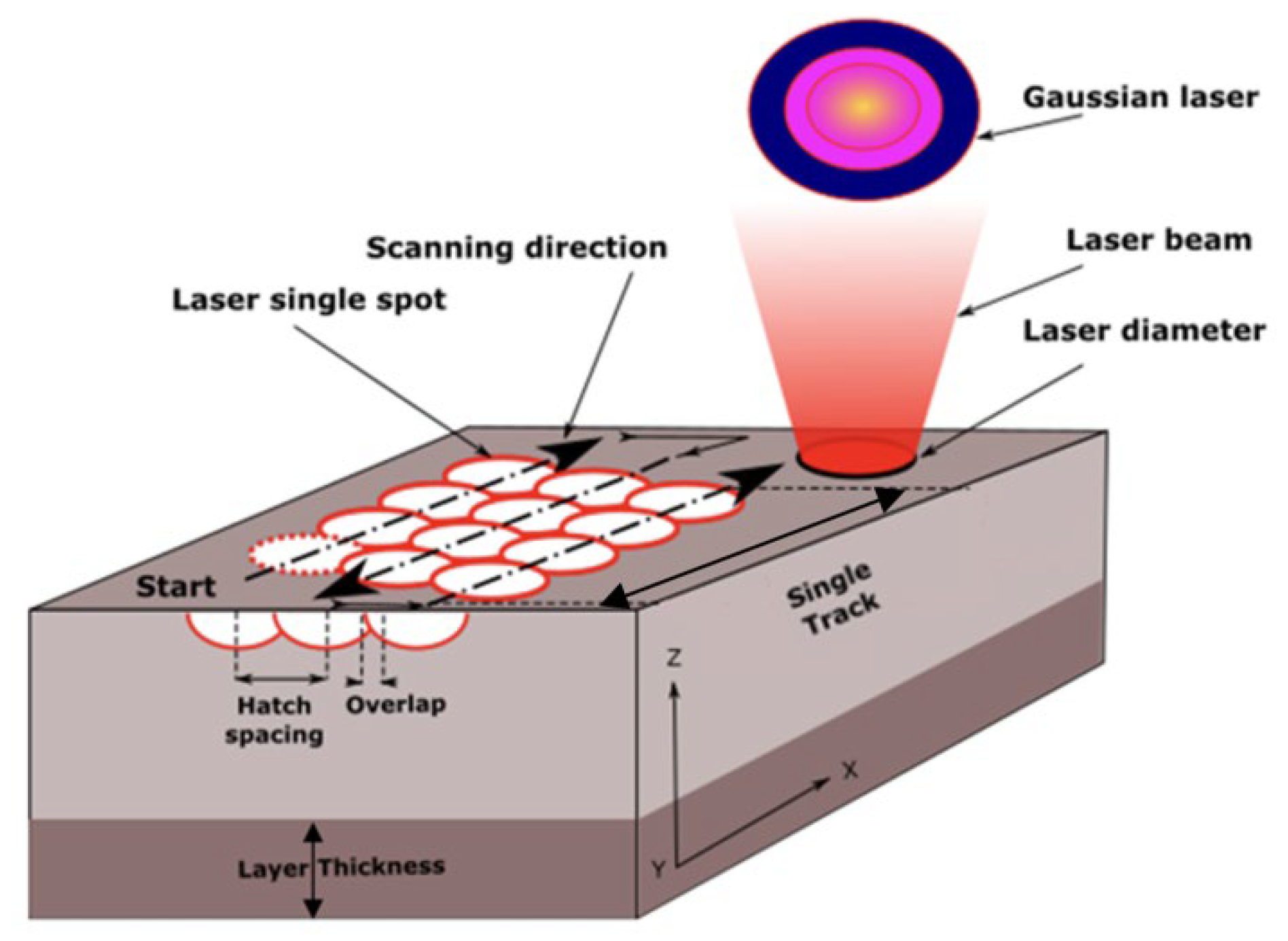

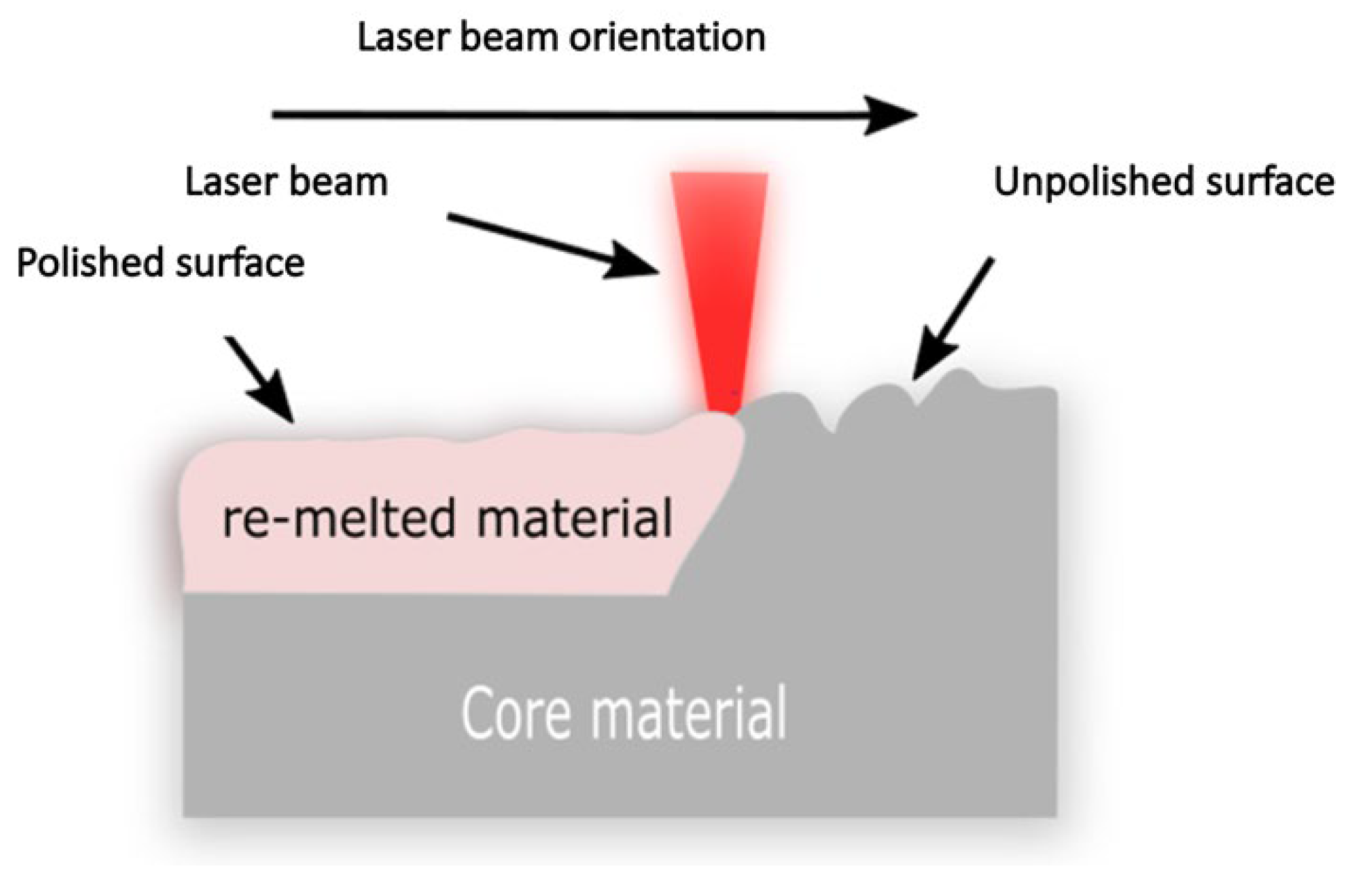

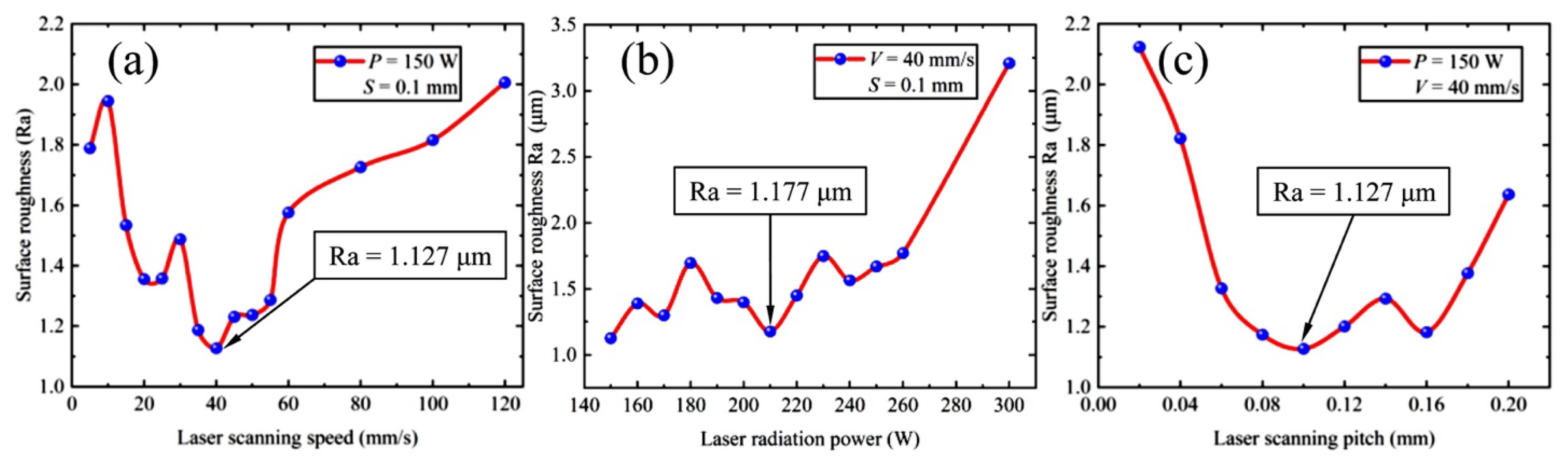

The poor surface roughness associated with additively manufactured parts can influence the surface integrity and geometric tolerances of produced components. In response to this issue, laser polishing (LP) has emerged as a potential technique for improving the surface finish and producing parts with enhanced properties. Many studies have been conducted to investigate the effect of LP on parts produced using additive manufacturing. The results showed that applying such a unique treatment can significantly enhance the overall performance of