1. Biological Processes for Hydrogen Production

The various biological processes used for the production of hydrogen can be classified into photosynthetic processes, fermentative processes and processes with microbial electrolysis cells (MECs). Photosynthetic processes (direct and indirect biophotolysis) are biological processes in which solar energy is used to drive water-splitting photosynthesis and to generate hydrogen from the energy-rich electrons produced in the process by photosynthetic microorganisms (green algae, cyanobacteria)

[1][2]. The MEC process is a biological hydrogen production process in which a hydrogen evolution reaction is catalyzed by electroactive bacteria in the presence of anaerobic conditions

[2][27]. Anaerobic fermentation is one of the most commonly used processes for biohydrogen production from waste substrates

[3][16]. Depending on the types of microorganisms used and whether they require light to maintain their life cycle, fermentation processes can be divided into photo-fermentation, dark fermentation and processes integrating photo- and dark fermentation

[4][28].

2. Microbiology of Biohydrogen-Producing Systems

The biological processes of biohydrogen production are directly influenced by the process conditions, which must meet the requirements for microbial growth. These processes are catalyzed by microorganisms under optimal environmental conditions. The characteristics of these microorganisms differ greatly depending on the substrate and the process conditions

[5][15]. When substrates with high organic content are used for biohydrogen production, such as industrial wastewater and waste activated sludge, the leading biological method is the process of dark fermentation, which is discussed in this section.

In order to realize the two main advantages of waste management and energy generation—or the principle of “waste-to-biohydrogen”—organic waste is preferred as the substrate for hydrogen production via the fermentation process. Real waste samples typically contain complex compounds, such as polysaccharides, proteins and lipids. As polysaccharides can be more easily converted to hydrogen, a high hydrogen yield can be obtained, while proteins and lipids have lower energy conversion efficiency. However, they are essential for microbial growth

[6][13]. The most favorable condition for biohydrogen production from different types of organic waste is a high concentration of soluble substrate. Mesophilic conditions are also preferred because they require lower temperatures and lower energy consumption compared to thermophilic conditions. An acidic pH, which can be maintained without the addition of chemicals, increases the attractiveness and environmental sustainability of this process. In addition, the short residence time means a smaller reactor volume, which helps to reduce the capital and operating costs of the process

[7][29].

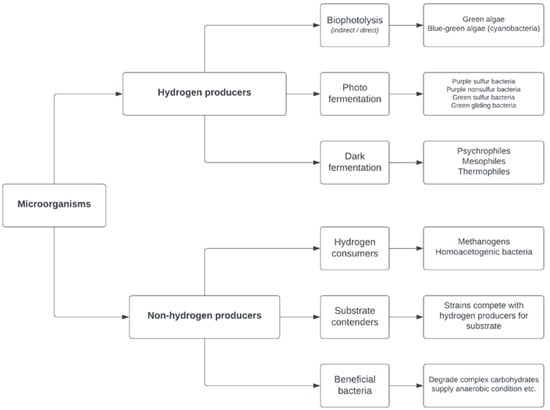

The microorganisms present in biohydrogen-producing systems can be defined as hydrogen producers or non-hydrogen producers (

Figure 1). In terms of their hydrogen-producing metabolism, hydrogen producers can be classified as photosynthetic microorganisms or fermentative microorganisms (photo-fermentation—e.g.,

Rhodobacter,

Chromatium; and dark fermentation—e.g.,

Clostridium,

Enterobacter,

Citrobacter). Hydrogen-producing systems are heterogeneous and interacting ecosystems. In addition to the dependence of the biohydrogen yield on the hydrogen producers, other microbial groups also contribute to the essential functionality of the ecosystem. Microorganisms that are not able to produce hydrogen are categorized as non-hydrogen producers, with the three subgroups of hydrogen consumers, substrate contenders and beneficial bacteria. The undesirable microbial group of hydrogen consumers can reduce the efficiency of biohydrogen production systems due to their consumption of the produced hydrogen and their forming of methane or acetate. Substrate contenders compete with hydrogen producers for the substrate and in this way negatively influence the biohydrogen yield

[6][13].

