To examine the application and significance of 3D printing technology in pavement maintenance engineering, a review of the current developments in principles, types, materials, and equipment for 3D printing was conducted. A comparison and analysis of traditional methods and 3D printing for asphalt pavement maintenance led to an investigation of 3D asphalt printing technologies and equipment. As a result, the following suggestions and conclusions are proposed: 3D printing technology can increase the level of automation and standardization of pavement maintenance engineering, leading to effective improvements in worker safety, climate adaptability, repair accuracy, etc. For on-site repair of cracks and minor potholes, utilizing material extrusion technology a mobile 3D asphalt printing robot with a screw extrusion device can be used for accuracy and flexibility.

1. Introduction

Prolonged traffic loads and environmental factors can cause asphalt pavement [

1,

2,

3] to develop cracks, potholes, and other forms of distress [

4,

5,

6]. If not addressed promptly, these distresses can escalate and compromise the road structure and traffic safety. With a vast road network and a high proportion of maintenance required, maintaining roads in China is a very challenging task [

7]. The most common methods for repairing cracks in asphalt pavement are pouring, sealing, and digging-patching, using materials such as modified asphalt and resin [

8,

9]. For pothole repair, traditional methods involve removing old material and filling with new material, using either hot-mixed or cold-mixed asphalt mixture [

10]. These maintenance methods often require multiple workers and can be time-consuming and risky, especially in areas with heavy traffic [

11]. They also rely heavily on manual labor, reducing the ability to withstand changing weather and environmental conditions [

12]. Additionally, individual differences among workers can lead to a lack of precision and standardization in maintenance engineering.

As an important method under the umbrella of additive manufacturing, 3D printing technology combines cutting-edge technologies such as 3D digital modeling, electromechanical control, computer science, material science, and structural mechanics [

13]. Further, 4D printed parts that can alter their shape over time because of their dynamic capability are also gradually developing [

14]. As a crucial part of the “third industrial revolution”, 3D printing technology has found applications in fields such as biomedicine, industrial manufacturing, food processing, aerospace, and civil engineering [

15,

16]. With its advantages of automation, high efficiency, and precise control, 3D printing is increasingly being used in road engineering. In 2018, Jaeheum et al. [

17] created a 3D digital model of concrete pavement potholes using multi-dimensional photography and photogrammetric software algorithms. When a 3D-printed plastic mold corresponding to the damaged areas is used to cast concrete patches, the time spent blocking the road could be reduced from 7 d to 2 h, resulting in economic benefits. By leveraging the automation, efficiency, and precision of 3D printing technology in pavement maintenance, the risks, inefficiencies, and quality issues associated with manual labor can be reduced. However, there remains a need for more comprehensive discussion and analysis on the subject.

2. Asphalt as 3D Printing Material

As asphalt is a temperature-sensitive material with special mechanical properties, the viscoelastic properties of asphalt [

61,

75,

76,

77] can be changed with temperature variation. The stress-strain curves of asphalt are nonlinear under loading. In order to describe the mechanical properties of asphalt in the viscoelastic state more accurately, the stiffness modulus (ratio of stress to total strain under a certain time (t) and temperature (T)) [

78,

79] is commonly used. The stiffness modulus can describe the properties of asphalt, but it also contains the effects of temperature and load time. (1) The fluidity and plastic deformation capacity of asphalt would improve with the increase in temperature, accompanied by a decrease in stiffness modulus. The viscosity and deformation would enhance with the reduction of temperature. (2) With the shortening of the loading time, the stiffness modulus of asphalt increases and the deformation resistance becomes stronger.

Materials used for 3D printing require essential printability, including fluidity, extrudability, and buildability [

71,

80]. Fluidity refers to the ability of material to move smoothly during feeding and to provide a continuous material to print nozzles. Extrudability refers to the ability of material to extrude smoothly from the print nozzle without blockage or salivation. Buildability refers to the ability for material to resist its own gravity and that of subsequent print layers without deformation and to ensure good interlaminar bonding. At higher temperature, asphalt material has good fluidity and extrudability. At lower temperature, good bonding between layers can be ensured based on the greater viscosity of asphalt. The requirements of buildability can be met through deformation resistance. Therefore, the requirement of 3D printing can be fulfilled by controlling the temperature to regulate the printability of asphalt. In addition to common based and polymer modified asphalt, fine aggregate or fiber [

81,

82] can be added to expand the scope of application for 3D asphalt printing technology.

3. Types of 3D Asphalt Printing Technology

As summarized in

Section 2.2., which covers the printing principle and typical materials used in different 3D printing technologies, the following insights can be gleaned. Out of the seven types of 3D printing technologies, the material used in vat photopolymerization is photosensitive. Binder jetting and sheet lamination, on the other hand, utilize powder and sheets as their respective materials. For powder bed fusion and directed energy deposition, metals and polymers would be melted by heat sources such as lasers and plasma arcs at above 3000 °C [

83,

84]. Due to the high cost and limited heating range, the above-mentioned five types of printing technologies are not suitable for use with asphalt.