the part. In LP processes, the surface of the part is re-melted by the laser, resulting in smaller peaks and shallower valleys, which enable the development of smoother surfaces with the help of gravity and surface tension. Precise selection of laser parameters is essential to achieve optimal enhancement in the surface finish, microstructure, and mechanical properties of the treated parts.

- additive manufacturing

- laser polishing

- laser re-melting

1. Introduction

2. Laser Polishing Mechanisms

3. LP of Titanium Alloys

3.1. Mechanical Properties

3.2. Microstructure and Surface Quality of Titanium Alloy

4. Laser Polishing of Inconel Alloys

4.1. Microstructure and Surface Quality of Inconel Alloys

4.2. Mechanical Properties

5. Cobalt Chromium—CoCr

5.1. Microstructure and Surface Quality of Cobalt Chromium

5.2. Mechanical Properties

6. Laser Polishing of Steel

6.1. Microstructure and Surface Quality of Steel

6.2. Mechanical Properties

7. Machine Learning in Laser Polishing

This entry is adapted from the peer-reviewed paper 10.3390/jmmp7030115

References

- Gora, W.S.; Tian, Y.; Cabo, A.P.; Ardron, M.; Maier, R.R.J.; Prangnell, P.; Weston, N.J.; Hand, D.P. Enhancing surface finish of additively manufactured titanium and cobalt chrome elements using laser based finishing. Phys. Procedia 2016, 83, 258–263.

