Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The Architecture, Engineering, and Construction (AEC) Industry 6.0 is the sixth transformative phase of the architectural, engineering, and construction sector, built on Industry 5.0. Industry 6.0 pioneers advancements in quantum computing, nanotechnology, artificial intelligence, and cloud-based energy solutions. Harmonization facilitates design, building, and maintenance processes, improving efficiency, accuracy, and sustainability. Construction has changed, like the 5.0 framework. Industry 5.0 uses AI and robotics to boost productivity, creativity, and supply chain alignment.

- Architecture, Engineering, and Construction (AEC) Industry 6.0

- sustainable smart buildings

- human-centric design

1. Industry and Society 1.0–6.0 in the Context of Development

-

Society 1.0–6.0 Evolutions

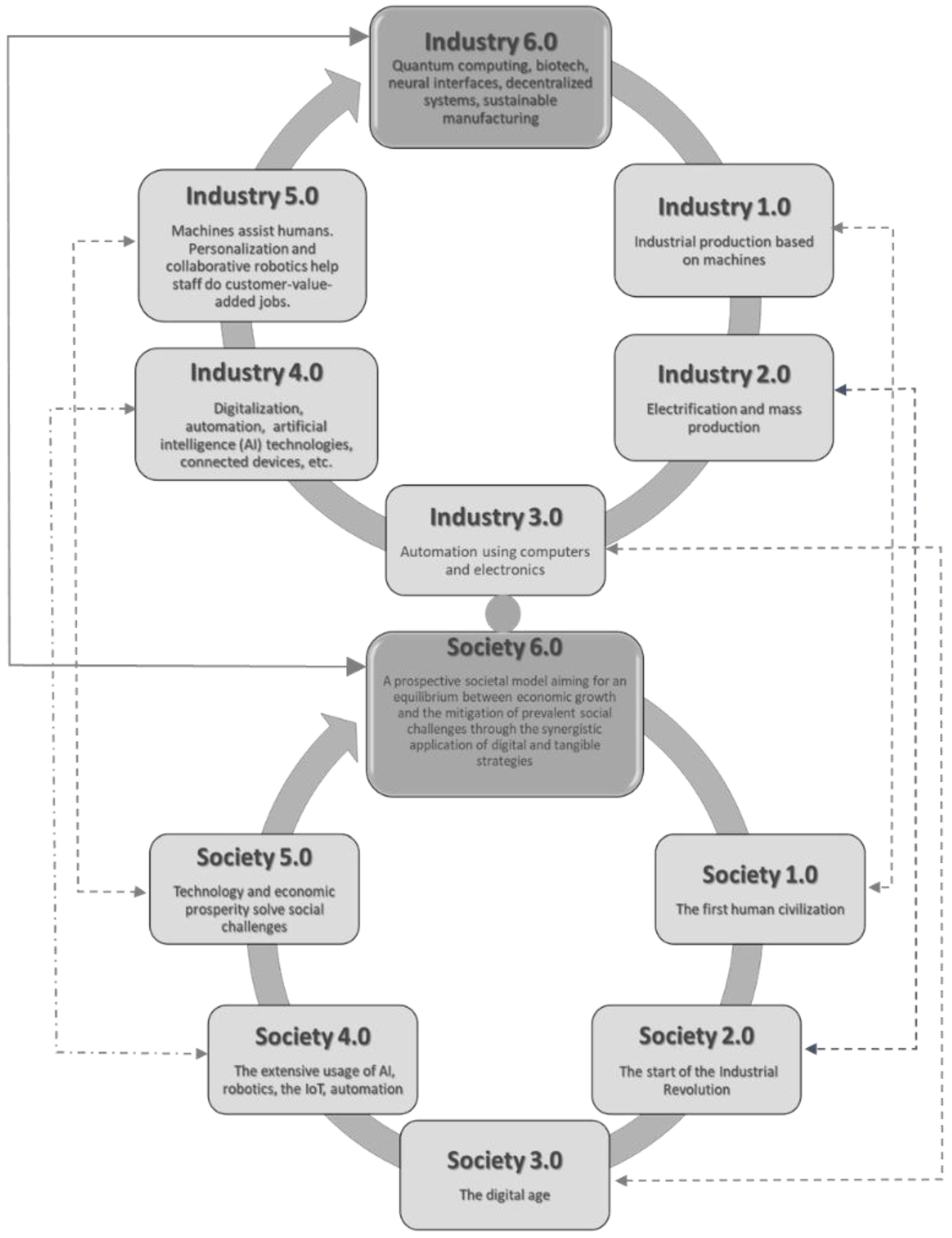

Technology has transformed civilization from 1.0 to 5.0. Each culture is briefly discussed. Society 1.0—the first human civilization—had rural settlements and pre-industrialization. Since the Internet’s invention, technology has improved dramatically [1]. Physical labor powered the economy without technology or communication. Agriculture fueled the economy, and longstanding norms stratified and governed society. Society 2.0 began with industrialized mass production [2]. Industrialization and mechanization transformed agriculture, manufacturing, transportation, and urbanization, creating Society 2.0. Society 3.0 and Industry 3.0 and 4.0 ushered in the digital age with the widespread use of computers, the Internet, and related technology. This study investigates digital technologies that are changing society [3]. In Society 3.0, ICT has helped firms go digital, internet commerce grew, and social media exploded. Information and communication have democratized the game. Public sector organizations must provide critical services and leverage cutting-edge techniques like artificial intelligence analytics that other industries have adopted [4]. They imagine Society 5.0. Technology and economic success remedy social issues in its compassionate world. AI, IoT, and robotics will help Society 5.0 address aging populations, environmental sustainability, healthcare, transportation, and more. Technology can also improve society. Society 6.0 envisions a future where digital and real-world solutions balance economic growth and social challenges [5].

-

Industry 1.0–6.0 of the Industrial Revolution

Over three centuries, new technology and industrial methods were introduced in five phases, starting in the 18th century. Steam-powered machinery began making items around 1780, according to Dixit and Uday Shanker (2023). Crafting and homesteading became common during this critical historical time [6]. Factory systems originated alongside the First Industrial Revolution. The Second Industrial Revolution introduced mass manufacturing and scientific administration to industry. CNC machinery and robotics enabled industry automation during the Third Industrial