Laser surface texturing (LST) is one of the most promising technologies for controllable surface structuring and the acquisition of specific physical surface properties needed in functional surfaces. The quality and processing rate of the laser surface texturing strongly depend on the correct choice of a scanning strategy.

- laser machining

- laser ablation

- processing rate

- scanning techniques

- heat accumulation

- plasma shielding

1. Introduction

2. Physical Limitations of Laser Surface Texturing

2.1. Plasma Shielding Effect

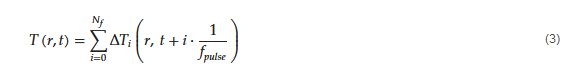

2.2. Heat Accumulation in Pulsed Laser Surface Processing

3. Scanning Techniques of LST

|

Scanning Strategy |

Scanning Technique |

Structure Period (µm) |

Processing Rate (cm2/min) |

Scanning Speed (m/s) |

Reference |

|

|---|---|---|---|---|---|---|

|

1 |

DLIP-head (ps-laser) |

Sample movement |

0.343–1.064 |

100–9000 |

1 |

|

|

2 |

DLIP-head (ps-laser) |

Galvanometer scanner |

0.532–1.064 |

0.7–10 |

16·10−3–6.8 |

|

|

3 |

LIPSS (fs-laser) |

Galvanometer scanner |

0.9 |

6.3 |

3 |

[118] |

|

4 |

Path cutting (fs-laser) |

Sample movement |

0.8 |

0.01 |

0.3 |

[131] |

|

5 |

Unidirectional scan (ps-laser) |

Sample rotation and acousto-optic beam deflection |

250 |

~46.8 |

1.5 (rotation) 40 (AOD scanning) |

[132] |

|

6 |

Hatch filling (ns-laser) |

Galvanometer scanner |

12.5–200 |

1.8–428 |

0.25–4 |

[129] |

|

7 |

Point-by-point ablation (fs-laser) |

Galvanometer scanner |

30–40 |

0.4–0.75 |

~0.05–0.2 |

|

|

8 |

Hatch filling (ps-laser) |

Galvanometer scanner |

2000 |

0.15–0.20 |

0.5 |

[135] |

|

9 |

Path writing (0.1 μs laser) |

Galvanometer scanner |

50 |

1.2 |

0.4–2 |

[136] |

|

10 |

Hatch filling (fs-laser) |

Galvanometer scanner |

4 |

8–25 |

4.5–17.1 |

[130] |

|

11 |

Interlaced (ps-laser) |

Galvanometer scanner |

1.2–6 |

0.017–2 |

0.024–0.6 |

[137] |

|

12 |

Hatch filling (ps-laser) |

Multibeam galvanometer scanner |

500 |

5400 |

20 |

[124] |

|

13 |

Hatch filling |

Polygon scanner |

14.5–40 |

148–7680 |

60–800 |

|

|

14 |

Hatch filling (ps-laser) |

Polygon scanner |

10 |

840 |

10–200 |

[73] |

|

15 |

Hatch filling (fs-laser) |

Polygon scanner |

1–12 |

0.03, approx. 60 |

25 |

[138] |

|

16 |

Hatch filling (fs, ps-laser) |

Polygon scanner |

40 |

43 |

15 |

[139] |

|

17 |

Laser pulse pattern |

Sample movement with mask |

20 |

1800 |

– |

|

|

18 |

Shifted path (ps-laser) |

Galvanometer scanner |

200 |

17.4 |

8 |

|

|

19 |

Shifted burst (ps-laser) |

Galvanometer scanner |

60–570 |

160 |

8 |

|

|

20 |

Unidirectional hatch |

Polygon scanner and self-organizing |

≲0.5 |

1510 |

560 |

[143] |

|

21 |

Hatch filling with multibeam |

Galvanometer scanner with DOE |

~0.4 |

1910 |

9 |

[116] |

|

22 |

Hatch filling with ns-laser |

Polygon scanner |

50 |

1386 |

200 |

[144] |

This entry is adapted from the peer-reviewed paper 10.3390/mi14061241

References

- He, F.; Liao, Y.; Lin, J.; Song, J.; Qiao, L.; Cheng, Y.; Sugioka, K. Femtosecond Laser Fabrication of Monolithically Integrated Microfluidic Sensors in Glass. Sensors 2014, 14, 19402–19440.

- Yang, T.; Lin, H.; Jia, B. Two-dimensional material functional devices enabled by direct laser fabrication. Front. Optoelectron. 2018, 11, 2–22.

- Etsion, I.; Halperin, G.; Becker, E. The effect of various surface treatments on piston pin scuffing resistance. Wear 2006, 261, 785–791.

- Schille, J.; Loeschner, U.; Ebert, R.; Scully, P.; Goddard, N.; Exner, H. Laser micro processing using a high repetition rate femto second laser. In Proceedings of the International Congress on Applications of Lasers and Electro-Optics, Wuhan, China, 23–25 March 2010; pp. 1491–1499.

- Zhang, L.; Lin, N.; Zou, J.; Lin, X.; Liu, Z.; Yuan, S.; Yu, Y.; Wang, Z.; Zeng, Q.; Chen, W.; et al. Super-hydrophobicity and corrosion resistance of laser surface textured AISI 304 stainless steel decorated with Hexadecyltrimethoxysilane (HDTMS). Opt. Laser Technol. 2020, 127, 106146.

