Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

The concept of the digital twin (DT) has been adopted as an important aspect in digital transformation of power systems. Microgrids (MG) can be seen as scaled-down versions of a centralised power system. A microgrid is a local power network that acts as a dependable island within bigger regional and national electricity networks, providing power without interruption even when the main grid is down. Microgrids are essential components of smart cities that are both resilient and sustainable, providing smart cities the opportunity to develop sustainable energy delivery systems.

- digital twin

- microgrid

- point of common coupling

- smart city

1. Solar Power

Solar power demand has been increasing extravagantly [1]. Although the construction of solar panels is a one-time investment, it requires high-quality maintenance to achieve its highest performance. Therefore, it is important to simulate and model it in advance for better operation, maintenance, planning, deployment, forecasting, fault diagnosis and asset performance management. The anatomy of groundwork, which has been performed in the area of solar panel digital twin, shows the importance of analytics to analyse asset data [2]. The photovoltaic (PV) panels, inverters, meters, environmental units, energy storage, plant and power grid can be designed with digital twins for solar power. Predictive analysis uses digital twins, which can be used to gain a better understanding of the failures and take preventive maintenance decisions.

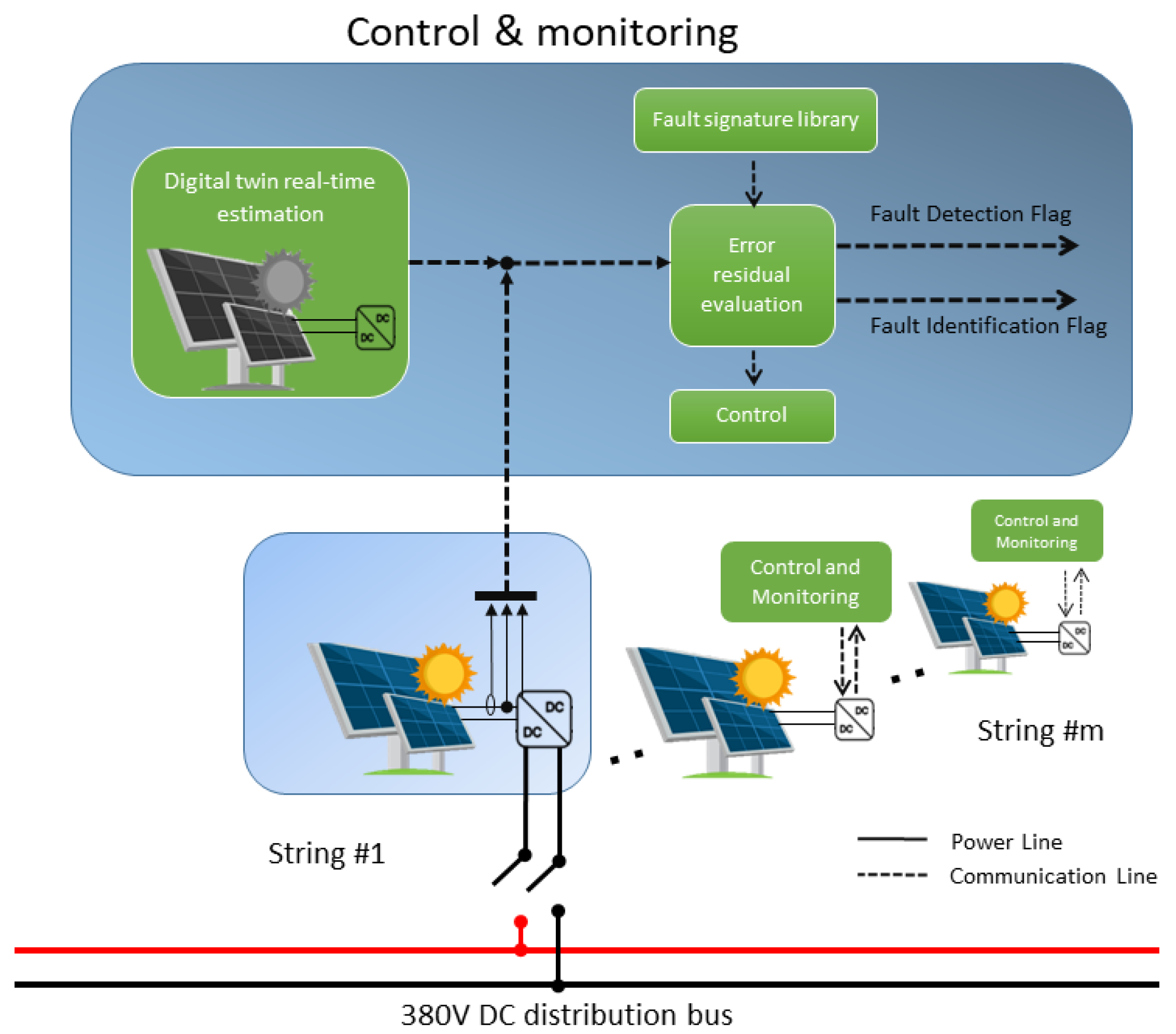

Photovoltaic systems are exposed to different faults due to their complex outdoor installations, increased number of power electronics elements and ageing, which can impact PV system performance and reliability. Assessment of photovoltaic module failures can be carried out with the use of digital twin technology. A holistic digital twin approach to fault detection and identification for PV systems was developed in [3] as shown in Figure 1. In this approach, a physics-based digital twin was built to estimate the panel current and voltage. The difference between the estimated values and values measured from the physical twin helps the system detect and identify PV installation faults in real-time effectively.

Figure 1. An overview of digital twin approach for fault diagnosis of the complete PV system.

The generated power by solar PV varies greatly because of its dependence on weather conditions. Therefore, forecasting power production will help in ensuring the reliability and availability of power. The forecasting model uses historical solar PV power data, solar irradiance, rainfall, temperature, etc., to forecast solar PV power output. Different machine learning algorithms [4] are applied to obtain the best prediction.

