Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Surekha K Satpute and Version 2 by Conner Chen.

Microbial surfactants as food additives comprise molecules that may be introduced to food in order to confer emulsifying, foaming, thickening, texture-improving, and/or preserving properties, along with the encapsulation of fat-soluble substances such as vitamins (called “direct food additives”).

- antimicrobial

- acute toxicity

- biosurfactants

1. Introduction

The term ‘food additives’ represents the substances that are added to food to retain or preserve and/or improve some physical properties, often taste, texture, freshness and appearance, along with its safety. However, it is additionally imperative to evaluate the food additives themselves for their potential harmful effects on human health before they are utilized for their desired applications. Among several substances available, surfactants are considered as the most multifarious agents explored for varied applications, such as detergents, pesticide application, cosmetics and microbial enhanced oil recovery processes, and the food-processing industry [1][2][3][1,2,3]. Surfactants are obtained from various sources, e.g., petrochemicals, fatty acids, microbial cells, etc. [4][5][4,5]. Some known natural surfactants, such as lecithin from egg yolk and milk proteins, are prominently used in salad dressings and for the enhancement of flavor, appearance, and texture of desserts [6][7][6,7]. The growing interest in surfactants and the identification of appropriate molecules with less toxicity and efficient surface characteristics have been of immense interest for both industrial and scientific communities.

Synthetic surfactants are linked with many health-related issues and drawbacks, among which intestinal dysfunction [8] is reported prominently. Surfactants are used in foods in relatively high concentrations, which might lead to severe intestinal permeability, which in turn may elicit various allergic and autoimmune diseases [9]. Surfactants increase intestinal permeability for a limited time in a precise and recurrent way in the presence of antigens and pathogens. It is crucial to note that there are no acceptable daily intake (ADI) guidelines for the use of surfactants in food production [10]. The ADI guidelines specify the highest amount or the limit of a particular chemical which can be consumed regularly over the period of a life span without any health-related issues or apparent side effects. Demands of green ingredients over synthetic additives (“green label”) have led to extensive research in pursuit of new microbial sources for the production of effective surface-active or emulsifying agents [11][12][11,12].

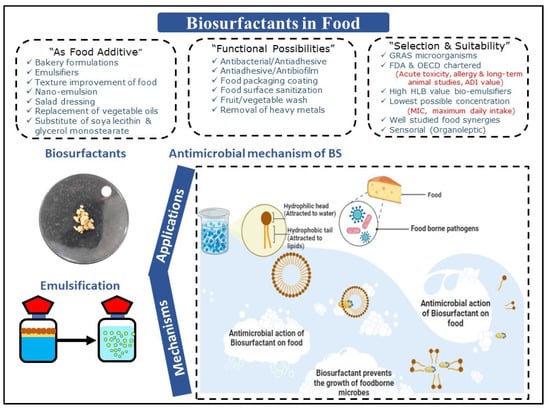

BSs are generally low-molecular-weight compounds with the ability to reduce surface tension noticeably, whereas BEs are high-molecular-weight molecules with efficient emulsifying abilities. BSs represent surface-active compounds of microbial origin. BEs are considered as BSs that are used as emulsifiers; therefore, the term BS is much wider and inclusive of BEs. Multifarious BS/BE molecules confer or provide various functional properties to food, such as emulsifying, additive, foam-forming, and wetting agents, in addition to pharmaceutical-related properties (antimicrobial, antiadhesive, antiviral, antibiofilm, etc.) [12][13][12,13]. Even though BSs and BEs have an unquestionable potential for replacing synthetic surfactants, with huge importance to food industries. Major blockages include high production cost and apprehension regarding their safety. The present research about BSs/BEs in food production is restricted to laboratory conditions, without detailing any assessment regarding their safety and hazard analysis, which has restricted their acceptance for several food-related applications [12][13][14][12,13,14]. It is important to note that committed guidelines for adopting BSs/BEs in food formulations do not exist; however, the recommendations to include them as all-purpose food additives might be accepted, and would grant their primary approval.

