Synthetic bone substitute materials (BSMs) are becoming the general trend of replacing autologous grafting for bone tissue engineering (BTE) in orthopedic research and clinical practice. As the main component of bone matrix, collagen type I has been playing a critical role in the construction of ideal synthetic BSMs for decades. Significant strides have been made in the field of collagen research, including the exploration of various collagen types, structure and sources, the optimization of preparation techniques, modification technologies, and the manufacture of various collagen-based materials. However, the poor mechanical properties, fast degradation, and lack of osteoconductive activity of collagen-based materials caused inefficient bone replacement and limited their translation into clinical reality. In the area of BTE, so far, attempts focused on the preparation of collagen-based biomimetic BSMs together with other inorganic materials and bioactive substances. By reviewing the approved products on the market, this manuscript updates the latest applications of collagen-based materials in bone regeneration and highlights the potential for further development in the field of BTE over the next ten years.

- collagen

- bone tissue engineering

- bone substitute materials

- collagen modifications

- composite bone scaffolds

1. Introduction

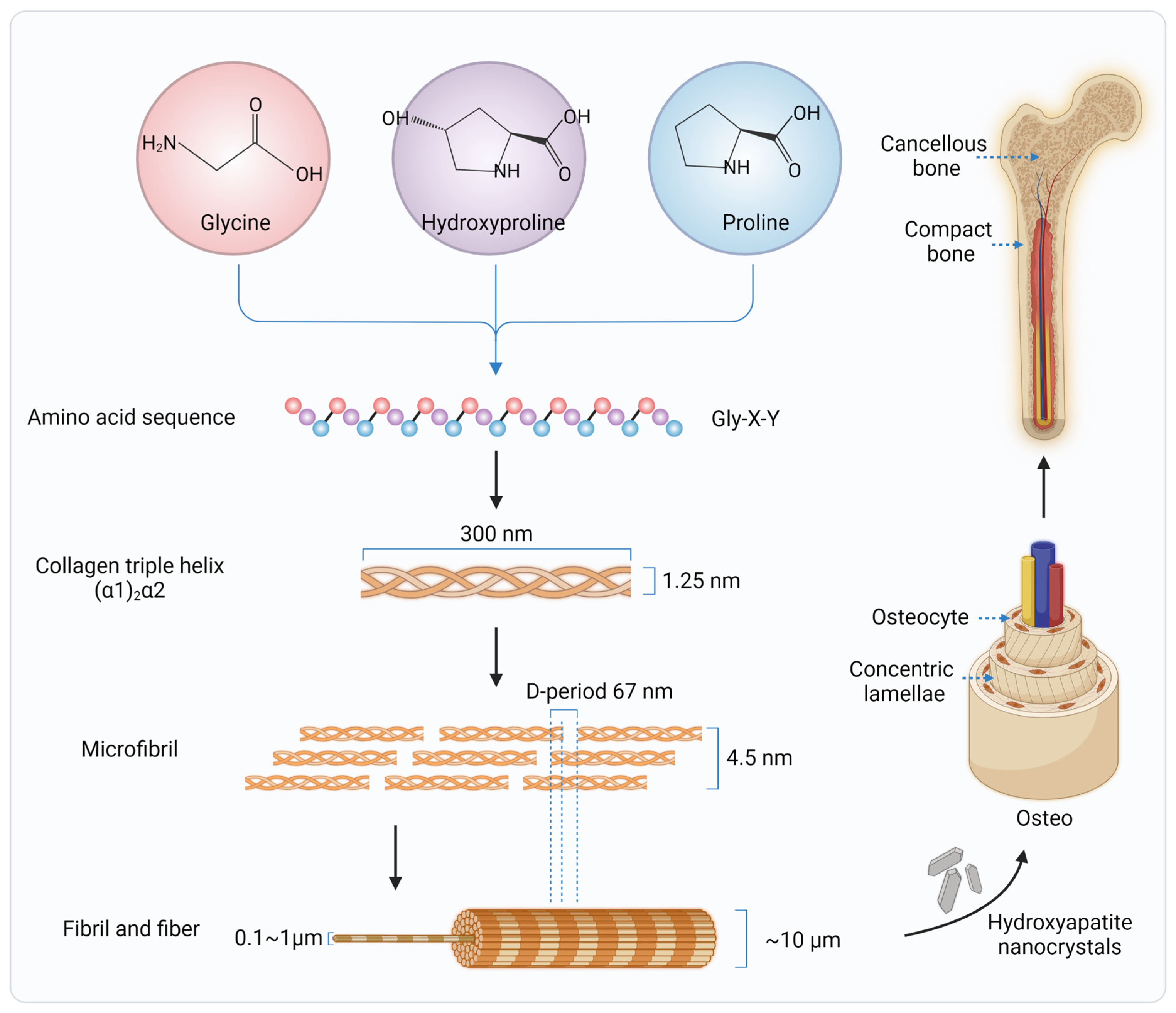

2. Collagen in Native Bone Tissues

Collagen (type I) is a major structural component of mammalian bone, constituting 90% of the organic components of the bone extracellular matrix (ECM) [19]. Thus, it has been stated that the ideal synthetic bone grafts should mimic the ECM of autologous bones as much as possible, since the ECM found in natural tissues supports cell attachment, proliferation, and differentiation [20]. Scaffolds should consist of appropriate ECM-like biochemistry and nano/micro-scale surface topographies in order to formulate favorable binding sites to actively regulate and control cell and tissue behavior [17,21][17][21]. Therefore, understanding the synthesis, structure, and distribution of collagen in bone tissue is critical for bone regeneration [17]. The process of collagen synthesis in bone tissue occurs mainly by fibroblasts and osteoblasts [22]. Within the cells, polypeptides formed in the endoplasmic reticulum are the building blocks of collagen, called alpha chains [23,24,25,26][23][24][25][26]. After translation and posttranslational modifications, three alpha chains are linked by disulfide bridges [27], then twisted into a triple helical procollagen [28]. The ability to form a triple helix is the most important property of collagen, which is mostly based on the repetitive Gly-X-Y triplet of alpha chains [22]. Glycine, with the smallest volume, is located at the inside of the triple helix. X is usually a proline, but could also be other amino acids; and Y is often hydroxyproline. The alpha chains are twisted in a left-handed way, while the triple helixes are folded in a right-handed helix because of the presence of hydrogen bonds. The formed triple helical procollagen is excreted into ECM by transport vesicles. In the ECM, the globular N- and C-terminal propeptides are removed from procollagen by the N- and C- proteinases, which is the key step in the formation of mature collagen [25]. The helix dimension is on the order of 1.25 nm wide and 300 nm long [29], with a mass of ~285 kDa. The removal of the N- and C- terminal propeptides would trigger the self-assembly of supramolecular structures (collagen microfibrils, fibrils, and fibers). Finally, the covalent crosslinking and non-covalent bonds stabilize these supramolecular structures [30]. In bone, groups of five triple helical collagen molecules form microfibrils. The microfibrils are spontaneously organized into fibrils and fibers that can be up to 1 cm in length and 1 mm in diameter and with the characteristic 67 nm banding feature, called the D-period [31,32][31][32]. The hydroxyapatite (HA) nanocrystals are deposited by osteoblasts on the collagen fibrils, constituting the inorganic and organic phases of the bone matrix. The bone matrix is thus hierarchically structured, consisting of a 65% mineral phase, HA, a 35% organic phase (~90% type I collagen, 5% noncollagenous proteins, and 2% lipids by weight), and a residual amount of water (Figure 1). All these scales play an important role in the remarkable mechanical properties of bone. HA provides the rigidity, and collagen fibers improve the toughness of bone. Thus, to better mimic the native bone tissue, collagens used in synthetic bone materials should maintain their natural structure as much as possible. This imposes high requirements on collagen sources and extraction techniques.

3. Applications of Collagen in Bone Tissue Regeneration and Engineering

The earliest reports of the use of collagen in the biomedical field date back to the 19th century [107][33]. Currently, collagens directly extracted from animal tissues, or produced as recombinant proteins, with or without further modifications according to crosslinking, polymerization, or fibrillization, have been widely applied in vitro as standardized 3D materials to investigate the influence of microstructural and mechanical features on cell behaviors, such as cell attachment, cell contraction, cell motility, and related gene expressions [108,109][34][35]. Collagen-based materials in various forms, including membranes, sponges or matrices, hydrogel, and composite scaffolds, are also widely used in vivo to support bone tissue regeneration in different clinical applications [110,111][18][36] (Figure 2).