J. Shi et al. [5] proposed an algorithm to forecast the one-day-ahead power output of photovoltaic systems. Generally, there are two ways of forecasting PV power output; one is based on sunshine intensity, and another is based on system output. The intensity of sunlight is affected by a variety of factors, making it a nonlinear problem [5]. In a photovoltaic energy system, the hot spot is considered one of the main issues of PV modules, as local overheating can lead to module damage. Many data-driven approaches have recently been applied to find the hot spots in PV modules [6].

2. Wind Energy

Wind turbines are of two types, onshore wind turbines and offshore wind turbines. Due to adverse weather conditions they face, it is not easy to handle them manually. They are fitted with various sensors that continuously measure characteristics, such as wind speed, humidity, vibration and spindle temperature, resulting in continuous data streams [7]. Wind speed sensors are more error-prone, which deteriorates the performance of wind turbines and leads to faulty conditions. To detect fault sensors, Yang Li et al. [8] proposed a data-driven digital twin estimating the wind speed for the downwind turbines based on the wind speed measurements at the upwind turbines and their spatiotemporal correlation. The residual between the estimated and measured speeds is used to identify a possible fault. In [9], a condition monitoring approach for drivetrains on floating offshore wind turbines is proposed, utilising a DT framework. The data-driven DT uses a torsional dynamic model, online measurements and fatigue damage estimation to estimate the drivetrains’ remaining useful life (RUL). The proposed methodology has been simulated and tested to monitor the health of the turbine. However, only the mechanical aspect was considered in the model, while electrical aspects, such as power produced by wind, losses, etc., were not.

Sivalingam et al. [10] have established a physics-based methodology for predicting the RUL of electrical components, especially power converters. SCADA data are used to derive the wind turbine’s wind profile, such as wind speed, temperature, yaw angle and electrical power generation. The suggested methodology has been tested for both fixed and floating wind farm applications. In [11], a digital twin was developed based on the turbine’s geometric and aerodynamic properties to monitor the health of onshore wind turbines continuously. Data from the manufacturer catalogues were used to calibrate the system.

