Berries are highly perishable and susceptible to spoilage, resulting in significant food and economic losses. The use of chemicals in traditional postharvest protection techniques can harm both human health and the environment. Consequently, there is an increasing interest in creating environmentally friendly solutions for postharvest protection.

- edible coatings

- essential oils

- postharvest preservation

- emerging technologies

- berries

1. Introduction

2. Brief View of Traditional Methods of Microbial Growth Control: Fungicides

3. Sustainable Alternatives for the Postharvest Protection of Berries

Table 1. Pros and cons of the main sustainable alternatives applied for berry preservation.

Technique |

Advantages |

Disadvantages |

Reference |

Chemical compounds |

• Inhibition of phytopathogenic fungi. Induction of stress responses.• Ethylene oxidation.• Inhibition of enzymatic activity.• Low cost of implementation at an industrial scale. |

• High concentrations cause discoloration, texture changes, and chemical burns.• Reduction in anthocyanin content.• Modification of taste and aroma.• Activity affected by environmental conditions and by interaction with food components.• Cytotoxic effect at high concentrations in plant cells. |

[18] |

Modified atmosphere packaging |

• Reduction in physical damage during transportation and storage due to the packaging.• Ethylene absorption.• Freshness preservation. |

• Moisture condensation.• It does not eliminate the bacteria, and the growth of anaerobic microorganisms can be promoted. |

[6] |

Low temperature |

• Decrease in microbial growth rate, reduction in respiration rate and water loss, delaying the ripening and senescence processes. |

• Temperatures below freezing produce mushy fruits that lose their texture and flavor.• Reduction in vitamin C. |

[19] |

Ultraviolet (UV) irradiation |

• Inhibition of microbial load.• Stimulation of the production of anthocyanins and flavonoids, improving the color, taste, and antioxidant properties of berries.• Fast and relatively low cost on a large scale. |

• Excessive exposure to UV light can cause damage to the cellular components of the berries, reducing their quality and shelf life.• Poor penetration capacity.• High cost.• Low consumer acceptance. |

[20] |

Pulsed electric field |

• Useful at the industrial scale.• Maintenance of nutritional value. |

• High cost of implementation at the industrial scale.• Strong conditions can affect vegetable cells, causing softening. |

[21] |

Cold plasma |

• Changes in the metabolism that extend the shelf life. |

• Diminution of anthocyanins content.• Softening.• High cost. |

[22] |

Ionized irradiation |

• Induction of stress response in the berries, increasing the production of antioxidants and other protective compounds, extending their shelf life. |

• Reduction in citric acid content in berries.• High cost, low consumer acceptance. |

[23] |

Ultrasound |

• Low cost of implementation. Inhibition of enzymes. |

• Softening |

[24] |

Edible coatings |

• Low cost of implementation.• Generation of added value products.• Increment of the nutritional value. Fully consumed.• Enhancement of the organoleptic properties.• Carrier of antioxidant and antimicrobial properties.• Reduction in weight loss. |

• Fermentation of the coated foods.• Optimization according to the requirements of each fruit.• Instability depends on storage conditions (polymers can absorb large amounts of water). |

[25] |

3.1. Green Chemical Compounds

3.1.1. Ozone

3.1.2. Hydrogen Peroxide

3.1.3. Peracetic Acid (PAA)

| Berry | Preservation Technique | Storage Conditions | Main Result | Reference |

|---|---|---|---|---|

| Blueberries | Peracetic acid (PAA, 85 µL/L) | 1 °C/4 weeks | Inhibition of Botrytis cinerea maintaining the quality parameters of the fruit during the storage. | [33] |

| Blackberries and grapes | Ozone (18 mg O3/L for 10 min) | 4 °C/ 20 days | Reduced fungal decay and loss of weight along with storage. | [26] |

| Strawberries, raspberries, and blueberries | Ozone (13 mg/m3 for 16 h at 1 ± 0.5 °C) and MAP (10 kPa O2 and 40 kPa CO2) | 4 °C/15 days | The treatment did not affect the quality parameters of the fruits. In the case of blueberries, it protected the total and individual content of anthocyanins. | [22] |

| Strawberries | γ-irradiation (2 kGy, at 0.5 kGy/min) | 4 °C/15 days | The antioxidant activity increased in comparison with untreated fruits. | [23] |

| Strawberries | γ-irradiation (2 kGy) | 4 °C/14 days | Decreased the proliferation of molds and yeasts; sensory and physicochemical scores were not affected in comparison to the non-treated. | [24] |