Figure 1.

Microbial groups present in hydrogen-producing systems.

Beneficial bacteria are precursors in hydrogen-producing systems that positively contribute to ecosystem sustainability. They assist in different mechanisms, such as oxygen consumption, pH regulation, substrate hydrolysis, cometabolism and cell granulation

[8][30]. Depleting oxygen traces in hydrogen-producing systems is a key part of sustaining anaerobic conditions, which are mandatory for the growth of strict anaerobic bacteria, such as

Clostridium. Facultative anaerobic microorganisms, such as bacteria from the genus

Bacillus and

Klebsiella sp., have the main roles in oxygen depletion

[8][9][30,31]. Some microbial species—for instance,

Streptococcus sp.—can contribute to the aggregation of microbial biomass in the reactor, resulting in the retention of microbial cells, which prevents biomass washout and increases resistance to undesirable operating conditions

[6][8][13,30].

A biohydrogen production system consists of complex microbial communities that rely on microbial interactions to create a stable and functioning ecosystem. From an engineering perspective, the production of hydrogen as a desired product can be achieved if the ecosystem is properly managed.

3. Role of Microorganisms in Dark Fermentation Process

The dark fermentation process is the most widely studied fermentation process for the utilization of waste materials. In this process, hydrogen-producing microorganisms can use organic fractions of waste materials as a source of carbon and produce biohydrogen without light and oxygen. The production of biohydrogen through dark fermentation has several advantages, such as a high production rate, the ability to efficiently use a variety of organic waste substrates, sustainability

[10][11][32,33] and no requirement for light energy

[12][34]. The disadvantages of the dark fermentative process include the accumulation of hydrogen in the fermentative system, which can lead to inhibition of bacterial metabolism

[13][35], and the relative sensitivity of the hydrogenate enzyme in dark-fermentative bacteria to oxygen, which can lead to lower hydrogen yields

[14][36]. Microorganisms involved in the dark fermentation process belong to the groups of facultative anaerobic bacteria or obligate anaerobic bacteria.

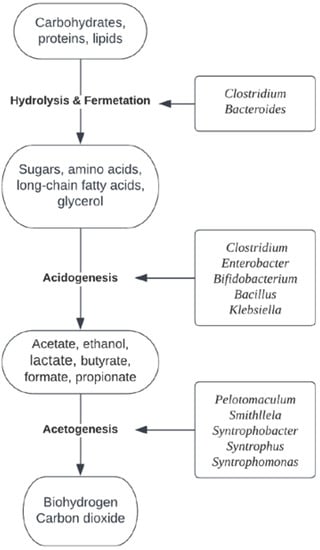

In dark fermentation, several biochemical processes occur in parallel with those of anaerobic digestion. Different microbial strains act synergistically to contribute to the degradation of organic compounds. The process of anaerobic digestion can be divided into four phases: hydrolysis, acidogenesis, acetogenesis and methanogenesis, with the last phase of methanogenesis being excluded in dark fermentation (

Figure 2).

Figure 2.

The biochemical pathway and dominant microbial genera in the dark fermentation process for organic complex compounds.

Complex compounds provide a substrate for microbial degradation in which hydrolysis of carbohydrates, proteins and lipids first occurs. These compounds are hydrolyzed by extracellular hydrolytic enzymes into sugars, amino acids and long-chain fatty acids. The microbial genera

Clostridium and

Bacteroides are two of the most important microbial strains and contribute to hydrolytic activities with extracellular hydrolytic enzymes (cellulose, lipase, protease)

[15][37]. Members of these groups are less sensitive to changes in environmental conditions and can grow rapidly using hydrolyzed products through fermentation

[16][38].

