Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Natural waxes are of plant or animal origin. They are resistant to moisture, oxidation, and microbiological decomposition. Plant waxes of commercial and industrial importance are obtained from various plant species and are used to produce cosmetic products, ink, varnishes, luster, candles, pastels, etc. Some of them are used in the composition of some edible coatings applied to various foodstuffs. By using them, the properties and quality of food products are preserved during storage.

- plant waxes

- cuticle

- edible coatings

1. Introduction

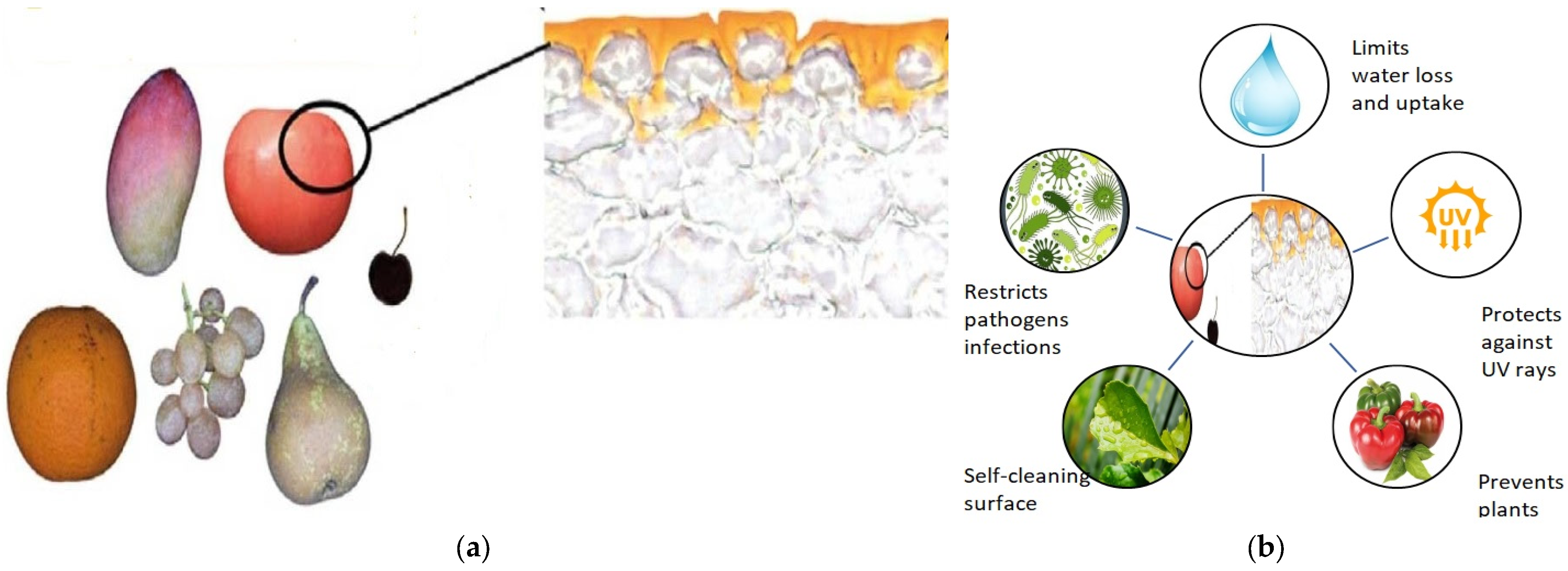

Fresh fruits and vegetables have a natural shell in the form of skin, covered by a cuticle (a natural shell of higher plants that covers and protects the flowers, leaves, fruits, and vegetables from adverse external influences) (Figure 1) and a shell in the case of nuts [1][2][3][4]. These natural barriers regulate the exchange of oxygen, carbon dioxide, and water and reduce the loss of volatile flavor and aroma substances. Nowadays, coating emulsions are used for foods, made up of different components, including wax, shellac, beeswax, morpholine, and candelilla, usually combined with carnauba wax [5][6][7].

In modern conditions, uncoated foodstuffs produced via food technology are not protected by a natural coating. Therefore, various edible coatings are applied to them, which protect the product from the adverse effects of the environment, thus preserving its properties and quality. Usually, the quality of foods decreases as a result of the loss of water and aromatic substances and as a result of the influence of oxygen on the individual components of the composition of the product. Therefore, attention should be paid to the properties of the used edible coatings for food products, regarding their permeability to oxygen, water vapor, and aromatic substances [8].

2. Plant Waxes—Types

Waxes are esters of high molecular weight monohydroxy alcohols and high molecular weight carboxylic acids. They are chemically different from fats and oils, from hydrocarbon or paraffin waxes, and from synthetic waxes such as carbowax [9]. Natural waxes are used in the food and cosmetic industries and have many other industrial applications [10].