| Goji berry | γ-irradiation (10 kGy, at 2.6 kGy/h) | 5 °C/50 days | Irradiation increased antioxidant activity by almost 30% in comparison with untreated fruits. | [37] |

| Blueberries | Cold plasma (4 kV/10 min) | 25 °C/10 days | Reduced decay, maintaining the quality and anthocyanin content of the fruits during storage. | [38] |

| Blueberries | Cold plasma (45 kV/50 s), ultraviolet (UV-C, 2.76 kJ/m2), or aqueous ozone (0.3 mg/L/5 min) | 20 °C/8 days | Cold plasma was the most effective treatment in the maintenance of the quality parameters, inhibiting the fungal decay and the growth of the microflora. | [39] |

| Strawberries | Electron beam irradiation (2 kGy, 70 cm/min) | 4 °C/14 days | Guaranteed microbial safety for up to 7 days and improved the physicochemical and sensorial properties of the coated fruits. | [40] |

| Strawberries, blackberries, and raspberries | Biodegradable packaging of gelatin- carboxymethylcellulose added with avocado peel extracts. | 25–28 °C/6 days | Protected the fruit from fungal growth during storage. | [41] |

| Blueberries | Biodegradable packaging based on polyvinyl pyrrolidone and carboxymethyl cellulose added with bacterial cellulose and guar gum. | 21 °C/15 days | Maintained the color and structure of the fruits after the storage period. | [42] |

| Blackberries and raspberries | Biodegradable packaging of poly (lactic acid) added with cyclodextrin and thymol. | 4 °C/ 21 days | Prolonged shelf life by one more compared with commercial clamshell packaging, this means 21 days. | [43] |

3.1.4. Organic Acids

3.2. Bioactive Compounds

3.3. Physical Methods

3.4. Biocontrol Agents (BCAs)

3.5. Molecular Tools to Improve Berry Preservation

4. Role of Artificial Intelligence (AI) in the Postharvest Protection of Berries

One of the primary applications of AI in berry preservation is in the monitoring of environmental conditions. AI algorithms can be used to analyze data from sensors that measure temperature, humidity, and other factors that affect berry quality. By monitoring these conditions in real time, AI systems can identify any deviations from the ideal conditions and take corrective actions. For example, if the temperature rises above a certain threshold, the AI system could adjust the cooling system to bring the temperature back down [58]. The prediction of berry quality can be achieved with the use of AI by analyzing data on factors such as berry size, color, and sugar content; it is possible to estimate how long the berries will remain fresh and identify any potential quality issues [4]. The use of mathematical models based on image analyses and electronic devices coupled with instrumental equipment provides new opportunities to apply AI in fruits and vegetable preservation. Image-processing algorithms recently were examined for estimating the TSS and pH of strawberries. Multiple linear regression and support vector machine regression (SVM-R) models were developed using RGB, HSV, and HSL color-space channels as input variables.

AI helps distributors make better decisions about transporting berries, reducing waste, and improving profitability. However, one of the primary challenges is the need for high-quality data. AI algorithms rely on large amounts of data to learn and make accurate predictions. Therefore, it is important to ensure that the data collected from sensors and other sources are accurate and representative of the conditions in which the berries are being stored. In addition to this, developing and implementing AI systems can be time-consuming and costly and requires expertise in data science and computer programming. Furthermore, there may be regulatory and ethical considerations associated with the use of AI in food production and preservation [1]. However, AI is the most powerful tool for improving berry preservation by providing more precise and efficient methods for monitoring and controlling environmental conditions.