Revolution. Finally, Industry 4.0—the Fourth Industrial Revolution—incorporates computer science and information technology into production. Long-term sustainability is also emphasized. Digital manufacturing, additive manufacturing, and cyber-physical systems promise to improve connectivity and communication while simplifying data to optimize products and processes, so many developed countries have invested heavily in intelligent manufacturing technologies [7]. Due to this change, more people are working remotely.

Modern industrial technologies facilitate the reconnection to nature. An important aspect of Industry 5.0 is the seamless collaboration of people and robots. M. Ergün and his colleagues emphasize this, claiming that computer-vision approaches may effectively address human-caused mistakes and difficulties. Using computer-aided techniques may improve this even further [8][9]. Experts are now more concerned with improving the customer experience due to the development of customized and cooperative robots instead of just striking a balance between human wants and what technology can provide.

The cyclical nature of industrial revolutions and altering manufacturing paradigms show that this dynamic has evolved. Technology changed relationships [10]. Industry 6.0 is a paradigm shift based on quantum breakthroughs, advanced biotechnologies, neural integration, decentralized autonomous systems, and a strong focus on sustainable production [11]. Figure 1 shows that this current iteration emphasizes resilience, human-centeredness, sustainability, and manufacturing methods.

Figure 1. The Evolution of Interactions between Industry and Society: From Version 1.0 to 6.0.

2. Benefits of AEC Industry 6.0 in Architecture and Construction

Industry 6.0 makes design and construction more connected and promotes dynamic industry networks. It encourages flexible supply chains, adaptable value networks, and unprecedented global information interchange [12]. AEC Industry 6.0 emphasizes creating a learning and equilibrium-oriented environment. Physical and virtual architectural and infrastructure aspects inspire a new approach to integrated project delivery [13]. Stakeholders can see and evaluate physical structures and virtual data to improve global cooperation, technical assistance, and decision-making. In AEC Industry 6.0, antifragile design prioritizes adaptability and strength. Unlike conventional buildings, this forward-thinking sector encourages a resilient system design that can resist and profit from shocks. Industry 6.0 considers functional and non-functional needs for architectural and construction systems, including openness, usability, security, and mobility [14]. These barriers now aid sophisticated projects. AEC Industry 6.0 should stimulate design and construction innovation. Human abilities and cutting-edge technology will make built settings more sustainable, effective, and beautiful [15]. These revolutionary methods will elevate architectural design and construction, enhancing human and environmental well-being.

