Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Food Science & Technology

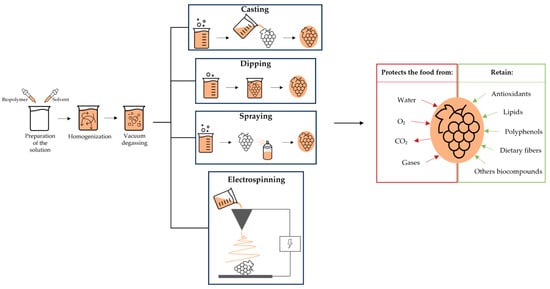

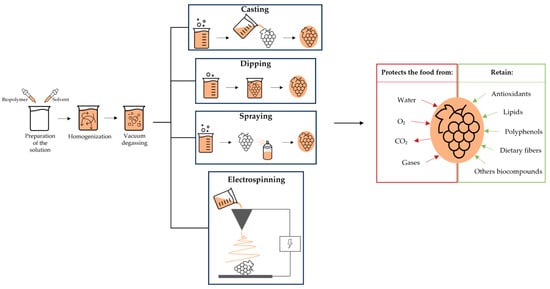

Edible coatings are made from natural food-grade materials, such as hydrocolloids (polysaccharides, proteins), lipids, and emulsifiers, produced with different techniques, such as dipping (immersing), spraying, spreading, brushing, pressing them/thermoforming, or extrusion. The most used method for coating is immersing, where food is dipped in a liquid containing food matrices, forming a film around the food and protecting all the components present.

- casting

- extrusion

- chitosan

- cellulose

- pectin

- carrageenan

- alginate

1. Introduction

Currently, one of the alternatives for prolonging food shelf-life is the creation of plastic packaging, which is already implemented in the market and has been used in consumers' daily lives for many years. The high usage of this alternative relies on its low cost and resistance, as well as being easy to mold [14,15]. Despite the aspects mentioned above, several studies [16,17,18] show that this solution is not a promising alternative, as it implies an overall increase in the use of plastic. In 2021, 390.700 million tonnes of plastic were produced worldwide, of which 57.200 million tonnes were made in Europe, with a gradual increase over the years [19]. Another disadvantage of this material is that it is not biodegradable, constituting a harmful environmental alternative. It is not beneficial for the lifestyle of the entire population and for all biodiversity. It is increasingly a more debatable and worrying issue. Because of this, several alternatives have been investigated to substitute this alternative for something more sustainable and not harmful to the environment.

The alternative to replacing plastic and consequently meeting the requirements of the extension of the shelf-life of food is the creation of edible coatings that are progressively a more cost-effective, sustainable, and environmentally effective solution in the use of primary packaging in the food industry. They can also be an alternative to replace commercial synthetic waxes made of oxidized polyethylene. These coatings protect food ingredients from oxidation and degradation caused by enzymes while also helping to preserve the flavors originating from each food, thus ensuring the viability of the active ingredients for a long time. Moreover, they may contain valuable additives, like antioxidants and phytonutrients [2,20,21]. In addition, depending on the coating, beneficial properties may be added, such as preventing chronic degenerative and cardiovascular diseases due to phenolic compounds and preventing reproductive, nervous system, inflammation, and immune system degeneration [22,23].

2. Techniques of Making Edible Coatings

2.1. Casting and Extrusion

Two techniques can be used to make edible films, namely casting and extrusion (Figure 1). Casting is a technique used in the laboratory that has the advantage of being accessible and straightforward. This technique is divided into three phases of preparation: solubilization, casting, and drying. Firstly, one dispersion/solution of a suitable solvent is prepared and then spread on the material's surface. Secondly, the prepared is dried since this technique uses the evaporation of the solvent to increase the solution viscosity, which will help to make an edible film with desirable properties [52]. The processing time, temperature, and drying conditions condition the effectiveness of creating a strong and promising film. As this technique is produced in three phases, the processing time is long and has an extended drying time, so it is not practicable for commercial film production [53,54]. This technique has been used in several studies with many different foods like okra leaves [55], cherry tomato [56], and mangoes [57] and plants like yerba mate [58].

