Throughout the history of human development, sea transport has been widely exploited for the movement of passengers and cargo in many nations, especially in archipelagic countries. Although sea passenger transport has gradually diminished over the past two decades, in part because of rapid developments in aviation and road transport, passengers continue to use cruises or ferries as the main means of transport for different purposes.

Throughout the history of human development, sea transport has been widely exploited for the movement of passengers and cargo in many nations, especially in archipelagic countries. The sea passenger transport has gradually diminished over the past two decades, in part because of rapid developments in aviation and road transport, passengers continue to use cruises or ferries as the main means of transport for different purposes.

- ferry

- navigation

- safety

1. Introduction

2. An Overview of Ferry Transportation in Taiwan

Recent years have seen an increase in cross-Taiwan Strait communications. Travel between Mainland China and Taiwan has increased at an 8 percent average annual growth rate between 2010 and 2018 [13][11]. As shown in Figure 1, currently there are four major ferry routes: (1) Tapie-Pingtan managed by the Lina Wheel (LW), (2) Keelung-Matsus/Dongyin served by Taiwan Horse Star (THS), (3) Kaohsiung-Penghu operated by Tai-hua Wheel (THW), and (4) Taichung-Pingtan operated by the Strait (ST). The specifications of each ferry are also exhibited in Table 1. In addition, there are a few minor ferry routes between Hualien and Suao, including Taitung port, Orchid Island, and Green Island.

| Ferry |  |

|

|

|

|

|---|---|---|---|---|---|

| Ship Profile | |||||

| Ship’s name | Tai-Hua Wheel (THW) | Taiwan Horse Star (THS) | Lina Wheel (LW) |

Strait (ST) |

|

| Build year | 1989 | 2015 | 2007 | 2006 | |

| Weight (tons) | 8134 | 4958 | 10,712 | 6556 | |

| Length (m) | 120.00 | 104.60 | 112.60 | 97.22 | |

| Width (m) | 19.30 | 16.00 | 30.50 | 26.60 | |

| Speed (knots) | 22 | 21 | 40 | 38 | |

| Passengers | 1150 | 580 | 800 | 750 | |

| Crew | 21 | 19 | 22 | 22 | |

| Operating route | Kaohsiung-Penghu | Keelung-Matsu | Taipei-Pingtan | Taichung-Pingtan | |

| Operated by | Taiwan Navigation Company | Taima Star company | Lina Travel agency | Strait Express | |

3. The Risk Factors of Navigation Safety

According to the European Union’s 2008 Safety Research Plan: Safer EURORO Report [14][12], the RFs for ferry safety were classified into four dimensions, including humanware, hardware, software, and environment [14][12]. Based on this framework, numerous navigation-related studies have been conducted. Organizational factors, environmental conditions, human mistakes in safety management, and other possible RFs for marine transportation have been identified in recent research [15,16,17][13][14][15]. People are often injured or killed, and the environment is often polluted as a result of these RFs. As a result, maritime operators and academics have paid particular attention to how to deal with these RFs in order to ensure maritime navigation safety [18][16]. Accordingly, wresearchers depend on previous research and IMO criteria for maritime navigation safety in this work. Based on Safer EURORO’s framework [14][12], this research focuses on the following four key safety evaluation factors for ferry transport: crew factor, ship hardware, ship management, and company management.3.1. Crew Factor (CF)

Relevant studies have indicated that human error is the primary cause of marine accidents, including personal knowledge, skills, talents, attitude, working drive, and awareness [19][17]. For example, human error was shown to be the root cause of more than 80% of shipping-related incidents [20][18]. Human error was to blame for 79% of European maritime disasters between 1981 and 1992 [21][19]. As a result, human error is responsible for over 79 percent of towing vessel groundings [22][20], almost 26 percent of fire and explosion incidents [23][21], and approximately 30 percent of onboard fires/explosions. There are internal and external components to the errors in terms of the crew members that could be differentiated. Internal human error can be attributable to work stress, knowledge, self-discipline, or crews’ perceived fatalism [24,25][22][23]. Conversely, external human error could be caused by the working environment (i.e., unclean workplace, noise, or pilotage-related deficiencies [18][16] or a harsh natural environment [16][14], which makes crew members lack foresight and concentration in their duties. Likewise, other onboard mistakes by crew members that could affect maritime operational safety include misjudgment and misunderstanding [21][19], inadequate technical knowledge [16][14], a lack of knowledge about the ship system [3][1], fatigue, poor rescue communication [16,21][14][19], or a lack of awareness of survival procedures [10][8]. It is argued that a crew member’s ability to respond professionally to shipping accidents is able to restrict a mass loss of property and life [11][9]. To sum up, passenger ferry safety assessments must take into account the importance of the crew factor.3.2. Ship Hardware (SH)

