The microbial and biochemical changes in different fermented foods due to the fermenting microorganisms. It has been a matter of study because it contributes to the enhancement of nutritional content in fermented foods due to various fermenting microorganisms that results in the modifications of foods ecosystems like on flavour, rheology, and shelf-life, as well as on the functional/nutritional characteristics of the foods. Fermentation technique has been used for centuries to upgrade food materials and to formulate a more acceptable product. It helps in the successful degradation of anti-nutritive compounds present in the fermented foods thus making it safe and consumable. This entry will help to know more about the potential of fermented foods to increase substantially the nutritional value of the world’s most abundant food resources. The fermentation process has converted the unpalatable food materials into attractive and nutritious foods to add variety and flavour to monotonous staple dishes. It also enhances the nutritional value of foods in terms of vitamins, antioxidants, volatile compounds and minerals, etc. This entry may promote microbial and biochemical changes in fermented foods in a broad manner that helps to understand the overall beneficial effect of microorganisms on fermented foods.

- Food fermentation, enzymes, fermenting microorganism

Fermentation is a process that helps break down large organic molecules by the action of microorganisms into simpler ones. For example, yeast enzymes convert sugars and starches into alcohol, while proteins are converted to peptides/amino acids. The microbial or enzymatic actions on food ingredients tend to ferment food, leading to desirable biochemical changes responsible for the significant modification to the food. Fermentation is a natural way of improving vitamins, essential amino acids, anti-nutrients, proteins, food appearance, flavors and enhanced aroma. Fermentation also helps in the reduction of the energy needed for cooking as well as it makes a safer product [1][2]. Therefore, microorganisms' activity plays a significant role in the fermentation of foods by showing changes in the foods' chemical and physical properties. Fermented foods have several advantages [3][4]:

- Fermented foods have a longer shelf life than the original foods.

- Enhancement of organoleptic properties, for example, cheese, has enhanced organoleptic properties in terms of taste than its raw substrate viz. milk.

- Removal of harmful/unwanted ingredients from raw materials- For example, during garri preparation, there is a reduction in the poisonous cyanide content of cassava, and the flatulence factors in soybeans are removed by fermentation.

- Enhancement of nutritional properties due to the presence of fermenting microorganisms. For example, yeast in bread and yeast and lactic acid bacteria in garri add to its nutritive quality.

- The fermentation process reduces the cooking time of food. For example, West African food, i.e., Ogi (prepared from fermented maize), and soybean products.

- The fermented products consist of higher in vitro antioxidant capacity. For example, fermented milk and yogurt consist of higher antioxidant properties compared to milk, as there is a release of biopeptides that follow the proteolysis of milk proteins, particularly α-casein, α-lactalbumin, and β-lactoglobulin.