Figure 1. Illustration of the application and protection of edible coatings in grapevine by-products.

Extrusion is a technique that can be applied in the industry, unlike the previous method. It begins with preparing the film-forming solution and introducing it in the feeding zone. The next step is kneading, where the mix is compressed, and the pressure, temperature, and density increase. The last stage is the heating stage, where the solution is extruded through a nozzle at a defined speed, and finally, the films are dried [59]. This technique is more sensitive since a high temperature and unsuitable pH may break the polypeptide chain of the protein, conditioning the formation of the edible film [60]. The advantage of this process is that it allows for a continuous operation with control of the temperature, size, form, and humidity, providing a more structured film and allowing for better dispersion of the active compounds [53].

2.2. Dipping (Immersion)

The dipping process has a wide application, even in the laboratory, for simplicity (Figure 1). First, the coating solution is prepared by dipping the food into the coat-forming solution for a specific time. Then, the coated food is left to dry at room temperature, and the excess solution is removed not to become a film with a large layer [61]. This method can be repeated with another solution for better coating [59]. This technique has the advantage that it is simple, short, and low-cost. The only downside of this process is that it uses a lot of film-making solutions, taking longer in preparation [60].

2.3. Electrospinning

Electrospinning is used chiefly in edible film packaging [62], Figure 1. This filmmaking process is inexpensive, easy to use, and versatile because it only uses an electric field to stretch a polymeric solution’s forming structures with a high specific surface so it is possible to coat the materials; that is, an electrostatic force is used to transform a polymeric solution into nanofibrous films. This process demonstrates a high surface–volume ratio and a small pore size distribution [52]. The only disadvantage is that this process presents a weak interaction between the electrolyte fibers, conferring destructive mechanical properties on the film [60].

2.4. Spraying

Spraying is a method where the coating solution is distributed on the surface of the food pieces from the drops that form in the equipment's nozzle, and it is the most used in the food industry (Figure 1). The advantage of this method is that it forms a coating with uniform thickness over the whole surface of the food, the quantity of the necessary solution is less, the possibility of contamination is lower, and it can be applied to food with large surfaces [59].

3.1. Polysaccharides

Polysaccharides are used to make edible films to preserve food, especially fruits and vegetables. Using these polysaccharides to make coatings is very popular due to their low cost and availability. Polysaccharide coatings offer barrier properties, such as water and gaseous permeability, and create modified internal atmospheric conditions, resulting in significant preservative effects [55]. Antioxidants and antibacterial characteristics are related to polysaccharide-based edible covering [2].

Chitosan is a natural cationic polysaccharide created by deacetylating the chitin found in animal shells, such as crustaceans, insect cuticles, and yeast [64]. In recent years, chitosan has been applied in several foods, like sweet cherries [104], kiwifruit [105], mango [106], litchi [107], grape [65,108,109], apricot [110], banana [111], and papaya [112], among others. Prathibhani et al. [105] studied the effect of an edible chitosan coating on kiwifruit. They showed that this coating has an effective preservation technique, reducing respiration activity and delaying weight loss and firmness changes, thereby delaying ripening.

Cellulose is the most widespread polymer in nature and is produced by various sources, such as plants, animals, and bacteria [2]. Bacterial cellulose is the most widely used biopolymer in making edible films and coatings, with the disadvantage of this polysaccharide having no antimicrobial activity [98]. Strnad et al. [68] showed that the combination of cellulose and chitosan is beneficial to producing the perfect edible film since the cellulose improved the mechanical strength, and the chitosan improved the antibacterial and biocompatible properties of the composites. The cellulose and chitin junction also produces a film that is biocompatible, biodegradable, non-toxic, antimicrobial, presents antioxidant activity, has low gas permeability, and, compared with protein cellulose, is less immunogenic and non-hemolytic [115].