3. Biogas Energy

In biogas plants, organic materials are transformed into biogas by physical and biochemical processes in anaerobic environments. As there is a lack of essential waste analysis, there may be decreases in the optimization of production processes and output stability. Machine learning and deep learning can help in the key waste selection and prediction improvement for biogas production [12][13]. Spinti et al. [14] proposed a digital twin approach to optimising boiler performance in uncertain conditions by combining Bayesian inference from science-based models and machine learning with decision theory. To implement it online in real-time, the simulated data extracted using the Bayesian analysis are evaluated using a Gaussian process regression as a fast and robust surrogate model.

Elmaz et al. [15] used four regression techniques to model the biomass gasification process of carbon monoxide, carbon dioxide and hydrogen peroxide outputs. These developed models can be utilised for predicting outputs in simulation platforms and real-world applications. For biogas production prediction, an RNN-based deep learning model was developed with the hybrid architecture of dual-stage attention, long short-term memory and variable selection networks. Wang et al. [16] studied different waste inputs and operating conditions that affect biogas production using industrial-scale anaerobic co-digestion data from 8 years, combining it with a tree-based pipeline optimisation tool. The significance of this work was that the tree-based pipeline optimisation tool was used with a larger data set than any previously catalogued work. But a true DT of biogas with a proper communication channel has not been achieved.

In the near future, IoT sensors may help collect data from the biogas field, integrating the recorded temperature, humidity, pressure, etc., in a dataset. The massive dataset can improve the training and provide a highly stable model. This learning can be implemented in MGs to reduce waste production and improve economic efficiency. The above-discussed RERs are three main energy resources integrated into the MG system.

4. Battery

Electrical utilities must supply energy continuously to meet the real-time demand of consumers. However, when energy demand decreases, such as in off-peak hours, the energy produced exceeds the demand. Therefore, using the battery as an energy storage device can store extra energy for future use and help maintain the energy in the microgrid. Storage is crucial to diversifying energy sources and providing renewable energy to the market. But their internal status is hard to measure. Traditional ways of estimating a battery’s internal states, such as state of charge (SOC) and state of health (SOH), are challenging to use with degrading batteries. Without a battery management system (BMS), safety, dependability, lifespan and affordability are compromised. With more battery cells and larger battery systems, wiring connection becomes more complex and expensive. To monitor battery health accurately, Li et al. [17] developed a model-based digital twin on the cloud with an adaptive extended H-infinity filter and particle swarm optimisation for SOC and SOH estimation.

Apart from SOC and SOH status, battery carbon emission is also a major concern. Electric vehicles and grid-scale energy storage are just two examples of how batteries will be critical in our low-carbon future. Even though the main problem remains in maximising the life and effectiveness of these devices, there is an opportunity for more intelligent control of battery systems with the emergence of ML methodologies [18].

A fully physics-based DT of a combustion engine in a power plant is demonstrated in [19] for the first time, including battery storage. A real-time engine model is constructed from a detailed, one-dimensional model, which is then reduced to a fast-running model. This digital twin concept offers predictive capabilities and advantages over previous black-box engine approaches, facilitating self-optimising integrated and coordinated grid-power plant control.

5. Electric Vehicle

Using emerging technologies, such as IoT, wireless networking and artificial intelligence (AI), the digital twin technology is improvising its application in the vehicle sector. Even being new to the vehicle industry, some practical ideas and theoretical work can be found.

The electricity in an electric car battery is stored in the form of chemical potential. Batteries can accept, store and release power at any time. ESS cell voltage or charge imbalances are developed due to undercharging, overcharging and temperature profiles. ESS cell voltage life will be prolonged by reducing imbalance and temperature impacts [20]. In addition, some other issues related to electric vehicle batteries are power electronic interfacing, sensitive energy management system, charging interfaces, etc.