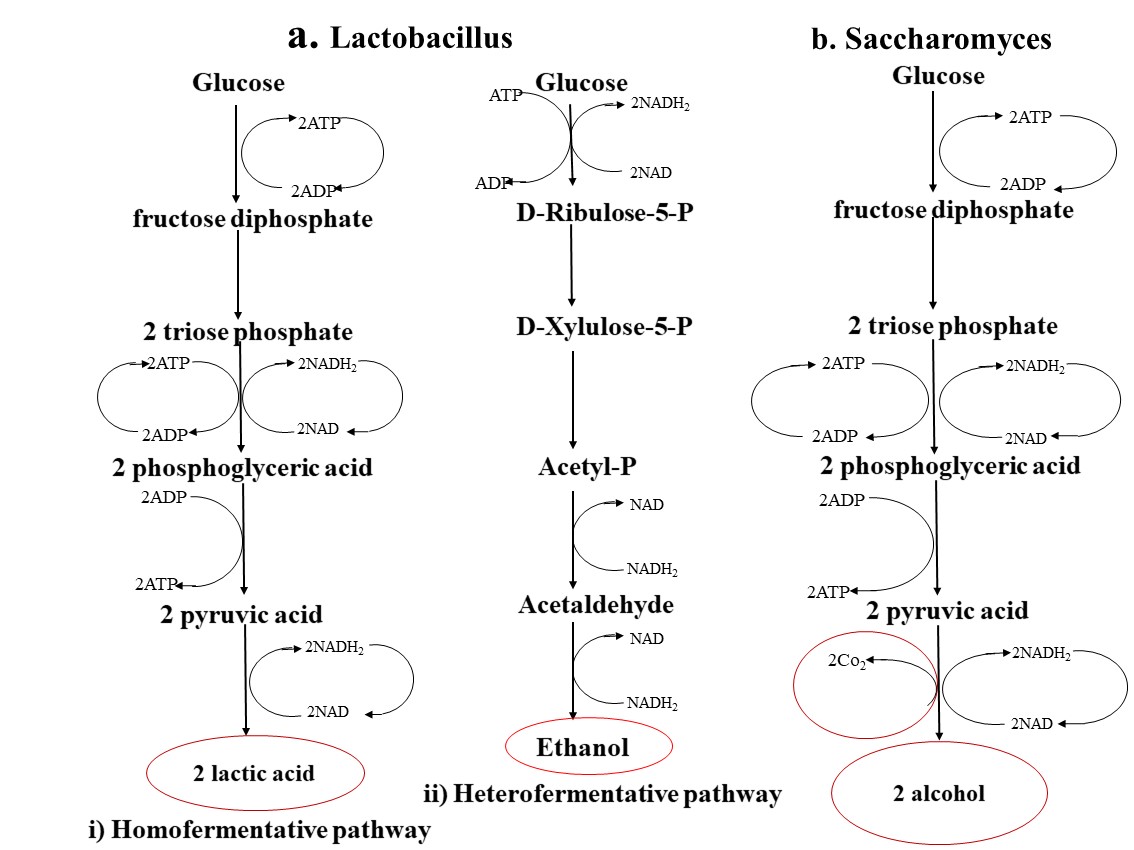

The composition of the substrates used and the fermenting microorganisms are the major factors that influence fermented food. Moreover, food treatment and the length of fermentation during processing also affect food fermentation[5]. For all the fermented foods and beverages that have been identified, lactic acid bacteria (L.A.B.) is the dominant microbiota, which has been considered the most critical part contributing to beneficial effects in fermented foods/beverages[6]. The fermenting microorganisms mainly involve L.A.B. like Enterococcus, Streptococcus, Leuconostoc, Lactobacillus, and Pediococcus[6] and yeasts and molds viz. Debaryomyces, Kluyveromyces, Saccharomyces, Geotrichium, Mucor, Penicillium, and Rhizopus species[7][8][9][10]. The fermentative sugar pathway for Lactobacillus and yeasts is mentioned in Fig 1. A list of some of the most commonly prepared fermented foods/beverages with their fermenting microorganisms is also discussed in Table 1. Despite adding beneficial effects during fermentation, microorganisms in food also help prevent many harmful chemicals and microorganisms during the fermentation process. These microorganisms are also responsible for the production of new enzymes that assist in digestion.

Figure 1. Sugar metabolism by Lactobacillus and Saccharomyces as representatives of L.A.B. and yeasts [11][12]

Table 1. Some of the most commonly prepared fermented foods/beverages with their fermenting microorganisms

|

Fermented foods/beverages |

Substrates used |

Microorganisms involved in fermentation |

|

Dairy products Curd Yogurt Cheese Yakult Kefir |

Milk and milk casein |

Lactobacillus bulgaricus, Lactococcus lactis, L. acidophilus, L. cremoris, L. casei, L. paracasei, L. thermophilus, L. kefiri, L. caucasicus, Penicillium camemberti, P. roqueforti, Acetobacter lovaniensis, Kluyveromyces lactis, Saccharomyces cerevisiae |

|

Vegetable products Kimchi Tempeh Natto Miso Sauerkraut |

Soybean, cabbage, ginger, cucumber, broccoli, radish |

Leuconostoc mesenteroides, Aspergillus sp., Rhizopus oligosporus, R. oryzae, L. sakei, L. plantarum, Thermotoga sp., L. hokkaidonensis, L. rhamnosus, Rhodotorula rubra, Leuconostoc carnosum, Bifidobacterium dentium, Enterococcus faecalis, Weissella confusa, Candida sake |