Plant waxes are waterproofing components found on the outer surface of plants. They are the main barrier against environmental stress. Some of them have gained GRAS (Generally Regarded as Safe) status approved by FDA, which allows their use in foods. Plant waxes such as candelilla wax, carnauba wax, rice bran wax, sunflower wax, etc. with commercial and industrial importance are derived from different plants and used for the production of cosmetics, ink, varnish, polish, candles, crayons, etc. They are also used to obtain edible coatings for various food commodities.

The main source of Carnauba wax (CW), sometimes called the “Queen of Waxes”, is the Brazilian palm tree (Coernicia cerifera Martius), also known as carnauba wax palm. The wax is found on the surface of the palm leaves. One of the unique characteristics of carnauba wax is that it contains long-chain alcohols and esters: unesterified alcohols (12%), x-hydroxy esters (14%), and esters of hydroxylated cinnamic acid (30%). Carnauba wax is one the hardest plant waxes, with melting temperatures ranging from 82.5 to 83 °C. Therefore, it is often used as a hardener to elevate the melting temperature of wax mixtures. Carnauba wax is the most commercially important plant wax. It has extensive applications in foods, confectionery coatings, cosmetics, automobiles, furniture wax, etc. [10], and CW-based emulsions, edible coatings, oleogels, etc. [11]. Food-related use of carnauba wax is outlined in the FDA regulation 21 CFR 184.1978 [12].