3. Additive Manufacturing (3D Printing)

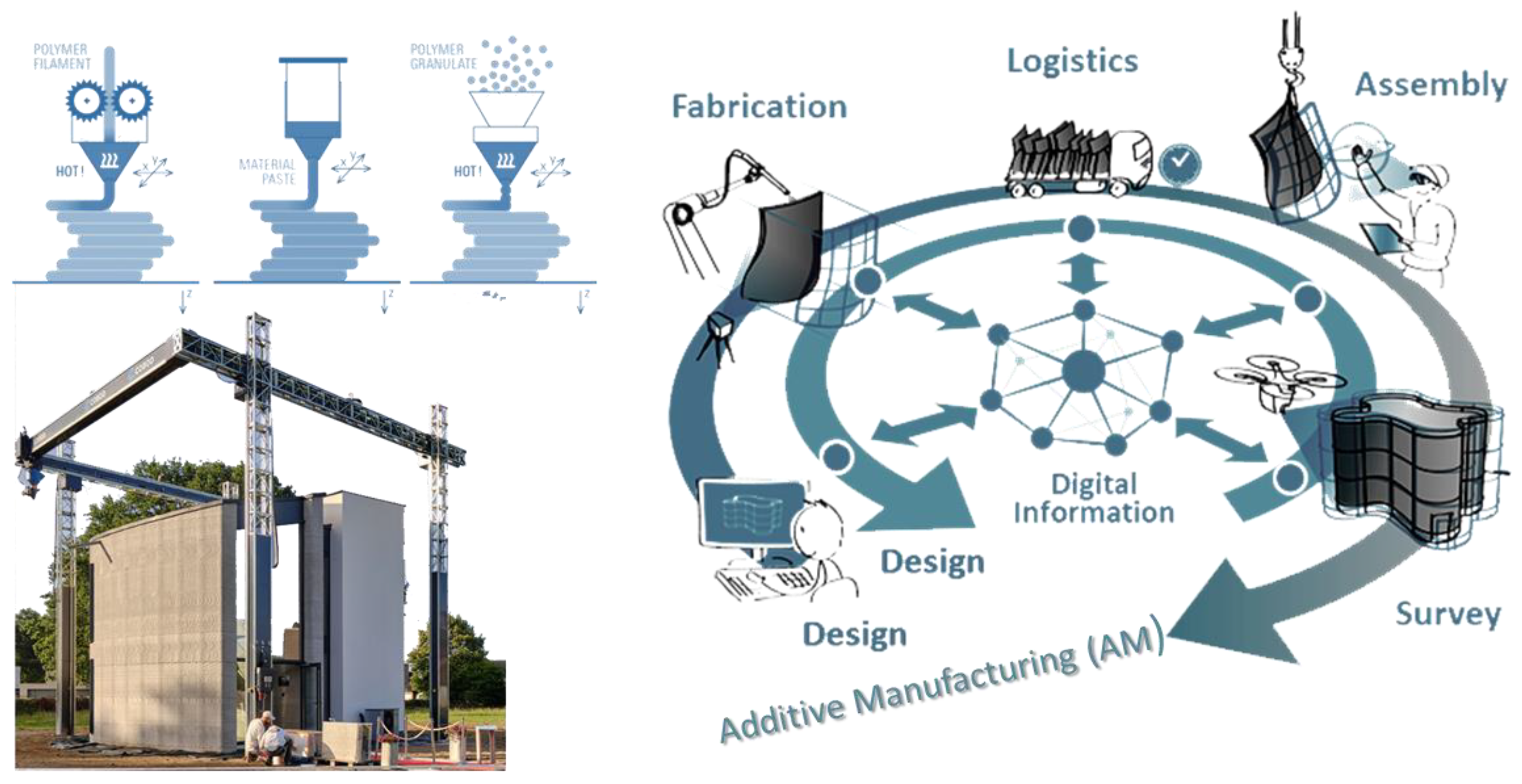

Production, distribution, and use processes are dramatically changing thanks to additive manufacturing (AM) technology, particularly in the architectural, engineering, and construction (AEC) industry [16]. This ground-breaking paradigm change, including a broad range of technologies, significantly impacts the production and use of a wide range of goods and parts. According to S. Salinas Monroy, P. Li, Y. Fang, and K. A. Polarities, this revolutionary movement created consumer goods and radically altered the architectural design field and the building sector. The core of the AM paradigm, 3D printing, uses a systematic process of successive layer-by-layer material deposition. This method of operation significantly lowers marginal manufacturing costs and promotes dramatic industrial supply chain simplification [17]. One notable benefit of additive manufacturing (AM) in the architecture, engineering, and construction (AEC) industry is its capacity to facilitate localized production [18]. The proximity of manufacturing facilities to customers can significantly alter the supply chain dynamics, improving efficiency and flexibility. Furthermore, additive manufacturing (AM) technology enables production with considerably reduced marginal costs and offers a potential pathway for enhanced economic efficiency in manufacturing and building procedures (see Figure 2).

Figure 2. Additive Manufacturing (AM) working process in AEC Industry 6.0.

Three-dimensional printing, or additive manufacturing, is changing the AEC industry. Three-dimensional printing provides customization and accuracy for making intricate panels, fittings, and other aesthetic features [19]. This method enhances the aesthetics and utility of buildings. Many companies now 3D print entire structures. Industrial-scale printers with fast-hardening concrete save construction time, cost, and environmental impact. Apis Cor offers 24-h home printing. Urban planners also utilize 3D printing to swiftly produce and change scale models of cityscapes [20]. As 3D printing in building advances, we expect more inventive uses.