|

Cereals Bahtura Ambali Chilra Dosa Kunu-Zaki Marchu |

Wheat, maize, sorghum, millet, rice |

L. pantheris, L. plantarum, Penicillium sp., S. cerevisiae, L. mesenteroides, E. faecalis, Trichosporon pullulans, Pediococcus acidilactici, P. cerevisiae, Delbrueckii hansenii, Deb. tamari |

|

Beverages Wine Beer Kombucha Sake |

Grapes, rice, cereals |

Aspergillus oryzae, Zygosaccharomyces bailii, S. cerevisiae, Acetobacter pasteurianus, Gluconacetobacter, Acetobacter xylinus, Komagataeibacter xylinus |

|

Meat Products Sucuk Salami Arjia Jama Nham |

Meat |

L. sakei, L. curvatus, L. plantarum, Leuconostoc carnosum, Leuconostoc gelidium, B. licheniformis, E. faecalis, E. hirae, E. durans, Bacillus subtilis, L. divergens, L. carnis, E. cecorum, B. lentus |

The essential factors in lactic acid fermentation are time, temperature, and relative humidity; for example, higher water activity (aw) and temperature aids in faster growth of L.A.B. and reducing the pH level. Smoke can contribute thousands of aroma and antimicrobial compounds such as organic acids (e.g., acetic, formic, butyric, isobutyric, and propionic acids), carbonyls, and phenols (antioxidants), contributing to the coagulation of surface proteins and inhibition of microorganisms [13].

The pH change is determined by the conversion of ammonia and lactate into lactic acid. This formation is done by adding carbohydrates produced from glycerol fermentation by bacteria and ammonia generated from amino acid fermentation. Acetic acid is also formed in this process of fermentation. Also, oxygen utilized through the metabolism process and other conditions influence the type of microorganisms and their metabolism, which affects the number of fermented carbohydrates and the production of lactose [14].

Cathepsin D (muscle's endogenous enzyme) breaks down myofibrillar proteins into polypeptides with low pH. Protein proteolysis produces volatiles and non-volatiles flavors in fermented sausages resulting in free amino acids and peptides. Based on the literature cited by Fadda et al, breakdown of flavor - and aroma producing compounds like myofibrillar and sarcoplasmic proteins is done with the help of L. plantarum and L. casei. For the development of the structure of fermented sausages, these myofibrillar proteins are more critical than sarcoplasmic proteins [15].

In fermented meat products, lipolysis is caused by microbial enzymes of muscle tissues, i.e., both endo- and exoenzymes [138], and oxidation of fatty acids results in the formation of alkanes, aldehydes, ketones, and alcohols [16].

Hydrolytic and oxidative changes, usually related to unsaturated fats and are autocatalytic, are responsible for the liberation of aromas and flavors (both good and bad flavors). There is a slight increase in thiobarbituric acid reactive substances (T.B.A.R.S.) in non-vacuum, whereas it remains stationary in vacuum packages. Lipolytic enzymes naturally present in meat are responsible for releasing fatty acids, and in semi-dry fully cooked products, the activity is minimal. Smoking and mold ripening can be used to reduce oxygen by direct consumption and reduction in light penetration. The sausage diameter also affects biochemical reactions involving greater diameter sausages (anaerobic) due to less oxidation. The concentration of glucose does not influence the maximum lipase activity; however, it is essential for rapid lipase production [17].

Conclusion

Around the globe for thousands of years, fermented foods are part of the human diet due to modifications in their natural form, contributing to enhanced flavor and high-profile nutritional properties without much information and knowledge of microbial functionality.