Because the thermoplastic properties of asphalt fulfill the requirements for ME technology, it can be utilized for the 3D printing of asphalt. Materials with similar properties to asphalt such as PLA [

85] and TPU [

86] have been widely used in industrial manufacturing for production of handicrafts, models, etc. The printing parameters and path planning of material extrusion have been researched in depth. In the realm of construction engineering, 3D concrete printing has made significant strides in terms of efficiency and versatility due to its ability to quickly form irregular structures. Screw extrusion [

87] is the most commonly used method for feeding material in large-scale 3D concrete printing, thanks to its high efficiency, precise accuracy, straightforward design, and low cost. This makes screw extrusion an ideal choice for material extrusion in the 3D printing of asphalt.

Material jetting is the process of depositing ejected fluid materials layer by layer. Among materials commonly used in material jetting, photosensitive resin, concrete, and metal powders can be hardened by ultraviolet ray, hydration reaction, and low temperature, respectively [

88]. Because asphalt hardens at a low temperature, material jetting can also be used for 3D asphalt printing. Different from filamentary asphalt extruded in material extrusion, droplet asphalt is jetted in material jetting technology at a higher printing temperature. Droplet asphalt is less controllable and less accurate than filamentary asphalt, so the application of material jetting should take full advantage of its high efficiency. Material jetting can be combined with air-feeding as a supplemental method of 3D asphalt printing.

4. Equipment of 3D Asphalt Printing Technology

In the existing research, some scholars have developed the equipment of 3D printing asphalt technology [

89]. In 2018, based on the frame structure and control system of RepRap Mendel 90, Jackson et al. [

90] modified the print head to 3D print granular asphalt at a printing temperature of 125–135 °C. The 3D printed asphalt showed up to nine times the ductility of cast samples with similar fracture strengths. A stepper motor was used to drive an auger screw. Asphalt was melted in a heating aluminum jacket by a thermistor, and a metal nozzle was used to improve heat conduction. Although the device achieved 3D asphalt printing, its print range was limited by the three-axis movement system, and it would be difficult for the print scale to meet the requirements of pavement maintenance, causing difficulties in practical engineering applications onsite. However, it can be used to make prefabricated patches in indirect repair. In 2018, researchers from Leeds University [

91] equipped a six-rotor unmanned aerial vehicle (UAV) with a delta-style 3D printer. The UAV can fill potholes using a printer head after detecting them. The UAV improves the mobility of the asphalt printing device, but how it might carry enough asphalt for repair is a problem that needs to be solved.

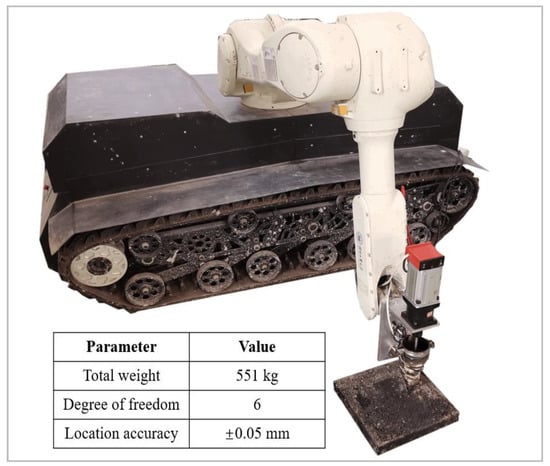

Figure 1 shows a mobile 3D asphalt printing robot (hereafter referred to as “equipment”) from the Hebei University of Technology. The equipment mainly consists of a lithium battery crawler vehicle, a robotic arm, an image acquisition system of pavement distress, a screw feed component, and a control system. The crawler vehicle is used to carry other components and move flexibly during the maintenance of early cracks and light potholes in asphalt pavements. The robot arm base can rotate 360 degrees, and the large arm and small arm can rotate 90 degrees and 180 degrees, respectively, ensuring flexible and accurate movement of the screw feed component at the end of the robot arm. The image acquisition system of pavement distress is used to collect information on early cracks and light potholes in pavement to provide a foundation for building 3D digital models, either with digital cameras or 3D laser scanners. The screw feed component is used to heat asphalt and extrude it precisely with 3D printing path planning and detection of the required amount. After the control system builds 3D digital models of the asphalt pavement distress using the image acquisition system, the results of slicing and path planning would be determined by the slicing software. Then, the movement of the robot arm is controlled to extrude fused asphalt from the extrusion nozzle to ensure the cooperative operation of equipment components in 3D printing maintenance of early cracks and light potholes.

Figure 1. Mobile 3D asphalt printing robot (@HEBUT LAB).

Equipment with a good balance of accuracy and flexibility in terms of printing scale would meet the practical needs of engineering. Furthermore, it would have the capability to carry a sufficient amount of asphalt for maintenance. As a result, it could effectively adapt to the nature of asphalt pavement distress maintenance during extended construction at dispersed job sites.

This entry is adapted from the peer-reviewed paper 10.3390/su15076237