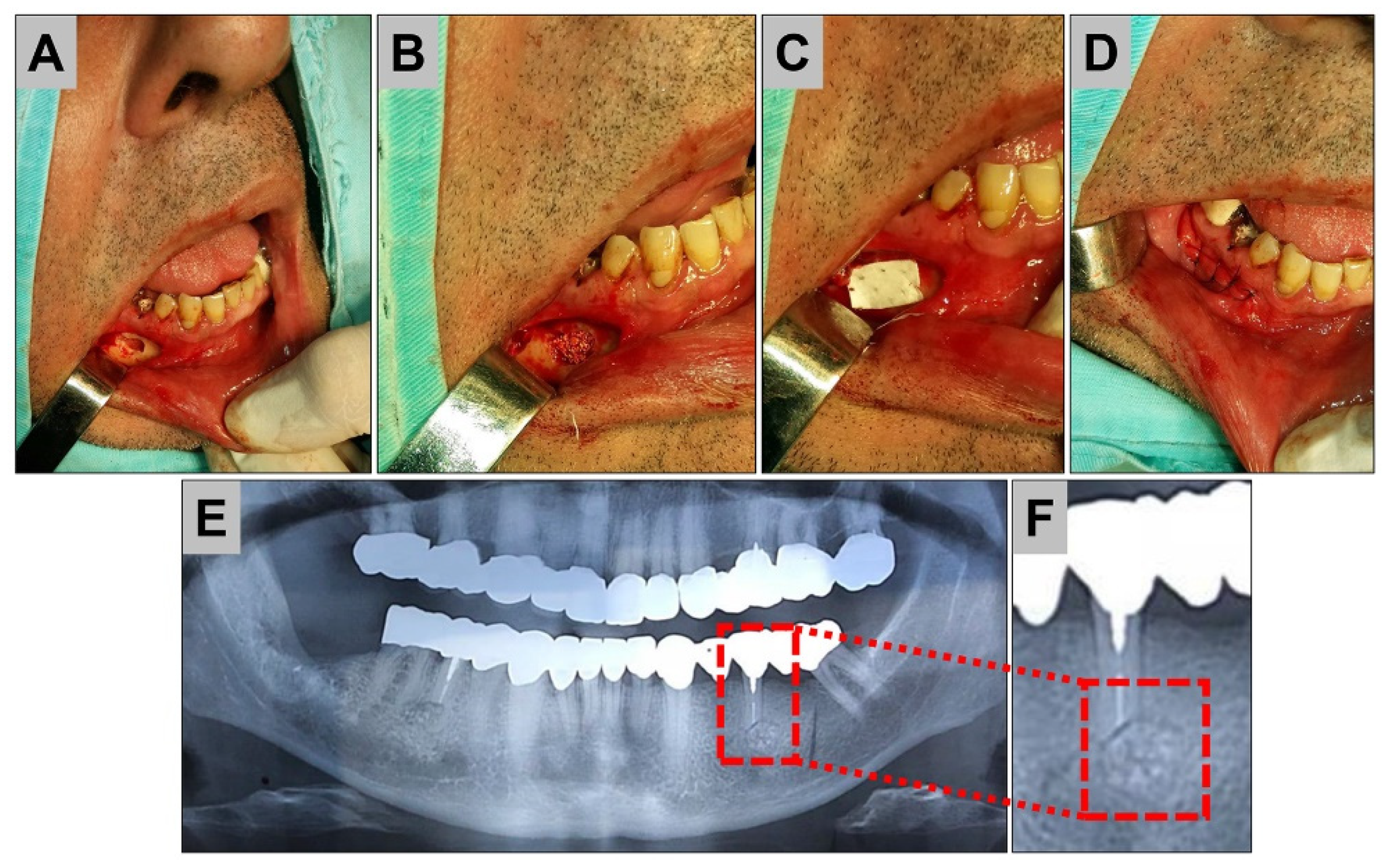

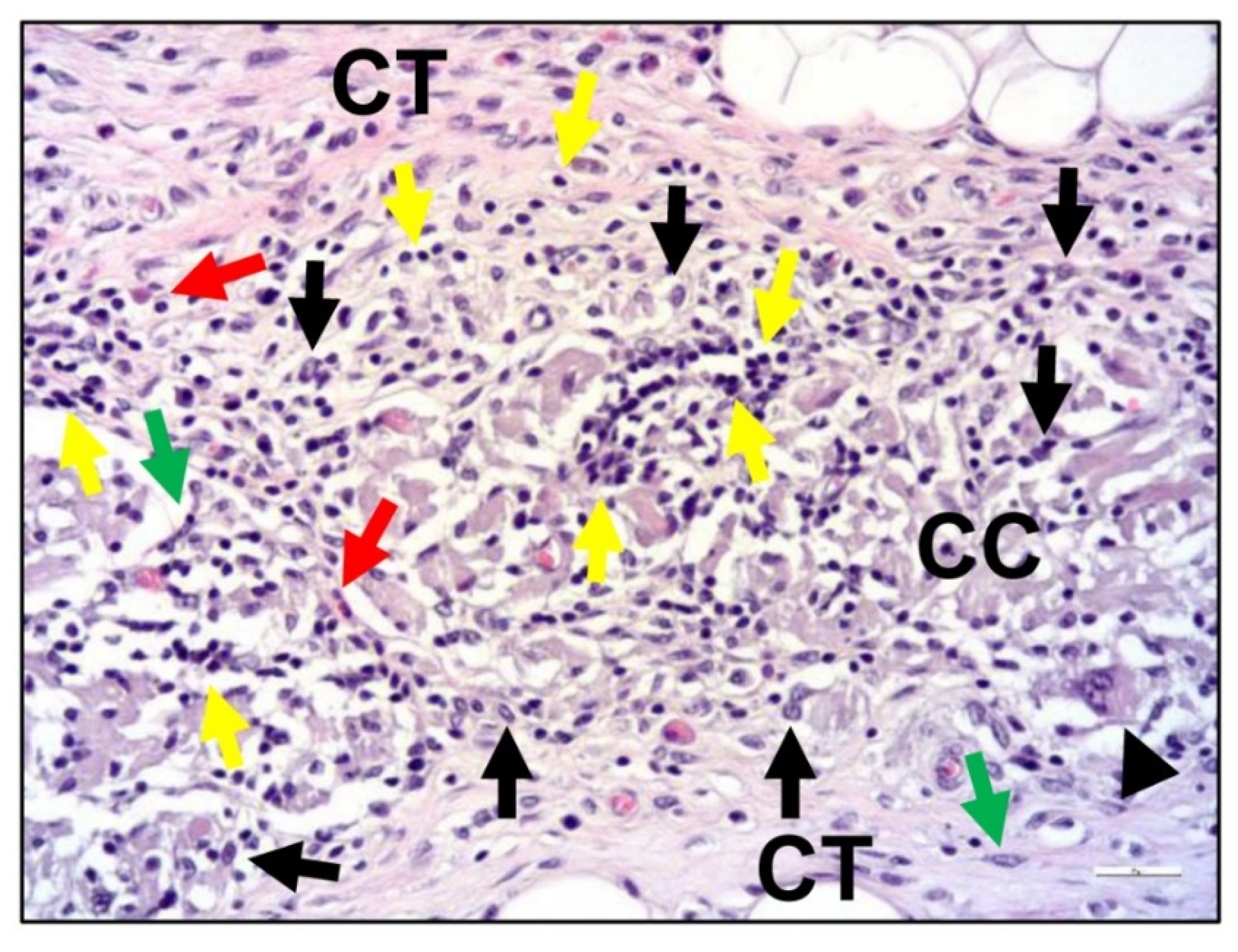

3.1. Collagen Membranes

Various kinds of membrane materials are applied in the clinical practice, such as in the field of dentistry, to achieve guided bone regeneration (GBR) [112][37] (Figure 3).

