An opposite way of overcoming the shielding effects can be achieved via the application of several laser pulses within a short time interval, shorter than that of a plasma plume, which will be expanded above the surface [

15,

66]. The plasma plume expanding cannot be avoided by the application laser pulse with a short time interval, down to 1–2 ps, but the energy conversion in such fast processes is able to change the ablation mechanism and suppress the shielding effects [

15,

66]. Such a shielding-suppressing regime is very dependent on processed materials, laser pulse intervals and even pairing of the laser pulses [

28]. The frequency of laser pulses for such a mechanism of plasma plume suppression should be in the hundreds of GHz or in THz and can be realized in burst regimes [

15,

67,

68,

69,

70]. Such a short interval between laser pulses can be achieved with special techniques of pulse dividing, such as crystals array or optical branches [

28,

71,

72]. A more practical approach is usually to use long enough time delays when the plasma is gone upon the arrival of the next pulse.

After ablation, a thin remelted layer with a number of point defects and dislocations, produced by ultrafast cooling and shock wave, remains in the laser spot area [

91,

92]. The output laser-irradiated surface will be contaminated by precipitation of the ablated products and associated oxidation of the upper surface layers [

93,

94,

95,

96]. In most cases, the surface ablation process has a semi-thermal character (

𝑘𝐵𝑇𝑖≥𝜀𝑏). For example, at Gaussian distribution of energy in the laser spot, the laser pulse residual heat stays in the subsurface layers and in the near-ablated zone. The residual heat in subsurface layers can be brought by secondary effects: heat conductivity from ablated layers, ballistic and diffusion effects, convective and radiating energy exchange between the ambient and solid target, and shock wave spreading [

37,

49,

93,

97,

98]. These residual effects have a great influence on the quality and efficiency of LST in a high-repetition multi-pulse regime [

31,

76,

99]. Of course, even a single laser pulse can produce many thermal effects: material boiling, oxidation and splash formation. These thermal effects have short-term character, and in the biggest cases, high-temperature fields dissipate within 2–5 µs [

41,

76]. However, in the case of multi-pulse laser surface processing, the residual heat is rising from pulse to pulse in the laser-affected zone. Such heat accumulation is able to prolong and intensify the thermal processes to an undesired level, although this occurs in the case whereby one single pulse is unable to initiate significant thermal processes.

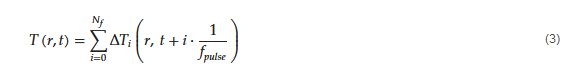

where

𝑇(𝑟,𝑡) is the temperature in the point

𝑟 at the time moment

𝑡,

𝑁𝑓 is the full number of the laser pulses in the pulse sequence,

∆𝑇𝑖 is the residual temperature after

𝑖-th laser pulse and

𝑓𝑝𝑢𝑙𝑠𝑒 is the laser pulse generation frequency. In this equation, the residual temperature

∆𝑇𝑖 after absorption of a discrete laser pulse can be approximately defined from a 3D model with an instance heat point source [

41,

100,

101]. A more detailed study of the heat accumulation effects under moving Gaussian laser spots was conducted by Bauer et al. [

40]. For evaluation of heat accumulation under a laser-scanned surface in a fixed subsurface point, a semi-planar thermal model can be applied [

76,

102]:

where

𝑥 is the coordinate of a fixed surface point,

𝑟𝑥 is the distance from the centre of the laser spot to the fixed surface point

𝑥,

𝛼 is the thermal diffusivity,

𝜌 is the material density and

𝑐

is the specific heat. It has been found that the maximal heat accumulation in a thin subsurface layer is achieved within a specific time interval when the laser beam central point has already passed the fixed subsurface point [

76,

102]. In the exemplary work of F. Bauer et al. [

40], the critical temperature for heat accumulation was defined through experiments involving offset temperature shifting in the laser-scanned surface. The defined offset temperature shift was compared with the corresponding temperature shift in thermal simulations. It was shown that the critical temperature for heat accumulation in steel surface processing has a value near 607 °C. Oxidation and surface degradation were detected at higher temperatures of the scanned surface preheating, even when other laser scanning parameters were not changed [

40,

76].

The correct choice of scanning strategy and optimization of laser beam parameters brings the possibility to overcome the aforementioned physical limitations, especially heat accumulation. The next development of the IR in-process fast measurements will be in on-fly control of the laser beam parameters during laser surface scanning. The on-fly IR control of the laser surface processing in combination with high-speed scanning technique is a way to achieve the high standards of Industry 4.0.