5. Nanotechnology Applied to Postharvest Protection of Berries

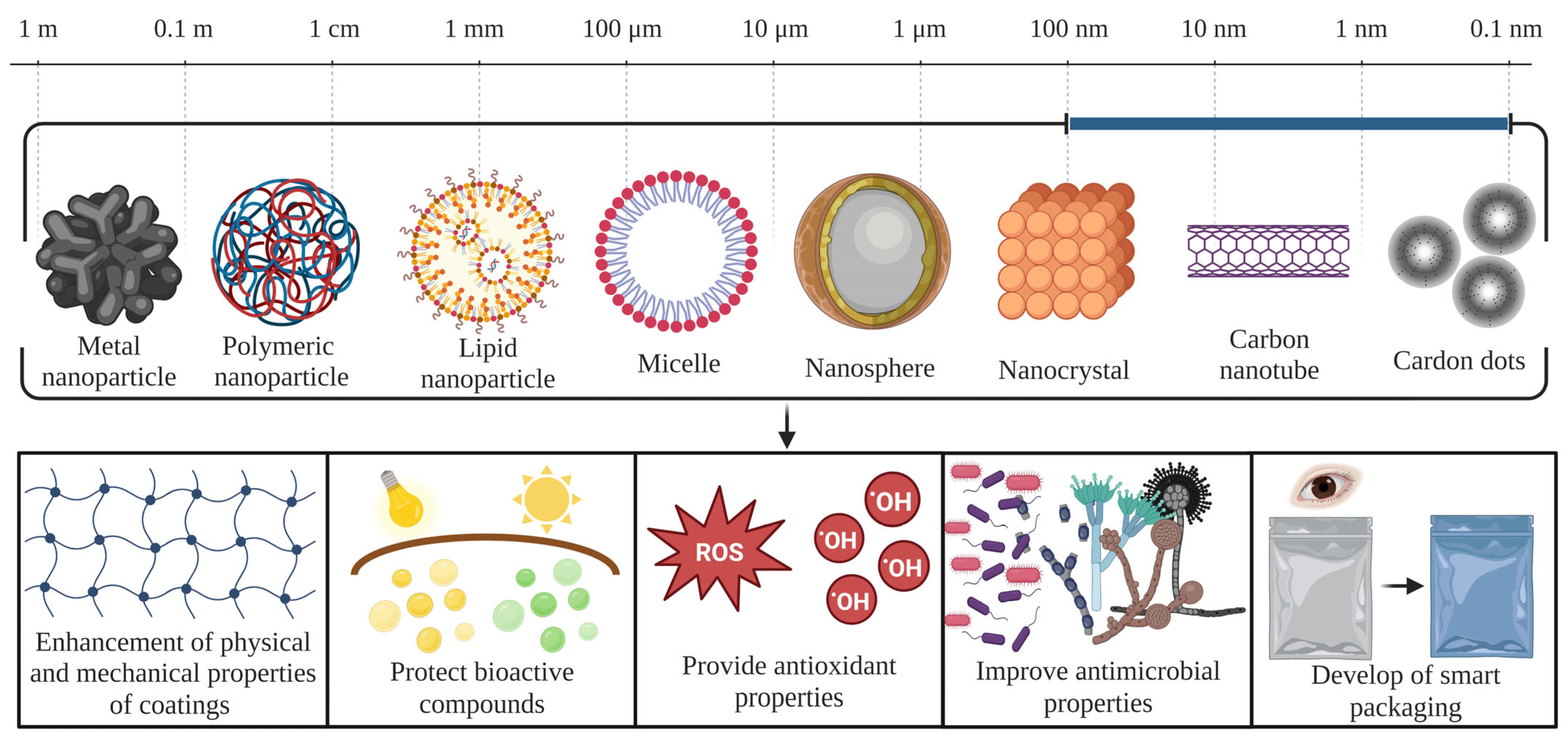

Nanotechnology has great potential in the postharvest protection of berries, which is an area of increasing concern due to substantial losses and deterioration in the quality of fruits during the handling and storage process [2]. Researchers have applied nanotechnology to the postharvest protection of berries in various innovative ways to extend berry shelf life (Figure 2). The coatings made or added with nanoparticles from natural sources, such as chitosan or cellulose nanocrystals, provide a protective barrier against moisture loss, gas exchange, and external pathogens, thus, improving the fruit’s quality and extending its shelf life [3]. Nanomaterials made of chitosan ethyl cellulose, alginate, poly-ε-caprolactone, polylactic acid, poly-D, L-lactide-co-glycolide, and cellulose acetate phthalate, were used as antimicrobial agents to inhibit the growth of pathogenic microorganisms, including fungi, yeast, bacteria, and viruses, or to develop composite coatings to improve the shelf life of berries [5]. Furthermore, they provide multiple advantages to food coatings, such as the enhancement of mechanical properties and selectivity to gas permeability. Moreover, nanotechnology-based edible coatings have been successfully used for the preservation of berries by the nanoencapsulation of EOs [7].

Figure 2. Main nanostructures used for berry preservation and their effect on coatings. The blue line indicates the range of the size of nanostructures.

Nanostructures are usually used with matrices of polysaccharides and proteins and are mainly used to modify the mechanical properties (tensile strength and elasticity), provide thermal stability and improve the permeability barrier towards water vapor and oxygen in food packaging [122]. The use of nanotechnology in the postharvest protection of berries provides a sustainable alternative to conventional methods, essential for meeting the growing demand for high-quality fruits and vegetables, reducing postharvest losses, and improving food security.