Pectin is the most used polysaccharide in food processing [74]. It can be found in many fruits and vegetables, such as banana peels, red pomelo peels, watermelon rinds, sugar beet pulp, sunflower heads, tomato pomace, and carrot pomace. However, most commercial pectin is obtained from citrus or apple pomace wastes [70,71]. Pectin polysaccharide structures contain β − 1, 4-linked galacturonic acid residues. Extraction of pectin allows for reusing the pomace that is not used in the fruit juice industry.

Regarding carrageenan, it is a natural polysaccharide extracted from red seaweed, such as Eucheuma cottonii, Mastocarpus stellatus, and Hypnea musciformis [60]. It is an absorbing polymer because it forms thermoreversible gels and viscous solutions. It becomes elastic and stable if Ca2+ is added, which is ideal for developing edible films [74].

Alginate is a polymer in brown algae's cell walls [75]. Alginate covering materials combine divalent cations, such as Mg2+, Ca2+, Al2+, Mn2+, and others. Due to their hydrophilic aspect, they are used to make edible solid coatings or films with low water resistance [122]. A disadvantage of this polymer is its poor mechanical properties; however, according to several studies, the alginate mixture with pectin and carrageenan improves the missing properties and forms a more protective and effective film [115].

Gums are naturally occurring polysaccharides with worldwide industrial uses and have been increasingly investigated for their desirable advantages in creating edible films [123]. Two categories divide gums: exudate gums and seed gums. Seed gums are the best known and used because they are easily accessible since they are extracted from plants, specifically from the epidermis of seeds, leaves, and bark. This category includes guar, locust bean, tara, tamarind, basil, and fenugreek gums. The exudate gum is used as a thickener, stabilizer, rheology modifier, soluble fiber, and fat replacer. Examples of exudate gum are gum ghatti, Persian, tragacanth, and shellac. Other gums are extensively used, like Arabic gum and xanthan gum [28]. Arabic gum is produced from the Acacia Senegal tree, and it has antioxidant and antifungal characteristics against fungi and antimicrobial properties advantageous for the creation of films. It has already been applied in the edible coatings industry in cereals [77] and fruit conservation [124].

Guar gum is obtained from the seed endosperm of Cyamopsis tetragonolobus. According to several studies, it has excellent film-forming capacities, is biocompatible, delays the loss of quality, and prolongs the shelf life of food. The study by Jiang et al. [82] demonstrates several procedures to improve this film: changes to the biopolymer, the addition of plasticizers, mixing with other polymers, the layer-by-layer (LBL) assembly technique, or the addition of plant extracts (Pes) and essential oils (Eos), thus showing improvements in the realization of edible coatings. In the study by Shubham et al. [133], the guar gum (1.5%) edible film created to preserve the quality of litchi was promising because it was capable of forming a protective barrier on the surface of litchi, maintaining fruit total soluble solids, pH, acidity, ascorbic acid, total sugar, reducing sugar, and non-reducing sugar over 12 days. Locust bean gum is a natural polymer obtained by crushing the endosperm of the seeds from a carob fruit pod [85]. To create an edible film, it is necessary to put the locust bean gum in hot water (80 °C) for solubilization [98].

Gum ghatti is an exudate gum from the tree Anogeissus Indifolia, which has good water oil emulsification stability and is a non-starch polysaccharide. The study by Eshghi et al. [92] that produced an edible coating to improve the quality of a specific type of table grape (Rishbaba) with a mix of chitosan and gum ghatti in different concentrations showed that the addition of gum ghatti to chitosan presented extra beneficial effects for weight loss and the titratable acidity, pH, and total soluble solids of the table grape. The mix of chitosan (1%) and gum ghatti (1%) showed the best concentration in forming an edible coating because it delayed losses in ascorbic acid, presented good membrane stability, and improved antioxidant enzyme activities of the Rishbaba grape during 60 days of storage at 0 ± 1 °C and 85% relative humidity. The film extended the shelf life and preserved the bioactive ingredients [92]. Tragacanth gum is an anionic biopolymer obtained from the dry sap of the species Astragalus that contains intumesce and water-soluble parts. It has a hydrophilic property that causes stabilizing and emulsifying properties [80,81].