4. Artificial Intelligence and Autonomous Robots

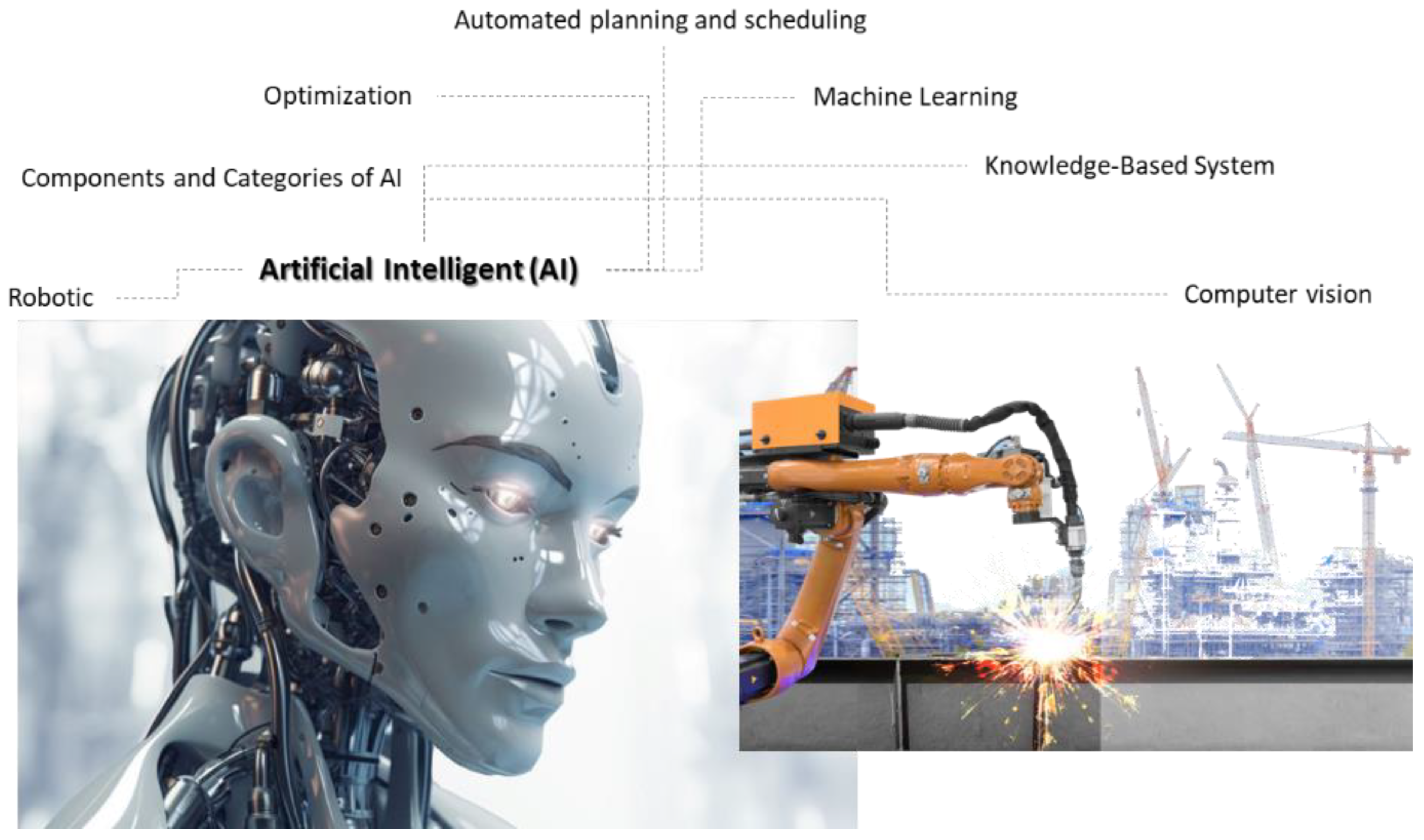

The harmonious marriage of Artificial Intelligence and autonomous robotics fundamentally redefines AEC Industry 6.0, spearheading an organizational and operational transformation [21]. These ingenious robotic systems can tackle complex tasks, heightening efficiency, bolstering safety, and streamlining cost-effectiveness. Utilizing Machine Learning algorithms, they autonomously adapt, learn, and perfect processes. Experts Mohsen Soori, Behrooz Arezoo, and Roza Dastres point out that AI, ML, and DL have breathed new life into sophisticated robots, increasing their intelligence, efficiency, and adaptability. Advanced robotics leverage these technologies for autonomous navigation, object recognition and manipulation, natural language processing, and predictive maintenance. Additionally, they facilitate the creation of collaborative robots, or ‘cobots,’ that seamlessly interact with humans in dynamic environments and tasks [22] (See Figure 3).

Figure 3. Artificial intelligence within autonomous robots’ interaction.

The applications include a broad spectrum, spanning from using artificial intelligence to anticipate equipment failures in the context of predictive maintenance to the execution of precise tasks by robots in advanced manufacturing. The importance of human–robot cooperation is also underscored, with robots being used to aid human employees rather than replace them [23]. The objective of AEC Industry 6.0 is to provide a more customized, environmentally conscious, and comprehensive industrial setting by integrating human creativity with artificial intelligence capabilities [24].