This entry is adapted from the peer-reviewed paper 10.3390/fermentation6040106

References

- Nkhata, S.G., Ayua, E., Kamau, E.H., and Shingiro, J.B., 2018. Fermentation and germination improve nutritional value of cereals and legumes through activation of endogenous enzymes. Food Sci. Nutr., 6(8), pp.2446-2458. doi: 10.1002/fsn3.846

- Xiang, H., Sun-Waterhouse, D., Waterhouse, G.I., Cui, C., and Ruan, Z., 2019. Fermentation-enabled wellness foods: A fresh perspective. Food Sci. Hum. Well., 8(3), pp.203-243. doi.org/10.1016/j.fshw.2019.08.003

- Melini, F., Melini, V., Luziatelli, F., Ficca, A.G., and Ruzzi, M., 2019. Health-promoting components in fermented foods: An up-to-date systematic review. Nutrients, 11(5), p.1189. doi: 10.3390/nu11051189

- Sanlier, N., Gokcen, B.B. and Sezgin, A.C., 2019. Health benefits of fermented foods. Crit. Rev. Food Sci. Nutr., 59(3), pp.506-527. doi:10.1080/10408398.2017.1383355.

- Okafor, N., 2009. Fermented foods and their processing. Biotechnology-Volume VIII: Fundamentals in Biotechnology, 8, p.19.

- Mokoena, M.P., 2017. Lactic acid bacteria and their bacteriocins: classification, biosynthesis, and applications against uropathogens: a mini-review. Molecules, 22(8), p.1255. doi: 10.3390/molecules22081255

- Anukam, K.C., and Reid, G., 2009. African traditional fermented foods and probiotics. J. Med. Food, 12(6), pp.1177-1184. doi: 10.1089/jmf.2008.0163

- Blandino, A., Al-Aseeri, M.E., Pandiella, S.S., Cantero, D., and Webb, C., 2003. Cereal-based fermented foods and beverages. Food Res. Int., 36(6), pp.527-543. doi:10.1016/S0963-9969(03)00009-7

- Vagelas, I., Gougoulias, N., Nedesca, E.D., and Liviu, G., 2011. Bread contamination with fungus. Carpath. J. Food Sci. Technol., 3, pp.1-6.

- Doyle, M.P., and Meng, J.I.A.N.G.H.O.N.G., 2006. Bacteria in food and beverage production. Prokaryotes. Springer, New York, pp.797-811. DOI: 10.1007/0-387-30741-9_23

- Pessione, E., 2012. Lactic acid bacteria contribution to gut microbiota complexity: lights and shadows. Front. Cell. Infect. Microbiol., 2, p.86. doi:10.3389/fcimb.2012.00086

- Pfeiffer, T., and Morley, A., 2014. An evolutionary perspective on the Crabtree effect. Front. Mol. Biosci., 1, p.17. doi:10.3389/fmolb.2014.00017

- Dalcanton, F., Carrasco, E., Perez-Rodríguez, F., Posada-Izquierdo, G.D., Falcao de Aragao, G.M. and Garcia-Gimeno, R.M., 2018. Modeling the combined effects of temperature, pH, and sodium chloride and sodium lactate concentrations on the growth rate of Lactobacillus plantarum ATCC 8014. J. Food Qual., 2018. doi: 10.1155/2018/1726761

- Juturu, V., and Wu, J.C., 2016. Microbial production of lactic acid: the latest development. Crit. Rev. Biotechnol., 36(6), pp.967-977. doi: 10.3109/07388551.2015.1066305

- Fadda, S., Vignolo, G., and Oliver, G., 2001. Meat protein degradation by tissue and lactic acid bacteria enzymes. In: Food Microbiology Protocols (pp. 147-162). Humana Press. doi:10.1385/1-59259-029-2:147

- Pasini, F., Soglia, F., Petracci, M., Caboni, M.F., Marziali, S., Montanari, C., Gardini, F., Grazia, L., and Tabanelli, G., 2018. Effect of fermentation with different lactic acid bacteria starter cultures on biogenic amine content and ripening patterns in dry fermented sausages. Nutrients, 10(10), p.1497. doi: 10.3390/nu10101497

- Karslioglu, B., Cicek, U., Kolsarici, N., and Candogan, K., 2014. Lipolytic changes in fermented sausages produced with Turkey meat: Effects of starter culture and heat treatment. Korean J. Food Sci. Ani. Res., 34(1), pp. 40-48. doi:10.5851/kosfa.2014.34.1.40