3. Scanning Techniques of LST

The need for increasing the throughput of LST technologies stimulates the development of new strategies for high-speed laser surface processing. There are several well-known scanning technologies for high-speed laser beam deflection: galvo scanners, polygon scanners, piezo scanners, static and resonant scanners, micro-lens scanners, electro-optic deflectors (EOD) and acousto-optic deflectors (AOD) [

21,

103,

126]. The inertial scanning systems have a maximal deflection angle and a number of resolvable spots on the scanned surface [

126]. There are two traditional techniques for high-speed laser surface machining with a large processing area: galvanometer beam scanning and polygon optical scanning systems [

127,

128]. The maximal scanning speed of the available galvanometer scanners lies in the range of 10–40 m/s, whereas the polygon scanner is able to achieve a scanning speed of more than 1000 m/s [

127,

129,

130]. The higher speed of the polygon scanners is of great benefit in the fast provision of LST in large areas. However, polygon scanners do not provide the smooth wall profiles of vector scans for cutting a circumference or trepanning large holes greater than 50–150 µm. The laser beam deflection in polygon scanners should be corrected by an additional galvanometer scanner. For LST, when the processed area is smaller than 15% of the working field, the polygon scanners are not cost-efficient, and alternative techniques will be more suitable [

127]. The correct choice of scanning strategy helps to improve the laser-processed surface quality and precision of the laser pulse delivery.

The output processing rate of LST depends on a favourable choice of the combination of the scanning strategy with different scanning techniques (

Table 1, rows 1 and 2). The maximal processing rate of 9000 cm

2/min for DLIP was found by a team from Fraunhofer Institute IWS [

131,

132,

133,

134]. The period and distribution of laser surface textured objects with DLIP are directly dependent on the wavelength of the laser beam [

135]. This limitation makes it difficult to apply the DLIP for texturing surfaces in cases of irregular structure or complex nonsymmetrical textures, for example, for super hydrophilic surfaces, high optical absorbance and hydrodynamic effects. The process of the formation of such a structure is based on self-organized effects, cone-like structure formation or programmable direct laser machining with spot size resolution [

136,

137,

138]. For the laser-controlled formation of fine complex submicron structures, a combination of the DLIP technique with dynamic systems has been provided. The processing rate of such a technique is about 0.7–10 cm

2/min [

132,

139]. The benefit of such a combination of DLIP with regular micro-texturing techniques gives the possibility to create unique hierarchical structures [

132,

140].

Submicron surface structures might be created by laser scanning with the self-organized formation of LIPSS [

116,

141]. In this case, the laser scanning parameters, such as laser spot overlapping and scanning speed, have a key role for highly regular LIPSS (

Table 1, rows 3 and 16). The achieved processing rate for LIPSS formation directly depends on the applied scanning speed. For example, I. Gnilitskyi et al. [

142] have reported a processing rate of LIPSS forming on stainless steel equal to 6.3 cm

2/min with a scanning speed of 3 m/s. The last study predicts several times higher processing rates with polygon scanners [

77]. LIPSS forming is competitive with industrial standards of nano-manufacturing (~1 cm

2 in 10 s) [

143]. Like the DILP technique, LIPSS might be applied for the formation of hierarchical surface structures in combination with micro-texturing. The benefit of such a solution is that the period of the upper LIPSS can be smaller than half of the laser wavelength [

143].

Another highly productive LST strategy is via forming an array of micro-objects by dividing the laser beam with diffraction or shadow masks [

144,

145,

146,

147] (

Table 1, rows 12 and 17). This scanning strategy could be used in cases when the pulse energy is high enough to be divided into multi-beams [

90]. The distance between laser spots is given by mask parameters or diffraction light distribution. In the case of the application of a solid-state static mask, the spot distance is constant, and part of the laser beam energy will be lost. The application of spatial light modulators (SLMs) gives us the possibility to change the laser spot distribution of the scanning process, but the average power will be limited to under 300 W [

148]. However, a processing rate of up to 1800–5400 cm

2/min in a multibeam scanning solution can be achieved [

148,

149].

LST by straight hatch lines is the most suitable strategy for the polygon scanner technology (

Table 1, rows 13–16, 20, 22). In this case, the laser beam scanning speed achieves high values, up to 800–2000 m/s [

42]. The polygon scanner has a throughput several times higher in comparison to galvanometer scanners [

150]. However, providing LST with a polygon scanner needs to involve a correlation between mirror position and laser pulse generation for the precise formation of micro-objects. This imposes a restriction on the scanning speed for LST. The maximal processing rates up to 7680 cm

2/min were achieved for a linear texture, and this was performed at 320 m/s [

77]. However, for polygon scanners, the problem of processing arrays of micro-objects with specific geometry remains unresolved [

151]. It is difficult to control the laser drilling of micro-objects with high-speed scanning, because there are substantial data in relation to large arrays with small objects or micro-objects, up to 800 MB per second [

130]. Additionally, there is not enough time for precise control of laser spot distribution inside every micro-object in the array. Moreover, ultra-high-speed laser beam processing with polygon scanning involves artefacts such as jitter, banding, bow and other problems characteristic of these systems. These artefacts involve two components: periodical and random. There are several hardware techniques for reducing polygon scanner artefacts, but known classic methods of laser beam processing of the array of objects in ultra-fast scanning systems do not have a fully finished solution to the mentioned problems, and scanning techniques must still be improved [

151,

152].