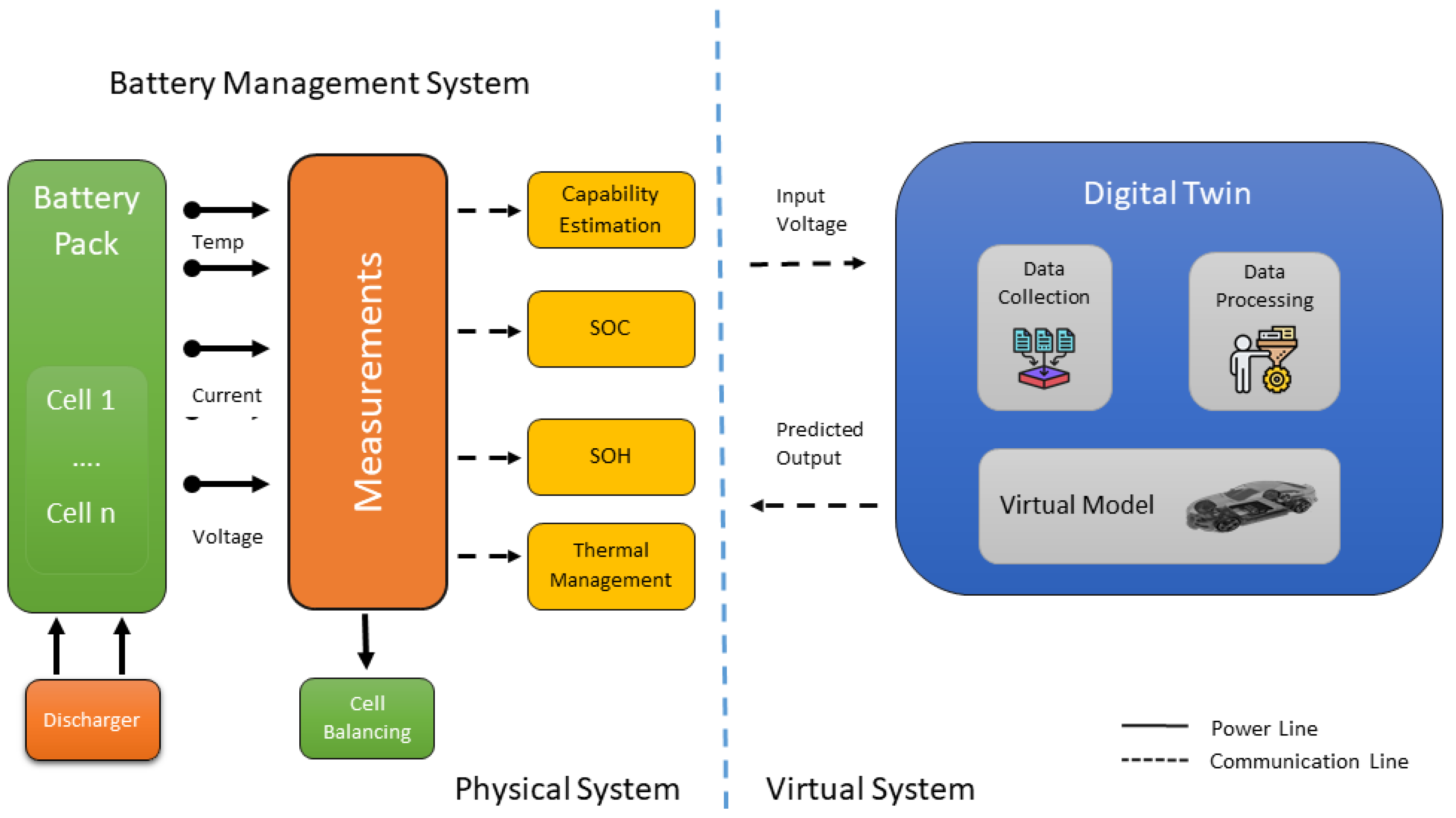

The authors in [21] have presented a consolidation of modern battery and battery management technologies for hybrid and pure electric vehicles, along with the progress and obstacles they have faced. A proper architecture [22] is required to implement a digital twin of the battery management system. The application of this architecture can be considered as a blueprint for a domain-specific meta-model of high-voltage battery systems and related processes over the whole life cycle. Through this meta-model, an actual system can be created. The research work [23] proposes a digital twin paradigm for the BMS, shown in Figure 2, to estimate and anticipate battery conditions with only a voltage sensor.