One of the most important variables in marine navigation safety is the condition of a ship’s mechanical equipment. Related studies indicated that ship accidents caused by mechanical failure range from 10% to 51% of total accidents [8][6]. In addition, ship structure is shown to be a critical factor in marine transportation’s overall safety. The general engineering and technical system, strength and stability, power and propulsion, and maneuverability are the four pillars of shipbuilding excellence [11][9]. Furthermore, studies have shown the importance of onboard equipment, such as excellent radio communication, nautical lights and searchlights, and the radar system [16][14], in ensuring ship navigational safety. Vessel operators should pay more attention to some ship equipment failures to reduce the potential risks, such as broken mooring lines, rusted bolts, damaged gas detectors, and crippled exhaust fans [19][17]. Additionally, other onboard rescue equipment, such as lifeboats, lifejackets, fire extinguishers, and seat belts [8[6][8][13][16],10,15,18], and communications systems, such as the Automatic Identification System (AIS), Very High Frequency (VHF) radios, and even the Ship Security Alert System (SSAS) for security, have also been demonstrated to be an indispensable part of marine navigational safety practices.3.3. Ship Management (SM)

Ship management is an essential part of maintaining and operating boats in a safe and efficient manner, as well as for minimizing the risk of accidents and mishaps. Since 1998, the maritime sector has used the International Safety Management (ISM) code to standardize ship management. This code mandates that ship operators follow standard operating procedures (SOPs) in order to optimize operational efficiency and minimize risk. In addition to crews’ abilities and expertise, the process of managing crew members onboard is widely considered to be an important aspect of increasing ship safety operations, such as crew working hours, workloads, and job allocations [26][24]. Furthermore, organizing regular exercise and periodic training programs are manifested to be a crucial part of marine risk-prevention strategies for major shipping lines such as COSCO and Yang Ming. On top of that, working on vessels requires a “team effort”; in other words, a “one-man-show” cannot operate the whole vessel effectively and efficiently. It is evident that good interpersonal relationships among seafarers, which enable them to coordinate and cooperate in the workplace, are important for performing operations smoothly and safely on board. Comprehensive maritime accident analyses also found that the lack of team training and poor communication between crews and third parties are prone to major accidents [18][16].3.4. Company Management (CM)

The process of company management is an important aspect that is crucial to optimizing ferry navigation and improving ferry operators’ business performances. For the role of company management in ferry navigation safety, the responsibilities delegated to an executive cover two categories: technical management and crew management. Arguably, technical management services, such as arranging and supervising dry dockings, repairs, alterations, and maintenance, ensure that the vessel’s machinery maintains a particular standard of operation and safety. In recent years, crew management has received more attention as an imperative facet of estimating the risks of maritime transportation. In practice, crew management for shipping companies mainly includes the development of safety procedures [3][1], crew manpower planning [26][24], and safety training systems [11][9]. On top of this, regulatory actions [19][17]; certification counterfeiting; poor inspection [18][16], incentive and punishment mechanisms [26][24]; and crew recruitment processes [3][1] are also a few of the numerous factors that affect ship navigation safety.4. Risk Matrix