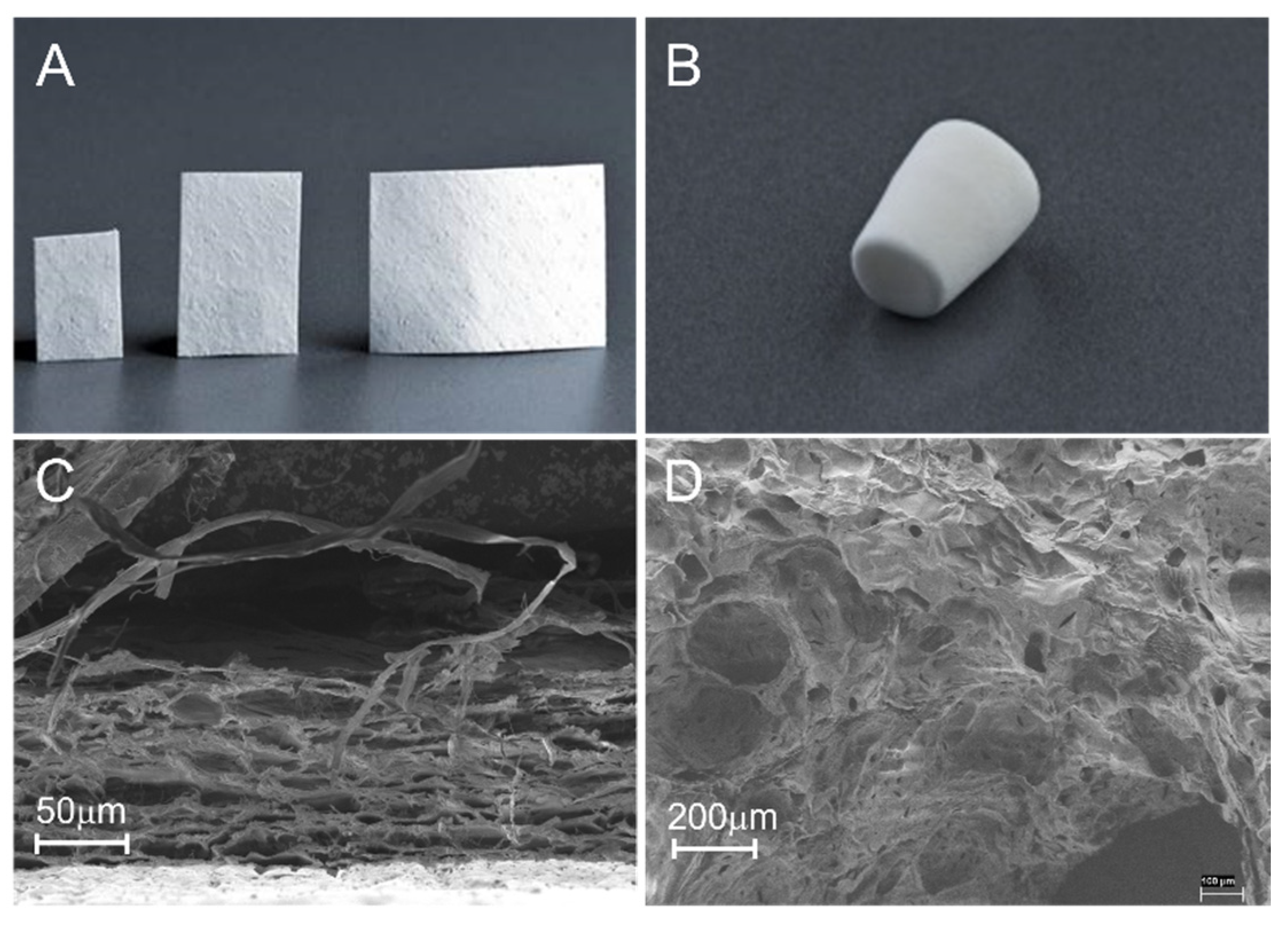

3.2. Collagen Sponges or Matrices

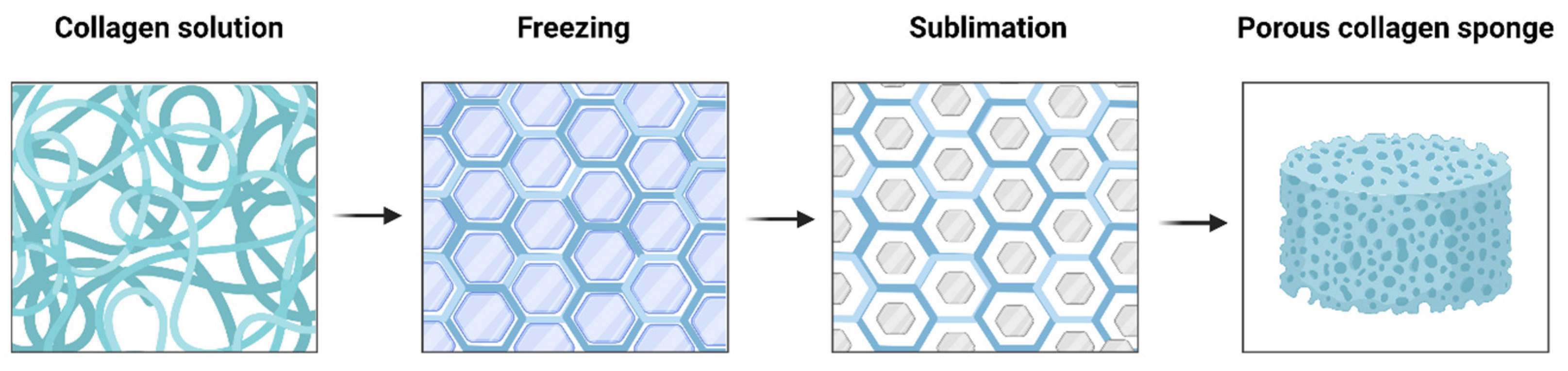

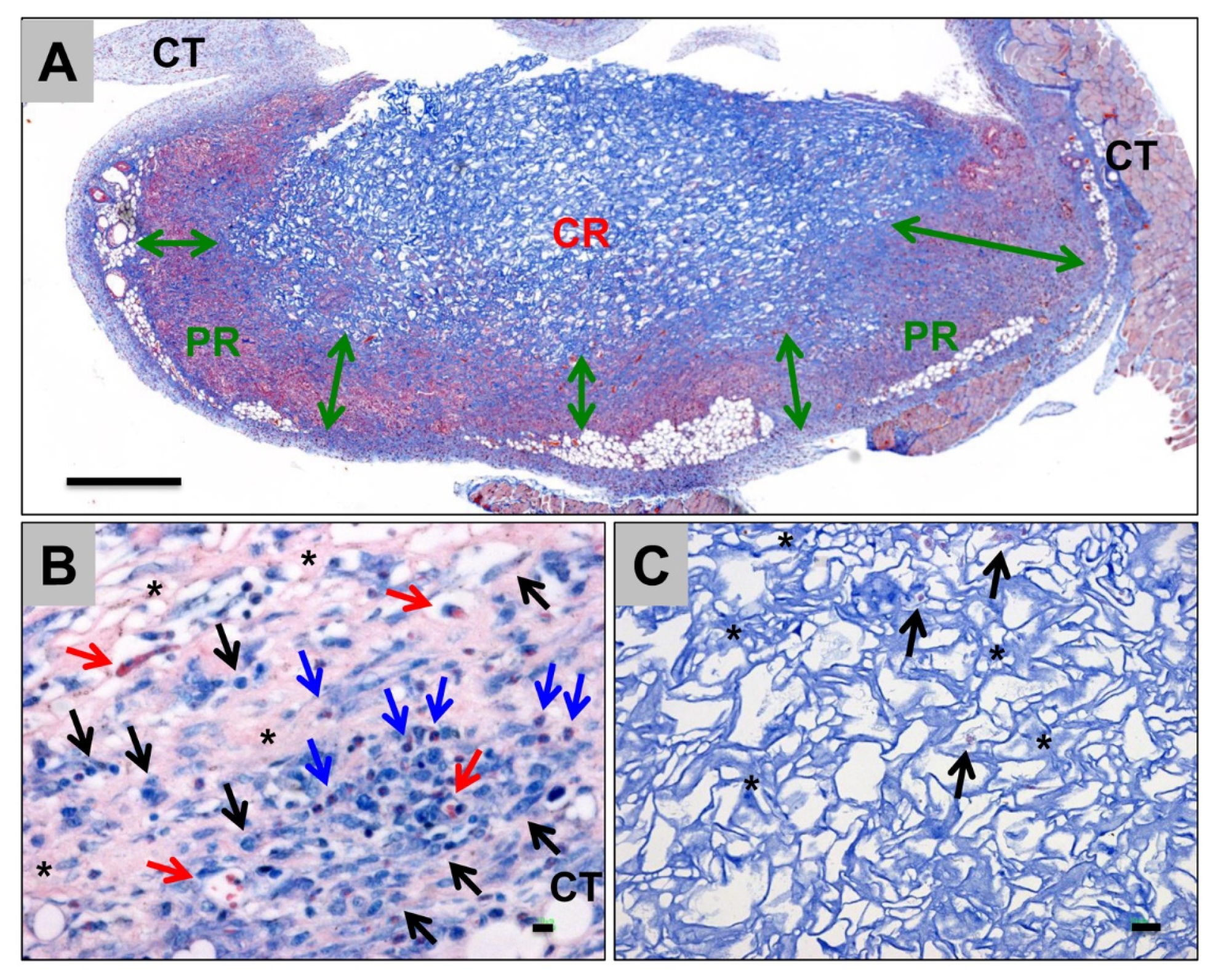

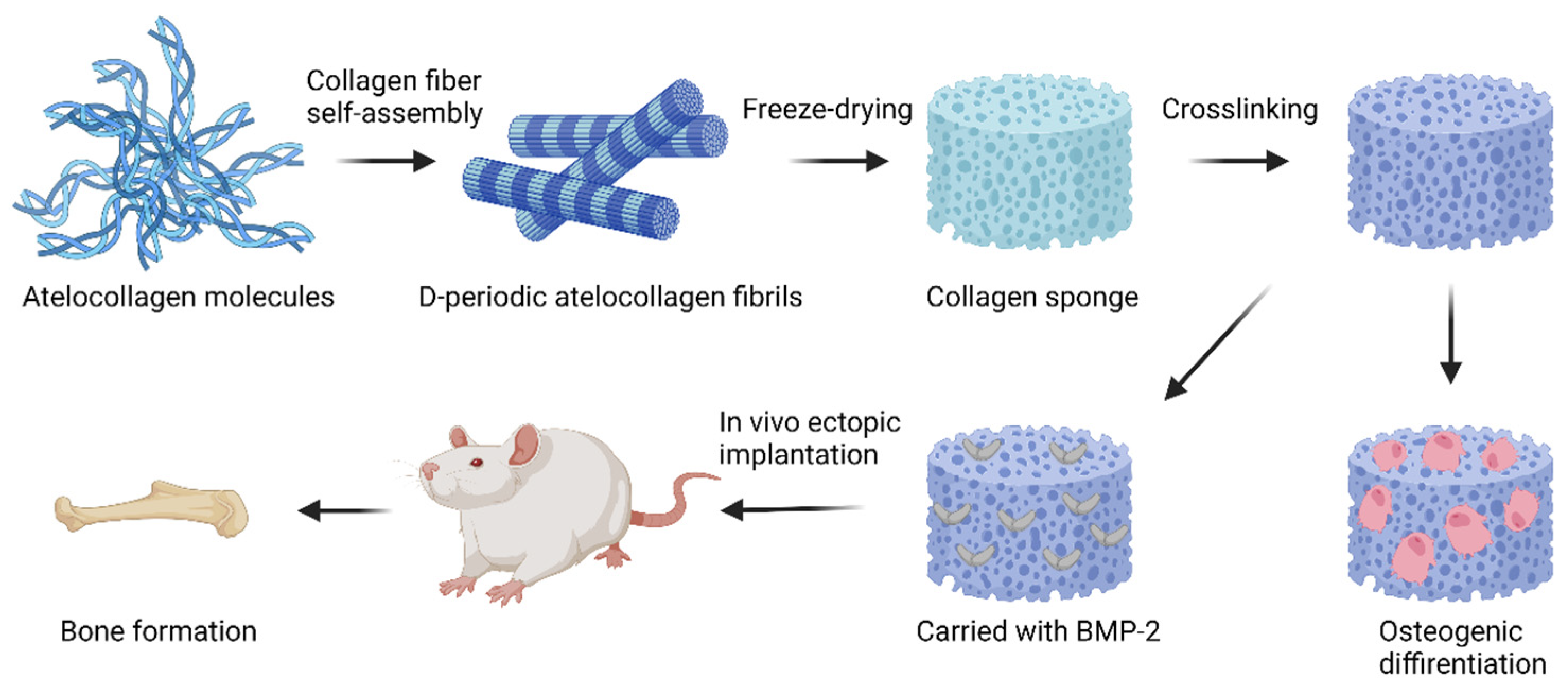

Collagen sponge is one of the most useful biomaterials owing to its excellent function and properties, as well as its easy processing, sterilization, and preservation [122][50]. Collagen sponges are generally formed using a freeze-drying process (also known as ice-crystal templating, lyophilization, or ice-segregation-induced self-assembly) (Figure 5) [123,124][51][52]. By altering the freezing conditions, such as freezing temperature, time, and molds, the pore size and shape of collagen sponge could be tailored [125][53]. For the optimal bioactivity of tissue regeneration, the pores should be large enough to permit cell migration and nutrient diffusion, and small enough to promote cell attachment [126,127][54][55].

3.3. Collagen Hydrogels

Hydrogels are water-swellable polymer materials with a 3D network structure formed through crosslinking reactions [133][61]. Naturally derived collagen hydrogels present more satisfying biocompatibility and biological activity compared to other synthetic polymers or hybrid polymers [134][62]. Similarly, they exhibit low stiffness and rapid degradation, which hamper their application in animal models and clinical tests [135][63]. To overcome these drawbacks, one approach is based on the self-assemble ability of collagen hydrogels, as they polymerize into a fibrillar structure at physiological pH and ionic strength and temperature following an entropy-driven process [136,137][64][65]. Another efficient strategy is the production of composite hydrogels formed by the combination of collagen hydrogels and synthetic components, including functionalized polymers and organic/inorganic nanoparticles and ions [133][61]. The hydrogel collagen nanocomposite, in combination with strontium and seeded mesenchymal stem cells, showed the highest radiographical and histological scores compared with only collagen hydrogel and other control groups in full-thickness bone defect regeneration in the rabbit model [138][66]. The application of nanomaterials to improve the mechanical properties of hydrogel showed enhanced stem cell adhesion and provide valuable guidance for the design of hydrogel-based materials [139][67]. Currently, a new generation of composite collagen hydrogels is widely applied as an injectable hydrogel scaffold for in situ bone tissue repair, flexible drug delivery systems (nanogels or microgels), and implanted bone tissue scaffolds using 3D-printing, electrospinning, or other techniques [133][61].3.4. Collagen-Based Composite Materials

3.4.1. Collagen Integrated with Organic or Inorganic Materials

In FDA and EU approved collagen-based composite material, collagen bone void fillers (CBVFs) are one of the protagonists, and they are used for the backfilling and structure stabilization of bone voids in orthopedic surgeries. CBVFs are commonly composed of inorganic materials, such as calcium sulfate or calcium phosphate augmented with hydroxyapatite, and a native tissue-derived collagen suspension or collagen hydrogels, providing improved biocompatibility, resorbability, and filling ability [140][68]. In recent decades, CBVFs and other collagen-based scaffolds have been introduced into various materials, such as hyaluronic acid, alginate, glycosaminoglycans (GAGs), silk fibroin (SF), metals, bioactive glasses, and some novel carbon-based materials [76,78,141,142,143,144][69][70][71][72][73][74]. For example, a mechanically robust, injectable, and thermoresponsive CBVF was formed with carboxylated single wall carbon nanotubes (COOH-SWCNTs), chitosan, and collagen, as reported by Kaur et al. [145][75]. They found that the material showed improved mechanical properties and bioactivity with the addition of COOH-SWCNTs [145][75].3.4.2. Collagen-Based Composite Materials Loaded with Growth Factors, Cells, or Drugs

Although collagen type I fibers contain multiple biological cues that could directly interact with cells to modulate their adhesion, proliferation, and differentiation, largely improving the biocompatibility and osteoconductivity of bone substitute materials, collagen alone is not osteoinductive [14]. Thus, to achieve effective bone replacement and sufficient tissue vascularization, collagen-based materials can be modified to include other bioactive substances, such as growth factors (e.g., BMPs, VEGFA, etc.), cells (e.g., BMSCs, osteoblasts, osteoclasts, HUVECs, etc.), and drugs (e.g., antibiotics). The first collagen bone graft loaded with recombinant human bone morphogenetic protein-2 (rhBMP-2) was approved by the FDA in 2002 [146][76]. However, after an initially promising start, concerns regarding safety and cost-effectiveness of BMPs have been raised [147][77]. A solution may be the optimization of the delivery system of BMPs to decrease the need for high doses of BMPs and to prevent their applications [148][78]. In addition to increasing the loading efficiency by these modifications, other attempts have been made by inhibiting the BMP antagonists and the combination of multiple growth factors [149][79]. In addition, collagen materials could be integrated with drugs for antibacterial, osteogenesis, and angiogenesis activity. Nabavi et al. reported that collagen hydrogel loaded with tacrolimus, which can enhance osteogenic differentiation by activating BMP receptors, showed improved bone formation compared with that of other non-tacrolimus groups [134][62]. Because of the interactions between the RGD (arginine-glycine-aspartate) sequence and stem cell integrin receptors, collagen-based materials can increase the adhesion, proliferation, and differentiation of stem cells, providing an ideal platform for cell delivery [134][62]. Recent studies have reported some rational designs of materials by surface modification and stiffness adjustment with nanomaterials to tune the tether mobility and anisotropic nanoscale presentation of RGD [139,150,151][67][80][81]. A collagen scaffold carried with dental pulp stem cells (DPSCs) showed a higher amount of calcification in the reconstructed defects [151][82]. However, in another study, in vivo micro-CT analysis confirmed that the acellular scaffolds generated larger volumes of bone than the DPSCs seeded scaffolds [153][83]. Some other attempts at creating collagen-based composites are also focusing on the integration of collagen with peptide delivery and gene therapy [154,155,156,157][84][85][86][87]. These studies remain controversial and have yet to be explored. Another promising direction is the synergistic effects of multiple bioactive cations on vascularization and bone defect repair, which is a much safer and simpler option [158][88].4. Conclusions and Perspectives