In the acidogenesis phase, the hydrolyzed products are further metabolized by acidogenic microbial communities into short-chain fatty acids (formate, acetate, propionate, butyrate). The accumulation of short-chain fatty acids leads to a subsequent drop in pH. The microorganisms in the acidogenic phase consist of facultative and obligate anaerobes, such as

Clostridium,

Enterobacter,

Bifidobacterium,

Bacillus and

Klebsiella [15][37]. In this phase, carbohydrates are converted into pyruvate via the glycolytic pathway

[17][39].

The metabolic pathway in the dark fermentation process is a limiting parameter that represents a crucial part of the processing steps

[18][22]. Depending on the fermentation pathway and end-products, the production of hydrogen may differ notably in terms of the microbial species (

Clostridium,

Bacillus,

Enterobacter) and the numerous forms of substrates under mesophilic conditions. Two primary pathways via which microorganisms produce hydrogen are acetate and butyrate fermentation. The hydrogen production reactions using acetate and butyrate fermentation are expressed in Equations (1) and (2), for which the theoretical values of 4 mol H

2/mol of glucose and 2 mol H

2/mol of glucose are obtained for acetate or butyrate as the end-product, respectively

[5][18][19][15,22,40].

Depending on the dominant formation of volatile fatty acids, there are several other fermentation types for the metabolic pathway. For propionate-type fermentation (Equation (3)) and ethanol-type fermentation, theoretical yields of 1 mol H

2/mol of glucose and 2 mol H

2/mol of glucose are obtained

[20][41]. Propionate fermentation should be avoided in a hydrogen-producing system due to the low hydrogen yield. Mixed-type fermentation usually occurs at the start-up level in the fermentation process when various fermentation types coexist

[6][13].

The “Thauer limit” is a term that refers to the theoretical hydrogen yield, which is restricted to 4 mol H

2/mol of glucose (Equation (1))

[21][42]. In recent years, studies have been conducted that showed the possibility of increasing hydrogen yield beyond the Thauer limit. Ergal et al. (2020) showed that applying an interdisciplinary approach involving physiology, ecology and biotechnology could, through the designed artificial bacterial consortium, increase the hydrogen yield to 5.6 mol H

2/mol of glucose. According to conducted studies

[22][43], the lack of an eco-biotechnological perspective could be the main factor limiting the establishment of advanced hydrogen-producing microbial consortia.

By-products such as butyrate or propionate require bioconversion using syntrophic acetogenesis. In the acetogenesis phase, substrates are converted into acetate, carbon dioxide and hydrogen by fermentative bacteria that have no hydrolytic activities. The most commonly reported syntrophic acetogens in anaerobic digesters belong to the genera

Pelotomaculum,

Smithllela and

Syntrophobacter (propionate degraders) and

Syntrophus and

Syntrophomonas (degraders of butyrate and other fatty acids)

[15][37]. Acetogenesis is the rate-limiting phase and plays an important role in ensuring stable operating conditions in anaerobic systems.

Obligate anaerobes are the most widely studied bacterial group for biohydrogen production (e.g.,

Clostridium). However, the combination of obligate anaerobic bacteria and facultative anaerobic bacteria in biohydrogen production may turn out to be a more advantageous approach

[23][44]. In anaerobic mesophilic fermentative ecosystems, the obligate anaerobic species of

Clostridium are considered the main hydrogen producers. However, with the development of molecular characterization techniques, other hydrogen-producing communities have been found. These anaerobic bacteria can be categorised as spore-forming obligate anaerobes (

Clostridium sp.); non-spore-forming obligate anaerobes (e.g.,

Ethanoligenens,

Acetanaerobacterium,

Megasphaera,

Acidaminococcus,

Prevotella) and fermentative facultative anaerobes (

Enterobacter, Citrobacter, Klebsiella)

[8][30].