The galvanometer scanner can create curved lines purposefully with the fast swinging of two deflection mirrors. This technique was applied in direct laser formation of an array of micro-objects with different structures (

Table 1, rows 6–11). The galvanometer scanner is able to achieve a processing rate of up to 428 cm

2/min for forming an array of micro-objects with a one-beam simple scanning technique at one pulse per object [

153]. The high precision formation of surface structures with hatch filling of more complex micro-objects reduces the processing rate to 25 cm

2/min [

38]. Noticeably higher processing rates with galvanometer scanners might be achieved by splitting the laser beam into several spots. In this case, a processing rate of up to 5400 cm

2/min is reached [

148]. A multibeam solution has potential for industrial applications, especially where there is a need to create a wide array of periodical surface microstructures [

116,

148].

Table 1. The surface processing rate of different scanning strategies.

|

Scanning Strategy

|

Scanning Technique

|

Structure Period (µm)

|

Processing Rate (cm2/min)

|

Scanning Speed

(m/s)

|

Reference

|

|

1

|

DLIP-head

(ps-laser)

|

Sample movement

|

0.343–1.064

|

100–9000

|

1

|

[131,132,133,134]

|

|

2

|

DLIP-head

(ps-laser)

|

Galvanometer scanner

|

0.532–1.064

|

0.7–10

|

16·10−3–6.8

|

[132,139]

|

|

3

|

LIPSS

(fs-laser)

|

Galvanometer scanner

|

0.9

|

6.3

|

3

|

[142]

|

|

4

|

Path cutting (fs-laser)

|

Sample movement

|

0.8

|

0.01

|

0.3

|

[154]

|

|

5

|

Unidirectional scan

(ps-laser)

|

Sample rotation and acousto-optic beam deflection

|

250

|

~46.8

|

1.5

(rotation)

40

(AOD scanning)

|

[155]

|

|

6

|

Hatch filling

(ns-laser)

|

Galvanometer scanner

|

12.5–200

|

1.8–428

|

0.25–4

|

[153]

|

|

7

|

Point-by-point ablation

(fs-laser)

|

Galvanometer scanner

|

30–40

|

0.4–0.75

|

~0.05–0.2

|

[156,157]

|

|

8

|

Hatch filling

(ps-laser)

|

Galvanometer scanner

|

2000

|

0.15–0.20

|

0.5

|

[158]

|

|

9

|

Path writing

(0.1 μs laser)

|

Galvanometer scanner

|

50

|

1.2

|

0.4–2

|

[159]

|

|

10

|

Hatch filling

(fs-laser)

|

Galvanometer scanner

|

4

|

8–25

|

4.5–17.1

|

[38]

|

|

11

|

Interlaced

(ps-laser)

|

Galvanometer scanner

|

1.2–6

|

0.017–2

|

0.024–0.6

|

[160]

|

|

12

|

Hatch filling

(ps-laser)

|

Multibeam galvanometer scanner

|

500

|

5400

|

20

|

[148]

|

|

13

|

Hatch filling

|

Polygon scanner

|

14.5–40

|

148–7680

|

60–800

|

[77,127,129]

|

|

14

|

Hatch filling

(ps-laser)

|

Polygon scanner

|

10

|

840

|

10–200

|

[42]

|

|

15

|

Hatch filling

(fs-laser)

|

Polygon scanner

|

1–12

|

0.03, approx. 60

|

25

|

[161]

|

|

16

|

Hatch filling

(fs, ps-laser)

|

Polygon scanner

|

40

|

43

|

15

|

[162]

|

|

17

|

Laser pulse pattern

|

Sample movement with mask

|

20

|

1800

|

–

|

[149,163]

|

|

18

|

Shifted path

(ps-laser)

|

Galvanometer scanner

|

200

|

17.4

|

8

|

[102,164]

|

|

19

|

Shifted burst

(ps-laser)

|

Galvanometer scanner

|

60–570

|

160

|

8

|

[102,113]

|

|

20

|

Unidirectional hatch

|

Polygon scanner and self-organizing

|

≲0.5

|

1510

|

560

|

[165]

|

|

21

|

Hatch filling with multibeam

|

Galvanometer scanner with DOE

|

~0.4

|

1910

|

9

|

[116]

|

|

22

|

Hatch filling with ns-laser

|

Polygon scanner

|

50

|

1386

|

200

|

[166]

|