- Yang, T.; Liu, C.; Chen, T.; Shao, M.; Jiang, C.; Lu, C.; Song, S. Parameter Optimization of RB-SiC Polishing by Femtosecond Laser. Materials 2023, 16, 1582.

- Turk, T.; Leu, M.C. Experimental study for improving the productivity of laser foil printing. Int. J. Adv. Manuf. Technol. 2023, 125, 5149–5162.

- Lohser, J. Evaluation of Electrochemical and Laser Polishing of Selectively Laser Melted 316l Stainless Steel; California Polytechnic State University: San Luis Obispo, CA, USA, 2018.

- Yang, G.; Wang, B.; Tawfiq, K.; Wei, H.; Zhou, S.; Chen, G. Electropolishing of surfaces: Theory and applications. Surf. Eng. 2017, 33, 149–166.

- Ali, M.; Almotari, A.; Algamal, A.; Alafaghani, A.; Abedi, H.; Qattawi, A. Effect of in-situ laser polishing on microstructure, surface characteristics, and phase transformation of lpbf martensitic stainless steel. In Proceedings of the ASME 2023 18th International Manufacturing Science and Engineering Conference, New Brunswick, NJ, USA, 12–16 June 2023; pp. 1–10.

- Dadbakhsh, S.; Hao, L.; Kong, C.Y. Surface finish improvement of LMD samples using laser polishing. Virtual Phys. Prototype 2010, 5, 215–221.

- Basha, S.M.; Bhuyan, M.; Basha, M.M.; Venkaiah, N.; Sankar, M.R. Laser polishing of 3D printed metallic components: A review on surface integrity. Mater. Today Proc. 2019, 26, 2047–2054.

- Ma, C.P.; Guan, Y.C.; Zhou, W. Laser polishing of additive manufactured Ti alloys. Opt. Lasers Eng. 2017, 93, 171–177.

- Zhang, J.; Lee, Y.J.; Wang, H. A Brief Review on the Enhancement of Surface Finish for Metal Additive Manufacturing. J. Miner. Met. Mater. Eng. 2021, 7, 1–14.

- Algamal, A.; Albat, M.A.; Ramineni, L.; Ali, M.; Almotari, A.; Alafaghani, A.; Sun, J.-Q.; Qattawi, A. Cradle-to-gate life cycle analysis of origami-based sheet metal for automobile parts. In Proceedings of the ASME 2022 International Mechanical Engineering Congress and Exposition, Columbus, OH, USA, 30 October–3 November 2022; pp. 1–10.

- Pong-Ryol, J.; Tae-Sok, J.; Nam-Chol, K.; Xing, F.; Kum-Hyok, J. Laser micro-polishing for metallic surface using UV nano-second pulse laser and CW laser. Int. J. Adv. Manuf. Technol. 2016, 85, 2367–2375.

- Fraunhofer Institute for Laser Technology (ILT). Laser Micro Polishing of Aluminum Materials. 2011. Available online: https://www.ilt.fraunhofer.de/content/dam/ilt/en/documents/annual_reports/ar11/JB11_P96.pdf69572 (accessed on 3 April 2023).

- Yasa, E.; Kruth, J.P. Microstructural investigation of selective laser melting 316L stainless steel parts exposed to laser re-melting. Procedia Eng. 2011, 19, 389–395.

- Yung, K.C.; Xiao, T.Y.; Choy, H.S.; Wang, W.J.; Cai, Z.X. Laser polishing of additive manufactured CoCr alloy components with complex surface geometry. J. Mater. Process. Technol. 2018, 262, 53–64.

- Zhihao, F.; Libin, L.; Longfei, C.; Yingchun, G. Laser Polishing of Additive Manufactured Superalloy. Procedia CIRP 2018, 71, 150–154.

- Yung, K.C.; Zhang, S.S.; Duan, L.; Choy, H.S.; Cai, Z.X. Laser polishing of additive manufactured tool steel components using pulsed or continuous-wave lasers. Int. J. Adv. Manuf. Technol. 2019, 105, 425–440.