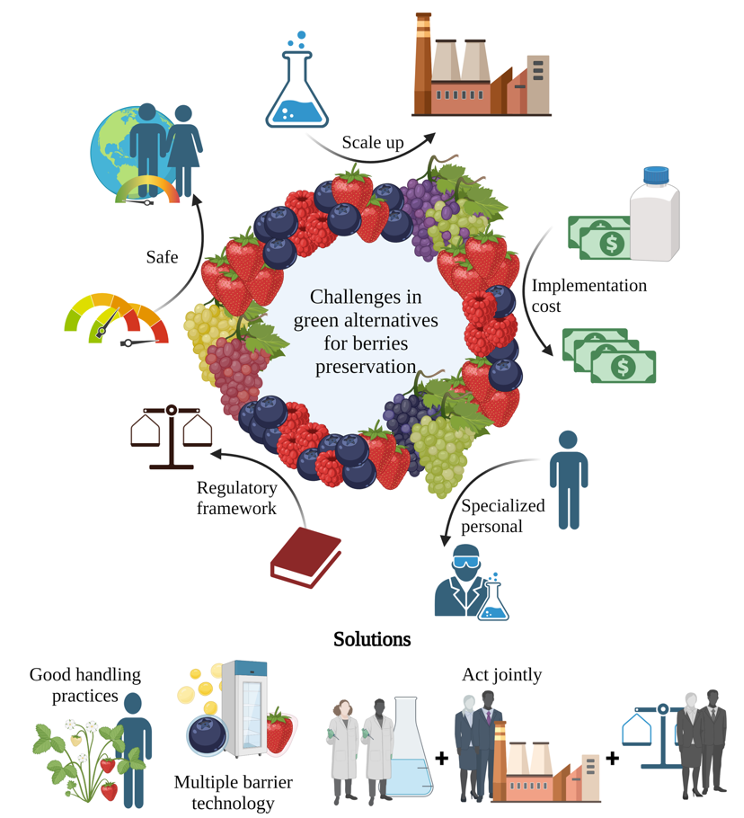

6. Current State and Challenges in the Implementation of Sustainable Alternatives at the Industrial Scale for Berry Protection

The rising concerns about synthetic fungicides and other chemical treatments’ negative environmental and health impacts have led to an increased interest in developing alternative solutions that are natural-based, such as the use of nanotechnology-based coatings and antioxidant compounds derived from plant extracts. There is a growing awareness of the development of sustainable alternatives at an industrial scale for the postharvest protection of berries that can contribute to improving the quality and quantity of fruit production, reducing postharvest losses and enhancing food security [8]. However, there are also several challenges associated with the implementation of sustainable alternatives for berries protection on a large scale, including cost, safety, compatibility, scaling up, and regulatory policies (Figure 3). One of the significant challenges in developing sustainable alternatives is the high cost of production. While the use of synthetic fungicides and other chemical treatments is relatively cheap, some sustainable alternatives, such as nanomaterials, can be expensive, and this may lead to profitability reduction [9]. Moreover, the implementation of sustainable methods requires specific knowledge and skills, thereby limiting their widespread application.

Another concern is the efficacy of sustainable protection methods against the diverse pathogens that berries encounter during harvesting, storage, and transportation. Moreover, improper hygienic and manufacturing practices promote their contamination with pathogenic bacteria such as E. coli and Salmonella, requiring customized treatment approaches, making it a complex and time-consuming process [6,66]. Large-scale industrial applications require the development of efficient technologies that can detect and respond to these challenges in real-time. This issue is less relevant in using fungicides and disinfectants because, in most cases, they have activity against several microorganisms [9].

Sustainable alternatives must be safe for consumption to protect human health. It is essential to ensure that the use of nanomaterials and other alternative solutions does not pose any risks to human health. In addition to this, the selected technique should be compatible with the fruit’s requirements during transportation and storage, such as temperature and humidity [10]. Currently, most of the alternatives reviewed in this paper were tested on a small scale. There is a need to scale up production to meet the demand for a large quantity of fruits. The challenge is to translate the laboratory concept of a sustainable alternative for the industrial scale. Finally, regulatory issues around the use of natural compounds and nano-based materials in the food industry remain a significant challenge. The implementation of sustainable alternatives at an industrial scale for berry protection is governed by several regulatory frameworks that ensure the use of safe and appropriate substances and technologies. Adherence to these regulations takes time and requires strict compliance, posing a challenge to the widespread adoption of sustainable protection methods.