- Chen, X.; Lei, Z.; Chen, Y.; Jiang, M.; Jiang, N.; Bi, J.; Lin, S. Enhanced wetting behavior using femtosecond laser-textured surface in laser welding-brazing of Ti/Al butt joint. Opt. Laser Technol. 2021, 142, 107212.

- He, C.; Yang, S.; Zheng, M. Analysis of synergistic friction reduction effect on micro-textured cemented carbide surface by laser processing. Opt. Laser Technol. 2022, 155, 108343.

- Luo, X.; Tian, Z.; Chen, C.; Jiang, G.; Hu, X.; Wang, L.; Peng, R.; Zhang, H.; Zhong, M. Laser-textured High-throughput Hydrophobic/Superhydrophobic SERS platform for fish drugs residue detection. Opt. Laser Technol. 2022, 152, 108075.

- Martan, J.; Moskal, D.; Smeták, L.; Honner, M. Performance and Accuracy of the Shifted Laser Surface Texturing Method. Micromachines 2020, 11, 520.

- Jaeggi, B.; Neuenschwander, B.; Hunziker, U.; Zuercher, J.; Meier, T.; Zimmermann, M.; Hennig, G. High precision and high throughput surface structuring by synchronizing mechanical axes with an ultra short pulsed laser system in MOPA arrangement. In Proceedings of the International Congress on Applications of Lasers and Electro-Optics, Orlando, FL, USA, 14–18 October 2012; pp. 1046–1053.

- Jaeggi, B.; Neuenschwander, B.; Meier, T.; Zimmermann, M.; Hennig, G. High precision surface structuring with ultra-short laser pulses and synchronized mechanical axes. Phys. Procedia 2013, 41, 319–326.

- Račiukaitis, G.; Brikas, M.; Gečys, P.; Voisiat, B.; Gedvilas, M. Use of high repetition rate and high power lasers in microfabrication: How to keep the efficiency high? J. Laser Micro/Nanoeng. 2009, 4, 186–191.

- Neuenschwander, B.; Jaeggi, B.; Schmid, M.; Hennig, G. Surface structuring with ultra-short laser pulses: Basics, limitations and needs for high throughput. Phys. Procedia 2014, 56, 1047–1058.

- Faas, S.; Bielke, U.; Weber, R.; Graf, T. Prediction of the surface structures resulting from heat accumulation during processing with picosecond laser pulses at the average power of 420 W. Appl. Phys. A 2018, 124, 612.

- Förster, D.J.; Faas, S.; Gröninger, S.; Bauer, F.; Michalowski, A.; Weber, R.; Graf, T. Shielding effects and re-deposition of material during processing of metals with bursts of ultra-short laser pulses. Appl. Surf. Sci. 2018, 440, 926–931.

- Itina, T.; Povarnitsyn, M.; Khishchenko, K. Laser Ablation: Effects and Applications; Black, S.E., Ed.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011; pp. 99–125.

- Xu, D.; Wu, W.; Malhotra, R.; Chen, J.; Lu, B.; Cao, J. Mechanism investigation for the influence of tool rotation and laser surface texturing (LST) on formability in single point incremental forming. Int. J. Mach. Tools Manuf. 2013, 73, 37–46.

- Batal, A.; Michalek, A.; Penchev, P.; Kupisiewicz, A.; Dimov, S. Laser processing of freeform surfaces: A new approach based on an efficient workpiece partitioning strategy. Int. J. Mach. Tools Manuf. 2020, 156, 103593.

- Sugioka, K. Progress in ultrafast laser processing and future prospects. Nanophotonics 2017, 6, 393–413.

- Khan, A.; Wang, Z.; Sheikh, M.A.; Whitehead, D.J.; Li, L. Laser micro/nano patterning of hydrophobic surface by contact particle lens array. Appl. Surf. Sci. 2011, 258, 774–779.

- Li, L.; Guo, W.; Wang, Z.B.; Liu, Z.; Whitehead, D.; Luk’yanchuk, B. Large-area laser nano-texturing with user-defined patterns. J. Micromech. Microeng. 2009, 19, 054002.

- Lai, N.D.; Lin, J.H.; Huang, Y.Y.; Hsu, C.C. Fabrication of two- and three-dimensional quasi-periodic structures with 12-fold symmetry by interference technique. Opt. Express 2006, 14, 10746.

- Georgiev, D.G.; Baird, R.J.; Avrutsky, I.; Auner, G.; Newaz, G. Controllable excimer-laser fabrication of conical nano-tips on silicon thin films. Appl. Phys. Lett. 2004, 84, 4881–4883.

- Simon, P.; Ihlemann, J. Ablation of submicron structures on metals and semiconductors by femtosecond UV-laser pulses. Appl. Surf. Sci. 1997, 109–110, 25–29.

- Marattukalam, J.J.; Karlsson, D.; Pacheco, V.; Beran, P.; Wiklund, U.; Jansson, U.; Hjörvarsson, B.; Sahlberg, M. The effect of laser scanning strategies on texture, mechanical properties, and site-specific grain orientation in selective laser melted 316L SS. Mater. Des. 2020, 193, 108852.

- Mugwagwa, L.; Dimitrov, D.; Matope, S.; Yadroitsev, I. Evaluation of the impact of scanning strategies on residual stresses in selective laser melting. Int. J. Adv. Manuf. Technol. 2019, 102, 2441–2450.