- Ukar, E.; Lamikiz, A.; López de Lacalle, L.N.; del Pozo, D.; Arana, J.L. Laser polishing of tool steel with CO2 laser and high-power diode laser. Int. J. Mach. Tools Manuf. 2010, 50, 115–125.

- Ramos-Grez, J.A.; Bourell, D.L. Reducing surface roughness of metallic freeform-fabricated parts using non-tactile finishing methods. Virtual Model. Rapid Manuf. Adv. Res. Virtual Rapid Prototyp. 2003, 21, 297–316.

- Morgan, R.H.; Papworth, A.J.; Sutcliffe, C.; Fox, P.; O’Neill, W. High density net shape components by direct laser re-melting of single-phase powders. J. Mater. Sci. 2002, 37, 3093–3100.

- Krishnan, A.; Fang, F. Review on mechanism and process of surface polishing using lasers. Front. Mech. Eng. 2019, 14, 299–319.

- Li, J.; Zuo, D. Laser polishing of additive manufactured Ti6Al4V alloy: A review. Opt. Eng. 2021, 60, 020901.

- Qin, J.; Chen, Q.; Yang, C.; Huang, Y. Research process on property and application of metal porous materials. J. Alloys Compd. 2016, 654, 39–44.

- Dutta, B.; Froes, F.H.S. The additive manufacturing (AM) of titanium alloys. Met. Powder Rep. 2017, 72, 96–106.

- Ventola, C.L. Medical Applications for 3D Printing: Current and Projected Uses. Pharm. Ther. 2014, 39, 704–711.

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196.

- Narasimharaju, S.R.; Zeng, W.; See, T.L.; Zhu, Z.; Scott, P.; Jiang, X.; Lou, S. A comprehensive review on laser powder bed fusion of steels: Processing, microstructure, defects and control methods, mechanical properties, current challenges and future trends. J. Manuf. Process. 2022, 75, 375–414.

- Li, Y.H.; Wang, B.; Ma, C.P.; Fang, Z.H.; Chen, L.F.; Guan, Y.C.; Yang, S.F. Material characterization, thermal analysis, and mechanical performance of a laser-polished Ti Alloy prepared by selective laser melting. Metals 2019, 9, 112.

- Tian, Y.; Gora, W.S.; Cabo, A.P.; Parimi, L.L.; Hand, D.P.; Tammas-Williams, S.; Prangnell, P.B. Material interactions in laser polishing powder bed additive manufactured Ti6Al4V components. Addit. Manuf. 2018, 20, 11–22.

- Li, K.; Zhao, Z.; Zhou, H.; Zhou, H.; Jin, J. Numerical analyses of molten pool evolution in laser polishing Ti6Al4V. J. Manuf. Process. 2020, 58, 574–584.

- Pfefferkorn, F.E.; Duffie, N.A.; Li, X.; Vadali, M.; Ma, C. Improving surface finish in pulsed laser micro polishing using thermocapillary flow. CIRP Ann. Manuf. Technol. 2013, 62, 203–206.

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminum alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477.

- Jaritngam, P.; Tangwarodomnukun, V.; Qi, H.; Dumkum, C. Surface and subsurface characteristics of laser polished Ti6Al4V titanium alloy. Opt. Laser Technol. 2020, 126, 106102.

- Zhang, D.; Yu, J.; Li, H.; Zhou, X.; Song, C.; Zhang, C.; Shen, S.; Liu, L.; Dai, C. Investigation of laser polishing of four selective laser melting alloy samples. Appl. Sci. 2020, 10, 760.

- Xiang, Z.; Yin, M.; Dong, G.; Mei, X.; Yin, G. Modeling of the thermal physical process and study on the reliability of linear energy density for selective laser melting. Results Phys. 2018, 9, 939–946.

- Li, C.; Guo, Y.B.; Zhao, J.B. Interfacial phenomena and characteristics between the deposited material and substrate in selective laser melting Inconel 625. J. Mater. Process. Technol. 2017, 243, 269–281.