Significant strides have been made in the field of collagen (type I) for bone tissue engineering. Advances in exploring various collagen sources, as well as extraction and purification processes, have made collagen preparation available with maximum native structure and minimum immunogenicity/antigenicity. Advances in collagen modifications have offered optimized collagen mechanical properties and biological resistance. For a wide variety of applications in bone grafting, collagens are often modified or combined with other materials to construct various bone substitute materials, such as collagen sponges, hydrogels, nanofibers/microfibers, or nanoparticles/microspheres. Collagen-based composites with bioceramic materials (e.g., HA, TCP, and BGs, etc.), carried with growth factors, peptides, cells, drugs, and genes, have made the multifunctionalized BSMs available with improved osteoconductivity, osteoinductivity, osteointegration, osteogenesis, and vascularization. Although many of them have shown great effects on bone regeneration in in vitro and in vivo studies, only a few of them are currently FDA- or EU- approved for clinical applications. These composites still face challenges regarding complete mechanical properties, biological stability and activity, immune response, regional vascularization, and other safety issues for human bone regeneration, which hinder their translations into clinical devices. However, in addition to the continuous development of new tools and technologies for material manufacturing, such as 3D printing and electrospinning, researchers are directing attention to patient-specific collagen-based materials. Rather than relying on the material alone, an integration of functional material manufacture and the innate regeneration potential of patients sheds new light on potential clinical translation within the next decade.

Reference

- Ghelich, P.; Kazemzadeh-Narbat, M.; Najafabadi, A.H.; , M.; Memić, A.; Tamayol, A. (Bio)manufactured Solutions for Treatment of Bone Defects with Emphasis on US-FDA Regulatory Science Perspective. NanoBiomed Res. 2022, 2, . https://doi.org/10.1002/anbr.202100073.

- Sakkas, A.; Wilde, F.; Heufelder, M.; Winter, K.; Schramm, A. Autogenous bone grafts in oral implantology-is it still a “gold standard”? A consecutive review of 279 patients with 456 clinical procedures. J. Implant. Dent. 2017, 3, 23. https://doi.org/10.1186/s40729-017-0084-4.

- Miron, R.J.; Sculean, A.; Shuang, Y.; Bosshardt, D.D.; Gruber, R.; Buser, D.; Chandad, F.; Zhang, Y. Osteoinductive potential of a novel biphasic calcium phosphate bone graft in comparison with autographs, xenografts, and DFDBA. Oral Implant. Res. 2016, 27, 668–675. https://doi.org/10.1111/clr.12647.

- Li, Y.; Liu, Y.; Li, R.; Bai, H.; Zhu, Z.; Zhu, L.; Zhu, C.; Che, Z.; Liu, H.; Wang, J.; et al. Collagen-based biomaterials for bone tissue engineering. Des. 2021, 210, 110049. https://doi.org/10.1016/j.matdes.2021.110049.

- Guo, L.; Liang, Z.; Yang, L.; Du, W.; Yu, T.; Tang, H.; Li, C.; Qiu, H. The role of natural polymers in bone tissue engineering. Control Release 2021, 338, 571–582. https://doi.org/10.1016/j.jconrel.2021.08.055.

- Laird, N.Z.; Acri, T.M.; Tingle, K.; Salem, A.K. Gene- and RNAi-activated scaffolds for bone tissue engineering: Current progress and future directions. Drug Deliv. Rev. 2021, 174, 613–627. https://doi.org/10.1016/j.addr.2021.05.009.

- Ballarre, J.; Manjubala, I.; Schreiner, W.H.; Orellano, J.C.; Fratzl, P.; Ceré, S. Improving the osteointegration and bone-implant interface by incorporation of bioactive particles in sol-gel coatings of stainless steel implants. Acta Biomater. 2010, 6, 1601–1609. https://doi.org/10.1016/j.actbio.2009.10.015.

- Bellucci, D.; Sola, A.; Cannillo, V. Hydroxyapatite and tricalcium phosphate composites with bioactive glass as second phase: State of the art and current applications. Biomed. Mater. Res. Part A 2016, 104, 1030–1056. https://doi.org/10.1002/jbm.a.35619.

- Bharadwaz, A.; Jayasuriya, A.C. Recent trends in the application of widely used natural and synthetic polymer nanocomposites in bone tissue regeneration. Sci. Eng. C 2020, 110, 110698. https://doi.org/10.1016/j.msec.2020.110698.

- Wahl, D.; Czernuszka, J. Collagen-hydroxyapatite composites for hard tissue repair. Cells Mater. 2006, 11, 43–56. https://doi.org/10.22203/ecm.v011a06.

- Gillman, C.E.; Jayasuriya, A.C. FDA-approved bone grafts and bone graft substitute devices in bone regeneration. Sci. Eng. C Mater. Biol. Appl. 2021, 130, 112466. https://doi.org/10.1016/j.msec.2021.112466.

- Chen, X.; Hao, W.; Li, X.; Xiao, Z.; Yao, Y.; Chu, Y.; Farkas, B.; Romano, I.; Brandi, F.; Dai, J. Functional Multichannel Poly(Propylene Fumarate)-Collagen Scaffold with Collagen-Binding Neurotrophic Factor 3 Promotes Neural Regeneration After Transected Spinal Cord Injury. Heal. Mater. 2018, 7, e1800315. https://doi.org/10.1002/adhm.201800315.

- Khan, S.N.; Cammisa, F.P.; Jr.; Sandhu, H.S.; Diwan, A.D.; Girardi, F.P.; Lane, J.M. The biology of bone grafting. Am. Acad. Orthop. Surg. 2005, 13, 77–86.

- Rico-Llanos, G.A.; Borrego-González, S.; Moncayo-Donoso, M.; Becerra, J.; Visser, R. Collagen Type I Biomaterials as Scaffolds for Bone Tissue Engineering. Polymers 2021, 13, . https://doi.org/10.3390/polym13040599.

- Ma, C.; Wang, H.; Chi, Y.; Wang, Y.; Jiang, L.; Xu, N.; Wu, Q.; Feng, Q.; Sun, X. Preparation of oriented collagen fiber scaffolds and its application in bone tissue engineering. Mater. Today 2021, 22, 100902. https://doi.org/10.1016/j.apmt.2020.100902.

- Gurumurthy, B.; Janorkar, A.V. Improvements in mechanical properties of collagen-based scaffolds for tissue engineering. Opin. Biomed. Eng. , 100253. https://doi.org/10.1016/j.cobme.2020.100253.

- Ferreira, A.M.; Gentile, P.; Chiono, V.; Ciardelli, G. Collagen for bone tissue regeneration. Acta Biomater. 2012, 8, 3191–3200. https://doi.org/10.1016/j.actbio.2012.06.014.

- Miller, E.J.; Gay, S. Collagen: An overview. In Methods in Enzymology; Academic Press: , 1982; pp. 3–32.

- Strom, S.C.; Michalopoulos, G. Collagen as a substrate for cell growth and differentiation. In Methods in Enzymology; Academic Press: Cambridge, MA, USA, 1982; pp. 544–555.

- Wu, S.; Liu, X.; Yeung, K.W.K.; Liu, C.; Yang, X. Biomimetic porous scaffolds for bone tissue engineering. Sci. Eng. R Rep. 2014, 80, 1–36. https://doi.org/10.1016/j.mser.2014.04.001.

- Canty, E.G.; Kadler, K.E. Procollagen trafficking, processing and fibrillogenesis. Cell Sci. 2005, 118, 1341–1353. https://doi.org/10.1242/jcs.01731.

- Brodsky, B.; Persikov, A.V. Molecular structure of the collagen triple helix. Protein Chem. 2005, 70, 301–339. https://doi.org/10.1016/S0065-323370009-7.

- Brodsky, B.; Ramshaw, J.A. The collagen triple-helix structure. Matrix Biol. 1997, 15, 545–554. https://doi.org/10.1016/s0945-053x(97)90030-5.

- Leung, M.K.; I Fessler, L.; Greenberg, D.B.; Fessler, J.H. Separate amino and carboxyl procollagen peptidases in chick embryo tendon. Biol. Chem. 1979, 254, 224–232.

- Bornstein, P. The biosynthesis of collagen. Rev. Biochem. 1974, 43, 567–603.

- Olsen, B.R.; Hoffmann, H.-P.; Prockop, D.J. Interchain disulfide bonds at the COOH-terminal end of procollagen synthesized by matrix-free cells from chick embryonic tendon and cartilage. Biochem. Biophys. 1976, 175, 341–350.

- Gallop, P.M.; O Blumenfeld, O.; Seifter, S. Structure and metabolism of connective tissue proteins. Rev. Biochem. 1972, 41, 617–672.

- Hodge, A.J.; Schmitt, F.O. The Charge Profile of the Tropocollagen Macromolecule and the Packing Arrangement in Native-Type Collagen Fibrils. Natl. Acad. Sci. USA 1960, 46, 186–197. https://doi.org/10.1073/pnas.46.2.186.

- Kadler, K.; Prockop, D.J. Protein structure and the specific heat of water. Nature 1987, 325, 395. https://doi.org/10.1038/325395b0.

- Mould, A.P.; Hulmes, D.J.; Holmes, D.F.; Cummings, C.; Sear, C.H.; Chapman, J.A. D-periodic assemblies of type I procollagen. Mol. Biol. 1990, 211, 581–594. https://doi.org/10.1016/0022-283690267-P.

- Chao, Y.-H.; Sun, J.-S. Biomechanics of Skeletal Muscle and Tendon. In: Frontiers in Orthopaedic Biomechanics. Springer: , 2020; pp. 37–73. https://doi.org/10.1007/978-981-15-3159-0_2.

- Sorushanova, A.; Delgado, L.M.; Wu, Z.; Shologu, N.; Kshirsagar, A.; Raghunath, R.; Mullen, A.M.; Bayon, Y.; Pandit, A.; Raghunath, M.; et al. The Collagen Suprafamily: From Biosynthesis to Advanced Biomaterial Development. Mater. 2019, 31, e1801651. https://doi.org/10.1002/adma.201801651.

- Gallo, N.; Natali, M.; Sannino, A.; Salvatore, L. An overview of the use of equine collagen as emerging material for biomedical applications. Funct. Biomater. 2020, 11, 79. https://doi.org/10.3390/jfb11040079.

- Browne, S.; Zeugolis, D.; Pandit, A. Collagen: Finding a solution for the source. Tissue Eng. Part A 2013, 19, 1491–1494. https://doi.org/10.1089/ten.TEA.2012.0721.

- Felician, F.F.; Xia, C.; Qi, W.; Xu, H. Collagen from Marine Biological Sources and Medical Applications. Chem. Biodivers. 2018, 15, e1700557. https://doi.org/10.1002/cbdv.201700557.

- Schmidt, M.M.; Dornelles, R.C.P.; Mello, R.O.; Kubota, E.H.; Mazutti, M.A.; Kempka, A.P.; Demiate, I.M. Collagen extraction process. Food Res. J. 2016, 23, 913–922.

- Zhou, C.; Li, Y.; Yu, X.; Yang, H.; Ma, H.; Yagoub, A.E.A.; Cheng, Y.; Hu, J.; Otu, P.N.Y. Extraction and characterization of chicken feet soluble collagen. LWT 2016, 74, 145–153. https://doi.org/10.1016/j.lwt.2016.07.024.