2. Biosurfactants as Food Additives

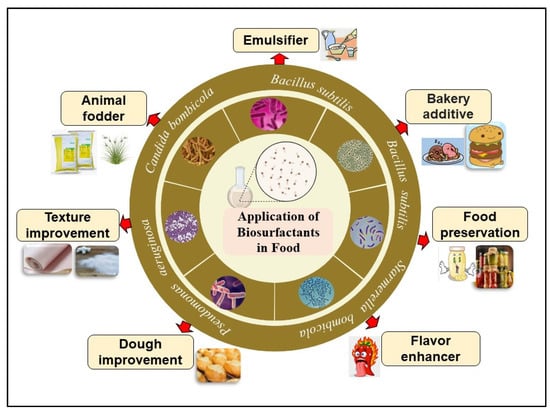

Food additives are compounds or substances that facilitate the enhancement of overall food properties. Since ancient times, some food additives such as salt, sugar, and SO2, have been utilized to preserve meats, fishes, beverages, etc. Currently, the journey of food additives has made huge advances, from kitchens and small factories to the advanced commercial scale. Food additives have been obtained from various natural sources, or synthesized chemically, and added to food items to achieve some positive technological benefits. Thus, food additives should solely serve the intended desired aims of preserving the nutritional quality of food, and not result in any negative effects. Based upon their functional properties, the World Health Organization (WHO) and the Food and Agriculture Organization (FAO) have broadly categorized additive compounds as (1) flavoring agents, (2) enzyme preparations, and (3) other additives. Microbial surfactants as food additives comprise molecules that may be introduced to food in order to confer emulsifying, foaming, thickening, texture-improving, and/or preserving properties, along with the encapsulation of fat-soluble substances such as vitamins (called “direct food additives”). Attributes such as antiadhesive/antimicrobial or food surface cleaning are termed as “indirect food additives” that are fulfilled through packaging, coating, or transport and storage processes. Microbial BSs pose antiadhesive and antimicrobial activity against several pathogens and have been listed in Table 1. BSs may interact with porins (proteins of cross cellular membranes) and may lead to leakage of the cytoplasmic content of the cell, resulting in cell death [13]. However, prior to the inclusion of BSs/BEs in food processing, they must undergo critical toxicological assessment protocols which test synergistic compatibility with food molecules, dosage limit determinations for daily intake, and potential protective effects of their use. Rhamnolipids (RLs) have been reported to improve various properties, such as dough stability, batter texture, and the volume and shape of bakery products [14]. A patent on ‘RLs in bakery products’ emphasizes the improvement of dough characteristics and the volume of bakery products after mixing with RLs [15]. Basically, L-rhamnose is a methyl pentose natural sugar found in varied microbial RLs [16], which is useful as a food additive. Kiran et al. [17] described the BSs of Nesterenkonia sp. for the enhancement of muffin texture. The Nesterenkonia sp. are obligate aerobes, grouped under the genus Micrococci, which grow optimally between 25 and 37 °C. Phylogenetic and chemotaxonomic analysis of isolates showed Kocuria, Kytococcus Dermacoccus, and Nesterenkonia under the genus Micrococcus [18]. Use of Nesterenkonia provides various additional benefits to the muffins, including a decrease in hardness, chewiness and gumminess compared to control treatments in the presence of 0.75% lipopeptide in the preparation mixture. The roles of microbial BSs/BEs (e.g., surfactin, RLs, lipopeptides, glycolipids, and emulsan) as emulsifiers, bakery additives, flavor enhancers, bread improvers, etc., are outlined in Figure 1 and listed in Table 2.Table 1.

Antiadhesive and antimicrobial roles of various microbial-originated biosurfactants against pathogens.

| ANTIADHESIVE | ||||||||||||||||||

| Microorganisms | Biosurfactant | Pathogens | Reference | |||||||||||||||

| Pseudomonas putida | Putisolvin I and II | Pseudomonas | sp. | [19] | ||||||||||||||

| Psedofactin II | Enterobacter faecalis | Proteus mirabilis, Candida | sp. | [20] | ||||||||||||||

| Bacillus subtilis | Fengycin | Salmonella enterica | [21] | |||||||||||||||

| - | Bakery additive | [ | 35] | Bacillus tequilensis | Lipopeptide | Streptococcus mutans | [22 | |||||||||||

