Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Polymer Science

Interpolymer complexes based on cellulose ethers are formed by combining different polymers through non-covalent interactions, resulting in stable structures.

- interpolymer complexes

- cellulose ethers

- mucoadhesion

- hydrogels

- drug delivery

1. Introduction

The initial reference to interpolymer complexes (IPCs) (also referred to as polymer-polymer complexes in some sources) can be traced back to the research documented in [1]. Subsequently, Bungenberg de Jong extended these investigations, as indicated in references [2,3,4,5]. The systematic studies in this field were first undertaken by Liquori, as evidenced by works [6,7]. During the period of 1970–1980, extensive research was conducted, which established the fundamental basis for the subsequent rapid progress in the study and application of interpolymer complexes. Notable contributions in this era were made by prominent scientists, such as Bekturov [8], Zezin [9], Papisov [10], Izumrudov, Kabanov [11], and Tsuchida [12], who played pivotal roles in leading these scientific endeavours.

IPCs exhibit a complex structural arrangement, which arises from the interaction between macromolecules of polymers possessing complementary chemical structures when in a solution. The characteristics of macromolecules are determined not only by the chemical structure of the polymer chain but also by the formation of macromolecular aggregates. Thus, the macromolecules exhibit higher-order structures, including the configuration and conformation of the polymer chains, in addition to their primary structures. The effects of aggregation are typically observed as phase separation phenomena, such as precipitation, gelation, coacervation, emulsification, as well as the crystallization and liquid crystallization of polymers, or the self-assembly of biopolymer subunits. At present, IPCs are recognized as highly promising materials for their ability to act as structure-forming agents in various types of dispersions [13,14,15,16].

The investigation into the growth of interpolymer complex (IPC) films is of significant interest both from a scientific perspective and for practical applications. The cooperative interaction of complementary structures found in IPCs plays a crucial role in chemistry, polymer physics, and molecular biology. Despite the extensive research conducted on interpolymer complexes, there remain unanswered questions concerning their experimental and theoretical data, highlighting the need for further scientific advancements in this field.

A comprehensive analysis of the available data leads to the following conclusions: the primary focus of IPC research lies in understanding the material’s structural construction, the physicochemical parameters that influence polycomplex growth, and the diverse range of applications for IPCs. Essential factors influencing the structural growth of IPCs include solution pH, the temperature at which functional group binding occurs, solution concentration, the presence of low molecular weight compounds, and other relevant parameters.

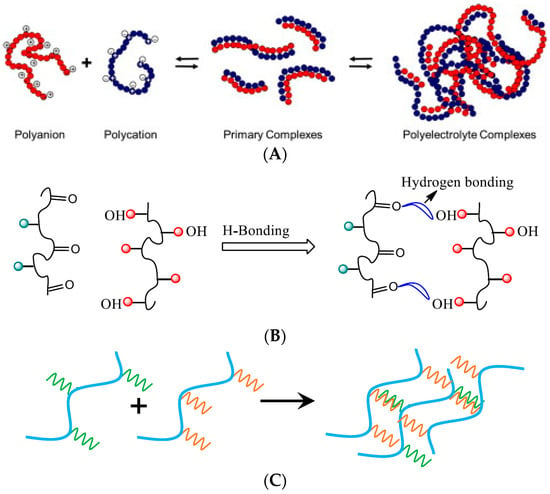

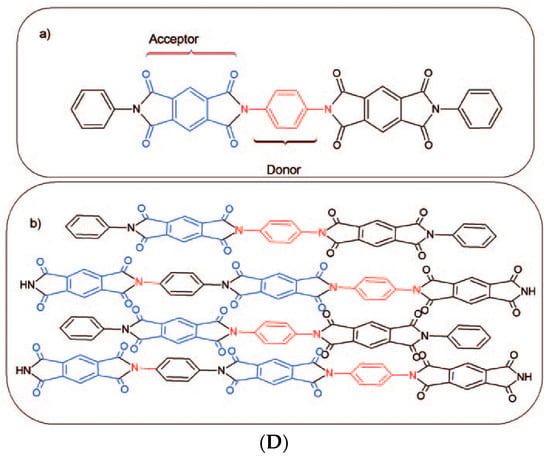

Based on the forces of interaction involved, intermacromolecular complexes can be categorized into the following four distinct classes (Figure 1):

2. Methods of Obtaining

Several methods have been established for obtaining interpolymer complexes, including the following:

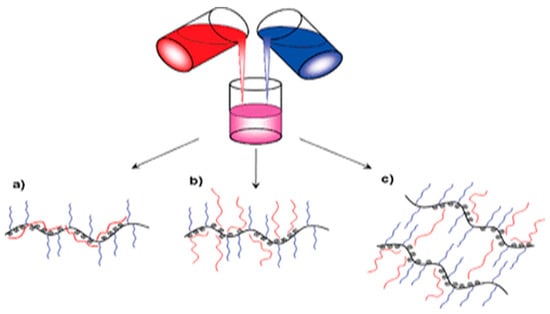

Among these approaches, one of the feasible and reliable methods for creating interpolymer complexes involves employing joint assembly processes within multicomponent polymer systems that contain complementary macromolecular components. Specifically, electrostatically controlled joint assembly is utilized, where water solutions of oppositely charged polyelectrolytes are mixed, leading to the formation of IPCs (Figure 2). These complexes represent macromolecular co-assemblies stabilized by an interconnected network of interpolymer salt bonds [28].

Figure 2. Mixing complementary macromolecules in solutions [32]. (a) Poly(sodium styrenesulfonate (PSS) is buried among the poly(ethylene oxide) brushes, (b) extended PSS chains from complex core, and (c) PSS chains bridging between complexes.

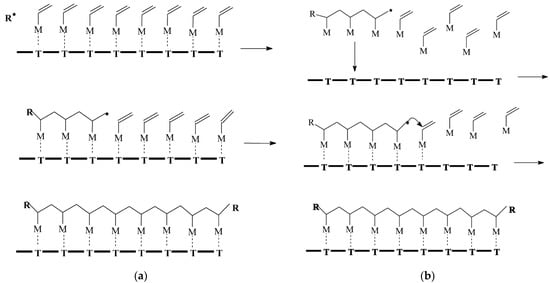

Matrix polymerization is an intriguing approach based on the conventional matrix synthesis model, which offers a means to synthesize composite materials that may be challenging or unattainable using alternative methods. Originally, the method was denoted as rreplica polymerization [46]; subsequently, it was assigned two additional designations, namely, “Template polymerization” and “Matrix polymerization”, which ultimately superseded the former term. The interpolymer complexes obtained through this method exhibit sufficient stability, and their polymer components can only be separated by disrupting the cooperative systems of intermolecular bonds [35]. Połowiński [34] differentiates between two distinct mechanisms of polymerization (Figure 3).

Figure 3. Example of matrix polymerization [34]. (a) The ‘zip’ mechanism, *—electrostatic, hydrogen bridges and (b) ‘pick-up’ mechanism, *—oligomer with critical length.

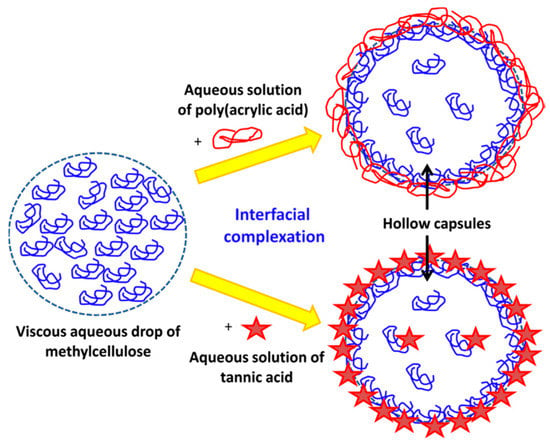

Another method for obtaining IPCs involves conducting a reaction at the interface of two immiscible liquid compounds. This technique relies on two solutions containing complementary polymers in separate solvents, resulting in the formation of a thin film of IPC at the phase boundary (Figure 4) [38].

Figure 4. Example of interfacial complexation [41].

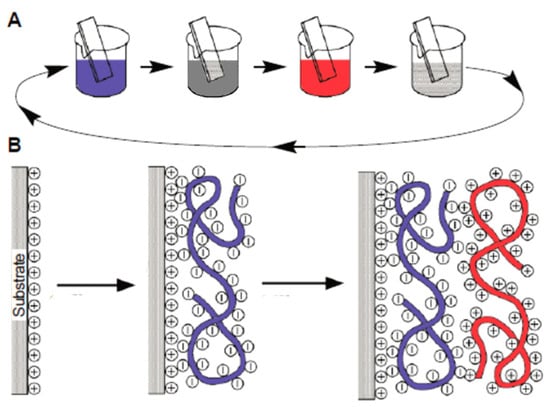

The application method on both solid and flexible surfaces entails the sequential deposition of polymer solutions capable of forming soluble and insoluble interpolymer complexes. This approach offers notable advantages, including precise control over coating thickness and the ability to develop materials with tailored physicochemical properties. Multilayer coatings can be applied to various surfaces, holding potential applications in the medical field and other scientific disciplines (Figure 5) [43,45].