Starch is a natural polymer composed of amylose (water-soluble) and amylopectin (water-insoluble) molecules that can form strong gels [2]. It is one of the most widely used polymers in the packaging and food industries. Several foods with starch can include films, such as cassava, corn, millet, wheat, rice, quinoa, sweet potatoes, peas, and tef [96]. Like so many others, the disadvantage of this polymer is that the mechanical quality is not good [73], and its hydrophilic nature is high, thus making the film permeable to water and sensitive to moisture, leading to reduced film permanence [99].

Agar is a polysaccharide extracted from specific red seaweed that possesses excellent film-forming ability and has the particularity of being insoluble in cold water but soluble in boiling water [96]. The application of this polymer is limited due to its shortcomings of strong hydrophilicity and weak mechanical properties, and it is relatively brittle, has low elasticity, and has poor thermal stability [144,145]. To overcome these limitations, the solution is in combination with other polymers, hydrophobic materials, plasticizers, nanoparticles, and antimicrobial agents [144].

Inulin is a fructan polysaccharide found in several plant species, like Liliaceae, Amaryllidaceae, Gramineae, and Compositae, that is soluble in hot water and slightly soluble in cold water. Despite its viscous properties, the viscosity decreases with an increase in temperature.

Konjac glucomannan is a water-soluble natural polysaccharide extracted from the tuber of Amorphophallus konjac that has been extensively used as a material of film that exhibits good film-forming ability. The low water resistance and low mechanical properties are disadvantages and limit the use of this polymer [102]. For this, the combination of Konjac glucomannan with other polymers is beneficial.

Pullulan is a protein developed by microbial fermentation and has a starch-like structure. The existing limitations of pullulan-based films are the hydrophilicity, brittleness, high cost, and lack of active functions [149]. Improving this characteristic can be performed with physical and chemical crosslinking, plasticizers, and combination with other polymers, such as pectin [150], chitosan [151,152,153], starch [154], sodium alginate [155], gelatin [156], konjac glucomannan [102], and others.

3.2. Proteins

Gelatin comes from animal sub-products, specifically pig skin, beef skin, pork, and cattle bones [99]. An edible film based on gelatin proves to be a cheap, biodegradable option and can absorb ultraviolet light due to the aromatic amino acids present in its structure. It has the disadvantage of having low thermal stability and weak mechanical and barrier properties, being more advantageous with the combination of other biopolymers [80].

In the study by Chen et al. [157], cherry tomatoes were coated with edible gelatin, chitosan, nisin, and cornstarch film. They showed that weight loss and total bacterial count were reduced, and higher firmness and better color were observed during the storage over 22 days.

Biodegradable polymers have experienced a notable upswing in popularity as of late, motivated by two main reasons: firstly, the rapid decrease in oil reserves worldwide and second, the urgency to reduce environmental pollution resulting from the use of non-biodegradable resources [163]. Zein, a prolamin polymer commercially available since 1938 [164], is a storage protein extracted from corn that is present mainly in corn residues [73,159]. It has the particularity of not dissolving in water, and the film must be prepared in a mixture of alcohol–water and acetic acid at alkaline pH and high concentrations of urea [160].