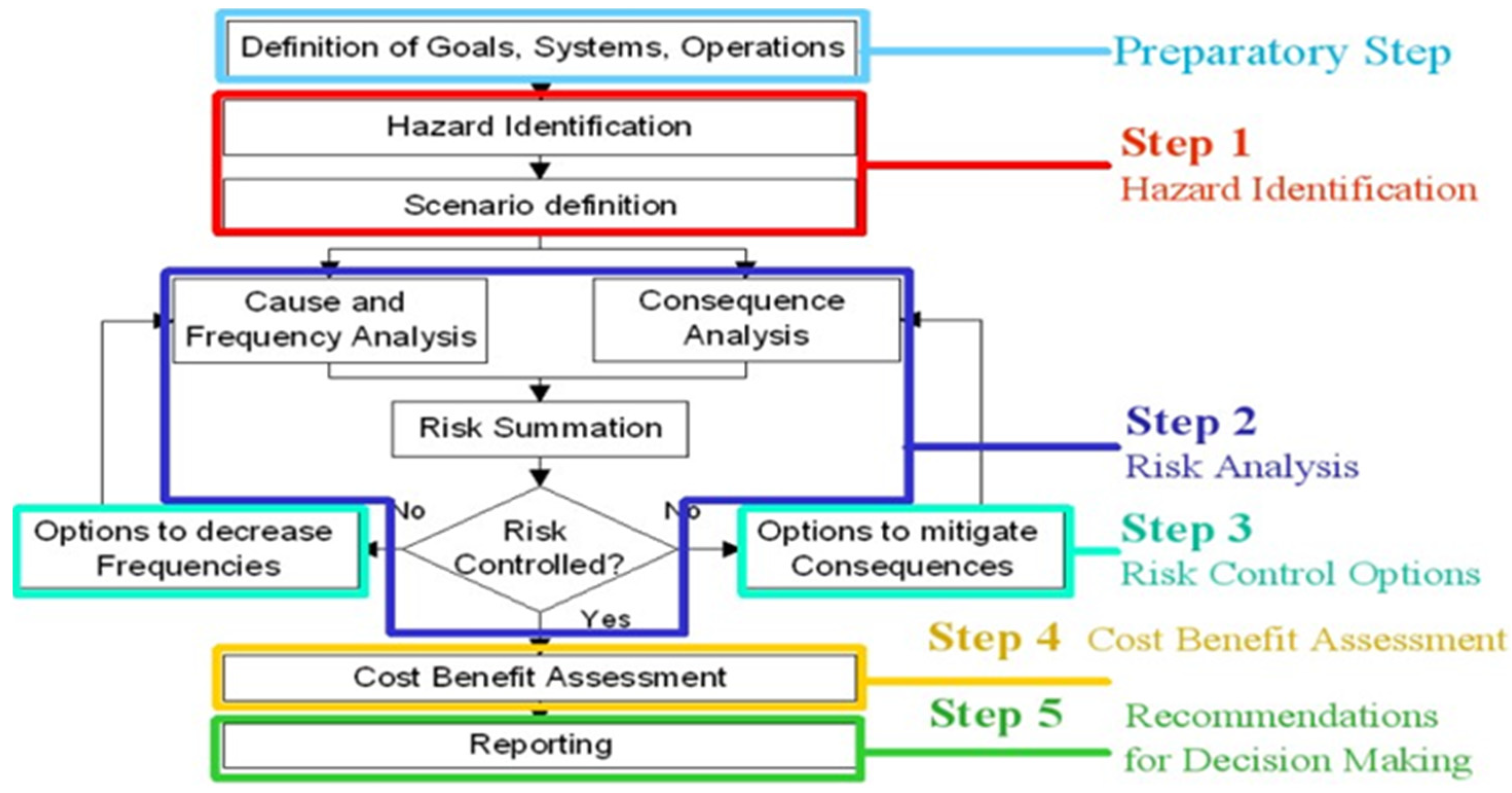

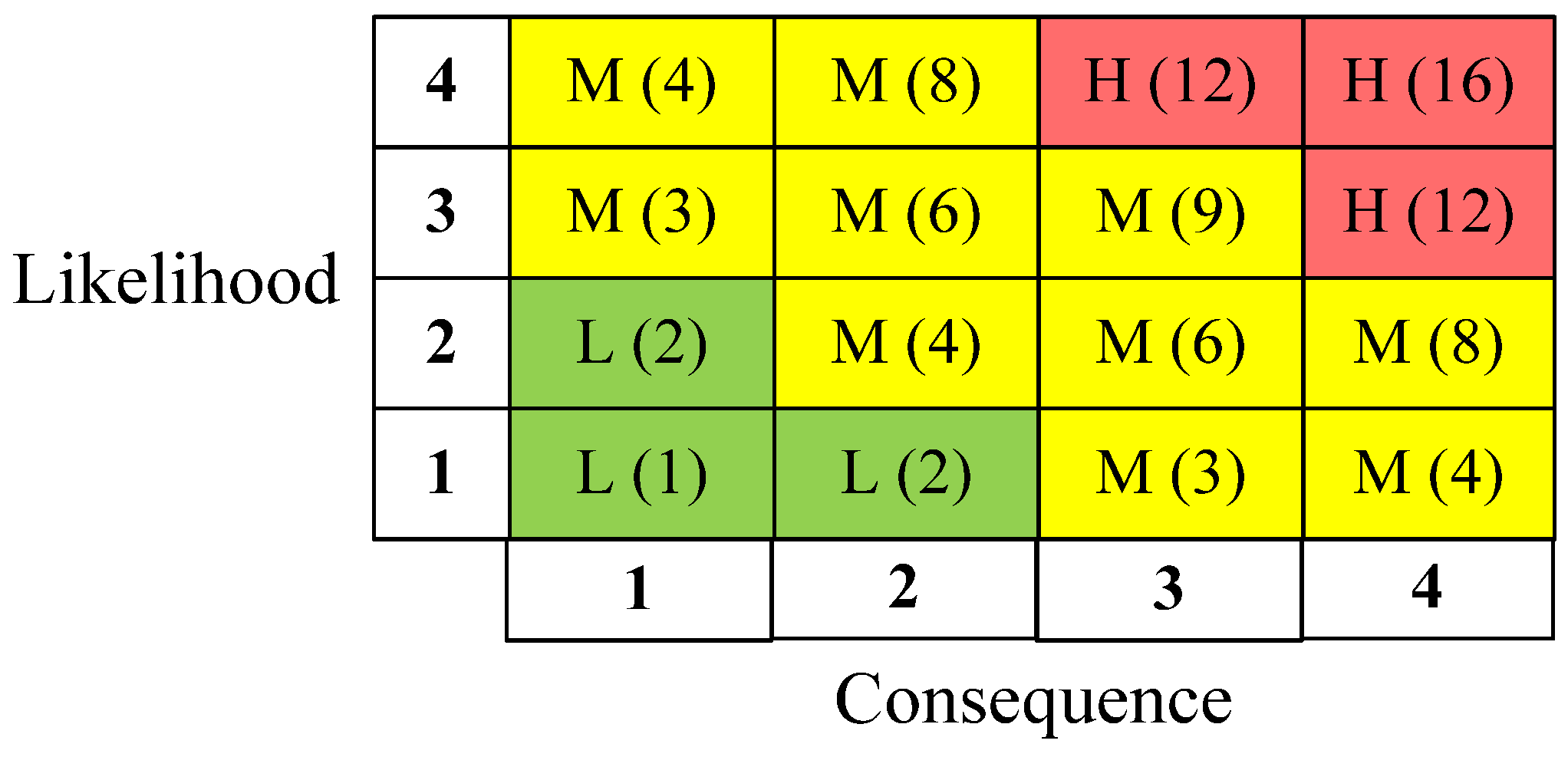

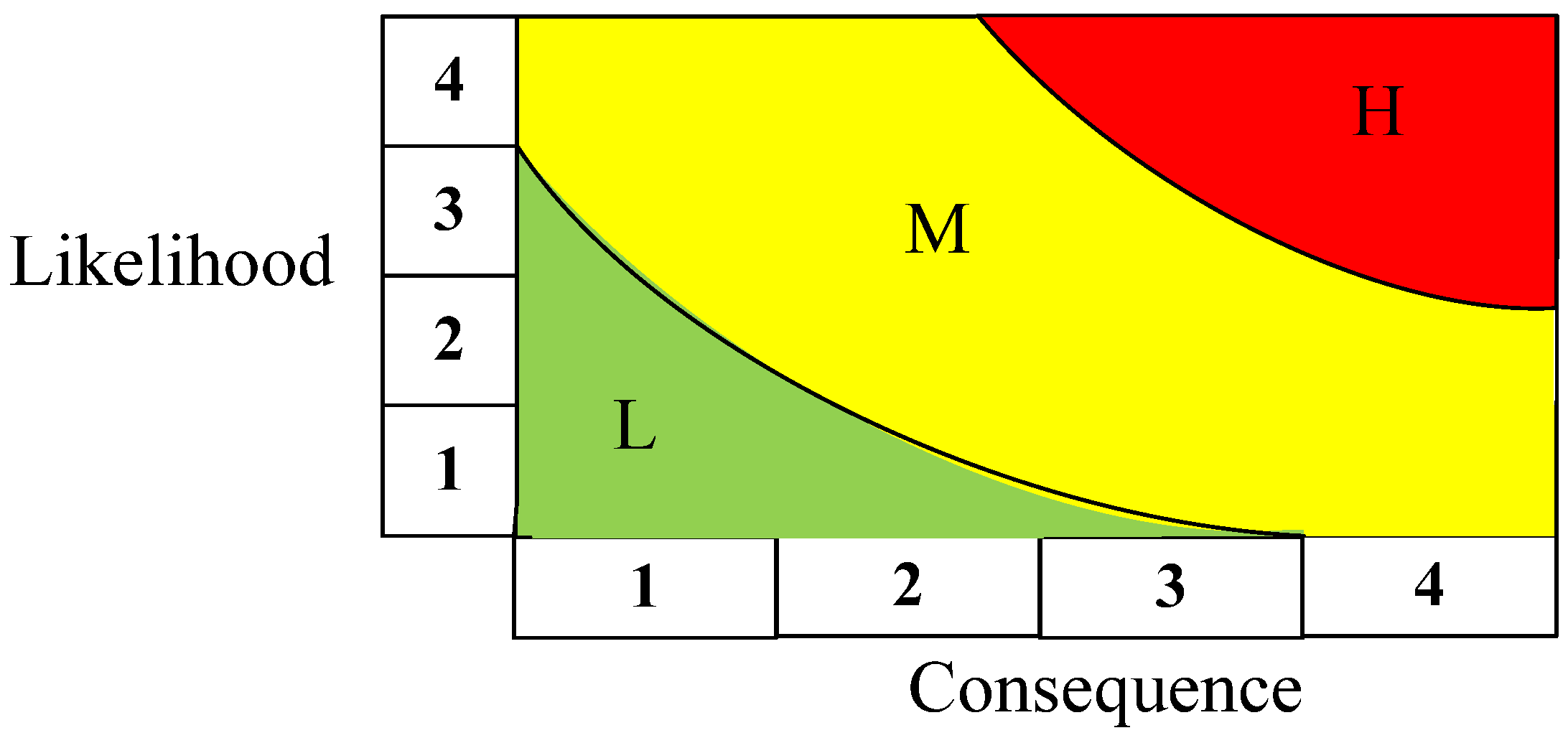

To improve maritime safety, the International Maritime Organization (IMO) proposed the Formal Safety Assessment (FSA) procedures to assess safety risks [27][25]. The process, shown in Figure 2, includes five steps: (1) hazard identification, (2) risk analysis, (3) risk control options, (4) cost-benefit assessment, and (5) recommendations on decisions [28][26]. In tThis article, the he hazard is defined as any accident that endangers the navigation safety of a ferry. Since the FSA procedure includes complete and concrete implementation steps, it was widely applied in many workplaces of safety management, including maritime transportations [25,26[23][24][27],29], container terminals [28][26], airfreight transportations [12][10], etc.

References

- Della, R.H.; Lirn, T.C.; Shang, K.C. The study of safety behavior in ferry transport. Saf. Sci. 2020, 131, 104912.

- Todd, D. The World Shipbuilding Industry, 1st ed.; Routledge: London, UK, 1985.

- BCC NEWS.Congo River: At Least 60 Drowned after Boat Capsizes. Available online: https://www.bbc.com/news/world-africa-56082260 (accessed on 5 March 2022).

- NORTHEST NOW. Bangladesh Ferry Capsize Toll Rises to 34. Available online: https://nenow.in/neighbour/bangladesh-ferry-capsize-toll-rises-to-34.html (accessed on 30 March 2022).

- Wikipedia. Sinking of MV Sewol 2022. Available online: https://en.wikipedia.org/wiki/Sinking_of_MV_Sewol (accessed on 30 March 2022).

- Ung, S. Navigation Risk estimation using a modified Bayesian Network modeling-a case study in Taiwan. Reliab. Eng. Syst. Saf. 2021, 213, 107777.