Figure 2. Digital twin for Battery Management System.

The battery’s health needs to be monitored because it degrades over time. In [24], the digital twin model of lithium-ion battery is proposed to predict the battery’s performance deterioration accurately by simulating the battery’s discharge process. Data from the observable parameters are used to indicate battery health (HI). The LSTM approach, with the temporal measurement as a HI, is used to create a battery digital twin. The digital twin model of the battery’s true capacity can be obtained by virtually draining it. Results from a series of experiments demonstrate the viability of this approach in dynamic operating situations. The drastic increase in demand for electric vehicles requires new and advanced infrastructures for charging. Yu et al. [24] discussed the idea of establishing a cognitive charging station infrastructure with power generation, energy storage and charging networks. DT and parallel intelligence (PI) enables smart and cognitive charging station architecture.

Various methods for modelling energy storage systems have been summarised. However, there is still a need for further study. DT is a novel method for this research work. In MG, the power converter is the third most crucial part. The converter in the MG system establishes connections among the various other parts of the system.

6. Power Converters

The power converter plays a vital role in the integration of components of the microgrid. Most of the MG’s generating sources (PV, wind turbine), storage devices and loads require power electronics interfacing devices. A literature survey on power electronic converters for MGs is mentioned in [25]. Power converters include DC converters, AC converters and back-to-back converters. When MGs are connected to the grid, converters behave as current sources sustaining MGs. On the other hand, it behaves as a voltage source while working in islanded mode [26]. Renewable energy sources generally produce DC as output power. To feed that power to the main AC grid, DC/AC converters are needed [27]. As a result, converters are critical to developing microgrids, and, therefore, special attention must be paid to them. The use of data-driven approaches and digital twin models can solve various challenges relating to power electronic equipment, such as device faults, health conditions, remaining life, optimisation and control.

When it comes to the protection of power converters, the part that is most likely to be affected by a malfunction is the power switch. Therefore, fault analysis is being phased out in favour of a data-driven method that makes use of ML to facilitate rapid diagnosis and protection from additional harm. Fault characteristics provide opportunities for data collection. DC–DC converters can now be monitored using a digital twin based on linear differential equations and the linearisation of the 4th order Runga–Kutta method [28]. The suggested approach can identify the internal parameters of the buck converter and create a digital twin buck converter with the same operation waveforms as the physical one, according to both theoretical and experimental results. With the suggested method, both MOSFET and capacitor can be monitored without the use of any extra circuits [29]. In this paper [30], a data-driven technique to deploy a local model network (LMN) for the identification of a DC–DC converter has been proposed. To have a deeper understanding of the efficacy of the suggested strategy, a DC microgrid is taken into consideration. Comparisons to a traditionally tuned PI control indicate that the proposed method is superior in both of the test conditions. As explained in the wind turbine section, [10], a credible physics-based model has been developed for forecasting the remaining useful life (RUL) of power converters in variable-speed wind turbines.

An approach to diagnostic monitoring of modular power electronic converter systems within subsystem control layers is proposed in [31]. This solution makes use of real-time probabilistic DTs that are integrated into the controllers of the system. A case study has also been presented using a digital twin-based diagnostics concept. Using dynamic neural networks, Wunderlich et al. [32] proposed an innovative method to create real-time models of power electronic converters. The proposed modelling methodology is evaluated against existing real-time modelling approaches as well as ML approaches proposed in the past and is proven to be superior to both sets of methodologies. The findings demonstrate that the model is very accurate.

Power converters function as the connecting switches between elements of the MG. The discussed works showed that DT can provide better real-time monitoring and optimised functioning of the power converters. A tabulated summary of the DT of microgrid components, with references and brief descriptions, is provided in Table 1.