5. Optimizing the AEC Industry with Cyber-Physical Systems and Smart Factory Simulations

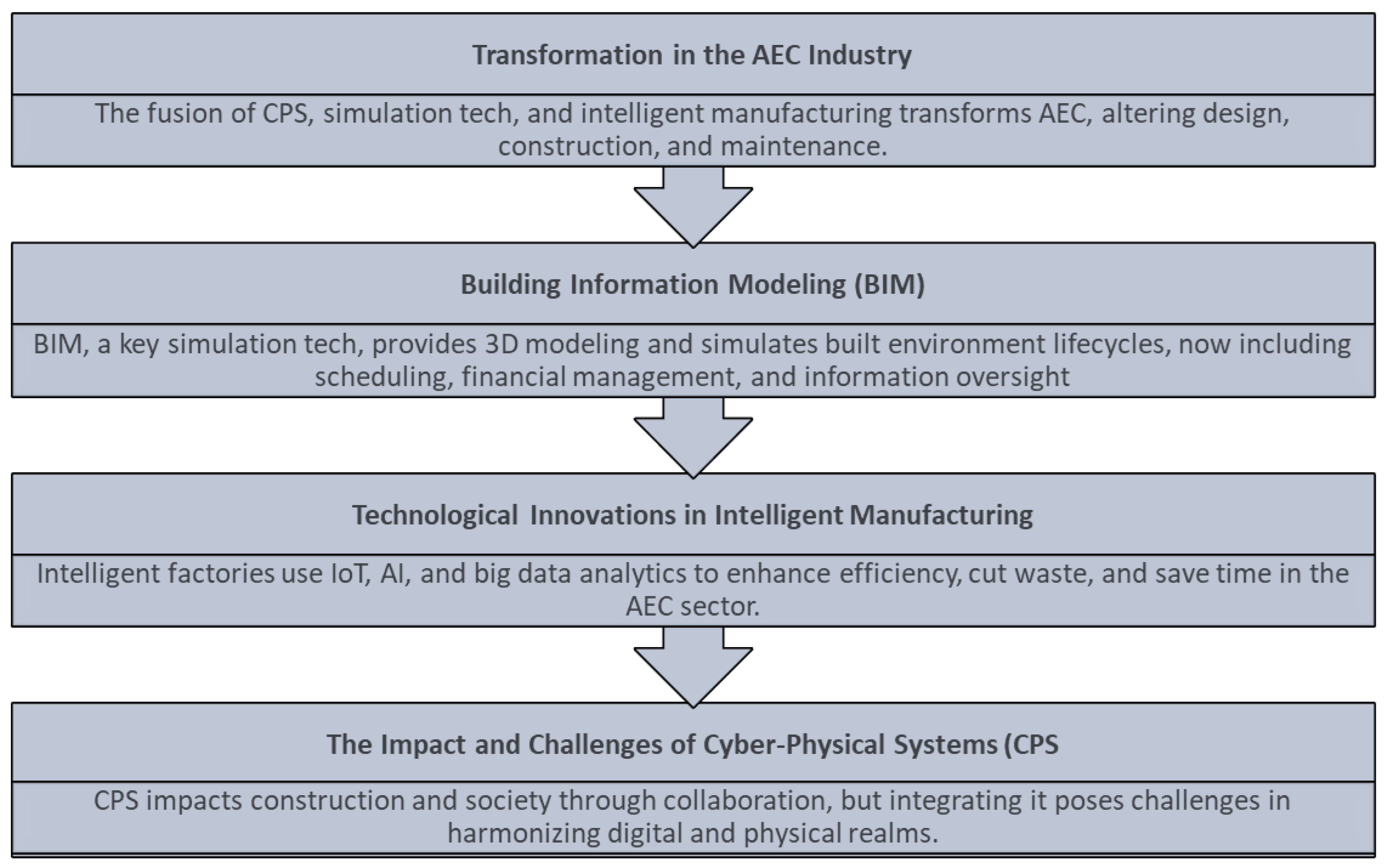

AEC is being transformed by Cyber-Physical Systems (CPS), simulation technologies, and intelligent manufacturing facilities. The changes above affect architecture, construction, and maintenance. Specialists such as Tran Duong Nguyen and Sanjeev Adhikari assert that the construction industry requires assistance in merging the digital and tangible realms. Data interpretation and execution need to be distinct. This gap causes data fragmentation, duplication, and construction life cycle inefficiency [25]. Cyber-Physical Systems (CPS) use computer, networking, and physical processes to detect structural faults and enable predictive maintenance. Building Information Modeling (BIM) is a leading simulation technology that lets stakeholders create sophisticated three-dimensional models to simulate the complete lifecycle of a built environment. Doukari, Omar, Mohamad Kassem, and David Greenwood explain that Building Information Modelling (BIM) has evolved from a computer-assisted tri-dimensional modeling tool to include chronological scheduling, fiscal oversight, and an information management structure that can improve decision-making across the entire life cycle of constructed assets. Building Information Modeling (BIM) is a vital simulation technology tool that allows stakeholders to create sophisticated three-dimensional models and simulate a built environment’s lifespan. According to Doukari, Omar, Mohamad Kassem, and David Greenwood, BIM evolved from a computer-aided tri-dimensional modeling tool to include chronological scheduling, financial oversight, and an information maze [26]. This technique optimizes performance and predicts potential problems. Smart factories within the Architecture, Engineering, and Construction (AEC) sector utilize IoT, AI, and big data analytics to enhance manufacturing [27]. Automated component production streamlines on-site assembly and reduces waste. These technologies improve architectural flexibility, safety, and efficiency. Integrating Cyber-Physical Systems (CPS) with intelligent manufacturing has transformed the construction sector, encouraging equipment and supplier collaboration. Hamzah M. et al. defined CPS as cyber-physical convergence. Interconnectedness allows global integration and substantially influences daily life, especially CPS implementation. This integration poses hurdles. CPS broadens perceptions and spurs innovation [28]. Digital twins improve building operations and help identify issues, while simulators provide a safe training environment (See Figure 4).

