You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 1 by Ahmed Rezk and Version 2 by Rita Xu.

Water desalination (WD) has been required for the supply of drinking water in a number of countries. Various technologies of WD utilize considerable thermal and/or electrical energies for removing undesirable salts. Desalination systems now rely on renewable energy resources (RERs) such as geothermal, solar, tidal, wind power, etc. The intermittent nature and changeable intensity constrain the wide applications of renewable energy, so the combination of energy storage systems (ESSs) with WD in many locations has been introduced.

- desalination

- renewable energy resources

- energy storage systems

1. Introduction

In the near future, the scarcity of global fresh water is a colossal danger due to serious overpopulation and the pollution of the available fresh water resources of the underground and rivers as a result of industrial waste. One of the most crucial solutions to avoid this danger is a new supply of clean drinking water. Seawater holds almost 97% of accessible water resources, making the use of WD technologies a successful solution to the potable water shortage [1]. In order to confront the rising demand for fresh water for drinking, WD is a technique that effectively removes dissolved salts. The admissible salinity range for potable water, according to the WHO (World Health Organization), is between 500 and 1000 ppm.

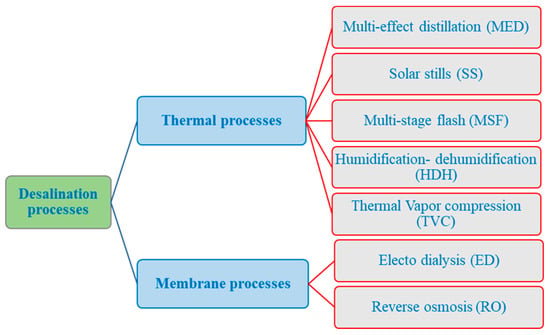

Generally, WD is accomplished either mechanically via membrane distillation or thermally by evaporation of seawater. Otherwise, large-scale WD projects involve a number of risks that should be precisely considered for evaluating the system’s feasibility [2]. The different methods of water desalination processes (WDPs) that are categorized into thermal and membrane are introduced in Figure 1. The thermal process contains humidification–dehumidification (HDH), solar stills (SS), vapor compression (VC), multi-stage flash (MSF), and multi-effect distillation (MED); the membrane techniques include reverse osmosis (RO) and electrodialysis (ED) [3][4][5][3,4,5]. Overall, the thermal WDP share is almost 35% of the global systems, while RO technology contributes nearly 61% [6].

Figure 1. Common water desalination processes.

Generally, the sources of waste heat are fundamentally categorized into low- and high-grade energies. High-grade sources of waste heat are recovered by various plant processes; however, the low-grade sources are not economically viable for recovery, and they are essentially rejected into the environment [7]. Waste heat, either low- or high- grade energy, is the elementary source of thermal energy losses in industrial processes such as the refining of petroleum, petrochemical, beverage and food, pulp and paper, textiles, etc. [8]. Thermal methods of WD systems may be on a large scale coupled with industrial applications based on the utilization of waste heat or small-scale systems integrated with electric heaters based on fossil fuels or renewable energy resources (RERs). Large-scale water desalination plants based on industrial applications, viz., MSF, MED, and RO, with relatively high water productivity were reviewed [9][10][9,10].

Joining both energy and fresh water frameworks can distinguish new options for enhancing the efficiency of the overall resource [11]. Detailed knowledge of the current combination of water and energy in water desalination systems (WDSs) is indispensable, along with a good understanding of key factors involved in decision making to recognize and realize the opportunities for required energy [12]. Water is necessary to refine petroleum products and cool the condensers in power plants. Additionally, energy is required for WD, the treatment of wastewater, purification, conveyance, and pumping for end use [13]. Improved knowledge based on the incorporation of water and energy was presented in many locations across the world [14]. Moreover, the developing issue of a multi-plant accompanying the economical implementation of energy and water was presented [15].

The energy that is demanded to drive WDSs could be supplied from RERs such as solar, wind, tidal energies, etc. One of the most popular technologies of WD is the HDH process. Since HDH systems operate at a modest operating pressure, only minimal mechanical energy is required to circulate air and water using fans and pumps [16]. HDH techniques have several benefits, including the capability to function in low-temperature conditions, ease of construction, cheap initial and operational costs, and integration with sustainable RERs, among others.