Table 1. Summary of the DT of Microgrid Components.

| Application | References | Description |

|---|---|---|

| Microgrid Components: Energy sources | ||

| Solar power | [3][4][5], | Different conditions such as fault assessment, forecasting power production and prediction of hot spots in PV modules using ML and DT techniques are mentioned in these papers. |

| Wind Energy | [7][8][9][10][11] | DT of offshore and onshore wind turbines for predicting RUL of components, monitoring of health, wind speed sensing and online condition monitoring are studied. |

| Biogas Energy | [12][13][14][15][16][33] | Dynamic forecasting using DT and predictive analytics, optimised operation of biomass boiler and data-driven approaches for biogas output prediction on the largest data set are discussed. |

| Microgrid Components: Energy storage | ||

| Battery | [17][18][19][22] | These papers focus on the emergence of ML technologies for better control of battery, the development of DT for BMS on the cloud, the architecture of DT to know the life cycle of battery and the formation of power plant’s DT including battery storage. |

| EV | [20][21][22][23][34] | These papers discuss ESS cell voltage life, architecture for DT of BMS, battery voltage assessment using regression model, health monitoring of battery and infrastructure management of charging stations using an intelligent system. |

| Microgrid Components: Power Converter | ||

| [25][26][27][28][29][30][31][32][35][36] | A data-driven approach to determine the capability of the buck-converter, diagnosis of the open switch problem and monitoring and identification of the DC–DC converter is covered in these references. Further, in [36], the pathway of establishing real-time models of power electronic converters is discussed. | |

Generally, the simulation studies and modelling on grid-connected microgrids are carried out considering physics-based, data-driven and hybridisation modelling techniques. These models are available on simulation platforms, such as MATLAB Simulink and Real Time Digital Simulator (RTDS). The simulation study on the impact of the operation of a grid-connected microgrid on the rest of the power system network does not mimic the real-world scenario due to the utilisation of a fixed microgrid model. The MGDT can address this challenge as it is considered to be closer to the real-world scenario. The present approach of microgrid simulation relies on fixed models of various components of microgrids. Therefore, the integrated system simulation results generally do not mimic the actual response on the ground. The data-driven approach helps in creating better models of the DT components. When integrated and connected with the rest of the power system network, we may get the simulation response close to real-world scenarios. Therefore, the MGDT can better mimic the real operation of the microgrid when connected to the simulation platform. Hence, MGDT can provide better insight into the impact of an event in the microgrid, such as a fault, on the rest of the grid operation. The necessity of continuously updating the models is a key challenge when establishing an MGDT for different systems/processes. Models must be continuously updated throughout the systems’ lifetime from real-time data streams collected through monitoring systems.

Microgrid is a small self-contained power system network having renewable energy sources (mostly wind and solar), a battery energy storage system and controllable loads. A microgrid acts as a single entity when interacting with the rest of the electrical power grid. As the structure and operation of the microgrid system are well established in the electrical power system literature, it has not been reviewed in the present manuscript of the paper. Being a relatively new concept, the present work focuses more on reviewing the concept of DT of the microgrid. DT of the microgrid is developed at the point of interconnection of the microgrid with the rest of the electrical grid to understand better the impact of microgrid operation on the rest of the electrical grid. The establishment of MGDT comprises a digital twin of each section of the microgrid. For the formulation of DT, the planning layout includes data from each unit of MG that needs to be collected to develop a model, model adaptation, algorithm formulation, bi-directional exchange of data between the physical and virtual model and model validations. The goal of MGDT is to improve the efficiency, life cycle cost, service quality, asset management and longevity of energy systems.

This entry is adapted from the peer-reviewed paper 10.3390/en16145525

References

- Reports, S.I. Global Market Outlook for Solar Power 2018–2022. 2018. Available online: https://resources.solarbusinesshub.com/solar-industry-reports/item/global-market-outlook-2018-2022 (accessed on 6 July 2022).

- Smiley, K.; Qu, X.; Galoppo, T.; Harper, K.E.; Kucheria, A.; Acharya, M.; Tarzanin, F. Managing solar asset performance with connected analytics. ABB Rev. 2019, 2019, 34–41.

- Jain, P.; Poon, J.; Singh, J.P.; Spanos, C.; Sanders, S.R.; Panda, S.K. A digital twin approach for fault diagnosis in distributed photovoltaic systems. IEEE Trans. Power Electron. 2020, 35, 940–956.