Figure 5. Application methods on solid and flexible surfaces [45]. (A) Schematic of the film deposition process using slides and beakers. (B) Simplified molecular picture of the first two adsorption steps, depicting film deposition starting with a positively charged substrate. The molecules and solutions of the polyanion and polycation are distinguished by the utilization of red and blue colors, respectively.

3. Methods of Studying IPCs

Throughout this research, a substantial body of scientific literature on interpolymer complexes and their preparation and analysis methods has been thoroughly examined. Notably, standardized approaches exist for investigating the partially formed complexes, including the following:

4. IPCs Based on Cellulose Ethers

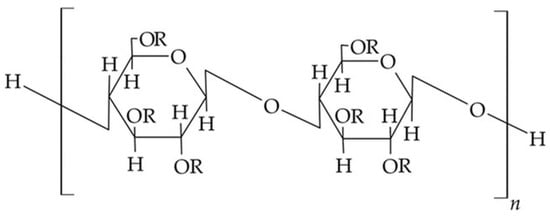

Cellulose ethers are derivatives of cellulose with a general chemical formula [C6H7O2(OH)3−x(OR)x]n, where n represents the degree of polymerization. In this formula, x denotes the number of hydroxyl (OH) groups substituted in a single unit of the cellulose macromolecule, while R represents an alkyl, acyl, or mineral acid residue. Each unit of the macromolecule contains three hydroxyl groups, which have the capability to undergo reactions to form ethers and esters. In the case of mixed cellulose esters, different substitutive radicals are present.

The most commonly encountered cellulose ethers and esters include ethers, such as carboxymethylcellulose, methylcellulose, ethyl cellulose, as well as methylhydroxypropyl cellulose, oxypropyl cellulose, and cyanethyl cellulose. Esters include cellulose acetates, cellulose nitrates, as well as acetylphthalyl cellulose, acetopropionates, acetobutyrates, and cellulose sulfates (Figure 6).

Figure 6. Chemical structure of cellulose esters/ether derivatives [55].

Cellulosic materials encompass a variety of cellulose derivatives, including cellulose esters, such as acetate, acetate trimellitate, acetate phthalate (CAP), hydroxypropyl methyl (HPM, also known as hypromellose) phthalate, and HPM acetate succinate. These esters are formed through the esterification of hydroxyl groups in cellulose using acetic, trimellitic, dicarboxylic phthalic, and succinic acids, or a combination of them.

Additionally, cellulosic materials also comprise cellulose ethers, such as methyl, ethyl, hydroxyethyl, hydroxyethyl methyl, hydroxypropyl (HP), HPM, and carboxymethyl ethers of cellulose. These ethers are formed by etherification of hydroxyl groups in cellulose using the appropriate alkyl halide (R-Cl) after the alkalization of cellulose, typically derived from wood pulp (Table 1).

Table 1. Cellulose and its derivatives (Figure 6).

|

Cellulose Esters |

R Groups |

Cellulose Ethers |

R Groups |

|---|---|---|---|

|

Acetate |

H, I |

Methylcellulose |

H, CH3 |

|

Acetate trimellitate |

H, I, II |

Ethyl cellulose |

H, CH2CH3 |

|

Acetate phthalate |

I, III |

Hydroxyethylmethyl cellulose |

H, CH3, [CH2CH2O]nH |

|

Hydroxypropyl methyl phthalate |

H, CH3, CH2CH(OH)CH3, III, IV |

Hydroxypropyl cellulose |

H, [CH2CH(CH3)O]nH |

|

Hydroxypropyl methyl phthalate acetate succinate |

H, CH3, CH2CH(OH)CH3, I, V |

Carboxymethylcellulose |

H, CH2COONa |

This entry is adapted from the peer-reviewed paper 10.3390/polym15153326

This entry is offline, you can click here to edit this entry!