Figure 4. The Digital Transformation of AEC Industry 6 future: Embracing CPS, BIM, and Intelligent Manufacturing.

6. Big Data Applications in the AEC Industry 6.0 Future

In the 6.0 era, merging Big Data technology with Internet of Things (IoT) devices provides a cutting-edge technique for managing complicated and extensive building project data. Technology integration helps create novel services for architectural, engineering, and construction (AEC) professionals and others [29]. The app improves building site analysis, decision-making, and operational efficiency. Big Data can help the AEC industry understand construction patterns, building practice trends, and project abnormalities. This can spur innovation and shape design, planning, and building processes. AEC Industry 6.0 raises work roles to improve client customization and give specialists unsurpassed creativity. Automation helps architects design for clients. AEC Industry 6.0 introduced client-focused value propositions. Real-time feedback and improved automation facilitate this shift. AEC Industry 6.0 integrates human knowledge and mechanical precision [30]. Collaboration promotes decision-making, problem-solving, design, and construction. Automated work management boosts morale by offering intellectually engaging roles, personal development, and job satisfaction. Inclusion is a goal of AEC Industry 6.0 [31]. This balances career advancement, employment, and skill development. AEC Industry 6.0 encourages green building. It enables eco-friendly buildings. Adaptation will determine AEC Industry 6.0’s success. Human-focused, resilient, green firms will lead. Human-oriented designs, resilient resilience, and inclusive sustainability—the pillars of AEC Industry 6.0—need more research [32].

This entry is adapted from the peer-reviewed paper 10.3390/su151813464

References

- Tavares, M.C.; Azevedo, G.; Marques, R.P. The Challenges and Opportunities of Era 5.0 for a More Humanistic and Sustainable Society—A Literature Review. Societies 2022, 12, 149.

- Hayat, A.; Shahare, V.; Sharma, A.K.; Arora, N. Introduction to Industry 4.0. In Blockchain and its Applications in Industry 4.0; Springer Nature: Singapore, 2023; pp. 29–59.

- Omrane, A.; Akbari, M.; Patra, G. How to Digitize Human Resource Management in the Era of Industry 4.0. In Digital Technologies for Smart Business, Economics, and Education: Towards a Promising Future; Springer International Publishing: Cham, Switzerland, 2023; pp. 1–18.

- Baragde, D.B. Information Technology for Enhancing Public Sector Sustainability. In Leadership and Governance for Sustainability; IGI Global: Hershey, PA, USA, 2023; pp. 204–221.

- Žižek, S.Š.; Mulej, M.; Potočnik, A. The Sustainable Socially Responsible Society: Well-Being Society 6.0. Sustainability 2021, 13, 9186.

- Dixit, U.S. Evolution of Manufacturing: Growing on a Circular Track. In Additive and Subtractive Manufacturing Processes; CRC Press: Boca Raton, FL, USA, 2023; pp. 1–30.

- Atieh, A.M.; Cooke, K.O.; Osiyevskyy, O. The role of intelligent manufacturing systems in implementing Industry 4.0 by small and medium enterprises in developing countries. Eng. Rep. 2023, 5, e12578.

- Hatır, M.E.; İnce, İ.; Korkanç, M. Intelligent detection of deterioration in cultural stone heritage. J. Build. Eng. 2021, 44, 102690.

- Hatır, E.; Korkanç, M.; Schachner, A.; Ince, I. The deep learning method applied to the detection and mapping of stone deterioration in open-air sanctuaries of the Hittite period in Anatolia. J. Cult. Herit. 2021, 51, 37–49.

- Pizoń, J.; Gola, A. Human–Machine Relationship—Perspective and Future Roadmap for Industry 5.0 Solutions. Machines 2023, 11, 203.

- Almusaed, A.; Yitmen, I.; Almsaad, A.; Akiner, İ.; Akiner, M.E. Coherent Investigation on a Smart Kinetic Wooden Façade Based on Material Passport Concepts and Environmental Profile Inquiry. Materials 2021, 14, 3771.

- Chourasia, S.; Tyagi, A.; Pandey, S.M.; Walia, R.S.; Murtaza, Q. Sustainability of Industry 6.0 in global perspective: Benefits and challenges. Mapan 2022, 37, 443–452.

- Li, F.; Laili, Y.; Chen, X.; Lou, Y.; Wang, C.; Yang, H.; Gao, X.; Han, H. Towards big data-driven construction industry. J. Ind. Inf. Integr. 2023, 35, 100483.