- Cumming, M.H.; Hall, B.; Hofman, K. Isolation and Characterisation of Major and Minor Collagens from Hyaline Cartilage of Hoki (Macruronus novaezelandiae). Drugs 2019, 17, . https://doi.org/10.3390/md17040223.

- Dincer, E.; Kivanc, M. Characterization of Lactobacillus plantarum strains isolated from Turkish pastırma and possibility to use of food industry. Food Sci. Technol. 2020, 40, 498–507. https://doi.org/10.1590/fst.05819.

- Tan, Y.; Chang, S.K. Isolation and characterization of collagen extracted from channel catfish (Ictalurus punctatus) skin. Food Chem. 2018, 242, 147–155. https://doi.org/10.1016/j.foodchem.2017.09.013.

- Sinthusamran, S.; Benjakul, S.; Kishimura, H. Comparative study on molecular characteristics of acid soluble collagens from skin and swim bladder of seabass (Lates calcarifer). Food Chem. 2013, 138, 2435–2441. https://doi.org/10.1016/j.foodchem.2012.11.136.

- Oliveira, V.D.M.; Neri, R.C.D.A.; Monte, F.T.D.D.; Roberto, N.A.; Costa, H.M.S.; Assis, C.R.D.; Santos, J.F.; Bezerra, R.S.; Porto, A.L.F. Crosslink-free collagen from Cichla ocellaris: Structural characterization by FT-IR spectroscopy and densitometric evaluation. Mol. Struct. 2019, 1176, 751–758. https://doi.org/10.1016/j.molstruc.2018.09.023.

- Dhakal, D.; Koomsap, P.; Lamichhane, A.; Sadiq, M.B.; Anal, A.K. Optimization of collagen extraction from chicken feet by papain hydrolysis and synthesis of chicken feet collagen based biopolymeric fibres. Food Biosci. 2018, 23, 23–30. https://doi.org/10.1016/j.fbio.2018.03.003.

- Arif, Z.U.; Khalid, M.Y.; Noroozi, R.; Sadeghianmaryan, A.; Jalalvand, M.; Hossain, M. Recent advances in 3D-printed polylactide and polycaprolactone-based biomaterials for tissue engineering applications. J. Biol. 2022, 218, 930–968. https://doi.org/10.1016/j.ijbiomac.2022.07.140.

- Chen, Z.; Fan, D.; Shang, L. Exploring the potential of the recombinant human collagens for biomedical and clinical applications: A short review. Mater. 2020, 16, 012001. https://doi.org/10.1088/1748-605X/aba6fa.

- Guo, Y.; Xu, B.; Wang, Y.; Li, Y.; Si, H.; Zheng, X.; Chen, Z.; Chen, F.; Fan, D. Dramatic promotion of wound healing using a recombinant human-like collagen and bFGF cross-linked hydrogel by transglutaminase. Biomater. Sci. Polym. Ed. 2019, 30, 1591–1603. https://doi.org/10.1080/09205063.2019.1652416.

- Sbricoli, L.; Guazzo, R.; Annunziata, M.; Gobbato, L.; Bressan, E.; Nastri, L. Selection of Collagen Membranes for Bone Regeneration: A Literature Review. Materials 2020, 13, . https://doi.org/10.3390/ma13030786.

- Tanzer, M.L. Cross-Linking of Collagen. Science 1973, 180, 561–566. https://doi.org/10.1126/science.180.4086.561.

- Otsubo, K.; Katz, E.P.; Mechanic, G.L.; Yamauchi, M. Cross-linking connectivity in bone collagen fibrils: The carboxy-terminal locus of free aldehyde. Biochemistry 1992, 31, 396–402. https://doi.org/10.1021/bi00117a013.

- Oryan, A.; Kamali, A.; Moshiri, A.; Baharvand, H.; Daemi, H. Chemical crosslinking of biopolymeric scaffolds: Current knowledge and future directions of crosslinked engineered bone scaffolds. J. Biol. Macromol. 2018, 107, 678–688. https://doi.org/10.1016/j.ijbiomac.2017.08.184.

- Ma, B.; Wang, X.; Wu, C.; Chang, J. Crosslinking strategies for preparation of extracellular matrixderived cardiovascular scaffolds. Regen. Biomater. 2014, 1, 81–89. https://doi.org/10.1093/rb/rbu009.

- Olde Damink, L.H.H.; Dijkstra, P.J.; Van Luyn, M.J.A.; Van Wachem, P.B.; Nieuwenhuis, P.; Feijen, J. Glutaraldehyde as a crosslinking agent for collagen-based biomaterials. Mater. Sci. Mater. Med. 1995, 6, 460–472.

- Gögele, C.; Hahn, J.; Elschner, C.; Breier, A.; Schröpfer, M.; Prade, I.; Meyer, M.; Schulze-Tanzil, G. Enhanced growth of lapine anterior cruciate ligamentderived fibroblasts on scaffolds embroidered from poly (l-lactide-co-ε-caprolactone) and polylactic acid threads functionalized by fluorination and hexamethylene diisocyanate cross-linked collagen foams. J. Mol. Sci. 2020, 21, 1132. https://doi.org/10.3390/ijms21031132.

- Hassan, R.M. Novel synthesis of natural cation exchange resin by crosslinking the sodium alginate as a natural polymer with 1, 6-hexamethylene diisocyanate in inert solvents: Characteristics and applications. J. Biol. Macromol. 2021, 184, 926–935. https://doi.org/10.1016/j.ijbiomac.2021.06.147.

- Yang, C. Enhanced physicochemical properties of collagen by using EDC/NHS-crosslinking. Mater. Sci. 2012, 35, 913–918. https://doi.org/10.1007/s12034-012-0376-5.

- Goodarzi, H.; Jadidi, K.; Pourmotabed, S.; Sharifi, E.; Aghamollaei, H. Preparation and in vitro characterization of crosslinked collagen–gelatin hydrogel using EDC/NHS for corneal tissue engineering applications. J. Biol. Macromol. 2019, 126, 620–632. https://doi.org/10.1016/j.ijbiomac.2018.12.125.

- Montalbano, G.; Borciani, G.; Cerqueni, G.; Licini, C.; Banche-Niclot, F.; Janner, D.; Sola, S.; Fiorilli, S.; Mattioli-Belmonte, M.; Ciapetti, G.; et al. Collagen hybrid formulations for the 3d printing of nanostructured bone scaffolds: An optimized genipin-crosslinking strategy. Nanomaterials 2020, 10, 1681. https://doi.org/10.3390/nano10091681.

- Wang, Z.; Liu, H.; Luo, W.; Cai, T.; Li, Z.; Liu, Y.; Gao, W.; Wan, Q.; Wang, X.; Wang, J.; et al. Regeneration of skeletal system with genipin crosslinked biomaterials. Tissue Eng. 2020, 11, 2041731420974861. https://doi.org/10.1177/2041731420974861.

- Cumming, M.H.; Leonard, A.R.; LeCorre-Bordes, D.S.; Hofman, K. Intra-fibrillar citric acid crosslinking of marine collagen electrospun nanofibres. J. Biol. Macromol. 2018, 114, 874–881. https://doi.org/10.1016/j.ijbiomac.2018.03.180.

- Andonegi, M.; de la Caba, K.; Guerrero, P. Effect of citric acid on collagen sheets processed by compression. Food Hydrocoll. 2020, 100, 105427. https://doi.org/10.1016/j.foodhyd.2019.105427.

- Salihu, R.; Razak, S.I.A.; Zawawi, N.A.; Kadir, M.R.A.; Ismail, N.I.; Jusoh, N.; Mohamad, M.R.; Nayan, N.H.M. Citric acid: A green cross-linker of biomaterials for biomedical applications. Polym. J. 2021, 146, 110271. https://doi.org/10.1016/j.eurpolymj.2021.110271.

- Ma, X.H.; Noishiki, Y.; Yamane, Y.; Iwai, Y.; Marato, D.; Matsumoto, A. Thermal cross-linking for biologically degradable materials. Preliminary report. ASAIO J. 1996, 42, M866–M871. https://doi.org/10.1097/00002480-199609000- 00115.

- Drexler, J.W.; Powell, H.M. Dehydrothermal crosslinking of electrospun collagen. Tissue Eng. Part C Methods 2011, 17, 9–17. https://doi.org/10.1089/ten.TEC.2009.0754.

- Prasertsung, I.; Damrongsakkul, S.; Saito, N. Crosslinking of a Gelatin Solutions Induced by Pulsed Electrical Discharges in Solutions. Plasma Process. Polym. 2013, 10, 792–797. https://doi.org/10.1002/ppap.201200148.

- Liguori, A.; Bigi, A.; Colombo, V.; Focarete, M.L.; Gherardi, M.; Gualandi, C.; Oleari, M.C.; Panzavolta, S. Atmospheric Pressure Non-Equilibrium Plasma as a Green Tool to Crosslink Gelatin Nanofibers. Rep. 2016, 6, 38542. https://doi.org/10.1038/srep38542.

- Davidenko, N.; Bax, D.V.; Schuster, C.F.; Farndale, R.W.; Hamaia, S.W.; Best, S.M.; Cameron, R.E. Optimisation of UV irradiation as a binding site conserving method for crosslinking collagen-based scaffolds. Mater. Sci. Mater. Med. 2016, 27, 1–17. https://doi.org/10.1007/s10856-015-5627-8.

- Weadock, K.S.; Miller, E.J.; Bellincampi, L.D.; Zawadsky, J.P.; Dunn, M. Physical crosslinking of collagen fibers: Comparison of ultraviolet irradiation and dehydrothermal treatment. Biomed. Mater. Res. 1995, 29, 1373–1379. https://doi.org/10.1002/jbm.820291108.

- Bax, D.V.; Davidenko, N.; Hamaia, S.W.; Farndale, R.W.; Best, S.M.; Cameron, R.E. Impact of UV-and carbodiimide-based crosslinking on the integrin-binding properties of collagen-based materials. Acta Biomater. 2019, 100, 280–291. https://doi.org/10.1016/j.actbio.2019.09.046.

- Nagaraj, S.; Easwaramoorthi, S.; Rao, J.R.; Thanikaivelan, P. Probing visible light induced photochemical stabilization of collagen in green solvent medium. J. Biol. Macromol. 2019, 131, 779–786. https://doi.org/10.1016/j.ijbiomac.2019.03.109.

- Cheng, S.; Wang, W.; Li, Y.; Gao, G.; Zhang, K.; Zhou, J.; Wu, Z. Cross-linking and film-forming properties of transglutaminasemodified collagen fibers tailored by denaturation temperature. Food Chem. 2019, 271, 527–535. https://doi.org/10.1016/j.foodchem.2018.07.223.

- Liu, Y.; Weng, R.; Wang, W.; Wei, X.; Li, J.; Chen, X.; Liu, Y.; Lu, F.; Li, Y. Tunable physical and mechanical properties of gelatin hydrogel after transglutaminase crosslinking on two gelatin types. J. Biol. Macromol. 2020, 162, 405–413. https://doi.org/10.1016/j.ijbiomac.2020.06.185.

- Olde Damink, L.H.H.; Dijkstra, P.J.; Van Luyn, M.J.A.; Van Wachem, P.B.; Nieuwenhuis, P.; Feijen, J. Crosslinking of dermal sheep collagen using hexamethylene diisocyanate. Mater. Sci. Mater. Med. 1995, 6, 429–434.