- Shipley, H.; McDonnell, D.; Culleton, M.; Coull, R.; Lupoi, R.; O’Donnell, G.; Trimble, D. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: A review. Int. J. Mach. Tools Manuf. 2018, 128, 1–20.

- Bornschlegel, B.; Finger, J. In-Situ Analysis of Ultrashort Pulsed Laser Ablation with Pulse Bursts. J. Laser Micro/Nanoeng. 2019, 14, 88–94.

- Ivanov, D.S.; Rethfeld, B. The effect of pulse duration on the interplay of electron heat conduction and electron-phonon interaction: Photo-mechanical versus photo-thermal damage of metal targets. Appl. Surf. Sci. 2009, 255, 9724–9728.

- Mannion, P.; Magee, J.; Coyne, E.; O’Connor, G.; Glynn, T. The effect of damage accumulation behaviour on ablation thresholds and damage morphology in ultrafast laser micro-machining of common metals in air. Appl. Surf. Sci. 2004, 233, 275–287.

- Schille, J.; Schneider, L.; Loeschner, U. Process optimization in high-average-power ultrashort pulse laser microfabrication: How laser process parameters influence efficiency, throughput and quality. Appl. Phys. A 2015, 120, 847–855.

- Moskal, D.; Martan, J.; Honner, M.; Beltrami, C.; Kleefoot, M.-J.; Lang, V. Inverse Dependence of Heat Accumulation on Pulse Duration in Laser Surface Processing with Ultra-Short Pulses. SSRN Electron. J. 2022, 213, 124328.

- Wang, J.; Ma, Y.; Liu, Y.; Yuan, W.; Song, H.; Huang, C.; Yin, X. Experimental investigation on laser ablation of C/SiC composites subjected to supersonic airflow. Opt. Laser Technol. 2019, 113, 399–406.

- Wang, H.; Liu, J.; Xu, Y.; Wang, X.; Ren, N.; Ren, X.; Hu, Q. Experimental characterization and real-time monitoring for laser percussion drilling in titanium alloy using transverse electric field assistance and/or lateral air blowing. J. Manuf. Process. 2021, 62, 845–858.

- Farid, N.; Harilal, S.S.; Ding, H.; Hassanein, A. Dynamics of ultrafast laser plasma expansion in the presence of an ambient. Appl. Phys. Lett. 2013, 103, 191112.

- Mitko, V.S.; Römer, G.R.B.E.; Huis in ’t Veld, A.J.; Skolski, J.Z.P.; Obona, J.V.; Ocelík, V.; De Hosson, J.T.M. Properties of High-Frequency Sub-Wavelength Ripples on Stainless Steel 304L under Ultra Short Pulse Laser Irradiation. Phys. Procedia 2011, 12, 99–104.

- Gamaly, E.G.; Rode, A. V Physics of ultra-short laser interaction with matter: From phonon excitation to ultimate transformations. Prog. Quantum Electron. 2013, 37, 215–323.

- Rethfeld, B.; Sokolowski-Tinten, K.; Von Der Linde, D.; Anisimov, S.I. Timescales in the response of materials to femtosecond laser excitation. Appl. Phys. A Mater. Sci. Process. 2004, 79, 767–769.

- König, J.; Nolte, S.; Tünnermann, A. Plasma evolution during metal ablation with ultrashort laser pulses. Opt. Express 2005, 13, 10597.

- Mildner, J.; Sarpe, C.; Götte, N.; Wollenhaupt, M.; Baumert, T. Applied Surface Science Emission signal enhancement of laser ablation of metals (aluminum and titanium) by time delayed femtosecond double pulses from femtoseconds to nanoseconds. Appl. Surf. Sci. 2014, 302, 291–298.

- Carrasco-García, I.; Vadillo, J.M.; Javier Laserna, J. Visualization of surface transformations during laser ablation of solids by femtosecond pump–probe time-resolved microscopy. Spectrochim. Acta Part B At. Spectrosc. 2015, 113, 30–36.

- Carrasco-García, I.; Vadillo, J.M.; Javier Laserna, J.; Laserna, J.J. Monitoring the dynamics of the surface deformation prior to the onset of plasma emission during femtosecond laser ablation of noble metals by time-resolved reflectivity microscopy. Spectrochim. Acta Part B At. Spectrosc. 2017, 131, 1–7.

- Rethfeld, B.; Sokolowski-Tinten, K.; Temnov, V.V.; Kudryashov, S.I.; Bialkowski, J.; Cavalleri, A.; von der Linde, D. Ablation dynamics of solids heated by femtosecond laser pulses. In Nonresonant Laser-Matter Interaction (NLMI-10); Libenson, M.N., Ed.; SPIE: San Francisco, CA, USA, 2001; Volume 4423, pp. 186–196.

- Wu, C.; Zhigilei, L.V. Microscopic mechanisms of laser spallation and ablation of metal targets from large-scale molecular dynamics simulations. Appl. Phys. A Mater. Sci. Process. 2014, 114, 11–32.

- Amoruso, S.; Bruzzese, R.; Pagano, C.; Wang, X. Features of plasma plume evolution and material removal efficiency during femtosecond laser ablation of nickel in high vacuum. Appl. Phys. A Mater. Sci. Process. 2007, 89, 1017–1024.

- Lorazo, P.; Lewis, L.J.; Meunier, M. Thermodynamic pathways to melting, ablation, and solidification in absorbing solids under pulsed laser irradiation. Phys. Rev. B 2006, 73, 134108.