| B. subtilis | ] | |||||||||||||||||

| Surfactin | Food preservative | [ | 36] | Candida spaerica | Lunasan | Streptococcus agalactiae | Pseudomonas aeruginosa | [23] | ||||||||||

| Pseudomonas sp. | Rhamnolipid | Dough improvement | [15] | Pseudomonas aeruginosa | Rhamnolipid | Yarrowia | sp. | [24] | ||||||||||

| Pseudomonas aeruginosa | Rhamnolipid | [16] | Candida lipolytica | Rufisan | Streptococcus | sp. | [25] | |||||||||||

| Nesterenkonia sp. | Lipopeptides | Texture improvement | [17] | Serretia marsecens | Glycolipid | Candida albicans | Pseudomonas aeruginosa | Bacillus pumilus | [26] | |||||||||

| Gliocadium virens | ||||||||||||||||||

| [ | ||||||||||||||||||

| Bacillus subtilis | - | Cookie dough | [37] | ANTIMICROBIAL | ||||||||||||||

| 27 | ] | |||||||||||||||||

| Pseudomonas aeruginosa | Rhamnolipids | |||||||||||||||||

| Bacillus subtilis | Lipopeptides | Bread improvement | [38] | Microorganisms | Biosurfactant (MIC µg/mL) |

Pathogens | ||||||||||||

| Candida bombicola | Reference | |||||||||||||||||

| Glycolipids | Cupcake additive | [ | 39] | Pseudomonas aeruginosa | Rhamnolipids (4–64) |

Alternaria alternata | Aureobasidium pullulans | (20–50) |

Alternaria mali | Brotrytis cinerea | Fusarium | sp. | Rhizoctonia solani | [28] | ||||

| Starmerella bombicola | Sophorolipids | Aspergillus niger | Candida albicans | Chaetonium globosum | Sophorolipids + curcumin | [40] | ||||||||||||

| Probiotic | (GRAS) | - | Animal fodder | [41] | Pseudomonas aeruginosa | Rhamnolipids (0.5–1.70) |

Brotrytis cinerea | Fusarium | sp. | Fusarium solani | Gliocadium virens | Penicillium funiculosum | Rhizoctonia solani | [29] | ||||

| Pseudomonas aeruginosa | Rhamnolipids | Brotrytis cinereal | [30] | |||||||||||||||

| Pseudomonas aeruginosa | Rhamnolipids (64–256) |

Brotrytis cinereal | Mucor miehei | Staphylococcus aureus | Bacillus cereus | [31] | ||||||||||||

| Pseudomonas | sp. | Rhamnolipid | Pseudomonas aeruginosa | [32] | ||||||||||||||

Figure 1.

Different roles of BSs/BEs in improving properties of food, including taste, texture, and flavor improvements.

Table 2.

Potential applications of biosurfactant bio emulsifiers in food system.

| FOOD ADDITIVES | ||||

| Microorganisms | Biosurfactant | Applications | Reference | |

| B. subtilis | Surfactants | Emulsifier | [33] | |

| C. utilis | - | Mayonnaise emulsifier | [34] | |

| B. subtilis | ||||

| EMULSIFICATION | ||||

| Microorganisms | ||||

| Biosurfactant type | ||||

| Emulsification material | ||||

| Reference | ||||

| Bacillus vallismortis | Exopolysaccharides | Essential oils | [42] | |

| Pseudomonas fluorescens | Exopolysaccharides | Edible oils | [43] | |

| Nesterenkonia | sp. | Lipopeptide | Unsaturated hydrocarbons | [18] |

| Candida utilis | Glycolipids | Vegetable oil | [44] | |

| Pseudomonas aeruginosa | Rhamnolipids | Saturated hydrocarbons | [45] | |

| Kluyveromyces marxianus | Mannoprotien | Corn oil | [46] | |

| Saccharomyces lipolytica | - | Cooking vegetable oil | [47] | |

| Candida utilis | Glycolipids | Canola oil | [48] | |

| Pseudomonas aeruginosa | Rhamnolipids | Nano-emulsion | [49] | |

Table 3.

HLB value evaluation of different surfactants.

Figure 2.

Applications of biosurfactants/bioemulsifiers in food, including their antimicrobial activities against pathogens.