Initially, non-renewable-energy-based resources were utilized to obtain desalination systems with 1000 m3 daily of drinking desalinated water by depleting 10,000 tons of oil yearly [17]. These systems increase greenhouse gas emissions, deplete the available limited stores of fossil fuels, and threaten the progress of sustainable development. Therefore, thermal WD technology depends on renewable energy for supplying thermal energy, which has a growing trend to provide abundant advantages compared to traditional energy resources. Solar energy appears to be the appropriate choice to supply the necessary thermal energy, particularly in regions having high solar irradiation and insufficient resources of fresh drinking water [18]. Seawater absorbs solar energy from the sun in thermal WDSs powered by solar energy, and then it evaporates as clean water droplets from the ocean’s surface. Finally, accumulating clouds are condensed, and rain is produced, providing fresh water for drinking.

As a result of the high energy consumption of reverse osmosis (RO) WDSs, which require almost 3–10 kWh of electricity to create 1 m³ of desalinated water, this technology is not sustainable [19]. RO-WDSs function with a nominal load of constant pressure and flow rate of the feed water to the membranes, while a variable operating load of RO-WDSs, i.e., different flow rater and feeding pressures, introduces outstanding results [20]. The benefits of combining wind energy [21] and photovoltaic (PV) panels [22] with RO-WDSs have already been implemented. Both gravitational potential and wind energies were combined in RO-WDSs [23]. Traditional WD processes such as TVC, MVC, and RO are the most commonly employed technologies in industries, whereas hybrid technologies such as MSF-RO [24][25][24,25], MED-adsorption systems [26], MED-RO [27], MED-MSF [28], etc., are developed to augment both the production of fresh water and the thermodynamic synergy.

One of the promising recent technologies for water desalination as well as power generation which have been implemented intensively is pressure retarded osmosis (PRO), which could be beneficial for recycling RO brine [29]. Generally, the PRO process has greatly evolved since 1973 due to the fast advances in membrane technologies. PRO consists mainly of a membrane and a hydro turbine to transfer the hydraulic energy into electric energy. It has a unique characteristic in which the waste stream can be reused as a feed supply into the PRO system. Initially, the fundamental challenge faced by the development of PRO techniques was to select a suitable membrane with reasonable mechanical stability, high salt rejection, and high permeability of water [30][31][30,31]. This method has a number of advantages according to its commercialization, such as operation throughout the day; not being affected by RESs, viz., wind and solar radiation; requiring a small footprint, etc. The descriptions of thermal and membrane WD technologies are introduced in Table 1.

Table 1. Descriptions of thermal and membrane WD technologies.

| Technology | Thermal | Membrane | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mechanism | Evaporation and condensation. |

▪ Relatively low cost.

▪ Effective in different applications.

▪ Appropriate for synthetic oil fluid.

| Pressure and concentration gradient driven. | |||||||

|

▪ Temperature reduction is necessary for heat transfer.

▪ Molten salts freeze around 120–230 °C.

|

|

Large-scale units for MED, MVC, MSF, and RO. | Applications | HDH, SS, TVC, MED, MSF. | ED, RO. | ||||

| Solid-state sensible heat materials |

▪ Proper for synthetic oil fluid.

|

| ▪ Effective in various industrial applications.

▪ Convenient for superheating and pre-heating in direct generation of steam.

|

|

▪ Not proper for condensation/ evaporation in steam collectors.

|

|

Large-scale usage of MED, MVC, MSF, and RO. | Operating temperature | 60–120 °C. | Less than 45 °C. |

| Driving force | Gradient of concentration and temperature. | Gradient of temperature and pressure. | ||||||||

| Form of energy required | Steam, waste heat, renewable energy, and limited mechanical power for the pumping processes. | Prime fossil energy or renewable-energy-driven power. |