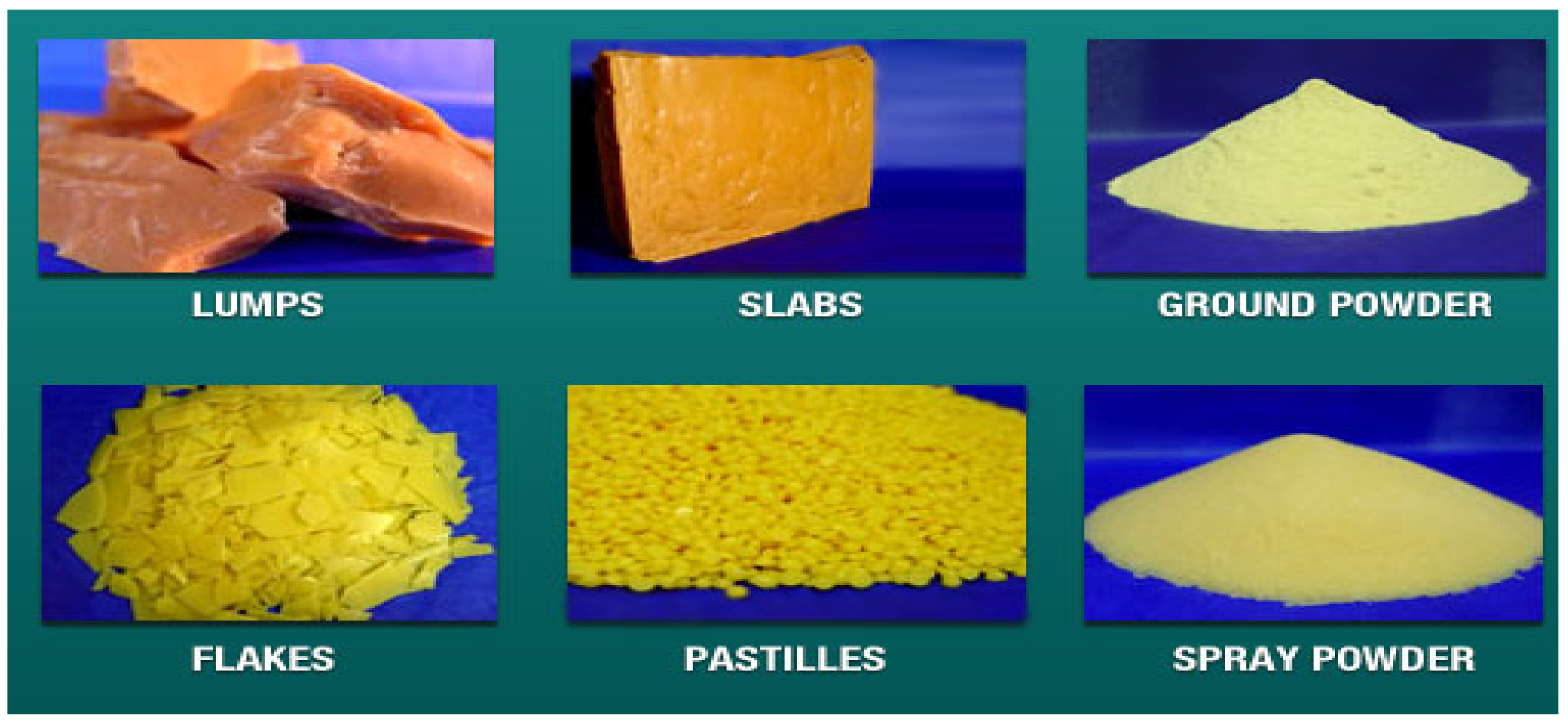

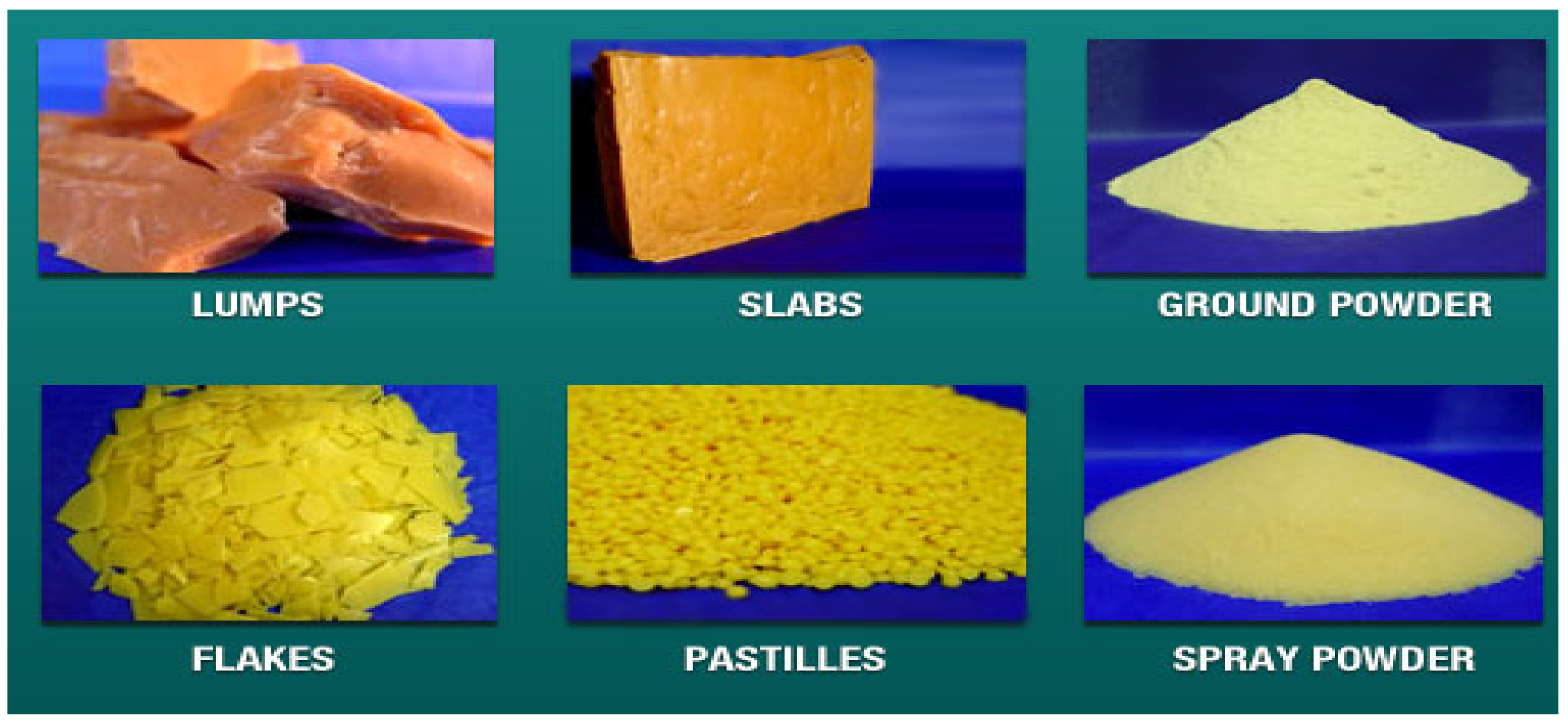

Candelilla wax, or The “Great Wax Rush” (Figure 2), is mainly obtained from the leaves of the plant E. antisyphilitica Zuccarini native to northern Mexican and southwest Texas [13]. Unpurified candelilla wax contains approximately 42% hydrocarbons, 39% wax, resin, and sitosteroyl esters, 8% free wax and resin acids, 6% lactones, and 5% free wax and resin alcohol. Candelilla wax is an FDA-approved food additive used for glazing in certain foods. Microemulsions of candelilla wax are used as coatings with good gloss for fruits [14].

Figure 2. Different Candelilla wax products, which differ in their presentation and refining grade. Source: Candelilla Institute, http://www.candelilla.org/?page_id=2, accessed on 1 March 2023.

Japan Wax (木蝋 Mokurō), known as sumac wax, sumach wax, vegetable wax, China green tallow, and Japan tallow, is a pale-yellow, waxy, water-insoluble solid with a gummy feel obtained from the berries and stems of the Rhus succedanea tree. It is not a true wax and contains 5% of fatty acid, resulting in more viscosity than other waxes. It thickens formulas, as well as gives a nice, malleable texture to the blend. It has been used by sumo wrestlers and geishas for centuries to shape and maintain their hairstyle. It is frequently used nowadays in haircare products. Japan wax is used in the composition of candles, furniture polishes, floor waxes, wax matches, soaps, food packaging, pharmaceuticals, cosmetics, pastels, crayons, buffing compounds, metal lubricants, adhesives, thermoplastic resins, and as a substitute for beeswax. Because it undergoes rancidification, it is not often used in foods [15].