- Thakur, G.; Rodrigues, F.C.; Singh, K. Crosslinking biopolymers for advanced drug delivery and tissue engineering applications. -Edge Enabling Technol. Regen. Med. 2018, 1078, 213–231. https://doi.org/10.1007/978-981-13-0950-2_11.

- Rýglová, Š.; Braun, M.; Suchý, T. Collagen and its modifications—Crucial aspects with concern to its processing and analysis. Mater. Eng. 2017, 302, 1600460. https://doi.org/10.1002/mame.201600460.

- Yang, X.; Wang, X.; Yu, F.; Ma, L.; Pan, X.; Luo, G.; Lin, S.; Mo, X.; He, C.; Wang, H. Hyaluronic acid/EDC/NHS-crosslinked green electrospun silk fibroin nanofibrous scaffolds for tissue engineering. RSC Adv. 2016, 6, 99720–99728. https://doi.org/10.1039/C6RA13713J.

- Adamiak, K.; Sionkowska, A. Current methods of collagen cross-linking: Review. J. Biol. Macromol. 2020, 161, 550–560. https://doi.org/10.1016/j.ijbiomac.2020.06.075.

- Lu, Z.; Liu, S.; Le, Y.; Qin, Z.; He, M.; Xu, F.; Zhu, Y.; Zhao, J.; Mao, C.; Zheng, L. An injectable collagen-genipin-carbon dot hydrogel combined with photodynamic therapy to enhance chondrogenesis. Biomaterials 2019, 218, 119190. https://doi.org/10.1016/j.biomaterials.2019.05.001.

- Kreger, S.T.; Bell, B.J.; Bailey, J.; Stites, E.; Kuske, J.; Waisner, B.; Voytik‐Harbin, S.L. Polymerization and matrix physical properties as important design considerations for soluble collagen formulations. Biopolymers 2010, 93, 690–707. https://doi.org/10.1002/bip.21431.

- Nam, K.; Kimura, T.; Kishida, A. Preparation Fibrillized Collagen-Glycosaminoglycan Complex Matrix Using Fibrillogenesis. Symp. 2015, 358, 95–105. https://doi.org/10.1002/masy.201500015.

- Kinoshita, S.; Mera, K.; Ichikawa, H.; Shimasaki, S.; Nagai, M.; Taga, Y.; Iijima, K.; Hattori, S.; Fujiwara, Y.; Shirakawa, J.-I.; et al. Nω-(carboxymethyl) arginine is one of the dominant advanced glycation end products in glycated collagens and mouse tissues. Oxidative Med. Cell. Longev. 2019, 2019, 9073451. https://doi.org/10.1155/2019/9073451.

- Radenković, M.; Alkildani, S.; Stoewe, I.; Bielenstein, J.; Sundag, B.; Bellmann, O.; Jung, O.; Najman, S.; Stojanović, S.; Barbeck, M. Comparative In Vivo Analysis of the Integration Behavior and Immune Response of Collagen-Based Dental Barrier Membranes for Guided Bone Regeneration (GBR). 2021, 11, 712. https://doi.org/10.3390/membranes11090712.

- Bourne, J.W.; Lippell, J.M.; Torzilli, P.A. Glycation cross-linking induced mechanical–enzymatic cleavage of microscale tendon fibers. Matrix Biol. 2014, 34, 179–184. https://doi.org/10.1016/j.matbio.2013.11.005.

- Dewle, A.; Pathak, N.; Rakshasmare, P.; Srivastava, A. Multifarious Fabrication Approaches of Producing Aligned Collagen Scaffolds for Tissue Engineering Applications. ACS Biomater. Sci. Eng. 2020, 6, 779–797. https://doi.org/10.1021/acsbiomaterials.9b01225.

- O’Brien, F.J.; Harley, B.A.; Yannas, I.V.; Gibson, L. Influence of freezing rate on pore structure in freezedried collagen-GAG scaffolds. Biomaterials 2004, 25, 1077–1086. https://doi.org/10.1016/s0142-961200630-6.

- Haugh, M.G.; Murphy, C.M.; O’Brien, F.J. Novel freeze-drying methods to produce a range of collagen-glycosaminoglycan scaffolds with tailored mean pore sizes. Tissue Eng. Part C Methods 2010, 16, 887–894. https://doi.org/10.1089/ten.TEC.2009.0422.

- Jiang, C.; Wang, Z.; Zhang, X.; Zhu, X.; Nie, J.; Ma, G. Crosslinked polyelectrolyte complex fiber membrane based on chitosan–sodium alginate by freeze-drying. RSC Adv. 2014, 4, 41551–41560. https://doi.org/10.1039/C4RA04208E.

- Chang, H.-I.; Wang, Y. Cell responses to surface and architecture of tissue engineering scaffolds. In Regenerative Medicine and Tissue Engineering-Cells and Biomaterials; InTechOpen: , 2011. https://doi.org/10.5772/21983.

- Santhiago, M.R.; Randleman, J.B. The biology of corneal cross-linking derived from ultraviolet light and riboflavin. Eye Res. 2021, 202, 108355. https://doi.org/10.1016/j.exer.2020.108355.

- Bapat, R.A.; Muthusamy, S.K.; Sidhu, P.; Mak, K.; Parolia, A.; Pichika, M.R.; Seow, L.L.; Tong, C.; Daood, U. Synthesis and Incorporation of Quaternary Ammonium Silane Antimicrobial into Self-Crosslinked Type I Collagen Scaffold: A Hybrid Formulation for 3D Printing. Biosci. 2022, 22, 2100326. https://doi.org/10.1002/mabi.202100326.

- Grønlien, K.G.; Pedersen, M.E.; Rønning, S.B.; Solberg, N.T.; Tønnesen, H.H. Tuning of 2D cultured human fibroblast behavior using lumichrome photocrosslinked collagen hydrogels. Today Commun. 2022, 31, 103635. https://doi.org/10.1016/j.mtcomm.2022.103635.

- Hernández‐Rangel, A.; Martin‐Martinez, E.S. Collagen based electrospun materials for skin wounds treatment. Biomed. Mater. Res. Part A 2021, 109, 1751–1764. https://doi.org/10.1002/jbm.a.37154.

- Liu, C.; Qiao, W.; Cao, H.; Dai, J.; Li, F.; Shi, J.; Dong, N. A riboflavin–ultraviolet light A-crosslinked decellularized heart valve for improved biomechanical properties, stability, and biocompatibility. Sci. 2020, 8, 2549–2563. https://doi.org/10.1039/C9BM01956A.

- Ding, Y.-W.; Zhang, X.-W.; Mi, C.-H.; Qi, X.-Y.; Zhou, J.; Wei, D.-X. Recent advances in hyaluronic acid-based hydrogels for 3D bioprinting in tissue engineering applications. Smart Mater. Med. 2023, 4, 59–68. https://doi.org/10.1016/j.smaim.2022.07.003.

- Vasilikos, I.; Teixeira, G.Q.; Seitz, A.; Nothelfer, J.; Haas, J.; Wilke, H.-J.; Mizaikoff, B.; Beck, J.; Hubbe, U.; Neidlinger-Wilke, C. Can UVA-light-activated riboflavin-induced collagen crosslinking be transferred from ophthalmology to spine surgery? A feasibility study on bovine intervertebral disc. PLoS ONE 2021, 16, e0252672. https://doi.org/10.1371/journal.pone.0252672.

- Orban, J.M.; Wilson, L.B.; Kofroth, J.A.; El-Kurdi, M.S.; Maul, T.M.; Vorp, D.A. Crosslinking of collagen gels by transglutaminase. Biomed. Mater. Res. Part A 2004, 68, 756–762. https://doi.org/10.1002/jbm.a.20110.

- Chen, R.-N.; Ho, H.-O.; Sheu, M.-T. Characterization of collagen matrices crosslinked using microbial transglutaminase. Biomaterials 2005, 26, 4229–4235. https://doi.org/10.1016/j.biomaterials.2004.11.012.

- Chau, D.Y.S.; Collighan, R.J.; Verderio, E.A.; Addy, V.L.; Griffin, M. The cellular response to transglutaminase-crosslinked collagen. Biomaterials 2005, 26, 6518–6529. https://doi.org/10.1016/j.biomaterials.2005.04.017.

- Kim, J.-K.; Bae, H.C.; Ro, D.H.; Lee, S.; Lee, M.C.; Han, H.-S. Enhancement of Cartilage Regeneration of Synovial Stem Cells/Hydrogel by Using Transglutaminase-4. Tissue Eng. Part A 2020, 27, 761-770. https://doi.org/10.1089/ten.tea.2020.0271.

- Malcor, J.-D.; Hunter, E.J.; Davidenko, N.; Bax, D.V.; Cameron, R.; Best, S.; Sinha, S.; Farndale, R.W. Collagen scaffolds functionalized with triple-helical peptides support 3D HUVEC culture. Regen Biomater. 2020, 7, 471–482. https://doi.org/10.1093/rb/rbaa025.

- Li, X.; Han, J.; Zhao, Y.; Ding, W.; Wei, J.; Li, J.; Han, S.; Shang, X.; Wang, B.; Chen, B.; et al. Functionalized collagen scaffold implantation and cAMP administration collectively facilitate spinal cord regeneration. Acta Biomater. 2016, 30, 233–245. https://doi.org/10.1016/j.actbio.2015.11.023.

- Fan, C.; Li, X.; Xiao, Z.; Zhao, Y.; Liang, H.; Wang, B.; Han, S.; Li, X.; Xu, B.; Wang, N.; et al. A modified collagen scaffold facilitates endogenous neurogenesis for acute spinal cord injury repair. Acta Biomater. 2017, 51, 304–316. https://doi.org/10.1016/j.actbio.2017.01.009.

- Caliari, S.; Ramirez, M.A.; Harley, B.A. The development of collagen-GAG scaffold-membrane composites for tendon tissue engineering. Biomaterials 2011, 32, 8990–8998. https://doi.org/10.1016/j.biomaterials.2011.08.035.

- Hinderer, S.; Sudrow, K.; Schneider, M.; Holeiter, M.; Layland, S.L.; Seifert, M.; Schenke-Layland, K. Surface functionalization of electrospun scaffolds using recombinant human decorin attracts circulating endothelial progenitor cells. Rep. 2018, 8, 110. https://doi.org/10.1038/s41598-017-18382-y.

- Girija, A.R.; Palaninathan, V.; Strudwick, X.; Balasubramanian, S.; Nair, S.D.; Cowin, A.J. Collagen-functionalized electrospun smooth and porous polymeric scaffolds for the development of human skin-equivalent. RSC Adv. 2020, 10, 26594–26603. https://doi.org/10.1039/d0ra04648e.

- Guo, B.; Lei, B.; Li, P.; Ma, P.X. Functionalized scaffolds to enhance tissue regeneration. Biomater. 2015, 2, 47–57. https://doi.org/10.1093/rb/rbu016.

- Parenteau-Bareil, R.; Gauvin, R.; Berthod, F. Collagen-based biomaterials for tissue engineering applications. Materials 2010, 3, 1863–1887. https://doi.org/10.3390/ma3031863.

- Harley, B.A.; Gibson, L.J. In vivo and in vitro applications of collagen-GAG scaffolds. Eng. J. 2008, 137, 102–121.

- Ryan, E.J.; Ryan, A.J.; González-Vázquez, A.; Philippart, A.; Ciraldo, F.E.; Hobbs, C.; Nicolosi, V.; Boccaccini, A.R.; Kearney, C.J.; O'Brien, F.J. Collagen scaffolds functionalised with copper-eluting bioactive glass reduce infection and enhance osteogenesis and angiogenesis both in vitro and in vivo. Biomaterials 2019, 197, 405–416.