Whey protein is a valuable by-product of cheese manufacturing that presents a sound barrier against aromas, lipids, and oxygen and has good mechanical properties. Still, its hydrophilic nature limits its capacity to act as a barrier against water vapor [162]. This limitation can be improved with enzymatic modification, like adding transglutaminase and numerous hydrophobic compounds, waxes, fatty acids, or acetylated monoglycerides like vegetable oils [171]. This protein needs a plasticizing agent to minimize the brittleness and extensibility of the film structure [172]. Glycerol is an example that can be used to improve the characteristics of an edible film with whey protein. It is promising because it can create a film with good mechanical and excellent oxygen barrier properties [173].

3.3. Lipids

Different types of waxes can be used in the food industry. An example is carnauba wax, which is extracted from the leaves of the carnauba trees and has more stable characteristics; it has excellent water vapor barrier properties, which have been widely recognized, and exhibits a high melting point and hardness, which can be used to develop a durable coating [54].

Beeswax is produced naturally by honeybees in the bees’ hive. It is well-known as hydrophobic and is used in making candles, metal casting, cosmetic products, textiles, polishes, and food processing [177]. It presents high plasticity, is viscoelastic, and has a low melting point [54]. This wax is beneficial with other polymers to make an edible film with good characteristics. For example, adding different concentrations (0, 2.5, 5, and 10 wt%) of beeswax in the edible film of cassava starch improved the moisture barrier and reduced the water solubility properties. Nevertheless, it also reduced the tensile strength, elongation, and flexural strength while enhancing the tensile and flexural modulus until five wt% beeswax [177].

4. Using Essential Oils, Plasticizers, Extracts, and Crosslinker Agents in the Edible Film with Biopolymers

Some strategies have been applied to improve the efficiency of some edible films and coatings. Adding essential oils is an example that can help in the antibacterial effect [181,182] and retain the qualities and benefits of food. There are several studies with the incorporation of different essential oils, such as thyme [183], oregano [184], grape seed, sea buckthorn [61], lemon [185], ginger [186], rosemary [175], clove [89], cinnamon [187], and lemongrass [130], among others.

Aloe vera is a plasticizer that can decrease weight loss and inhibit the maturity stage, as shown in the titratable acidity, pH, and total soluble solids. It has also been studied in several foods, such as tomatoes [25] and apples [185].

On the other hand, vanillin is a phenolic aldehyde organic compound derived from the vanilla bean that has inhibitory effects against yeasts, molds, and bacteria, thus controlling the decay of the fruit. Vanillin was studied in the conservation of tomato fruit [30] but had few studies with utilization in edible films.

Crosslinker agents are another alternative to improve the quality of edible films and have been studied recently. There are two types of crosslinker agents: green and chemical. Chemical crosslinker agents like, for example, glutaraldehyde have high reactivity, crosslinking solid properties, and increased stability, but their toxicity limits their application in food packaging films [190,191]. To resolve this problem, green crosslinker agents have been studied, like, for example, tannic acid, which has excellent antibacterial and antioxidant properties that improve the biopolymers' performance in food packaging films [190,192].

Deep eutectic solvents (DES) were defined as one system composed of a mixture of at least two compounds, a hydrogen-bond acceptor (tetraalkylammonium, quarternary ammonium, or phosphonium salts-HBA) and a hydrogen-bond donor (acids, amines, or alcohols-HBD), which are capable of self-associating [212,213]. It is a safe chemical that recently became a hot topic for use in the manufacturing of biopolymer-based films due to it being inexpensive, presenting a shallow environmental impact, having low toxicity, high renewability, high biodegradability, remarkable tunability, low cost, and particularity of having outstanding solvation properties that make it ideally suited for the extraction of bioactive compounds from various natural matrices [41,190]. Only in the last six years was it commonly used as a substitute for expensive organic solvents; year by year, it attracted more attention [214]. The mixture of choline chloride–citric acid (ChCl-CA), choline chloride–urea (ChCl-Urea), and choline chloride–glycerol (ChCl-Gly) are the DESs most used for plasticizing edible film [215].

This entry is adapted from the peer-reviewed paper 10.3390/coatings13081350

This entry is offline, you can click here to edit this entry!