Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Changyang Guan and Version 2 by Sirius Huang.

The driving range of electric vehicles (EVs) is still an important factor restricting their development. Although the rising battery energy density has reached a bottleneck, which is a key constraint, the drive energy management strategy also has a significant effect and can improve the driving range of EVs. Herein, the typical configurations of the dual-motor coupling drive system (DCDS) are introduced, and the power distribution strategies of the DCDS are comprehensively reviewed.

- electric vehicle

- energy efficiency

- power management

- independent drive

1. Introduction

Electric vehicles (EVs) are considered to be a significant solution to reduce air pollution caused by the transportation industry due to their zero-emission characteristics [1][2][3][1,2,3]. Meanwhile, EVs are also considered to be the best platform for autonomous vehicles because of their excellent control performance. However, the inadequate driving range of EVs is still a crucial constraint to their development [4]. The means to improve the driving range of EVs can be roughly summarized as design means and control means. The design means mainly refer to the design of the batteries, motors, and body structure of EVs, which are considered to be the fundamental means to increase the driving range of EVs. The control means mainly refer to the control of the vehicle subsystems, such as the braking system, steering system, and active suspension system, which could directly or indirectly reduce the driving energy, and they are generally quick-acting and effective means for improving the driving range of EVs.

2. Dual-Motor Coupling Drive System

The multi-motor coupling drive system (MCDS) is an electrical drive system that incorporates multiple motors coupled through a mechanical structure. This kind of drive system can optimize the working points of each motor by distributing power, torque, and speed among multiple motors to achieve energy conservation. Over the years, the MCDS has received widespread attention due to its energy conservation potential. Since two motors can almost fully release the energy conservation potential of the MCDS and more motors would not significantly improve the energy-saving effect due to possible increases in mass and cost, most of the research on MCDSs in recent years has focused on the dual-motor coupling drive system (DCDS). Therefore, this chapter mainly focuses on the DCDS.2.1. Configuration of DCDS

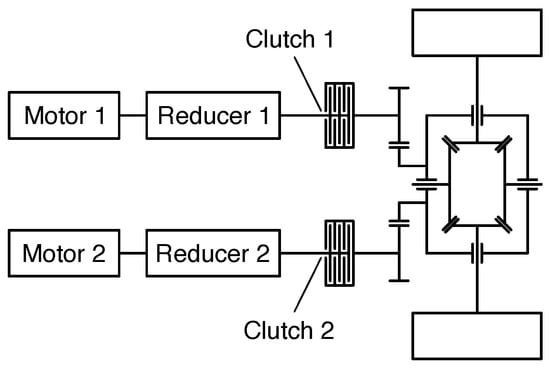

There are three types of DCDSs based on their power coupling patterns: the dual-motor torque-coupling drive system (DTCDS), the dual-motor speed-coupling drive system (DSCDS), and the variable dual-motor coupling drive system (VDCDS). Each type has distinct configurations. A characteristic of the DTCDS is that its output torque is the linear summation of the output torque of the two motors, and its output speed is proportional to the output speed of the two motors. Based on this characteristic, the efficiency of the DTCDS can be improved by distributing the output torque of the two motors to optimize the working points of each motor [5][6][21,22]. For a typical DTCDS, the output ends of the two motors are connected through a specially designed coupler or directly connected to the same element (Figure 1) so that the output torque of the drive system can be transferred freely between the two motors. Moreover, the DTCDS can switch between single-motor driving mode and dual-motor torque-coupling driving mode to reduce the transmission loss caused by the idle rotation of the non-driving motor, which can further improve the energy conservation potential of the DTCDS. This can be achieved through the utilization of clutches and the matching design of mechanical structures such as the reducer and coupler [7][23]. In addition, since torque coupling is the simplest power coupling pattern, the configuration of the DTCDS can be diverse. Broadly speaking, in addition to the typical DTCDS introduced above, the front-and-rear-independent-drive axle is also a kind of DTCDS.

Figure 1.

Schematic of typical DTCDS.

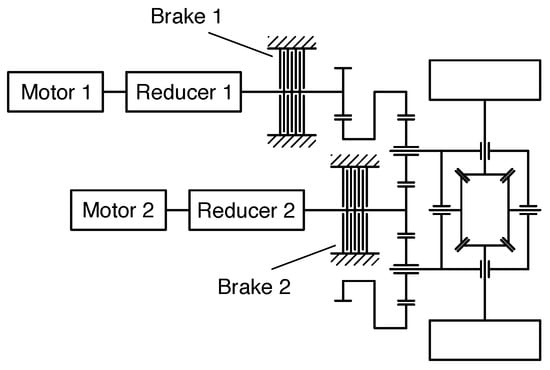

Figure 2.

Schematic of typical DSCDS.

Table 1.

Comparison of DTCDS and DSCDS.

| DCDS Configuration | Coupling Output Torque | Coupling Output Speed | Feasible Driving Modes |

|---|---|---|---|

| DTCDS | Linear summation of the output torque of the two motors | Proportional to the output speed of the two motors | Single-motor drive mode and dual-motor torque-coupling driving mode |

| DSCDS | Proportional to the output torque of the two motors | Linear summation of the output speed of the two motors | Single-motor drive mode and dual-motor speed-coupling driving mode |

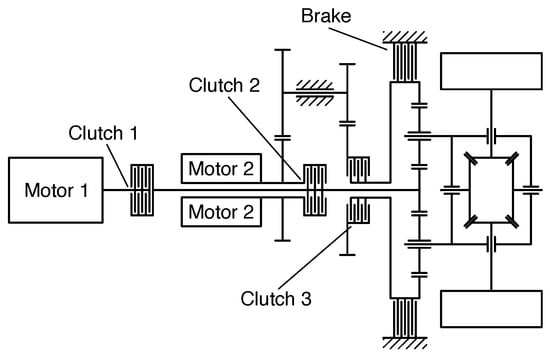

Figure 3.

Schematic of a novel VDCDS.

2.2. Power Distribution Strategy of DCDS

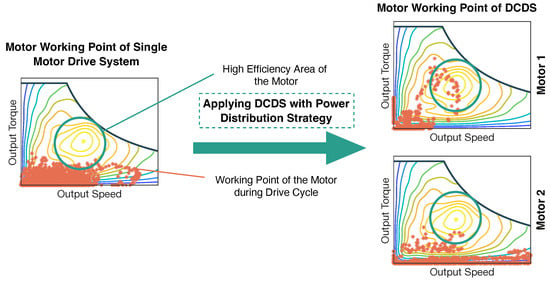

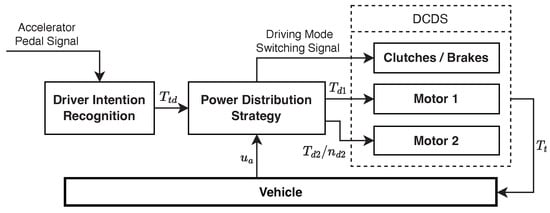

To tap into the energy-saving potential of the MCDS, a power distribution strategy is essential. The primary objective of a power distribution strategy is to optimize the distribution of output power from each motor, which aims to enhance the efficiency of the drive system without compromising its performance. As shown in Figure 4, for the DCDS, the main effect of a power distribution strategy is the optimization of the working points of two motors, resulting in an effective improvement in the load of the motors. This ensures that the working points of the motors can operate more within the high-efficiency area of the motors, thereby improving the driving efficiency of the DCDS.

Figure 4.

Working point optimization schematic of motors with power distribution strategy in DCDS.

Figure 5.

Typical power distribution control system of DCDS.