Despite these points, an increase in research interest has led to the development of several sustainable alternative approaches to the postharvest protection of berries, including the use of nanotechnology-based coatings and natural-based solutions. The scientists’ efforts are mainly focused on developing novel technologies and techniques in laboratory-based experiments. The gap between the research and industrial sectors should be reduced and aimed to promote a quick advance in the scale-up of the use of these technologies for berry preservation. Green alternatives for the postharvest protection of berries at an industrial scale are crucial for addressing food security challenges by preserving fruit quality and reducing postharvest losses, which are significant contributors to food waste.

Figure 3. The main challenge for the implementation of sustainable alternatives for the postharvest protection of berries.

7. Conclusions

Berry preservation is crucial for extending its shelf life and maintaining its quality. Traditional methods of preserving berries often involve the use of chemicals and other harmful techniques, which can have negative impacts on the environment and human health. However, several sustainable and eco-friendly postharvest protection strategies can be employed to preserve berries. These alternatives include the application of physical treatments, such as cold storage, modified environment packaging, natural coatings, and so on, as well as the use of natural substances, such as organic acids and essential oils. Additionally, advancements in nanotechnology have led to the development of nanocomposite coatings that can effectively protect berries from spoilage and extend their shelf life. Regarding this, the use of CDs is a promising alternative to developing smart coatings and packaging to enhance the shelf life of berries through agro-waste valorization. These strategies offer promising alternatives to traditional methods and can contribute to a more sustainable and environmentally friendly approach to berry preservation regarding the quality and safety of berries while minimizing our impact on the environment. The combination of two or more treatments can provide better results. However, it is important to consider that these technologies’ effectiveness strongly depends on the conditions used during the treatment (temperature, concentration, exposure time, etc.). Otherwise, the use of tools based on molecular biology is a promising alternative, of which the main concern is the resistance of the population to consume genetically engineered foods. Further research should be addressed to have a comprehensive understanding of the interaction of these factors and their effect on the microbiological, physicochemical, and sensorial properties of berries. Meanwhile, the joint work of scientists, industry, and government is the most reliable way to overcome the challenge that implies the implementation of sustainable alternatives for berry preservation. Investing in sustainable postharvest preservation practices can provide a variety of long-term benefits beyond immediate protection. These benefits have far-reaching implications for the environment, the economy, food security, and the overall sustainability of the agricultural systems.

This entry is adapted from the peer-reviewed paper 10.3390/foods12173159

References

- Kumar, S.; Baghel, M.; Yadav, A.; Dhakar, M.K. Postharvest biology and technology of berries. In Postharvest Biology and Technology of Temperate Fruits; Mir, S.A., Shah, M.A., Mir, M.M., Eds.; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 349–370. ISBN 9783319768434.

- Huynh, N.K.; Wilson, M.D.; Eyles, A.; Stanley, R.A. Recent advances in postharvest technologies to extend the shelf life of blueberries (Vaccinium sp.), raspberries (Rubus idaeus L.) and blackberries (Rubus sp.). J. Berry Res. 2019, 9, 709–724.

- Food and Agriculture Organization of the United Nations (FAOSTAT) Cultivos. Available online: http://www.fao.org/faostat/es/#data/QC (accessed on 10 May 2023).

- Bilawal, A.; Ishfaq, M.; Gantumur, M.A.; Qayum, A.; Shi, R.; Fazilani, S.A.; Anwar, A.; Jiang, Z.; Hou, J. A review of the bioactive ingredients of berries and their applications in curing diseases. Food Biosci. 2021, 44, 101407.

- Zamanpour, S.; Shakeri, G.; Afshari, A. Epidemiological evaluation of water- and outbreaks in the United States and Europe. J. Nutr. Fasting Health 2022, 10, 3.

- Romero, J.; Albertos, I.; Díez-Méndez, A.; Poveda, J. Control of postharvest diseases in berries through edible coatings and bacterial probiotics. Sci. Hortic. 2022, 304, 111326.

- Duarte, L.G.R.; Ferreira, N.C.A.; Fiocco, A.C.T.R.; Picone, C.S.F. Lactoferrin-Chitosan-TPP nanoparticles: Antibacterial action and axtension of strawberry shelf-life. Food Bioprocess Technol. 2023, 16, 135–148.

- Santos, C.; de Araújo Gonçalves, M.; de Macedo, L.F.; Torres, A.H.F.; Marena, G.D.; Chorilli, M.; Trovatti, E. Green nanotechnology for the development of nanoparticles based on alginate associated with essential and vegetable oils for application in fruits and seeds protection. Int. J. Biol. Macromol. 2023, 232, 123351.