- Liu, X.; Zheng, C.; Luo, X.; Wang, X.; Jiang, H. Recent advances of collagen-based biomaterials: Multihierarchical structure, modification and biomedical applications. Sci. Eng. C 2019, 99, 1509–1522.

- Rütsche, D.; Nanni, M.; Rüdisser, S.; Biedermann, T.; Zenobi‐Wong, M. Enzymatically Crosslinked Collagen as Versatile Matrix for In Vitro and In Vivo Co-Engineering of Blood and Lymphatic Vasculature. Mater. 2022, .

- Elgali, I.; Omar, O.; Dahlin, C.; Thomsen, P. Guided bone regeneration: Materials and biological mechanisms revisited. J. Oral Sci. 2017, 125, 315–337. https://doi.org/10.1111/eos.12364.

- Cochran, D.L.; Hermann, J.S.; Schenk, R.K.; Higginbottom, F.L.; Buser, D. Biologic width around titanium implants. A histometric analysis of the implanto‐gingival junction around unloaded and loaded nonsubmerged implants in the canine mandible. Periodontol. 1997, 68, 186–197. https://doi.org/10.1902/jop.1997.68.2.186.

- Thoma, D.S.; Bienz, S.P.; Figuero, E.; Jung, R.E.; Sanz-Martín, I. Efficacy of lateral bone augmentation performed simultaneously with dental implant placement: A systematic review and meta‐analysis. Clin. Periodontol. 2019, 46, 257–276. https://doi.org/10.1111/jcpe.13050.

- Feng, S.; Zhong, Z.; Wang, Y.; Xing, W.; Drioli, E. Progress and perspectives in PTFE membrane: Preparation, modification, and applications. Membr. Sci. 2018, 549, 332–349. https://doi.org/10.1016/j.memsci.2017.12.032.

- Almazrooa, S.A.; Noonan, V.; Woo, S.-B. Resorbable collagen membranes: Histopathologic features. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. 2014, 118, 236–240. https://doi.org/10.1016/j.oooo.2014.04.006.

- Lee, C.H.; Singla, A.; Lee, Y. Biomedical applications of collagen. J. Pharm. 2001, 221, 1–22. https://doi.org/10.1016/s0378-517300691-3.

- Rahighi, R.; Panahi, M.; Akhavan, O.; Mansoorianfar, M. Pressure-engineered electrophoretic deposition for gentamicin loading within osteoblast-specific cellulose nanofiber scaffolds. Chem. Phys. 2021, 272, 125018. https://doi.org/10.1016/j.matchemphys.2021.125018.

- Liu, Y.; Zhang, Y.; An, Z.; Zhao, H.; Zhang, L.; Cao, Y.; Mansoorianfar, M.; Liu, X.; Pei, R. Slide-ring structure-based double-network hydrogel with enhanced stretchability and toughness for 3D-bio-printing and its potential application as artificial smalldiameter blood vessels. ACS Appl. Bio Mater. 2021, 4, 8597–8606. https://doi.org/10.1021/acsabm.1c01052.

- Rider, P.; Kačarević, P.; Elad, A.; Rothamel, D.; Sauer, G.; Bornert, F.; Windisch, P.; Hangyási, D.; Molnar, B.; Hesse, B.; et al. Analysis of a Pure Magnesium Membrane Degradation Process and Its Functionality When Used in a Guided Bone Regeneration Model in Beagle Dogs. Materials 2022, 15, 3106. https://doi.org/10.3390/ma15093106.

- Rider, P.; Kačarević, P.; Elad, A.; Tadic, D.; Rothamel, D.; Sauer, G.; Bornert, F.; Windisch, P.; Hangyási, D.B.; Molnar, B.; et al. Biodegradable magnesium barrier membrane used for guided bone regeneration in dental surgery. Mater. 2022, 14, 152–168. https://doi.org/10.1016/j.bioactmat.2021.11.018.

- Chvapil, M. Collagen sponge: Theory and practice of medical applications. Biomed. Mater. Res. 1977, 11, 721–741. https://doi.org/10.1002/jbm.820110508.

- Schoof, H.; Apel, J.; Heschel, I.; et al. Control of pore structure and size in freeze‐dried collagen sponges. Biomed. Mater. Res. 2001, 58, 352–357. https://doi.org/10.1002/jbm.1028.

- Offeddu, G.; Ashworth, J.; Cameron, R.; Oyen, M. Structural determinants of hydration, mechanics and fluid flow in freeze-dried collagen scaffolds. Acta Biomater. 2016, 41, 193–203. https://doi.org/10.1016/j.actbio.2016.05.024.

- Zhang, Y.; Wang, C.; Jiang, W.; Zuo, W.; Han, G. Influence of stage cooling method on pore architecture of biomimetic alginate scaffolds. Rep. 2017, 7, . https://doi.org/10.1038/s41598-017-16024-x.

- Murphy, C.M.; Haugh, M.G.; O'Brien, F.J. The effect of mean pore size on cell attachment, proliferation and migration in collagen–glycosaminoglycan scaffolds for bone tissue engineering. Biomaterials 2010, 31, 461–466. https://doi.org/10.1016/j.biomaterials.2009.09.063. Epub 2009 Oct 9.

- Loh, Q.L.; Choong, C. Three-dimensional scaffolds for tissue engineering applications: Role of porosity and pore size. 2013, 19, 485–502. https://doi.org/10.1089/ten.TEB.2012.0437.

- Briquez, P.S.; Tsai, H.-M.; Watkins, E.A.; Hubbell, J.A. Engineered bridge protein with dual affinity for bone morphogenetic protein-2 and collagen enhances bone regeneration for spinal fusion. Adv. 2021, 7, eabh4302. https://doi.org/10.1126/sciadv.abh4302.

- Acri, T.M.; Laird, N.Z.; Jaidev, L.R.; Meyerholz, D.K.; Salem, A.K.; Shin, K. Nonviral gene delivery embedded in biomimetically mineralized matrices for bone tissue engineering. Tissue Eng. Part A 2021, 27, 1074–1083. https://doi.org/10.1089/ten.TEA.2020.0206.

- Borrego-González, S.; Rico-Llanos, G.; Becerra, J.; Díaz-Cuenca, A.; Visser, R. Sponge-like processed D-periodic selfassembled atelocollagen supports bone formation in vivo. Sci. Eng. C 2021, 120, 111679. https://doi.org/10.1016/j.msec.2020.111679.

- Cyr, J.A.; Husmann, A.; Best, S.M.; Cameron, R.E. Complex architectural control of ice-templated collagen scaffolds using a predictive model. Acta Biomater. 2022, 153, 260–272. https://doi.org/10.1016/j.actbio.2022.09.034.

- Joukhdar, H.; Seifert, A.; Jüngst, T.; Groll, J.; Lord, M.S.; Rnjak‐Kovacina, J. Ice templating soft matter: Fundamental principles and fabrication approaches to tailor pore structure and morphology and their biomedical applications. Mater. 2021, 33, 2100091. https://doi.org/10.1002/adma.202100091.

- Xue, X.; Hu, Y.; Deng, Y.; Su, J. Recent advances in design of functional biocompatible hydrogels for bone tissue engineering. Funct. Mater. 2021, 31, 2009432. https://doi.org/10.1002/adfm.202009432.

- Nabavi, M.H.; Salehi, M.; Ehterami, A.; Bastami, F.; Semyari, H.; Tehranchi, M.; Semyari, H. A collagen-based hydrogel containing tacrolimus for bone tissue engineering. Drug Deliv. Transl. Res. 2020, 10, 108–121. https://doi.org/10.1007/s13346-019-00666-7.

- Zeimaran, E.; Pourshahrestani, S.; Fathi, A.; Razak, N.A.B.A.; Kadri, N.A.; Sheikhi, A.; Baino, F. Advances in bioactive glass-containing injectable hydrogel biomaterials for tissue regeneration. Acta Biomater. 2021, 136, 1–36. https://doi.org/10.1016/j.actbio.2021.09.034.

- Kadler, K.E.; Hojima, Y.; Prockop, D.J. Assembly of collagen fibrils de novo by cleavage of the type I pC-collagen with procollagen C-proteinase. Assay of critical concentration demonstrates that collagen self-assembly is a classical example of an entropy-driven process. Biol. Chem. 1987, 262, 15696–15701.

- Ngo, P.; Ramalingam, P.; Phillips, J.A.; Furuta, G.T. Collagen gel contraction assay. Cell-Cell Interact. 2006, , 103–109. https://doi.org/10.1385/1-59745-113-4, 103.

- Gharati, G.; Shirian, S.; Sharifi, S.; Mirzaei, E.; Bakhtirimoghadam, B.; Karimi, I.; Nazari, H. Comparison capacity of collagen hydrogel and collagen/strontium bioglass nanocomposite scaffolds with and without mesenchymal stem cells in regeneration of critical sized bone defect in a rabbit animal model. Trace Elem. Res. 2022, 200, 3176–3186. https://doi.org/10.1007/s12011-021-02909-6.

- Yin, B.; Yang, H.; Yang, M. Integrating Soft Hydrogel with Nanostructures Reinforces Stem Cell Adhesion and Differentiation. Compos. Sci. 2022, 6, . https://doi.org/10.3390/jcs6010019.

- Magister, S.; Kolaczko, J.; Sattar, A.; Wetzel, R.J. Clinical parameters and radiographic resorption of a novel magnesium based bone void filler. Injury 2022, 53, 947–952. https://doi.org/10.1016/j.injury.2021.11.057.

- Amirian, J.; Makkar, P.; Lee, G.H.; Paul, K.; Lee, B.T. Incorporation of alginate-hyaluronic acid microbeads in injectable calcium phosphate cement for improved bone regeneration. Lett. 2020, 272, 127830. https://doi.org/10.1016/j.matlet.2020.127830.

- Gélébart, P.; Cuenot, S.; Sinquin, C.; Halgand, B.; Sourice, S.; Le Visage, C.; Guicheux, J.; Colliec-Jouault, S.; Zykwinska, A. Microgels based on Infernan, a glycosaminoglycanmimetic bacterial exopolysaccharide, as BMP-2 delivery systems. Polym. 2022, 284, 119191. https://doi.org/10.1016/j.carbpol.2022.119191.

- Glenske, K.; Donkiewicz, P.; Köwitsch, A.; Milosevic-Oljaca, N.; Rider, P.; Rofall, S.; Franke, J.; Jung, O.; Smeets, R.; Schnettler, R.; et al. Applications of Metals for Bone Regeneration. J. Mol. Sci. 2018, 19, . https://doi.org/10.3390/ijms19030826.

- Kargozar, S.; Mozafari, M.; Ghodrat, S.; Fiume, E.; Baino, F. Copper-containing bioactive glasses and glassceramics: From tissue regeneration to cancer therapeutic strategies. Sci. Eng. C Mater. Biol. Appl. 2021, 121, 111741. https://doi.org/10.1016/j.msec.2020.111741.

- Kaur, K.; Paiva, S.S.; Caffrey, D.; Cavanagh, B.L.; Murphy, C.M. Injectable chitosan/collagen hydrogels nano-engineered with functionalized single wall carbon nanotubes for minimally invasive applications in bone. Sci. Eng. C 2021, 128, 112340. https://doi.org/10.1016/j.msec.2021.112340.

- McKay, W.F.; Peckham, S.M.; Badura, J.M. A comprehensive clinical review of recombinant human bone morphogenetic protein-2 (INFUSE® Bone Graft). Orthop. 2007, 31, 729–734. https://doi.org/10.1007/s00264-007-0418-6.