- Wang, W.J.; Yung, K.C.; Choy, H.S.; Xiao, T.Y.; Cai, Z.X. Effects of laser polishing on surface microstructure and corrosion resistance of additive manufactured CoCr alloys. Appl. Surf. Sci. 2018, 443, 167–175.

- Yung, K.C.; Wang, W.J.; Xiao, T.Y.; Choy, H.S.; Mo, X.Y.; Zhang, S.S.; Cai, Z.X. Laser polishing of additive manufactured CoCr components for controlling their wettability characteristics. Surf. Coatings Technol. 2018, 351, 89–98.

- Dos Santos Solheid, J.; Seifert, H.J.; Pfleging, W. Laser surface modification and polishing of additive manufactured metallic parts. Procedia CIRP 2018, 74, 280–284.

- Chang, C.S.; Chen, T.H.; Li, T.C.; Lin, S.L.; Liu, S.H.; Lin, J.F. Influence of laser beam fluence on surface quality, microstructure, mechanical properties, and tribological results for laser polishing of SKD61 tool steel. J. Mater. Process. Technol. 2016, 229, 22–35.

- Lamikiz, A.; Sánchez, J.A.; López de Lacalle, L.N.; Arana, J.L. Laser polishing of parts built up by selective laser sintering. Int. J. Mach. Tools Manuf. 2007, 47, 2040–2050.

- Li, N.; Fan, P.; Zhu, Q.; Cui, B.; Silvain, J.F.; Lu, Y.F. Femtosecond laser polishing of additively manufactured parts at grazing incidence. Appl. Surf. Sci. 2023, 612, 155833.

- Li, C.; Liu, D.; Liu, G.; Liu, S.; Jin, X.; Bai, Y. Surface characteristics enhancement and morphology evolution of selective-laser-melting (SLM) fabricated stainless steel 316L by laser polishing. Opt. Laser Technol. 2023, 162, 109246.

- Behjat, A.; Shamanian, M.; Taherizadeh, A.; Lannunziata, E.; Bagherifard, S.; Saboori, A.; Iuliano, L. Microstructure-electrochemical behavior relationship in post processed AISI316L stainless steel parts fabricated by laser powder bed fusion. J. Mater. Res. Technol. 2023, 23, 3294–3311.

- Gaidys, M.; Žemaitis, A.; Gečys, P.; Gedvilas, M. Efficient surface polishing using burst and biburst mode ultrafast laser irradiation. RSC Adv. 2023, 13, 3586–3591.

- Ukar, E.; Lamikiz, A.; De Lacalle, L.N.L.; Liebana, F.; Etayo, J.M.; Del Pozo, D. Laser polishing operation for die and molds finishing. Adv. Mater. Res. 2010, 83–86, 818–825.

- Hofele, M.; Schanz, J.; Burzic, B.; Lutz, S.; Merkel, M.; Riegel, H. Laser based post processing of additive manufactured metal parts. In Proceedings of the Lasers in Manufacturing Conference 2017, München, Germany, 26–29 June 2017; pp. 1–12.

- Avilés, R.; Albizuri, J.; Ukar, E.; Lamikiz, A.; Avilés, A. Influence of laser polishing in an inert atmosphere on the high cycle fatigue strength of AISI 1045 steel. Int. J. Fatigue 2014, 68, 67–79.

- Caggiano, A.; Teti, R.; Alfieri, V.; Caiazzo, F. Automated laser polishing for surface finish enhancement of additive manufactured components for the automotive industry. Prod. Eng. 2021, 15, 109–117.

- Abedi, H.; Abdollahzadeh, M.; Almotari, A.; Ali, M.; Mohajerani, S.; Elahinia, M.; Qattawi, A. Additively manufactured NITIHF shape memory alloy transformation temperature evaluation by radial basis function and perceptron neural networks. In Proceedings of the ASME 2023 18th International Manufacturing Science and Engineering Conference, New Brunswick, NJ, USA, 12–16 June 2023; pp. 1–9.