- Sankar, P.; Shashikala, H.D.; Philip, R. Effect of laser beam size on the dynamics of ultrashort laser-produced aluminum plasma in vacuum. Phys. Plasmas 2019, 26, 013302.

- Arnold, N.; Gruber, J.; Heitz, J. Spherical expansion of the vapor plume into ambient gas: An analytical model. Appl. Phys. A Mater. Sci. Process. 1999, 69, S87–S93.

- Trusso, S.; Barletta, E.; Barreca, F.; Fazio, E.; Neri, F. Time resolved imaging studies of the plasma produced by laser ablation of silicon in O2/Ar atmosphere. Laser Part. Beams 2005, 23, 149–153.

- Choi, T.Y.; Grigoropoulos, C.P. Plasma and ablation dynamics in ultrafast laser processing of crystalline silicon. J. Appl. Phys. 2002, 92, 4918–4925.

- Tański, M.; Barbucha, R.; Kocik, M.; Garasz, K.; Mizeraczyk, J. Investigation of the Laser Generated Ablation Plasma Plume Dynamics and Plasma Plume Sound Wave Dynamics. In Laser Technology 2012: Applications of Lasers; Woliński, W.L., Jankiewicz, Z., Romaniuk, R.S., Eds.; SPIE: San Francisco, CA, USA, 2013; Volume 8703, p. 87030O.

- Gacek, S.; Wang, X. Plume splitting in pico-second laser-material interaction under the influence of shock wave. Phys. Lett. Sect. A Gen. At. Solid State Phys. 2009, 373, 3342–3349.

- Gacek, S.; Wang, X. Dynamics evolution of shock waves in laser-material interaction. Appl. Phys. A Mater. Sci. Process. 2009, 94, 675–690.

- Misra, A.; Thareja, R.K. Investigation of laser ablated plumes using fast photography. IEEE Trans. Plasma Sci. 1999, 27, 1553–1558.

- Diwakar, P.K.; Harilal, S.S.; Phillips, M.C.; Hassanein, A. Characterization of ultrafast laser-ablation plasma plumes at various Ar ambient pressures. J. Appl. Phys. 2015, 118, 043305.

- Keller, W.J.; Shen, N.; Rubenchik, A.M.; Ly, S.; Negres, R.; Raman, R.N.; Yoo, J.-H.; Guss, G.; Stolken, J.S.; Matthews, M.J.; et al. Physics of picosecond pulse laser ablation. J. Appl. Phys. 2019, 125, 085103.

- Olsson, R.; Powell, J.; Palmquist, A.; Brånemark, R.; Frostevarg, J.; Kaplan, A.F.H. Production of osseointegrating (bone bonding) surfaces on titanium screws by laser melt disruption. J. Laser Appl. 2018, 30, 042009.

- Ullmann, F.; Loeschner, U.; Hartwig, L.; Szczepanski, D.; Schille, J.; Gronau, S.; Knebel, T.; Drechsel, J.; Ebert, R.; Exner, H. Highspeed Laser Ablation Cutting of Metal. In High-Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications II; Dorsch, F., Ed.; SPIE: San Francisco, CA, USA, 2013; Volume 8603, p. 860311.

- Semerok, A.; Sallé, B.; Wagner, J.-F.; Petite, G. Femtosecond, picosecond, and nanosecond laser microablation: Laser plasma and crater investigation. Laser Part. Beams 2002, 20, 67–72.

- Povarnitsyn, M.E.; Itina, T.E.; Khishchenko, K.V.; Levashov, P.R. Suppression of ablation in femtosecond double-pulse experiments. Phys. Rev. Lett. 2009, 103, 195002.

- Letan, A.; Audouard, E.; Mishchik, K.; Hönninger, C.; Mottay, E. Use of Bursts for Femtosecond Ablation Efficiency Increase. In Lasers in Manufacturing; John Wiley & Sons: Hoboken, NJ, USA, 2019; pp. 1–6.

- Kerse, C.; Kalaycloĝ Lu, H.; Elahi, P.; Çetin, B.; Kesim, D.K.; Akçaalan, Ö.; Yavaş, S.; Aşlk, M.D.; Öktem, B.; Hoogland, H.; et al. Ablation-cooled material removal with ultrafast bursts of pulses. Nature 2016, 537, 84–88.

- Gaudiuso, C.; Giannuzzi, G.; Volpe, A.; Lugarà, P.M.; Choquet, I.; Ancona, A. Incubation during laser ablation with bursts of femtosecond pulses with picosecond delays. Opt. Express 2018, 26, 8958–8968.

- Moskal, D.; Martan, J.; Smazalová, E.; Houdková, Š. Influence of initial surface state on laser surface texturing result. In Proceedings of the METAL 2016-25th Anniversary International Conference on Metallurgy and Materials, Brno, Czech Republic, 25–27 May 2016.

- Fang, Z.; Zhou, T.; Perrie, W.; Bilton, M.; Schille, J.; Löschner, U.; Edwardson, S.; Dearden, G. Pulse Burst Generation and Diffraction with Spatial Light Modulators for Dynamic Ultrafast Laser Materials Processing. Materials 2022, 15, 9059.

- Mur, J.; Petkovšek, R. Near-THz bursts of pulses—Governing surface ablation mechanisms for laser material processing. Appl. Surf. Sci. 2019, 478, 355–360.