- Rana, M.; Rahman, A.; Jin, J. A data-driven approach for forecasting state level aggregated solar photovoltaic power production. In Proceedings of the 2020 International Joint Conference on Neural Networks (IJCNN), Glasgow, UK, 19–24 July 2020; pp. 1–8.

- Shi, J.; Lee, W.-J.; Liu, Y.; Yang, Y.; Wang, P. Forecasting power output of photovoltaic systems based on weather classification and support vector machines. IEEE Trans. Ind. Appl. 2012, 48, 1064–1069.

- Chen, H.; Yi, H.; Jiang, B.; Zhang, K.; Chen, Z. Data-driven detection of hot spots in photovoltaic energy systems. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 1731–1738.

- Ciuriuc, A.; Rapha, J.I.; Guanche, R.; Domínguez-García, J.L. Digital tools for floating offshore wind turbines (FOWT): A state of the art. Energy Rep. 2022, 8, 1207–1228.

- Li, Y.; Shen, X. A novel wind speed-sensing methodology for wind turbines based on digital twin technology. IEEE Trans. Instrum. Meas. 2022, 71, 1–13.

- Moghadam, F.K.; Nejad, A.R. Online condition monitoring of floating wind turbines drivetrain by means of digital twin. Mech. Syst. Signal Process. 2022, 162, 108087.

- Sivalingam, K.; Sepulveda, M.; Spring, M.; Davies, P. A Review and Methodology Development for Remaining Useful Life Prediction of Offshore Fixed and Floating Wind turbine Power Converter with Digital Twin Technology Perspective. In Proceedings of the 2018 2nd International Conference on Green Energy and Applications (ICGEA), Singapore, 24–26 March 2018; Voluem 2018, pp. 197–204.

- Pimenta, F.; Pacheco, J.; Branco, C.; Teixeira, C.; Magalhães, F. Development of a digital twin of an onshore wind turbine using monitoring data. J. Phys. Conf. Ser. 2020, 1618, 022065.

- Chiu, M.-C.; Wen, C.-Y.; Hsu, H.-W.; Wang, W.-C. Key wastes selection and prediction improvement for biogas production through hybrid machine learning methods. Sustain. Energy Technol. Assess. 2022, 52, 102223.

- Shahsavar, M.M.; Akrami, M.; Gheibi, M.; Kavianpour, B. Constructing a smart framework for supplying the biogas energy in green buildings using an integration of response surface methodology, artificial intelligence and petri net modelling. Energy Convers. Manag. 2021, 248, 114794.

- Spinti, J.P.; Smith, P.J.; Smith, S.T. Atikokan Digital Twin: Machine learning in a biomass energy system. Appl. Energy 2021, 310, 118436.

- Elmaz, F.; Yücel, Ö.; Mutlu, A.Y. Predictive modeling of biomass gasification with machine learning-based regression methods. Energy 2020, 191, 116541.

- Wang, Y.; Huntington, T.; Scown, C.D. Tree-based automated machine learning to predict biogas production for anaerobic co-digestion of organic waste. ACS Sustain. Chem. Eng. 2021, 9, 12990–13000.

- Li, W.; Rentemeister, M.; Badeda, J.; Jöst, D.; Schulte, D.; Sauer, D.U. Digital twin for battery systems: Cloud battery management system with online state-of-charge and state-of-health estimation. J. Energy Storage 2020, 30, 101557.

- Wu, B.; Widanage, W.D.; Yang, S.; Liu, X. Battery digital twins: Perspectives on the fusion of models, data and artificial intelligence for smart battery management systems. Energy AI 2020, 1, 100016.

- Söderäng, E.; Hautala, S.; Mikulski, M.; Storm, X.; Niemi, S. Development of a Digital Twin for Real-Time Simulation of a Combustion Engine-Based Power Plant with Battery Storage and Grid Coupling. SSRN Electron. J. 2021, 266, 115793.

- Habib, A.A.; Hasan, M.K.; Mahmud, M.; Motakabber, S.; Ibrahimya, M.I.; Islam, S. A review: Energy storage system and balancing circuits for electric vehicle application. IET Power Electron. 2021, 14, 1–13.

