the use of low-temperature waste heat below 70 °C. Sun [22] put the compressor between the generator and the absorber, producing a heating temperature of the new system up to 125 °C.

Figure 5. Hybrid heat pump cycles. (a) Compressor between absorber and evaporator, (b) Compressor between generator and condenser, (c) Hybrid heat pump heat exchanger, (d) Air source hybrid heat pump cycle.

In order to obtain a heating temperature above 100 °C, Sun [23] coupled the compression cycle with the second absorption cycle type, as shown in Figure 5c; the hot water temperature could reach 135 °C and the COP was 3.6. Gao [24][25] proposed a new type of air source hybrid heat pump, as shown in Figure 5d. The new cycle could increase the input temperature from 10 °C to 100 °C with a COP of 1.4. Zhang [26] proposed a new system coupling a two-stage cascade heat pump with an absorption heat pump, and found that the new system would be more advantageous when the heating temperature lift was more than 150 °C.

This entry is adapted from the peer-reviewed paper 10.3390/en16124591

References

- National Bureau of Statistics. China Energy Statistical Yearbook 2022; China Statistics Press: Beijing, China, 2022.

- Liu, S.Y.; Lin, Z.Z.; Jiang, Y.C.; Zhang, T.H.; Yang, L.; Tan, W.T.; Lu, F. Modelling and discussion on emission reduction transformation path of China’s electric power industry under “double carbon” goal. Heliyon 2022, 8, e10497.

- Bergamini, R.; Jensen, J.K.; Elmegaard, B. Thermodynamic competitiveness of high temperature vapor compression heat pumps for boiler substitution. Energy 2019, 182, 110–121.

- Yan, H.; Hu, B.; Wang, R.Z. Air-source heat pump heating based water vapor compression for localized steam sterilization applications during the COVID-19 pandemic. Renew. Sustain. Energy Rev. 2021, 145, 111026.

- Luo, B.; Zou, P. Performance analysis of different single stage advanced vapor compression cycles and refrigerants for high temperature heat pumps. Int. J. Refrig. 2019, 104, 246–258.

- Malyshev, A.A.; Malinina, O.S.; Tatarenko, Y.V.; Kireev, V.S. Exergy characteristics of a steam compressor heat pump. AIP Conf. Proc. 2019, 2141, 030005.

- Luo, B.J. Oil flooded compression cycle enhancement for two-stage heat pump in cold climate region: System design and theoretical analysis. Energy Convers. Manag. 2016, 115, 52–59.

- Wang, H.L.; Jia, N.; Tian, J.R. Performance analysis of two stage compression cycle with an internal heat exchanger. Appl. Mech. Mater. 2014, 540, 110–113.

- Zhang, H.; Zhang, Y.T.; Xu, J.Y.; Wang, L.; Huang, Z. Performance Analysis of Internal Heat Exchanger-Based Quasi-Two-Stage Vapor Compression Heat Pump System for High-Temperature Steam Production. Energy Technol. 2020, 8, 2000623.

- Jiang, S.; Wang, S.G.; Yu, Y.; Ma, Z.J.; Wang, J.H. Further analysis of the influence of interstage configurations on two-stage vapor compression heat pump systems. Appl. Therm. Eng. 2021, 184, 116050.

- Jiang, S.; Wang, S.G.; Jin, X.; Zhang, T.F. A general model for two-stage vapor compression heat pump systems. Int. J. Refrig. 2015, 51, 88–102.

- Ma, X.L.; Zhang, Y.F.; Fang, L.; Yu, X.H.; Li, X.Q.; Sheng, Y.; Zhang, Y. Performance analysis of a cascade high temperature heat pump using R245fa and BY-3 as working fluid. Appl. Therm. Eng. 2018, 140, 466–475.

- Kim, D.H.; Park, H.S.; Kim, M.S. Optimal temperature between high and low stage cycles for R134a/R410A cascade heat pump based water heater system. Exp. Therm. Fluid Sci. 2013, 47, 172–179.

- Kim, D.H.; Kim, M.S. The effect of water temperature lift on the performance of cascade heat pump system. Appl. Therm. Eng. 2014, 67, 273–282.

- Wu, W.; Zhang, X.L.; Li, X.T.; Shi, W.X.; Wang, B.L. Comparisons of different working pairs and cycles on the performance of absorption heat pump for heating and domestic hot water in cold regions. Appl. Therm. Eng. 2012, 48, 349–358.

- Xu, Z.Y.; Mao, H.C.; Liu, D.S.; Wang, R.Z. Waste heat recovery of power plant with large scale serial absorption heat pumps. Energy 2018, 165, 1097–1105.

- Yang, X.J.; You, S.J.; Zhang, H. Economical optimization for double-stage LiBr absorption heat pumps. Phys. Procedia 2012, 24, 114–121.

- Balderas-Sánchez, I.N.; Rivera, W.; Jiménez-García, J.C. Thermodynamic analysis of a novel absorption heat transformer. Appl. Therm. Eng. 2019, 162, 114268.

- Zhang, H.S.; Zhao, H.B.; Li, Z.L. Thermodynamic performance study on solar-assisted absorption heat pump cogeneration system in the coal-fired power plant. Energy 2016, 116, 942–955.

- Feng, H.M.; Bao, R.Q.; Liu, F.C.; Shen, J.B.; Yu, Y. Study on new type II lithium bromide absorption compression composite heat pump system. Energy Energy Conserv. 2019, 9, 45–47.

- Schweigler, C.; Helm, M.; Eckert, T. Flexible heat pump or chiller with hybrid water/LiBr absorption/compression cycle. Int. J. Refrig. 2019, 105, 178–187.

- Sun, J.; Ma, S.C.; Huo, C.; Ge, Z.H.; Zhou, S.X. Performance analysis of new compression absorption heat pump cycle based on steam working fluid. Acta Energ. Sol. Sin. 2022, 43, 15–20.

- Sun, J.; Ma, S.C.; Huo, C.; Liu, J.Y.; Ge, Z.H.; Yang, Y.P. Study on a hybrid heat exchanger based on absorption and compression cycles. J. Eng. Thermophys. 2021, 40, 9–15.

- Gao, J.T.; Xu, Z.Y.; Wang, R.Z. Enlarged temperature lift of hybrid compression-absorption heat transformer via deep thermal coupling. Energy Convers. Manag. 2021, 234, 113954.

- Gao, J.T.; Xu, Z.Y.; Wang, R.Z. An air-source hybrid absorption-compression heat pump with large temperature lift. Appl. Energy 2021, 291, 116810.

- Zhang, X.; Wang, R.Z.; Xu, Z.Y. Air-source hybrid absorption-compression heat pumps with three-stage thermal coupling configuration for temperature lift over 150 °C. Energy Convers. Manag. 2022, 271, 116304.

This entry is offline, you can click here to edit this entry!