- Bruening, S.; Du, K.; Jarczynski, M.; Jenke, G.; Gillner, A. Ultra-fast laser micro processing by multiple laser spots. Procedia CIRP 2018, 74, 573–580.

- Kuang, Z.; Perrie, W.; Leach, J.; Sharp, M.; Edwardson, S.P.; Padgett, M.; Dearden, G.; Watkins, K.G. High throughput diffractive multi-beam femtosecond laser processing using a spatial light modulator. Appl. Surf. Sci. 2008, 255, 2284–2289.

- Bauer, F.; Michalowski, A.; Kiedrowski, T.; Nolte, S. Heat accumulation in ultra-short pulsed scanning laser ablation of metals. Opt. Express 2015, 23, 1035–1043.

- Weber, R.; Graf, T.; Freitag, C.; Feuer, A.; Kononenko, T.; Konov, V.I. Processing constraints resulting from heat accumulation during pulsed and repetitive laser materials processing. Opt. Express 2017, 25, 3966.

- Martan, J.; Prokešová, L.; Moskal, D.; Ferreira de Faria, B.C.; Honner, M.; Lang, V. Heat accumulation temperature measurement in ultrashort pulse laser micromachining. Int. J. Heat Mass Transf. 2021, 168, 120866.

- Loeschner, U.; Schille, J.; Streek, A.; Knebel, T.; Hartwig, L.; Hillmann, R.; Endisch, C. High-rate laser microprocessing using a polygon scanner system. J. Laser Appl. 2015, 27, S29303.

- Schille, J.; Schneider, L.; Streek, A.; Kloetzer, S.; Loeschner, U. High-throughput machining using high average power ultrashort pulse lasers and ultrafast polygon scanner. In Proceedings of the Laser-Based Micro- and Nanoprocessing X, San Francisco, CA, USA, 13–18 February 2016; Klotzbach, U., Washio, K., Arnold, C.B., Eds.; Volume 9736, p. 97360R.

- Fraggelakis, F.; Mincuzzi, G.; Lopez, J.; Manek-Hönninger, I.; Kling, R. Texturing metal surface with MHz ultra-short laser pulses. Opt. Express 2017, 25, 18131.

- Jaeggi, B.; Neuenschwander, B.; Schmid, M.; Muralt, M.; Zuercher, J.; Hunziker, U. Influence of the pulse duration in the ps-regime on the ablation efficiency of metals. Phys. Procedia 2011, 12, 164–171.

- Kramer, T. Increasing the Specific Removal Rate for Ultra Short Pulsed Laser-Micromachining by Using Pulse Bursts. J. Laser Micro/Nanoeng. 2017, 12, 107–114.

- Schille, J.; Schneider, L.; Hartwig, L.; Loeschner, U. High-rate laser processing of metals using high-average power ultrashort pulse lasers. In Proceedings of the 38th International MATADOR Conference, Yunlin, Taiwan, 28–30 March 2015; pp. 135–152.

- Jaeggi, B.; Remund, S.; Streubel, R.; Goekce, B. Laser Micromachining of Metals with Ultra-Short Pulses: Factors Limiting the Laser Micromachining of Metals with Ultra-Short Pulses: Factors Limiting the Scale-Up Process. J. Laser Micro/Nanoeng. 2017, 12.

- Moskal, D.; Martan, J.; Kučera, M.; Houdková, Š.; Kromer, R. Picosecond laser surface cleaning of AM1 superalloy. Phys. Procedia 2016, 83, 249–257.

- Di Niso, F.; Gaudiuso, C.; Sibillano, T.; Mezzapesa, F.P.; Ancona, A.; Lugarà, P.M. Role of heat accumulation on the incubation effect in multi-shot laser ablation of stainless steel at high repetition rates. Opt. Express 2014, 22, 12200–12210.

- Förster, D.J.; Weber, R.; Graf, T. Heat accumulation effects on efficiency during laser drilling of metals. In Proceedings of the Lasers in Manufacturing Conference, München, Germany, 26–29 June 2017.

- Bornschlegel, B.; Köller, J.; Finger, J. In-situ analysis of heat accumulation during ultrashort pulsed laser ablation. J. Laser Micro/Nanoeng. 2020, 15, 56–62.

- Ancona, A.; Röser, F.; Rademaker, K.; Limpert, J.; Nolte, S.; Tunnermann, A. High speed laser drilling of metals using a high repetition rate, high average power ultrafast fiber CPA system. Opt. Express 2008, 16, 8958–8968.

- Taylor, L.L.; Scott, R.E.; Qiao, J. Integrating two-temperature and classical heat accumulation models to predict femtosecond laser processing of silicon. Opt. Mater. Express 2018, 8, 648.

- Bulgakova, N.M.; Zhukov, V.P.; Mirza, I.; Meshcheryakov, Y.P.; Tomáštík, J.; Michálek, V.; Haderka, O.; Fekete, L.; Rubenchik, A.M.; Fedoruk, M.P.; et al. Ultrashort-pulse laser processing of transparent materials: Insight from numerical and semi-analytical models. In Proceedings of the Laser Applications in Microelectronic and Optoelectronic Manufacturing (LAMOM) XXI, San Francisco, CA, USA, 13–18 February 2016; Volume 9735, p. 97350N.

- Zhanwen, A.; Zou, G.; Wu, Y.; Wu, Y.; Feng, B.; Xiao, Y.; Huo, J.; Jia, Q.; Du, C.; Liu, L. Temporal and spatial heat input regulation strategy for high-throughput micro-drilling based on multi-beam ultrafast laser. Opt. Laser Technol. 2022, 155, 108424.