- Liu, W.; Placke, T.; Chau, K.T. Overview of batteries and battery management for electric vehicles. Energy Rep. 2022, 8, 4058–4084.

- Merkle, L.; Segura, A.S.; Torben Grummel, J.; Lienkamp, M. Architecture of a digital twin for enabling digital services for battery systems. In Proceedings of the 2019 IEEE International Conference on Industrial Cyber Physical Systems (ICPS), Taipei, Taiwan, 6–9 May 2019; pp. 155–160.

- Li, H.; Kaleem, M.B.; Chiu, I.-J.; Gao, D.; Peng, J. A digital twin model for the battery management systems of electric vehicles. In Proceedings of the 2021 IEEE 23rd Int Conf on High Performance Computing & Communications; 7th Int Conf on Data Science & Systems; 19th Int Conf on Smart City; 7th Int Conf on Dependability in Sensor, Cloud & Big Data Systems & Application (HPCC/DSS/SmartCity/DependSys), Haikou, China, 20–22 December 2021; pp. 1100–1107.

- Yu, G.; Ye, X.; Xia, X.; Chen, Y. Towards cognitive ev charging stations enabled by digital twin and parallel intelligence. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–5 August 2021; pp. 290–293.

- Jamil, M.; Hussain, B.; Abu-Sara, M.; Boltryk, R.J.; Sharkh, S.M. Microgrid power electronic converters: State of the art and future challenges. In Proceedings of the 2009 44th International Universities Power Engineering Conference (UPEC), Glasgow, UK, 1–4 September 2009; pp. 1–5.

- Khodaei, A. Resiliency-oriented microgrid optimal scheduling. IEEE Trans. Smart Grid 2014, 5, 1584–1591.

- Dragicevic, T.; Vasquez, J.C.; Guerrero, J.M.; Skrlec, D. Advanced lvdc electrical power architectures and microgrids: A step toward a new generation of power distribution networks. IEEE Electrif. Mag. 2014, 2, 54–65.

- Peng, Y.; Wang, H. Application of digital twin concept in condition monitoring for dc-dc converter. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 2199–2204.

- Peng, Y.; Zhao, S.; Wang, H. A digital twin based estimation method for health indicators of dc–dc converters. IEEE Trans. Power Electron. 2021, 36, 2105–2118.

- Rouzbehi, K.; Miranian, A.; Escaño, J.M.; Rakhshani, E. A Data-Driven Based Voltage Control Strategy for DC-DC Converters: Application to DC Microgrid. Electronics 2019, 8, 493.

- Milton, M.; De La O, C.; Ginn, H.L.; Benigni, A. Controller-embeddable probabilistic real-time digital twins for power electronic converter diagnostics. IEEE Trans. Power Electron. 2020, 35, 9850–9864.

- Wunderlich, A.; Santi, E. Digital Twin Models of Power Electronic Converters Using Dynamic Neural Networks. In Proceedings of the 2021 IEEE Applied Power Electronics Conference and Exposition (APEC), Phoenix, AZ, USA, 14–17 June 2021; pp. 2369–2376.

- Cinar, S.; Cinar, S.O.; Wieczorek, N.; Sohoo, I.; Kuchta, K. Integration of Artificial Intelligence into Biogas Plant Operation. Processes 2021, 9, 85.

- Bhatti, G.; Mohan, H.; Raja Singh, R. Towards the future of ssmart electric vehicles: Digital twin technology. Renew. Sustain. Energy Rev. 2021, 141, 110801.

- Planas, E.; Andreu, J.; Garate, J.; De Alegría, I.M.; Ibarra, E. AC and DC technology in microgrids: A review. Renew. Sustain. Energy Rev. 2015, 43, 726–749.

- O’Dwyer, E.; Pan, I.; Charlesworth, R.; Butler, S.; Shah, N. Integration of an energy management tool and digital twin for coordination and control of multi-vector smart energy systems. Sustain. Cities Soc. 2020, 62, 102412.

This entry is offline, you can click here to edit this entry!