- Lee, D.; Shayan, M.; Gwon, J.; Picha, D.H.; Wu, Q. Effectiveness of cellulose and chitosan nanomaterial coatings with essential oil on postharvest strawberry quality. Carbohydr. Polym. 2022, 298, 120101.

- Palumbo, M.; Attolico, G.; Capozzi, V.; Cozzolino, R.; Corvino, A.; de Chiara, M.L.V.; Pace, B.; Pelosi, S.; Ricci, I.; Romaniello, R.; et al. Emerging postharvest technologies to enhance the shelf-life of fruit and vegetables: An overview. Foods 2022, 11, 3925.

- Basak, J.K.; Madhavi, B.G.K.; Paudel, B.; Kim, N.E.; Kim, H.T. Prediction of total soluble solids and pH of strawberry fruits using RGB, HSV and HSL colour spaces and machine learning models. Foods 2022, 11, 2086.

- Bell, S.R.; Hernández Montiel, L.G.; González Estrada, R.R.; Gutiérrez Martínez, P. Main diseases in postharvest blueberries, conventional and eco-friendly control methods: A review. LWT Food Sci. Technol. 2021, 149, 7–12.

- Ezrari, S.; Lazraq, A.; El Housni, Z.; Radouane, N.; Belabess, Z.; Mokrini, F.; Tahiri, A.; Amiri, S.; Lahlali, R. Evaluating the sensitivity and efficacy of fungicides with different modes of action against Neocosmospora solani and Fusarium species, causing agents of citrus dry root rot. Arch. Phytopathol. Plant Prot. 2022, 55, 1117–1135.

- Li, X.; Zhang, Z.H.; Qiao, J.; Qu, W.; Wang, M.S.; Gao, X.; Zhang, C.; Brennan, C.S.; Qi, X. Improvement of betalains stability extracted from red dragon fruit peel by ultrasound-assisted microencapsulation with maltodextrin. Ultrason. Sonochem. 2022, 82, 105897.

- Wang, F.; Saito, S.; Michailides, T.J.; Xiao, C.L. Postharvest use of natamycin to control Alternaria rot on blueberry fruit caused by Alternaria alternata and A. arborescens. Postharvest Biol. Technol. 2021, 172, 111383.

- Nguyen, K.; Sanchez, C.L.; Brammer-Robbins, E.; Pena-Delgado, C.; Kroyter, N.; El Ahmadie, N.; Watkins, J.M.; Aristizabal-Henao, J.J.; Bowden, J.A.; Souders, C.L.; et al. Neurotoxicity assessment of QoI strobilurin fungicides azoxystrobin and trifloxystrobin in human SH-SY5Y neuroblastoma cells: Insights from lipidomics and mitochondrial bioenergetics. Neurotoxicology 2022, 91, 290–304.

- Macías-Gallardo, F.; Barajas-Díaz, C.G.M.; Mireles-Arriaga, A.I.; Ozuna, C. Strawberry variety influences the effectiveness of postharvest treatment with gaseous ozone: Impact on the physicochemical, microbiological, and bioactive properties of the fruit. Processes 2023, 11, 346.

- Pinto, L.; Palma, A.; Cefola, M.; Pace, B.; D’Aquino, S.; Carboni, C.; Baruzzi, F. Effect of modified atmosphere packaging (MAP) and gaseous ozone pre-packaging treatment on the physico-chemical, microbiological and sensory quality of small berry fruit. Food Packag. Shelf Life 2020, 26, 100573.

- Jaramillo-Sánchez, G.; Contigiani, E.V.; Castro, M.A.; Hodara, K.; Alzamora, S.M.; Loredo, A.G.; Nieto, A.B. Freshness maintenance of blueberries (Vaccinium corymbosum L.) during postharvest using ozone in aqueous phase: Microbiological, structure, and mechanical issues. Food Bioprocess Technol. 2019, 12, 2136–2147.

- Hasani, M.; Wu, F.; Warriner, K. Validation of a vapor-phase advanced oxidation process for inactivating Listeria monocytogenes, its surrogate Lactobacillus fructivorans, and spoilage molds associated with green or red table grapes. J. Food Sci. 2020, 85, 2645–2655.

- Pagès, M.; Kleiber, D.; Violleau, F. Ozonation of three different fungal conidia associated with apple disease: Importance of spore surface and membrane phospholipid oxidation. Food Sci. Nutr. 2020, 8, 5292–5297.