- Shugaev, M.V.; Gnilitskyi, I.; Bulgakova, N.M.; Zhigilei, L.V. Mechanism of single-pulse ablative generation of laser-induced periodic surface structures. Phys. Rev. B 2017, 96, 205429.

- Wu, C.; Christensen, M.S.; Savolainen, J.M.; Balling, P.; Zhigilei, L.V. Generation of subsurface voids and a nanocrystalline surface layer in femtosecond laser irradiation of a single-crystal Ag target. Phys. Rev. B Condens. Matter Mater. Phys. 2015, 91, 035413.

- Bulgakova, N.; Panchenko, A.; Zhukov, V.; Kudryashov, S.; Pereira, A.; Marine, W.; Mocek, T.; Bulgakov, A. Impacts of Ambient and Ablation Plasmas on Short- and Ultrashort-Pulse Laser Processing of Surfaces. Micromachines 2014, 5, 1344–1372.

- Lee, J.M.; Watkins, K.G. In-process monitoring techniques for laser cleaning. Opt. Lasers Eng. 2000, 34, 429–442.

- Verdier, M.; Costil, S.; Coddet, C.; Oltra, R.; Perret, O. On the topographic and energetic surface modifications induced by laser treatment of metallic substrates before plasma spraying. Appl. Surf. Sci. 2003, 205, 3–21.

- Křenek, T.; Pola, J.; Docheva, D.; Stich, T.; Fajgar, R.; Kovářík, T.; Pola, M.; Martan, J.; Moskal, D.; Jandová, V.; et al. Porous micro/nano structured oxidic titanium surface decorated with silicon monoxide. Surf. Interfaces 2021, 26, 101304.

- Afanasiev, Y.V.; Chichkov, B.N.; Demchenko, N.N.; Isakov, V.A.; Zavestovskaya, I.N. Ablation of metals by ultrashort laser pulses: Theoretical modeling and computer simulations. J. Russ. Laser Res. 1999, 20, 89–115.

- Dausinger, F.; Hugel, H.; Konov, V.I. Micromachining with ultrashort laser pulses: From basic understanding to technical applications. In Proceedings of the ALT’02 International Conference on Advanced Laser Technologies, Adelboden, Switzerland, 15–20 September 2002; Weber, H.P., Konov, V.I., Graf, T., Eds.; Volume 5147, pp. 106–115.

- Sedao, X.; Lenci, M.; Rudenko, A.; Faure, N.; Pascale-Hamri, A.; Colombier, J.P.; Mauclair, C. Influence of pulse repetition rate on morphology and material removal rate of ultrafast laser ablated metallic surfaces. Opt. Lasers Eng. 2019, 116, 68–74.

- Weber, R.; Graf, T.; Berger, P.; Onuseit, V.; Wiedenmann, M.; Freitag, C.; Feuer, A. Heat accumulation during pulsed laser materials processing. Opt. Express 2014, 22, 11312.

- Rykalin, N. Rascety Teplovych Processov Pri Svarke; Jerohin, A., Ed.; MASGIZ: Moscow, Russia, 1951.

- Carslaw, H.S.; Jaeger, J. Conduction of Heat in Solids, 2nd ed.; Oxford at the Clarendon Press: London, UK, 1959.

- Moskal, D. Thermo-Physical Processes and Ultrashost Pulse Laser Scanning Methods in Surface Texturing. Ph.D. Thesis, University of West Bohemia, Plzeň, Czech Republic, 2019.

- Zimmermann, M.; Jaeggi, B.; Neuenschwander, B. Improvements in ultra-high precision surface structuring using synchronized galvo or polygon scanner with a laser system in MOPA arrangement. In Proceedings of the Laser Applications in Microelectronic and Optoelectronic Manufacturing (Lamom) XX, San Francisco, CA, USA, 7–12 February 2015; Roth, S., Nakata, Y., Neuenschwander, B., Xu, X., Eds.; Volume 9350, p. 935016.

- Römer, G.R.B.E.; Bechtold, P. Electro-optic and Acousto-optic Laser Beam Scanners. Phys. Procedia 2014, 56, 29–39.

- De Loor, R.; Penning, L.; Slagle, R. A need for speed in laser processing and micromachining. Laser Tech. J. 2014, 3, 32–34.

- Žemaitis, A.; Gaidys, M.; Gečys, P.; Račiukaitis, G.; Gedvilas, M. Rapid high-quality 3D micro-machining by optimised efficient ultrashort laser ablation. Opt. Lasers Eng. 2019, 114, 83–89.

- De Loor, R. Polygon Scanner System for Ultra Short Pulsed Laser Micro-Machining Applications. Phys. Procedia 2013, 41, 544–551.

- Streek, A.; Lee, M. Ultrafast Material Processing with High-Brightness Fiber Lasers. Laser Tech. J. 2017, 14, 22–25.

- Lasagni, A.; Benke, D.; Kunze, T.; Bieda, M.; Eckhardt, S.; Roch, T.; Langheinrich, D.; Berger, J. Bringing the direct laser interference patterning method to industry: A one tool-complete solution for surface functionalization. J. Laser Micro/Nanoeng. 2015, 10, 340–344.