Ouricury wax is a brown-colored wax obtained from the leaves of a Brazilian feather palm (Syagrus coronata) by scraping the leaf surface. Harvesting ouricury wax is more difficult than carnauba wax, as ouricury wax does not flake off the surface of the leaves. The physical properties of ouricury wax resemble carnauba wax, so it can be used as a substitute where light color is not required, e.g., in carbon paper inks, molding lubricants, and polishes [12][16].

Rice bran wax is another high-melting vegetable wax found in rice husks (O. sativa). It is obtained as a by-product from the de-waxing of rice bran oil [12]. The rice bran wax is a reddish brown, dark composite separated from rice bran oil and has good nutritional properties. It is separated from rice bran, which has several health-benefiting components. Rice bran wax (RBW) has been approved by the FDA as a safe food additive (21 CFR, 172.890). It has extensive applications due to its relatively low cost and abundance in Asia. It can be used as an efficient edible coating substance due to its excellent film-forming properties. The RBW has been effectively used in several food applications, such as forming oleogels, structured lipids, and edible coating of food products [17].

Sunflower wax is found in the seed and seed hulls of sunflower (H. annuus). It is obtained through the winterization of sunflower oil. Like rice bran wax, it is a hard wax. Sunflower wax has not been approved for GRAS status by the FDA. Therefore, its applications are primarily in cosmetics, such as lipsticks, mascaras, lip balms, emulsions, etc. It functions as a consistency modifier and regulates the hardness, texture, and mold release of cosmetic formulations. It can also be used as a replacement for candelilla wax, carnauba wax, and rice bran wax [10].

The cuticle is synthesized in the epidermal cells of various plants, such as leaves, fruits, stems, and flowers, as a barrier between the plant surface and the environment. The cuticle is a hydrophobic layer composed of two lipophilic components, cuticular wax, and cutin. One of the most important functions of the cuticle is due to its hydrophobic component: the waxes [18]. Cuticular wax (obtained from the leaf/peel wastes of fresh fruit and vegetables, etc.) is a continuous layer outside or within the cuticle of plants. The presence of waxes on the leaf/fruit surface affects the degree of colorization, and the effect varies according to the plant species [19]. Berry wax is isolated from the cuticle of different varieties of berry fruits. It is obtained from the peel berry wastes from the berry juice industry and is a potential source of natural waxes. Waxes find application in food packaging, cosmetic industries, coatings, etc. [20].

3. Necessity, Advantages, and Disadvantages of Edible Coatings Based on Plant Waxes

Coatings based on plant waxes used in food technology are subtle, invisible to the naked eye, and safe for consumers. Applied to food products, they slow down the loss of moisture, gases (oxygen and carbon dioxide), and volatile components of the composition, and they improve the appearance and mechanical properties of the product.

Coatings based on plant waxes are also considered as a layer of edible materials used and located between the components of the product, providing a barrier to overall exchange.

Edible coatings are consumed together with the product on which they are applied. Therefore, the components included in their composition, such as antimicrobials, antioxidants, and food additives, should not affect the properties of food.

The addition of some anti-browning components in edible coatings can cause an unpleasant nuance in the aroma, especially when their concentration is high [21]. There are limited studies that present the sensor characteristics of fresh-cut fruits with applied coatings in the composition, in which food additives are included. The taste of these components is considered an extremely important point, as most of the components have a naturally bitter, astringent, or another aftertaste that will change consumer preferences. It was found that the presence of vitamin E reduces the surface gloss of coated strawberries, and this affects the appearance of the product and consumer preferences [22].

The need to use edible coatings based on plant waxes in food technology is directly related to the fact that they have some advantages over synthetic ones. A major advantage of edible over synthetic coatings is that they can be consumed together with the food on which they are applied. Their use contributes to reducing environmental pollution. The coatings are prepared entirely from plant waxes, so their degradation is faster than polymer materials. The coatings can emphasize the organoleptic properties of the product on which they are applied since they contain various components (flavoring substances, coloring agents, and sweeteners). Coatings can be used for individual packaging of small quantities of a certain product, especially for goods that are not individually packaged, such as pears, nuts, strawberries, etc. It is possible to apply them inside heterogeneous products between individual layers. Thus, they protect the product from becoming wet and prevent the passage of moisture into it (pizza, pie, candies, etc.). Coatings can also be considered a source of antimicrobial, antioxidant, and anti-browning (cut, filleted fruit) components. They are most often applied to the surface of the product, thus preventing the penetration of unwanted components through the surface to the interior of the product. It is also possible to use edible coatings with multilayer packaging materials together with non-edible ones.