- Intarasit, S.; Saengnil, K. Transient production of H2O2 and NO induced by ascorbic acid coincides with promotion of antioxidant enzyme activity and reduction of pericarp browning of harvested longan fruit. Sci. Hortic. 2021, 277, 109784.

- Heo, S.; Kim, S.; Kang, D. The role of hydrogen peroxide and peroxiredoxins throughout the cell cycle. Antioxidants 2020, 9, 280.

- Alexandre, E.M.C.; Brandão, T.R.S.; Silva, C.L.M. Assessment of the impact of hydrogen peroxide solutions on microbial loads and quality factors of red bell peppers, strawberries and watercress. Food Control 2012, 27, 362–368.

- FDA. CFR—Code of Federal Regulations Title 21. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?fr=173.315 (accessed on 28 March 2023).

- Saito, S.; Wang, F.; Obenland, D.; Xiao, C.L. Effects of peroxyacetic acid on postharvest diseases and quality of blueberries. Plant Dis. 2021, 105, 3231–3237.

- Nicolau-Lapeña, I.; Abadias, M.; Bobo, G.; Aguiló-Aguayo, I.; Lafarga, T.; Viñas, I. Strawberry sanitization by peracetic acid washing and its effect on fruit quality. Food Microbiol. 2019, 83, 159–166.

- Ao, X.W.; Eloranta, J.; Huang, C.H.; Santoro, D.; Sun, W.J.; Lu, Z.D.; Li, C. Peracetic acid-based advanced oxidation processes for decontamination and disinfection of water: A review. Water Res. 2021, 188, 116479.

- Pérez-Lavalle, L.; Carrasco, E.; Valero, A. Strategies for microbial decontamination of fresh blueberries and derived products. Foods 2020, 9, 1558.

- Barkaoui, S.; Madureira, J.; Santos, P.M.P.; Margaça, F.M.A.; Miloud, N.B.; Mankai, M.; Boudhrioua, N.M.; Cabo Verde, S. Effect of ionizing radiation and refrigeration on the antioxidants of strawberries. Food Bioprocess Technol. 2020, 13, 1516–1527.

- Barkaoui, S.; Mankai, M.; Miloud, N.B.; Kraïem, M.; Madureira, J.; Verde, S.C.; Boudhrioua, N. Effect of gamma radiation coupled to refrigeration on antioxidant capacity, sensory properties and shelf life of strawberries. LWT Food Sci. Technol. 2021, 150, 112088.

- Mladenova, R.B.; Aleksieva, K.I.; Nacheva, I.B. Effect of gamma irradiation on antiradical activity of goji berry fruits (Lycium barbarum) evaluated by EPR spectroscopy. J. Radioanal. Nucl. Chem. 2019, 320, 569–575.

- Hu, X.; Sun, H.; Yang, X.; Cui, D.; Wang, Y.; Zhuang, J.; Wang, X.; Ma, R.; Jiao, Z. Potential use of atmospheric cold plasma for postharvest preservation of blueberries. Postharvest Biol. Technol. 2021, 179, 111564.

- Zhou, D.; Wang, Z.; Tu, S.; Chen, S.; Peng, J.; Tu, K. Effects of cold plasma, UV-C or aqueous ozone treatment on Botrytis cinerea and their potential application in preserving blueberry. J. Appl. Microbiol. 2019, 127, 175–185.

- Barkaoui, S.; Mankai, M.; Miloud, N.B.; Kraïem, M.; Madureira, J.; Verde, S.C.; Boudhrioua, N. E-beam irradiation of strawberries: Investigation of microbiological, physicochemical, sensory acceptance properties and bioactive content. Innov. Food Sci. Emerg. Technol. 2021, 73, 102769.

- Vargas-Torrico, M.F.; von Borries-Medrano, E.; Aguilar-Méndez, M.A. Development of gelatin/carboxymethylcellulose active films containing Hass avocado peel extract and their application as a packaging for the preservation of berries. Int. J. Biol. Macromol. 2022, 206, 1012–1025.

- Bandyopadhyay, S.; Saha, N.; Brodnjak, U.V.; Sáha, P. Bacterial cellulose and guar gum based modified PVP-CMC hydrogel films: Characterized for packaging fresh berries. Food Packag. Shelf Life 2019, 22, 100402.

- Velázquez-Contreras, F.; García-Caldera, N.; Padilla de la Rosa, J.D.; Martínez-Romero, D.; Núñez-Delicado, E.; Gabaldón, J.A. Effect of PLA active packaging containing monoterpene-cyclodextrin complexes on berries preservation. Polymers 2021, 13, 1399.