- Aguilar-Morales, A.I.; Alamri, S.; Lasagni, A.F. Micro-fabrication of high aspect ratio periodic structures on stainless steel by picosecond direct laser interference patterning. J. Mater. Process. Technol. 2018, 252, 313–321.

- Lang, V.; Roch, T.; Lasagni, A.F. High-Speed Surface Structuring of Polycarbonate Using Direct Laser Interference Patterning: Toward 1 m2 min−1 Fabrication Speed Barrier. Adv. Eng. Mater. 2016, 18, 1342–1348.

- Lang, V.; Rank, A.; Lasagni, A.F. Large Area One-Step Fabrication of Three-Level Multiple-Scaled Micro and Nanostructured Nickel Sleeves for Roll-to-Roll Hot Embossing. Adv. Eng. Mater. 2017, 19, 1700126.

- Burrowg, G.M.; Gaylord, T.K. Multi-beam interference advances and applications: Nano-electronics, photonic crystals, metamaterials, subwavelength structures, optical trapping, and biomedical structures. Micromachines 2011, 2, 221–257.

- Razi, S.; Madanipour, K.; Mollabashi, M. Laser surface texturing of 316L stainless steel in air and water: A method for increasing hydrophilicity via direct creation of microstructures. Opt. Laser Technol. 2016, 80, 237–246.

- Mutlak, F.A.H.; Ahmed, A.F.; Nayef, U.M.; Al-zaidi, Q.; Abdulridha, S.K. Improvement of absorption light of laser texturing on silicon surface for optoelectronic application. Optik 2021, 237, 166755.

- Ancona, A.; Joshi, G.; Volpe, A.; Scaraggi, M.; Lugarà, P.; Carbone, G. Non-Uniform Laser Surface Texturing of an Un-Tapered Square Pad for Tribological Applications. Lubricants 2017, 5, 41.

- Furlan, V.; Demir, A.G.; Pariani, G.; Bianco, A.; Previtali, B. A new approach to Direct Laser Interference Patterning with scanner optics for high productivity. In Proceedings of the European Society for Precision Engineering and Nanotechnology, Conference Proceedings-18th International Conference and Exhibition, EUSPEN 2018, Venice, Italy, 4–8 June 2018; pp. 49–50.

- Cardoso, J.T.; Aguilar-Morales, A.I.; Alamri, S.; Huerta-Murillo, D.; Cordovilla, F.; Lasagni, A.F.; Ocaña, J.L. Superhydrophobicity on hierarchical periodic surface structures fabricated via direct laser writing and direct laser interference patterning on an aluminium alloy. Opt. Lasers Eng. 2018, 111, 193–200.

- Hauschwitz, P.; Martan, J.; Bičišťová, R.; Beltrami, C.; Moskal, D.; Brodsky, A.; Kaplan, N.; Mužík, J.; Štepánková, D.; Brajer, J.; et al. LIPSS-based functional surfaces produced by multi-beam nanostructuring with 2601 beams and real-time thermal processes measurement. Sci. Rep. 2021, 11, 22944.

- Sandra, H.; Kirner, S.V.; Rosenfeld, A. Laser-Induced Periodic Surface Structures—A Scientific Evergreen. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 9000615.

- Gnilitskyi, I.; Derrien, T.J.-Y.; Levy, Y.; Bulgakova, N.M.; Mocek, T.; Orazi, L. High-speed manufacturing of highly regular femtosecond laser-induced periodic surface structures: Physical origin of regularity. Sci. Rep. 2017, 7, 8485.

- Martínez-Calderon, M.; Rodríguez, A.; Dias-Ponte, A.; Morant-Miñana, M.C.; Gómez-Aranzadi, M.; Olaizola, S.M. Femtosecond laser fabrication of highly hydrophobic stainless steel surface with hierarchical structures fabricated by combining ordered microstructures and LIPSS. Appl. Surf. Sci. 2016, 374, 81–89.

- Mottay, E.; Delaigue, M.; Schöps, B.; Dalla-Barba, G.; Audouard, E.; Hönninger, C.; Bernard, O.; Mishchik, K. Efficient micro processing with high power femtosecond lasers by beam engineering and modelling. Procedia CIRP 2018, 74, 310–314.

- Myles, D.T.E.; Ziyenge, M.; Shephard, J.D.; Milne, D.C. Scanned mask imaging solid state laser tool for cost effective flip chip—Chip scale package manufacture. J. Laser Micro/Nanoeng. 2015, 10, 106–109.

- Chang, Y.H.; Lin, Y.C.; Liu, Y.S.; Liu, C.Y. Light-extraction enhancement by cavity array-textured n-polar GaN surfaces ablated using a KrF laser. IEEE Photonics Technol. Lett. 2012, 24, 2013–2015.

- Horn, A.; Kalmbach, C.C.; Moreno, J.G.; Schütz, V.; Stute, U.; Overmeyer, L. Laser-Surface-Treatment for Photovoltaic Applications. Phys. Procedia 2012, 39, 709–716.

- Zhu, G.; Whitehead, D.; Perrie, W.; Allegre, O.J.; Olle, V.; Li, Q.; Tang, Y.; Dawson, K.; Jin, Y.; Edwardson, S.P.; et al. Thermal and optical performance characteristics of a spatial light modulator with high average power picosecond laser exposure applied to materials processing applications. Procedia CIRP 2018, 74, 594–597.