The disadvantages of coatings are connected with their composition and properties, with the thickness of the layer applied on the surface of foods, the cost of the components included in the composition of coatings and the absence of requirements for the composition and application of edible coatings [23][24][25].

Thick coatings prohibit oxygen exchange and cause off-flavor development. Sometimes due to the surface of foods and chosen method of applying the edible coatings a thick layer of the coating can form, which reduces the properties and efficiency of the edible coatings. Some coatings are hygroscopic in nature, which helps to increase the growth of certain microorganisms, which do not allow coatings to fulfill their main purpose.

4. Edible Coatings Based on Lipids Applied in the Food Industry

The increased demands of consumers nowadays raise the question of active packaging—a type of packaging that changes the conditions around the product itself, in order to preserve its quality and freshness, improve its sensory properties, and thus also guarantee food safety and storage duration.

Through the use of packaging for food products, the aim is to preserve their quality and safety from the moment of their production until their use by consumers. A very important function of packaging is the protection of goods from physical, chemical, or biological damage. The most widely distributed and used packaging material that fully meets these criteria is polyethylene and similar materials, which have been used in the food industry for more than 50 years. These materials are not only harmless, cheap, and applicable, but also suitable for packaging various goods and have good flexibility.

Nowadays, the main part of the materials used as raw materials for packaging are by-products of the processing of petroleum products and are practically non-degradable. This is the main reason why food packaging, like all other disposable packaging used to store foods for a short period of time, creates a serious global problem.

The world production of packaging materials is more than 180 million tons per year, and it is increasing every year [26]. A major limitation of using plastic packaging materials is the fact that their degradation period is long. Another point is the direct dependence of the production of polyethylene packaging on the extraction of petroleum products, and the reserves on a global scale are significantly decreasing with each subsequent year, along with increasing oil prices [27].

The properties of lipid edible coatings have been extensively investigated in recent years. By means of lipid films, unwanted loss of water vapor from foodstuffs is regulated, the quality is improved, and their shelf life is extended. By replacing synthetic packaging materials with edible lipid coatings, waste is reduced, and the recyclability of synthetic packaging materials is increased.

Various lipid components, such as animal fats and vegetable oils, are used in the production of edible coatings. Edible lipids are neutral lipids, waxes, and resins, which usually provide a coating material for fresh products, provide an effective moisture barrier property, and improve surface appearance. Resin coating is fairly effective for water loss [28]. Resins are a group of substances secreted by special plant cells in response to injury or infection in many trees and shrubs [29]. Lipid coatings have excellent moisture-protecting properties, and as a coating component, they add shine to confectionery and sugar products. Waxes are used in the composition of coatings in order to reduce respiration and moisture loss [30].

Kester and his colleagues offer an edible coating in a composition in which lipids and cellulose are combined. The edible coating is rated as a good barrier and protects the commodity from water vapor loss [31]. Cellulose-based coatings with included wax provide the best balance between the loss of aromatic substances and the prevention of natural storage losses of the goods due to water loss. These coatings are applied to fresh fruit immediately after harvest in order to preserve (reduce) the loss of aroma substances [32].

The structure of the matrix of some edible coatings includes wheat gluten and lipids, which are the main components that retain the loss of water vapor. It has been established that the combination of wheat gluten protein with diacetyl tartrate ester of monoglycerides reduces the penetration of water vapor, increases the strength of the coating, and ensures its transparency [33].

Lipid–cellulose edible coatings are designed to retain the moisture in two-component food products stored in a frozen state. It is applied between the two components of the bread and tomato sauce product. It was found that the coating successfully arrests moisture migration from the tomato sauce to the bread during storage [34].

It was established that the inclusion of plasticizers in the composition of lipid edible coatings prevents the appearance of pores and cracks after their application. For example, the addition of sunflower oil to starch-based coatings reduces the water vapor permeability of it [35].

Edible wax coatings are widely used in the food industry in order to extend the shelf-life of foods by regulating gas exchange and moisture migration. Waxes (carnauba wax, paraffin wax, etc.) are commercially used as a protective coating for fresh fruits and vegetables. They reduce moisture loss and surface abrasion during fruit handling. Generally, wax coatings are resistant to moisture loss as compared to lipid and non-lipid coating. Wax coating is effective on citrus, apple, mature green tomato, cucumber, and other vegetables, such as asparagus, beans, carrots, eggplant, okra, sweet potatoes, turnips, etc., where a shiny surface is desired. Beneficial properties of lipid-based coatings include good compatibility with other coating agents and high water vapor and gas barrier properties as compared to polysaccharide and protein-based coatings [36]. The lipid-based coating gives a greasy surface and undesirable organoleptic properties such as a waxy taste and lipid rancidity [37][38].