2. Desalination Systems Based on Renewable Energy Resources

Renewable energy is accessible everywhere, which makes it an effective alternative to depleted fossil fuels. Renewable energy is becoming continuously reliable, with decreasing costs year-on-year; therefore, renewable energy is a practicable choice in different regions. With the rising demand for desalinated drinking water, renewable-energy-powered WDSs have a massive worldwide potential market [32]. The dependence on depleted fossil fuels for WDSs continues, since they are the most reliable energy form and cost-effective. However, developing WDSs based on fossil fuels has a number of challenges, i.e., high energy demand and emissions of CO2. There is considerable potential in integrating WD technologies with RERs, by supporting technically and funding feasible renewable energy systems. Sustainable WD schemes are technically feasible for producing remarkable amounts of desalinated water using the available RERs [33]. When compared to traditional fossil-fuel-powered WDSs, the combination of WDSs and RERs has been discovered as a more sustainable, desirable, and financially feasible choice. A global analysis of utilizing solar energy for WD was conducted [34].

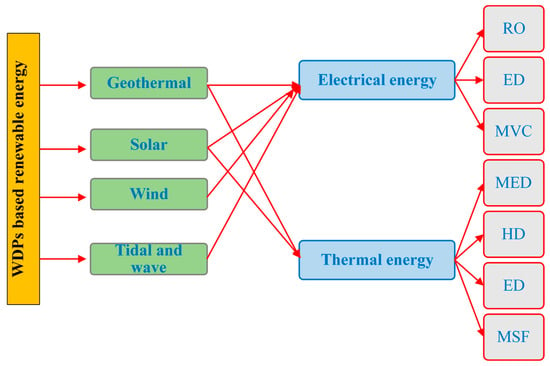

Recent advancements in WD technologies contribute to lowered cost, affordability, and higher efficiency. In recent years, energy consumed by WDSs based on RERs has been significantly reduced. Utilization of RERs such as solar, geothermal, wind, tidal, etc., for WDSs appears to introduce sustainable alternatives. Figure 2 illustrates the various paths through which common RERs may be employed to drive various WDS processes. The WD technology should be integrated with proper RERs, having the ability to use the available RERs effectively.

Figure 2. Possible pathways for renewable-energy-driven WD techniques.

3. Energy Storage for Water Desalination

The fundamental issue with RERs for WDSs is their intermittent discontinuous form and intensity, which restrict their widespread applicability in a variety of sites. In addition, the costs associated with the technologies of WD based on RERs are another major barrier to the successful implementations of these available and sustainable RERs. Energy storage technologies that could improve the performance of RERs for WDSs aid in improving the intermittent behavior of RERs and may enhance the long-term sustainability of WDS investment. WD technologies powered by thermal energy may employ the storage units known as TES to capture, store, and then release energy to correspond to the trends of energy demand and supply. TES could be combined with readily available energy supplies, whether waste heat or renewable energy [35]. From thermodynamic aspects, the heat capacity of storage materials is proportional to their specific heat, volume, density, and operating temperature difference [36].

The functions of TES units include charging, storing, and discharging [37]. TES in WDSs can be implemented by diverse principal methods: sensible TES, using either solid or liquid materials; phase-change/latent energy storage; and thermochemical energy storage. Sensible TES is accomplished via the fundamental modes of heat transfer, i.e., convection, conduction, and radiation, whereas phase-change heat storage materials are known as latent-heat-storing materials. Usually, the solid–liquid phase is highlighted, whereas liquid–solid phase change involves solidification/melting for discharging/charging processes. It is a cyclical process that demonstrates the durability and thermal stability of a material as a thermal storage medium [38].

Sensible heat storage (SHS) materials for WDSs are superabundant in nature, making them convenient, economical, and accessible, whereas latent heat storage (LHS) material increases nocturnal production of fresh water [39]. TES can store and transport with the working fluids associated with operating parameters such as pressure and temperature. According to the availability of thermal resources, the working medium’s capacity to store thermal energy determines its suitability for use. One of the auspicious materials for TES systems is phase-change material (PCM); however, the commonly employed PCMs have limited thermal conductivity. However, nanotechnology uses a highly efficient thermal system to enhance the functionality of the TES system and is suitable in terms of the efficiency of the recovery process, financial feasibility, and environmental aspects. Thus, raising the thermal conductivity of PCM composites via different nanoparticles is an encouraging option for improving thermal performance. Table 2 lists the benefits and drawbacks of the various TES system types.