- Abbott, C.; Allott, R.M.; Bann, B.; Boehlen, K.L.; Gower, M.C.; Rumsby, P.T.; Stassen Boehlen, I.; Sykes, N. New techniques for laser micromachining MEMS devices. In Proceedings of the High-Power Laser Ablation IV, Taos, NM, USA, 21–26 April 2002; Phipps, C.R., Ed.; Volume 4760, p. 281.

- Lopez, J.; Mishchik, K.; Mincuzzi, G.; Audouard, E.; Mottay, E. Efficient Metal Processing Using High Average Power Ultrafast Laser. J. Laser Micro/Nanoeng. 2017, 12, 1–8.

- Marshall, G.F. Handbook of Optical and Laser Scanning; Marshall, G.F., Stutz, G.E., Eds.; CRC Press: Boca Raton, FL, USA, 2018; ISBN 9781315218243.

- Jaeggi, B.; Neuenschwander, B.; Zimmermann, M.; Loor, R.D.; Penning, L. High throughput ps-laser micro machining with a synchronized polygon line scanner. In Proceedings of the 8th International Conference on Photonic Technologies LANE 2014, Fürth, Germany, 8–11 September 2014; pp. 1–8.

- Dunn, A.; Wlodarczyk, K.L.; Carstensen, J.V.; Hansen, E.B.; Gabzdyl, J.; Harrison, P.M.; Shephard, J.D.; Hand, D.P. Laser surface texturing for high friction contacts. Appl. Surf. Sci. 2015, 357, 2313–2319.

- Schille, J. Highspeed Laser Micro Processing using Ultrashort Laser Pulses. J. Laser Micro/Nanoeng. 2014, 9, 161–168.

- Dmitriev, P.A.; Makarov, S.V.; Milichko, V.A.; Mukhin, I.S.; Samusev, A.K.; Krasnok, A.E.; Belov, P.A. Direct Femtosecond Laser Writing of Optical Nanoresonators. J. Phys. Conf. Ser. 2016, 690, 012021.

- Bruening, S.; Hennig, G.; Eifel, S.; Gillner, A. Ultrafast Scan Techniques for 3D-μm Structuring of Metal Surfaces with high repetitive ps-laser pulses. Phys. Procedia 2011, 12, 105–115.

- Lin, Y.; Han, J.; Cai, M.; Liu, W.; Luo, X.; Zhang, H.; Zhong, M. Durable and robust transparent superhydrophobic glass surfaces fabricated by a femtosecond laser with exceptional water repellency and thermostability. J. Mater. Chem. A 2018, 6, 9049–9056.

- Abbott, M.; Cotter, J. Optical and electrical properties of laser texturing for high-efficiency solar cells. J. Optoelectron. Adv. Mater. 2006, 14, 225–235.

- Sampedro, J.; Ferre, R.; Fernández, E.; Pérez, I.; Cárcel, B.; Molina, T.; Ramos, J.A. Surface Functionalization of AISI 316 Steel by Laser Texturing of Shaped Microcavities with Picosecond Pulses. Phys. Procedia 2012, 39, 636–641.

- Liu, Z.; Xu, W.; Hou, Z.; Wu, Z. A Rapid Prototyping Technique for Microfluidics with High Robustness and Flexibility. Micromachines 2016, 7, 201.

- Wlodarczyk, K.L.; Lopes, A.A.; Blair, P.; Maroto-Valer, M.M.; Hand, D.P.; Wlodarczyk, K.L.; Lopes, A.A.; Blair, P.; Maroto-Valer, M.M.; Hand, D.P. Interlaced Laser Beam Scanning: A Method Enabling an Increase in the Throughput of Ultrafast Laser Machining of Borosilicate Glass. J. Manuf. Mater. Process. 2019, 3, 14.

- Mincuzzi, G.; Gemini, L.; Faucon, M.; Kling, R. Extending ultra-short pulse laser texturing over large area. Appl. Surf. Sci. 2016, 386, 65–71.

- Schille, J.; Schneider, L.; Ullmann, F.; Mauersberger, S.; Löschner, U. Bio-inspirierte Funktionalisierung von Technischen Oberflächen Durch Hochrate- Lasermikrostrukturierung. In ThGOT Thementage Grenz- und Oberflächentechnik und 5. Kolloquium Dünne Schichten in der Optik; INNOVENT e.V.: Jena, Germany, 2017; Available online: https://www.innovent-jena.de/en/about-us/contact (accessed on 27 April 2023).

- Riveiro, A.; Maçon, A.L.B.; del Val, J.; Comesaña, R.; Pou, J. Laser Surface Texturing of Polymers for Biomedical Applications. Front. Phys. 2018, 6, 16.

- Martan, J.; Moskal, D.; Kučera, M. Laser surface texturing with shifted method—Functional surfaces at high speed. J. Laser Appl. 2019, 31, 022507.

- Moskal, D.; Martan, J.; Kučera, M. Shifted Laser Surface Texturing (sLST) in Burst Regime. J. Laser Micro/Nanoeng. 2019, 14, 179–185.

- Schille, J.; Schneider, L.; Mauersberger, S.; Szokup, S.; Höhn, S.; Pötschke, J.; Reiß, F.; Leidich, E.; Löschner, U. High-Rate laser surface texturing for advanced tribological functionality. Lubricants 2020, 8, 33.

- Roessler, F.; Streek, A. Accelerating laser processes with a smart two-dimensional polygon mirror scanner for ultra-fast beam deflection. Adv. Opt. Technol. 2021, 10, 297–304.