Carnauba wax is considered safe for human consumption by several certified organizations. European Union has authorized carnauba wax (E 903) as a food additive (coating agent). In 2012, the Panel of Additives and Nutrient Sources (ANS) on the safety of carnauba wax for human consumption jointly assessed by the Joint FAO/WHO Expert Committee on Food Additives (JECFA), and Scientific Committee on Food (SCF), and they determined 7 mg/kg body weight/day [6]. Its hydrophobic nature and meltability make it an attractive alternative to petroleum-based synthetic wax for coatings of fruits and vegetables, and in recent years, it has been explored as an additive in biopolymer-based composite packaging films. Incorporation in coatings improves their hydrophobicity, barrier against light, etc. [39][40]. Carnauba wax emulsion coating showed good commercial attributes such as glossiness, early drying nature, and reduced physiological weight loss. Its extended shelf life and enhanced antioxidant activity of packaged eggplants during storage up to 12 days [41]. Some examples connected with the application of Carnauba wax in the composition of edible coating are presented in Table 1.

Table 1. Application of Carnauba wax (CW) in composition of edible coatings.

| Commodities | Coatings/Emulsions | Advantages | Source |

|---|---|---|---|

| Fresh tomatoes | Carnauba wax nanoemulsion. | Improve the gloss of tomatoes. | Miranda et al. [42]. |

| Strawberries | Bio-nanocomposite coatings developed using arrowroot starch (AA), cellulose nanocrystals (CNC), carnauba wax nanoemulsion (CWN), and Cymbopogon martinii and Mentha spicata essential oils (CEO and MEO, respectively). | Preserve the post-harvest quality of fresh strawberries. | Gonçalves de Oliveira Filho et al. [43] |

| Eggplant | Poly ethylene glycol and Sodium alginate in CW emulsion. | Improve shelf life of eggplant during storage in both unpackaged and packaged. | Singh et al. [41] |

| Fresh-cut apples |

Edible coatings/films formulated with cassava starch, glycerol, carnauba wax, and stearic acid. | Improve barrier properties of coatings applied in fresh-cut apples (respiration rate and water vapor resistance). | Chiumarelli et al. [44] |

| Indian jujube (Zizyphus mauritiana Lamk.) fruit | Carnauba wax (CW) and CW containing glycerol monolaurate (CW-GML) coating. | Shelf-life extension and quality maintenance of jujube fruit stored at 20 °C. | Chen et al. [45] |

| ‘Valencia’ orange fruit |

Carnauba wax-nanoclay emulsion. | Retarding respiration rates and weight loss, preserving sensory and nutritional quality of fruits. | Motamedi et al. [46] |

| Sweet potato (Ipomoea batatas (L.) Lam.) roots | Carnauba wax-based nanoemulsion without or with glycerol monolaurate. | Preserve food quality and extend shelf life of sweet potato roots. | Huqing et al. [47] |

| Fresh and minimally processed apples |

Edible coatings made up of starch, carrageenan, soy proteins, corn zein, whey proteins, and waxes. | Improve functional properties of apples besides sensory and nutritional attributes. | Aayush et al. [48] |

| Fuji’ apples | Carnauba-shellac wax-based nanoemulsion containing lemongrass oil. | Improve the quality of ‘Fuji’ apples during storage. | Wan-Shin et al. [49] |

This entry is adapted from the peer-reviewed paper 10.3390/coatings13050911

References

- Bai, J.; Plotto, A.; Baldwin, E. Edible Coatings and Films to Improve Food Quality; Hagenmaier, R., Bai, J., Eds.; CRC Press: Boca Raton, FL, USA, 2011; pp. 185–242.

- Maringgal, B.; Hashim, N.; Syafinaz, I.; Amin Tawakkal, M.; Tengku Muda Mohamed, M. Recent advance in edible coating and its effect on fresh/fresh-cut fruits quality. Trends Food Sci. Technol. 2020, 96, 253–267.

- Nor, S.; Ding, P. Trends and advances in edible biopolymer coating for tropical fruit: A review. Food Res. Int. 2020, 134, 109208.

- Fernández-Muñoz, R.; Heredia, A.; Domínguez, E. The role of cuticle in fruit shelf-life. Curr. Opin. Biotechnol. 2022, 78, 102802.

- Martin, L.; Rose, J. There’s more than one way to skin a fruit: Formation and functions of fruit cuticles. J. Exp. Bot. 2014, 65, 4639–4651.

- Andréa Silva de Freitas, C.; Henrique Machado de Sousa, P.; Josino Soares, D.; Ytalo Gomes da Silva, J.; Rathinaraj Benjamin, S.; Izabel Florindo Guedes, M. Carnauba wax uses in food—A review. Food Chem. 2019, 291, 38–48.

- Puttalingamma, V. Edible coatings of carnauba wax—A novel method for preservation and extending longevity of fruits and vegetables—A review. Int. J. Food Saf. 2014, 16, 1–5.

- Pashova, S. Application of Vegetable Waxes in Food Technology; IK SAFO: Lovech, Bulgaria, 2011; pp. 147–148.

- Bodmier, R.; Hermann, J. Encyclopedia of Pharmaceutical Technology. In Waxes; Swarbrick, J., Boylan, J.C., Eds.; Marcel Deckker Inc.: New York, NY, USA, 1997; Volume 16, pp. 335–361.