- Mia, M.J.; Uddin, M.I.; Awal, Z.I.; Abdullah, A. An era of inland water transport accidents and casualties: The case of a low-income country. J. Int. Marit. 2021, 5, 32–39.

- Lau, Y.Y.; Lu, C.S.; Weng, H.K. The effects of safety delivery and safety awareness on passenger behaviour in the ferry context. Marit. Policy Manag. 2021, 48, 46–60.

- Lu, C.S.; Tseng, P.-H. Identifying crucial safety assessment criteria for passenger ferry services. Saf. Sci. 2012, 50, 1462–1471.

- Hsu, W.K.; Huang, S.H.S.; Tseng, W.J. Evaluating the risk of operational safety for dangerous goods in airfreights–A revised risk matrix based on fuzzy AHP. Transp. Res. D. Transp. Environ. 2016, 48, 235–247.

- National Development Council. Taiwan Statistical Data Book; damit Erscheinen Eingestellt: Taipei, Taiwan, 2019.

- Safer EURORO Report, Design for Safety: An Integrated approach to Safe European RoRo Ferry Design 2008. Available online: http://research.dnv.com/skj/safereuroro/safer_euroro_1_final.pdf (accessed on 30 March 2022).

- Hsu, W.K. Ports’ service attributes for ship navigation safety. Saf. Sci. 2012, 50, 244–252.

- Khan, B.; Khan, F.; Veitch, B.; Yang, M. An operational risk analysis tool to analyze marine transportation in Arctic waters. Reliab. Eng. Syst. Saf. 2018, 169, 485–502.

- Zhang, M.; Zhang, D.; Yao, H.; Zhang, K. A probabilistic model of human error assessment for autonomous cargo ships focusing on human–autonomy collaboration. Saf. Sci. 2020, 130, 104838.

- Kececi, T.; Arslan, O. SHARE technique: A novel approach to root cause analysis of ship accidents. Saf. Sci. 2017, 96, 1–21.

- Mutmainnah, W.; Bowo, L.; Sulistiyono, A.; Furusho, M. Causative chaindifference for each type of accidents in Japanese Maritime Traffic Systems (MTS). Mar. Navig.—Proc. Int. Conf. Mar. Navig. Saf. Sea Transp. 2017, 11, 489–494.

- Bowo, L.P.; Furusho, M. Human error assessment and reduction technique for marine accident analysis: The case of ship grounding. Trans. Navig. 2018, 3, 1–7.

- de Osés, F.X.M.; Ventikos, N.P. A Critical Assessment of Human Element Regarding Maritime Safety: Issue, Planning, and Practice. 2003. Available online: https://www.researchgate.net/publication/33421049_A_Critical_Assessment_of_Human_Element_Regarding_Maritime_Safety (accessed on 30 March 2022).

- Dhillon, B.S. Transportation Systems Reliability and Safety, 1st ed.; CRC Press: Boca Raton, FL, USA, 2019.

- Mutmainnah, W.; Furusho, M. 4M Overturned Pyramid (MOP) Model Utilization: Case Studies on Collision in Indonesian and Japanese Maritime Traffic Systems (MTS). Mar. Navig.—Proc. Int. Conf. Mar. Navig. Saf. Sea Transp. 2016, 10, 257–264.

- Havold, J.I. Safety culture and safety management aboard tankers. Reliab. Eng. Syst. Saf. 2010, 95, 511–519.

- Hsu, W.K.; Lian, S.J.; Huang, S.H. Risk assessment of operational safety for oil tankers-a revised risk matrix. J. Navig. 2017, 70, 775–788.

- Hsu, W.K.; Huang, S.H.; Yeh, R.F. An assessment model of safety factors for product tankers in coastal shipping. Saf. Sci. 2015, 76, 74–81.

- Kontovas, C.A.; Psaraftis, H.N. Formal safety assessment: A critical review. Mar. Technol. SNAME News 2009, 46, 45–59.

- Hsu, W.K.; Huang, S.H.; Wu, S.W. A 3D continuous risk matrix for risk assessment of operational safety in inland container terminals. Proc. Inst. Mech. Eng. M J. Eng. Marit. Environ. 2022, 236, 315–325.

- Hsu, W.K.; Kao, J.C. The safety of ship berthing operations at port dock—A gap assessment model based on fuzzy AHP. Int. J. Marit. Eng. 2017, 159, A377–A392.