Most of this microbial diversity in hydrogen-producing systems originates from indigenous microbial cultures in untreated substrates or inocula. Mixed microbial cultures, which can be used as inocula in the dark fermentative process, can come from a great variety of sources, such as soil, sediment, animal manure (cow/poultry), organic waste

[6][13], leachate

[24][45], anaerobic activated sludge

[10][25][26][27][28][29][20,32,46,47,48,49], sewage sludge

[30][31][32][33][50,51,52,53], compost

[34][35][17,54] and wastewater

[36][37][38][55,56,57]. Anaerobic activated sludge is a mixed microbial culture that is the primary inoculum for the dark fermentation process due its diversity of hydrogen-producing strains, as well as beneficial microbial strains

[6][13].

Pure cultures can also be applied for biohydrogen production via the dark fermentation process. The most widely studied hydrogen-producing cultures are from the

Clostridium genus

[39][58], with leading research on

Clostridium beijerinckii and

Clostridium butyricum [9][12][40][31,34,59]. Other species, such as

Bacillus and

Enterobacter, can often be found in coexistence with

Clostridium [6][13]. In addition, other genera, such as

Ethanoligenens,

Escherichia,

Citrobacter and

Klebsiella, are also biohydrogen producers according to the literature

[15][37].

Significant efforts have been directed towards isolating and identifying new hydrogen-producing species with specific capabilities, such as species that can be used with different substrates and species that have tolerance to extreme conditions or high efficiency in hydrogen production. Murugan et al. (2018)

[41][60] succeeded in isolating

Acinetobacter junii AH4 as a potential bacterial strain that can be used for efficient hydrogen production. This biohydrogen-producing bacterium was isolated from pretreated anaerobic sludge samples from the dairy industry. Murugan et al. (2021)

[42][61] demonstrated biohydrogen production by the abovementioned hydrogen-producing strain from various industrial wastewaters. In the study by Litti et al. (2022)

[30][50], a new hydrogen-producing strain—

Thermoanaerobacterium thermosaccharolyticum SP-H2—was isolated with a thermophilic acidogenic reactor inoculated with municipal sewage sludge from the processing of carbohydrate-rich simulated food waste. The newly isolated strain showed promising results in the dark fermentation of carbohydrate-rich wastewater under thermophilic conditions.

To optimize the dark fermentation process, external microbial strains can be inoculated into the hydrogen-producing system. Pretreatment of the inoculum is a common approach used to select specific spore-forming, hydrogen-producing bacteria and inhibit hydrogen-consuming bacteria

[43][62]. Different pretreatment methods can greatly alter the microbial community composition and, thus, microbial activity

[44][63]. Yin et al. (2023)

[45][64] evaluated the effects of the type of inoculum and investigated methods to accelerate the start-up of a hydrogen production system. It was found that, after start-up, the dominant strain for hydrogen production in different types of inoculum sludge was

Thermoanaerobacterium thermosaccharolyticum strain TG57. Furthermore, pretreatment of the substrate can lead to an efficient hydrogen production system, as Yang and Wang (2020)

[46][65] found. After chemical pretreatment with sodium citrate followed by ultrasonic pretreatment of waste activated sludge, hydrogen-producing bacteria were enriched, especially those of the genera

Clostridium sensu stricto and

Paraclostridium, which led to a synergistic increase in hydrogen yield and energy conversion efficiency. An interesting discovery was made by Chen et al. (2021)

[47][66] when they investigated the effect of butyrate on hydrogen production. The results showed that butyric acid inhibited fermentative hydrogen production at pH 5.5–7.0, levels associated with undissociated acids. The addition of butyric acid to the system decreased the substrate utilization rate, as well as the accumulation of volatile fatty acids. The addition of butyric acid affected the microbial ecology of the biohydrogen production system, and the proportion of non-hydrogen-producing bacterial strains, such as

Bacillus,

Klebsiella,

Acinetobacter and

Pseudomonas, increased. Recent research

[28][48] has shown that combining waste streams can increase microbial hydrogen production during anaerobic fermentation. An environmentally friendly method using waste such as corncob can enhance solubilization, hydrolysis and acetogenesis in dark fermentation and contribute to the enrichment of hydrolytic microorganisms (e.g.,

Bacteroides sp. and

Leptolinea sp.).