- Tinto, W.; Elufioye, T.; Roach, J. Waxes; Pharmacognosy; Badal, S., Delgoda, R., Eds.; Academic Press: Cambridge, MA, USA, 2017; Chapter 22; pp. 443–455.

- Néstor, E.; Ledesma, A.; Bautista-Hernández, I.; Rojas, R.; Aguilar-Zárate, P.; del Pilar Medina-Herrera, N.; Castro-López, C.; Cristian Guadalupe Martínez-Ávila, G. Candelilla wax: Prospective suitable applications within the food field. LWT Food Sci. Technol. 2022, 159, 113170.

- Lan, Y. Waxes. In Encyclopedia of Food Chemistry; Melton, L., Shahidi, F., Varelis, P., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 312–316.

- Arato, M.; Speelman, S.; Van Huylenbroeck, G. The contribution of non-timber forest products towards sustainable rural development: The case of Candelilla wax from the Chihuahuan Desert in Mexico. Nat. Resour. Forum 2014, 38, 141–153.

- Hagenmaier, R.; Baker, R. Edible Coatings from Candelilla Wax Microemulsions. J. Food Sci. 1996, 61, 562–565.

- Krendlinger, E.; Wolfmeier, W. Natural and Synthetic Waxes: Origin, Production, Technology and Applications; Wiley-VCH: Hoboken, NJ, USA, 2022.

- Pashova, S. Plant Waxes—Nature, Types and Application; Forum Ware International. In Excellence in Business, Commodity Science and Tourism; Special Issue; Bucharest Academy of Economic Studies: Bucharest, Romania; International Society of Commodity Science and Technology (IGWT): Wien, Austria, 2011; Volume 1, pp. 166–170.

- Modupalli, N.; Natarajan, V. Fractionation and extraction of functional compounds from rice bran wax. Pharma Innov. J. 2022, 11, 1682–1686.

- Bhanot, V.; Fadanavis, S.; Panwar, J. Revisiting the architecture, biosynthesis and functional aspects of the plant cuticle: There is more scope. Environ. Exp. Bot. 2021, 183, 104364.

- George, N. Chapter five—How Pathogens Attack Plants. In Plant Pathology, 5th ed.; Agrios, G.N., Ed.; Academic Press: Cambridge, MA, USA, 2005; pp. 175–205.

- Trivedi, P.; Karppinen, K.; Klavins, L.; Kviesis, J.; Sundqvist, P.; Nguyen, N.; Heinonen, E.; Klavins, M.; Jaakola, L.; Väänänen, J.; et al. Compositional and Morphological Analyses of Wax in Northern Wild Berry Species. Food Chem. 2019, 295, 441–448.

- Rojas-Grau, M.; Sobrino-Lopez, A.; Tapia, M.; Martin-Bellosso, O. Browning Inhibition in Fresh-cut ‘Fuji’ Apple Slices by Natural Antibrowning Agents. J. Food Sci. 2006, 71, S59–S65.

- Han, C.; Lederer, C.; McDaniel, M.; Zhao, Y. Sensory Evaluation of Fresh Strawberry (Fragarai ananassa) Coated with Chitosan-based Edible Coatings. J. Food Sci. 2005, 70, S172–S178.

- Okcu, Z.; Yavuz, Y.; Kerse, S. Edible Film and Coating Applications in Fruits and Vegetables. Alınteri J. Agric. Sci. 2018, 33, 221–226.

- Raghav, P.; Agarwal, N.; Saini, M. Edible coating of fruits and vegetables: A review. Int. J. Sci. Res. Mod. Educ. 2016, I, 188–204.

- Radev, R. Edible Films and Coatings for Food Products—Advantages and Disadvantages. Union of Scientists: Varna, Bulgaria, 2021; Volume 10, pp. 43–51.

- Tice, P. Packaging Materials. 4. Polyethylene for Food Packaging Applications. International Life Sciences Institute Report. 2003. Available online: http://orig.ilsi.org/file/PM4_Polyethylene.pdf (accessed on 12 November 2022).

- Weber, C.; Haugaard, V.; Festersen, R.; Bertelsen, G. Production and Application of Bio based Packaging Materials for the Food Industry. Food Addit. Contam. 2002, 19, 172–177.

- Morillon, V.; Debeaufort, F.; Blond, G.; Capelle, M.; Voilley, A. Factors affecting the moisture permeability of lipid based edible films: A review. Crit. Rev. Food Sci. Nutr. 2002, 42, 67–89.

- Debeaufort, F.; Quezada, G.; Voilley, A. Edible films and coating: Tomorrow’s packaging: A review. Crit. Rev. Food Sci. Nutr. 1998, 38, 299–313.