- Li, Y.; Wu, C. Enhanced inactivation of Salmonella Typhimurium from blueberries by combinations of sodium dodecyl sulfate with organic acids or hydrogen peroxide. Food Res. Int. 2013, 54, 1553–1559.

- Zhang, W.; Jiang, Y.; Zhang, Z. The role of different natural organic acids in postharvest fruit quality management and its mechanism. Food Front. 2023, 1–17.

- Perumal, A.B.; Huang, L.; Nambiar, R.B.; He, Y.; Li, X.; Sellamuthu, P.S. Application of essential oils in packaging films for the preservation of fruits and vegetables: A review. Food Chem. 2022, 375, 131810.

- Zhao, L.; Duan, G.; Zhang, G.; Yang, H.; Jiang, S.; He, S. Electrospun functional materials toward food packaging applications: A review. Nanomaterials 2020, 10, 150.

- Kwekkeboom, K.L.; Tostrud, L.; Costanzo, E.; Coe, C.L.; Serlin, R.C.; Ward, S.E.; Zhang, Y. The role of inflammation in the pain, fatigue, and sleep disturbance symptom cluster in advanced cancer. J. Pain Symptom Manag. 2018, 55, 1286–1295.

- Chavez-Diaz, I.F.; Mena-Violante, H.G.; Hernandez-Lauzardo, A.N.; Oyoque-Salcedo, G.; Oregel-Zamudio, E.; Angoa-Perez, M.V. Postharvest control of rhizopus stolonifer on blackberry (Rubus fruticosus) by blackberry native crop bacteria. Rev. la Fac. Cienc. Agrar. 2019, 51, 306–317.

- Zhang, X.; Gao, Z.; Zhang, X.; Bai, W.; Zhang, L.; Pei, H. Control effects of Bacillus siamensis G-3 volatile compounds on raspberry postharvest diseases caused by Botrytis cinerea and Rhizopus stolonifer. Biol. Control 2020, 141, 104135.

- Zhou, Y.; Li, W.; Zeng, J.; Shao, Y. Mechanisms of action of the yeast Debaryomyces nepalensis for control of the pathogen Colletotrichum gloeosporioides in mango fruit. Biol. Control 2018, 123, 111–119.

- Di Francesco, A.; Ugolini, L.; Lazzeri, L.; Mari, M. Production of volatile organic compounds by Aureobasidium pullulans as a potential mechanism of action against postharvest fruit pathogens. Biol. Control 2015, 81, 8–14.

- Arrebola, E.; Sivakumar, D.; Korsten, L. Effect of volatile compounds produced by Bacillus strains on postharvest decay in citrus. Biol. Control 2010, 53, 122–128.

- Jiménez-Bermúdez, S.; Redondo-Nevado, J.; Muñoz-Blanco, J.; Caballero, J.L.; López-Aranda, J.M.; Valpuesta, V.; Pliego-Alfaro, F.; Quesada, M.A.; Mercado, J.A. Manipulation of strawberry fruit softening by antisense expression of a pectate lyase gene. Plant Physiol. 2002, 128, 751–759.

- Cai, J.; Mo, X.; Wen, C.; Gao, Z.; Chen, X.; Xue, C. FvMYB79 positively regulates strawberry fruit softening via transcriptional activation of FvPME38. Int. J. Mol. Sci. 2022, 23, 101.

- López-Casado, G.; Sánchez-Raya, C.; Ric-Varas, P.D.; Paniagua, C.; Blanco-Portales, R.; Muñoz-Blanco, J.; Pose, S.; Matas, A.J.; Mercado, J.A. CRISPR/Cas9 editing of the polygalacturonase FaPG1 gene improves strawberry fruit firmness. Hortic. Res. 2023, 10, uhad011.

- Gopi, V.; Samruban, J. Biotechnology approaches enhancing improved post harvest technology of fruit crops. In Recent Advances in Agricultural and Allied Sciences; 2020; pp. 12–34. ISBN 9788194563198. Available online: https://www.researchgate.net/profile/Gopi-Venkatachalapathy/publication/371491441_Chapter_-2_2_BIOTECHNOLOGY_APPROACHES_ENHANCING_IMPROVED_POST_HARVEST_TECHNOLOGY_OF_FRUIT_CROPS/links/6486bfdab3dfd73b777f847b/Chapter-2-2-BIOTECHNOLOGY-APPROACHES-ENHANCING-IMPROVED-POST-HARVEST-TECHNOLOGY-OF-FRUIT-CROPS.pdf (accessed on 15 August 2023).