Table 2. Characteristics of TES systems.

| Thermal Energy Storage | Advantages | Disadvantages | Desalination Applications | ||||

|---|---|---|---|---|---|---|---|

| Liquid-state sensible heat materials |

▪ High storing capacity. | ||||||

| Phase-change material (PCM) |

▪ Latent heat storing enables heat transfer at constant temperature.

|

| ▪ Available material.

▪ Convenient for evaporation and condensation process.

|

|

▪ Not suitable for superheating and pre-heating.

▪ Quite early stage of development.

|

|

Large-scale usage for MSF, MED, RO, and MVC. |

| Water/steam |

▪ Latent heat storage (LHS) enables heat transfer at constant temperature.

▪ Low material requirements.

▪ Convenient for both evaporation and condensation processes.

|

|

▪ Not suitable for superheating and pre-heating.

|

|

Large-scale units. | ||

| Hot water |

▪ Low cost for storing process under 100 °C.

▪ Effective in different industrial usage.

|

|

▪ Sensible heat storing needs a temperature drop.

▪ Not proper for power generation.

|

|

Solar still, HDH, membrane distillation and low-temperature processes. |

In the last decades, the prompt growth in heat capacity of various RERs requires further advancements in ESSs that can store the excessive rise in energy capacity. The quantity of energy stored by SHS material is directly impacted by the temperature differential between the storage medium at the inflow and outflow, the mass flow rate, and the storage medium’s heat capacity [40]. Depending on the medium temperature, the stored energy inside the TES system may be utilized for diverse purposes. Low-temperature applications of WD are suitable for energy resources with a temperature range of 60–80 °C, whereas other industrial processes and the production of electrical power require energy resources with a temperature range of 100–400 °C [41]. Sensible heat TES systems using water as a working medium can store energy under the boiling water temperature; as a result, only WD at low temperatures, such as that in solar stills, multi-effect evaporation systems, membranes, HDH-WDSs, etc., may use them. On the other hand, liquid salt materials or solid-state materials can store high-grade thermal energy within a 200–500 °C temperature range, which is ideal for electric power generation integrated with WDPs, such as multi-effect evaporation of MED, MSF, and M/TVC.

The unavoidable fluctuations of various RERs such as solar, wind, and others, make it exceedingly difficult to connect these systems with cooling/heating needs and client electricity demands. Therefore, massive research has investigated different technologies of ESSs, both thermal and electrical, to fulfill more stability of power supply for WDSs [42]. Furthermore, implementing convenient energy technology can create significant challenges for establishing grid stability; thus, energy storage of excess RER output is critical for voltage and power balance. Electricity storage is required for backup generation, frequency control, load balancing, peak shaving, and thermal energy management.

In addition, the power demand of WDSs does not permanently and conveniently match the electrical power supply; therefore, suitable ESSs are requisite for a reliable power supply. Recently, the most convenient devices for storing electricity have been batteries that supply electricity periodically as needed. However, the batteries emit toxic harmful substances during malfunction situations and at disposal times [43]. Batteries are promising techniques for storing electrical energy. Recent advances in battery technology promise practical energy storage with low self-discharge rates and high energy densities (gravimetric and volumetric) [44]. Batteries are required in WDSs driven by RERs, to prevent the inevitable dumping of energy and elevate the running period for producing fresh water. However, these batteries are costly and have a limited lifespan.

As a result of extensive progress in RERs, traditional ESSs such as batteries cannot counter the requirements of energy storage, particularly when the grid connection is not accessible. Flow batteries introduce a promising solution for the high density of energy and lifetime [45][46][45,46]. In spite of this, their application is accompanied by high cost due to the issues related to the materials and technical circumstances that should be solved prior to the commercialization of the product [47]. Accordingly, innovative methods are required to find methods of effective energy storage, such as electrolyzer/fuel cell cycle systems [48][49][48,49].