- Avena-Bustillos, R.; Krochta, J.; Saltveit, M.; Rojas-Villegas, R.; Sauceda-Pbrez, J. Optimization of Edible Coating Formulations on Zucchini to Produce Water Loss. J. Food Eng. 1994, 21, 197–214.

- Kester, J.; Fennema, O. An Edible Film of Lipids and Cellulose Ethers: Barrier Properties to Moisture Vapor Transmission and Structural Evaluation. J. Food Sci. 1989, 54, 1383–1389.

- Nisperos-Carriedo, M.; Shaw, P.; Baldwin, E. Changes in Volatile Flavor Components of Pineapple Orange Juice as Influenced by the Application of Lipid and Composite Films. J. Agric. Food Chem. 1990, 38, 1382–1387.

- Gontard, N.; Duchez, C.; Cuq, J.; Guilbert, S. Edible Composite Films of Wheat Gluten and Lipids: Water Vapor Permeability and Other Physical Properties. Int. J. Food Sci. Technol. 1994, 29, 39–50.

- Kester, J.; Fennema, O. An Edible Film of Lipids and Cellulose Ethers: Performance in a Model Frozen-Food System. J. Food Sci. 1989, 54, 1390–1392.

- Garcia, M.; Martino, M.; Zaritzky, N. Lipid Addition to Improve Barrier Properties of Edible Starch-based Films and Coatings. J. Food Sci. 2000, 65, 941–944.

- Greener, I.; Fennema, O. Lipid-based edible films and coatings. Lipid Technol. 1992, 4, 34–38.

- Robertson, G. Food Packaging, Principle and Practices, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2009.

- Vaishali, H.; Samsher, V.; Chaudhary, S.; Mithun, K. Importance of edible coating on fruits and vegetables: A review. J. Pharmacogn. Phytochem. 2019, 8, 4104–4110.

- Devi, L.; Kalita, S.; Mukherjee, A.; Kumar, S. Carnauba wax-based composite films and coatings: Recent advancement in prolonging postharvest shelf-life of fruits and vegetables. Trends Food Sci. Technol. 2022, 129, 296–305.

- Saji, V. Wax-based artificial superhydrophobic surfaces and coatings. Colloids Surf. A Physicochem. Eng. Asp. 2020, 602, 125–132.

- Singh, S.; Khemariya, P.; Rai, A.; Rai, A.C.; Koley, T.; Singh, B. Carnauba wax-based edible coating enhances shelf-life and retain quality of eggplant (Solanum melongena) fruits. LWT Food Sci. Technol. 2016, 74, 420–426.

- Miranda, M.; Mori, M.; Ribeiro, M.; Spricigo, P.; Pilon, L.; Mitsuyuki, M.; Correa, D.; Ferreira, M. Carnauba wax Nano emulsion applied as an edible coating on fresh tomato for postharvest quality evaluation. Heliyon 2022, 8, e09803.

- De Oliveira Filho, J.; Albiero, B.; Calisto, Í.; Bertolo, M.; Oldoni, F.; Egea, M.; Junior, S.; de Azeredo, H.; Ferreira, M. Bio-nanocomposite edible coatings based on arrowroot starch/cellulose nanocrystals/carnauba wax nano emulsion containing essential oils to preserve quality and improve shelf life of strawberry. Int. J. Biol. Macromol. 2022, 219, 812–823.

- Chiumarelli, M.; Hubinger, M. Stability, solubility, mechanical and barrier properties of cassava starch—Carnauba wax edible coatings to preserve fresh-cut apples. Food Hydrocoll. 2012, 28, 59–67.

- Huiyun, C.; Zhengxuan, S.; Huqing, Y. Effect of carnauba wax-based coating containing glycerol monolaurate on the quality maintenance and shelf-life of Indian jujube (Zizyphus mauritiana Lamk.) fruit during storage. Sci. Hortic. 2019, 244, 157–164.

- Motamedi, E.; Nasiri, J.; Malidarreh, T.; Kalantari, S.; Naghavi, M.; Safari, M. Performance of carnauba wax-nanoclay emulsion coatings on postharvest quality of ‘Valencia’ orange fruit. Sci. Hortic. 2018, 240, 170–178.

- Huqing, Y.; Xia, L.; Guoquan, L. Effect of Carnauba Wax–Based Coating Containing Glycerol Monolaurate on Decay and Quality of Sweet Potato Roots during Storage. J. Food Prot. 2018, 81, 1643–1650.

- Aayush, K.; McClements, D.; Sharma, S.; Sharma, R.; Singh, G.; Sharma, K.; Oberoi, K. Innovations in the development and application of edible coatings for fresh and minimally processed Apple. Food Control 2022, 141, 109188.

- Wan-Shin, J.; Hye-Yeon, S.; Nak-Bum, S.; Ji-Hyun, L.; Sea, M.; Kyung, S. Quality and microbial safety of ‘Fuji’ apples coated with carnauba-shellac wax containing lemongrass oil. LWT Food Sci. Technol. 2014, 55, 490–497.

This entry is offline, you can click here to edit this entry!