- Duggal, A.S.; Malik, P.K.; Gehlot, A.; Singh, R.; Gaba, G.S.; Masud, M.; Al-Amri, J.F. A sequential roadmap to Industry 6.0: Exploring future manufacturing trends. It Commun. 2022, 16, 521–531.

- Nasir, O.; Mohammad, A.K. Exploring the role of parametric architecture in building design: An inclusive approach. Facta Univ. Ser. Archit. Civ. Eng. 2023, 21, 95–114.

- Leschok, M.; Cheibas, I.; Piccioni, V.; Seshadri, B.; Schlüter, A.; Gramazio, F.; Kohler, M.; Dillenburger, B. 3D printing facades: Design, fabrication, and assessment methods. Autom. Constr. 2023, 152, 104918.

- Monroy, S.S.; Li, P.; Fang, Y.; Loparo, K.A. Blockchain-Empowered Distributed Additive Manufacturing-as-a-Service: An Architectural Perspective; IEEE Network: Piscataway, NJ, USA, 2023.

- Tuvayanond, W.; Prasittisopin, L. Design for Manufacture and Assembly of Digital Fabrication and Additive Manufacturing in Construction: A Review. Buildings 2023, 13, 429.

- Almusaed, A.; Alasadi, A.; Almssad, A. A Research on the Biophilic Concept upon School’s Design from Hot Climate: A Case Study from Iraq. Adv. Mater. Sci. Eng. 2022, 2022, 7994999.

- Bereitschaft, B. The changing ethnic-racial profile of ‘very walkable urban neighborhoods in the US (2010–2020): Are minorities under-represented? Urban Stud. 2023, 60, 638–654.

- Ha, H.T.; Daljit, S. (Eds.) Southeast Asian Affairs 2023; Institute of Southeast Asian Studies: Singapore, 2023.

- Soori, M.; Arezoo, B.; Dastres, R. Artificial intelligence, machine learning and deep learning in advanced robotics, a review. Cogn. Robot. 2023, 3, 54–70.

- Safdari, A. From Basic Empathy to Basic Trust in Human-Robot Relation: A Phenomenological Proposal. In ALIFE 2023: Ghost in the Machine: Proceedings of the 2023 Artificial Life Conference; MIT Press: Cambridge, MA, USA, 2023.

- uz Zaman, U.K.; Siadat, A.; Baqai, A.A.; Naveed, K.; Kumar, A.A. (Eds.) Handbook of Manufacturing Systems and Design: An Industry 4.0 Perspective; CRC Press: Boca Raton, FL, USA, 2023.

- Nguyen, T.D.; Adhikari, S. The Role of BIM in Integrating Digital Twin in Building Construction: A Literature Review. Sustainability 2023, 15, 10462.

- Doukari, O.; Kassem, M.; Greenwood, D. Building Information Modelling. In Disrupting Buildings: Digitalisation and the Transformation of Deep Renovation; Springer International Publishing: Cham, Switzerland, 2023; pp. 39–51.

- Soori, M.; Arezoo, B.; Dastres, R. Internet of things for smart factories in industry 4.0, a review. Internet Things Cyber-Phys. Syst. 2023, 3, 192–204.

- Hamzah, M.; Islam, M.M.; Hassan, S.; Akhtar, M.N.; Ferdous, M.J.; Jasser, M.B.; Mohamed, A.W. Distributed Control of Cyber-Physical Systems on Various Domains: A Critical Review. Systems 2023, 11, 208.

- Almusaed, A.; Almssad, A.; Alasadi, A. Analytical interpretation of energy efficiency concepts in the housing design process from hot climate. J. Build. Eng. 2018, 21, 254–266.

- Yadav, R.; Arora, S.; Dhull, S. A Pathway to Industrial Revolution 6.0. Int. J. Mech. Eng. 2022, 7, 1452–1459.

- Hickey, J.P. A Study of Gender Diversity in US Architecture, Engineering, and Construction (AEC) Industry Leadership. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2023.

- Alves, J.; Lima, T.M.; Gaspar, P.D. Is Industry 5.0 a Human-Centred Approach? A Systematic Review. Processes 2023, 11, 193.

This entry is offline, you can click here to edit this entry!