- James, A.W.; LaChaud, G.; Shen, J.; Asatrian, G.; Nguyen, V.; Zhang, X.; Ting, K.; Soo, C.; Md; A Sears, N.; et al. A review of the clinical side effects of bone morphogenetic protein-2. Tissue Eng. Part B Rev. 2016, 22, 284–297. https://doi.org/10.1089/ten.TEB.2015.0357.

- Oryan, A.; Alidadi, S.; Moshiri, A.; Bigham-Sadegh, A. Bone morphogenetic proteins: A powerful osteoinductive compound with non‐negligible side effects and limitations. Biofactors 2014, 40, 459–481. https://doi.org/10.1002/biof.1177.

- Schneider, H.; Sedaghati, B.; Naumann, A.; Hacker, M.C.; Schulz-Siegmund, M. Gene silencing of chordin improves BMP-2 effects on osteogenic differentiation of human adipose tissue-derived stromal cells. Tissue Eng. Part A 2014, 20, 335–345. https://doi.org/10.1089/ten.TEA.2012.0563.

- Wong, D.S.H.; Li, J.; Yan, X.; Wang, B.; Li, R.; Zhang, L.; Bian, L. Magnetically Tuning Tether Mobility of Integrin Ligand Regulates Adhesion, Spreading, and Differentiation of Stem Cells. Nano 2017, 17, 1685–1695.

- Wong, S.H.D.; Yin, B.; Yang, B.; Lin, S.; Li, R.; Feng, Q.; Yang, H.; Zhang, L.; Yang, Z.; Li, G.; et al. Anisotropic Nanoscale Presentation of Cell Adhesion Ligand Enhances the Recruitment of Diverse Integrins in Adhesion Structures and Mechanosensing-Dependent Differentiation of Stem Cells. Funct. Mater. 2019, 29, 1806822.

- Chamieh, F.; Collignon, A.-M.; Coyac, B.R.; Lesieur, J.; Ribes, S.; Sadoine, J.; Llorens, A.; Nicoletti, A.; Letourneur, D.; Colombier, M.-L.; et al. Accelerated craniofacial bone regeneration through dense collagen gel scaffolds seeded with dental pulp stem cells. Rep. 2016, 6, . https://doi.org/10.1038/srep38814.

- Park, H.; Collignon, A.-M.; Lepry, W.C.; Ramirez-GarciaLuna, J.L.; Rosenzweig, D.H.; Chaussain, C.; Nazhat, S.N. Acellular dense collagen-S53P4 bioactive glass hybrid gel scaffolds form more bone than stem cell delivered constructs. Sci. Eng. C 2021, 120, 111743. https://doi.org/10.1016/j.msec.2020.111743.

- Raftery, R.M.; Walsh, D.P.; Ferreras, L.B.; Castaño, I.M.; Chen, G.; LeMoine, M.; Osman, G.; Shakesheff, K.M.; Dixon, J.E.; O'Brien, F.J. Highly versatile cell-penetrating peptide loaded scaffold for efficient and localised gene delivery to multiple cell types: From development to application in tissue engineering. Biomaterials 2019, 216, 119277. https://doi.org/10.1016/j.biomaterials.2019.119277.

- Boda, S.K.; Almoshari, Y.; Wang, H.; Wang, X.; Reinhardt, R.A.; Duan, B.; Wang, D.; Xie, J. Mineralized nanofiber segments coupled with calciumbinding BMP-2 peptides for alveolar bone regeneration. Acta Biomater. 2019, 85, 282–293. https://doi.org/10.1016/j.actbio.2018.12.051.

- Egberink, R.O.; Zegelaar, H.M.; El Boujnouni, N.; Versteeg, E.M.M.; Daamen, W.F.; Brock, R. Biomaterial-Mediated Protein Expression Induced by Peptide-mRNA Nanoparticles Embedded in Lyophilized Collagen Scaffolds. Pharmaceutics 2022, 14, 1619. https://doi.org/10.3390/pharmaceutics14081619.

- Wang, P.; Perche, F.; Midoux, P.; Cabral, S.; Malard, V.; Correia, I.J.; Ei-Hafci, H.; Petite, H.; Logeart-Avramoglou, D.; Pichon, C. In Vivo bone tissue induction by freeze-dried collagennanohydroxyapatite matrix loaded with BMP2/NS1 mRNAs lipopolyplexes. Control. Release 2021, 334, 188–200. https://doi.org/10.1016/j.jconrel.2021.04.021.

- Fan, L.; Körte, F.; Rudt, A.; Jung, O.; Burkhardt, C.; Barbeck, M.; Xiong, X. Encapsulated vaterite-calcite CaCO3 particles loaded with Mg2+ and Cu2+ ions with sustained release promoting osteogenesis and angiogenesis. Bioeng. Biotechnol. 2022, 10, 983988. https://doi.org/10.3389/fbioe.2022.983988.

References

- Ghelich, P.; Kazemzadeh-Narbat, M.; Najafabadi, A.H.; Samandari, M.; Memić, A.; Tamayol, A. (Bio)manufactured Solutions for Treatment of Bone Defects with Emphasis on US-FDA Regulatory Science Perspective. Adv. NanoBiomed Res. 2022, 2, 2100073.

- Sakkas, A.; Wilde, F.; Heufelder, M.; Winter, K.; Schramm, A. Autogenous bone grafts in oral implantology-is it still a “gold standard”? A consecutive review of 279 patients with 456 clinical procedures. Int. J. Implant. Dent. 2017, 3, 23.

- Miron, R.J.; Sculean, A.; Shuang, Y.; Bosshardt, D.D.; Gruber, R.; Buser, D.; Chandad, F.; Zhang, Y. Osteoinductive potential of a novel biphasic calcium phosphate bone graft in comparison with autographs, xenografts, and DFDBA. Clin. Oral Implant. Res. 2016, 27, 668–675.

- Li, Y.; Liu, Y.; Li, R.; Bai, H.; Zhu, Z.; Zhu, L.; Zhu, C.; Che, Z.; Liu, H.; Wang, J.; et al. Collagen-based biomaterials for bone tissue engineering. Mater. Des. 2021, 210, 110049.

- Guo, L.; Liang, Z.; Yang, L.; Du, W.; Yu, T.; Tang, H.; Li, C.; Qiu, H. The role of natural polymers in bone tissue engineering. J. Control Release 2021, 338, 571–582.

- Laird, N.Z.; Acri, T.M.; Tingle, K.; Salem, A.K. Gene- and RNAi-activated scaffolds for bone tissue engineering: Current progress and future directions. Adv. Drug Deliv. Rev. 2021, 174, 613–627.

- Ballarre, J.; Manjubala, I.; Schreiner, W.H.; Orellano, J.C.; Fratzl, P.; Ceré, S. Improving the osteointegration and bone-implant interface by incorporation of bioactive particles in sol-gel coatings of stainless steel implants. Acta Biomater. 2010, 6, 1601–1609.

- Bellucci, D.; Sola, A.; Cannillo, V. Hydroxyapatite and tricalcium phosphate composites with bioactive glass as second phase: State of the art and current applications. J. Biomed. Mater. Res. Part A 2016, 104, 1030–1056.

- Bharadwaz, A.; Jayasuriya, A.C. Recent trends in the application of widely used natural and synthetic polymer nanocomposites in bone tissue regeneration. Mater. Sci. Eng. C 2020, 110, 110698.

- Wahl, D.; Czernuszka, J. Collagen-hydroxyapatite composites for hard tissue repair. Eur. Cells Mater. 2006, 11, 43–56.

- Gillman, C.E.; Jayasuriya, A.C. FDA-approved bone grafts and bone graft substitute devices in bone regeneration. Mater. Sci. Eng. C Mater. Biol. Appl. 2021, 130, 112466.

- Chen, X.; Hao, W.; Li, X.; Xiao, Z.; Yao, Y.; Chu, Y.; Farkas, B.; Romano, I.; Brandi, F.; Dai, J. Functional Multichannel Poly(Propylene Fumarate)-Collagen Scaffold with Collagen-Binding Neurotrophic Factor 3 Promotes Neural Regeneration After Transected Spinal Cord Injury. Adv. Heal. Mater. 2018, 7, e1800315.

- Khan, S.N.; Cammisa, F.P., Jr.; Sandhu, H.S.; Diwan, A.D.; Girardi, F.P.; Lane, J.M. The biology of bone grafting. J. Am. Acad. Orthop. Surg. 2005, 13, 77–86.

- Rico-Llanos, G.A.; Borrego-González, S.; Moncayo-Donoso, M.; Becerra, J.; Visser, R. Collagen Type I Biomaterials as Scaffolds for Bone Tissue Engineering. Polymers 2021, 13, 599.

- Ma, C.; Wang, H.; Chi, Y.; Wang, Y.; Jiang, L.; Xu, N.; Wu, Q.; Feng, Q.; Sun, X. Preparation of oriented collagen fiber scaffolds and its application in bone tissue engineering. Appl. Mater. Today 2021, 22, 100902.

- Gurumurthy, B.; Janorkar, A.V. Improvements in mechanical properties of collagen-based scaffolds for tissue engineering. Curr. Opin. Biomed. Eng. 2020, 17, 100253.

- Ferreira, A.M.; Gentile, P.; Chiono, V.; Ciardelli, G. Collagen for bone tissue regeneration. Acta Biomater. 2012, 8, 3191–3200.

- Liu, X.; Zheng, C.; Luo, X.; Wang, X.; Jiang, H. Recent advances of collagen-based biomaterials: Multihierarchical structure, modification and biomedical applications. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 99, 1509–1522.

- Miller, E.J.; Gay, S. Collagen: An overview. In Methods in Enzymology; Academic Press: Cambridge, MA, USA, 1982; pp. 3–32.

- Strom, S.C.; Michalopoulos, G. Collagen as a substrate for cell growth and differentiation. In Methods in Enzymology; Academic Press: Cambridge, MA, USA, 1982; pp. 544–555.

- Wu, S.; Liu, X.; Yeung, K.W.K.; Liu, C.; Yang, X. Biomimetic porous scaffolds for bone tissue engineering. Mater. Sci. Eng. R Rep. 2014, 80, 1–36.

- Canty, E.G.; Kadler, K.E. Procollagen trafficking, processing and fibrillogenesis. J. Cell Sci. 2005, 118, 1341–1353.

- Brodsky, B.; Persikov, A.V. Molecular structure of the collagen triple helix. Adv. Protein Chem. 2005, 70, 301–339.

- Brodsky, B.; Ramshaw, J.A. The collagen triple-helix structure. Matrix Biol. 1997, 15, 545–554.

- Leung, M.K.; Fessler, L.I.; Greenberg, D.B.; Fessler, J.H. Separate amino and carboxyl procollagen peptidases in chick embryo tendon. J. Biol. Chem. 1979, 254, 224–232.

- Bornstein, P. The biosynthesis of collagen. Annu. Rev. Biochem. 1974, 43, 567–603.

- Olsen, B.R.; Hoffmann, H.-P.; Prockop, D.J. Interchain disulfide bonds at the COOH-terminal end of procollagen synthesized by matrix-free cells from chick embryonic tendon and cartilage. Arch. Biochem. Biophys. 1976, 175, 341–350.

- Gallop, P.M.; Blumenfeld, O.O.; Seifter, S. Structure and metabolism of connective tissue proteins. Annu. Rev. Biochem. 1972, 41, 617–672.

- Hodge, A.J.; Schmitt, F.O. The Charge Profile of the Tropocollagen Macromolecule and the Packing Arrangement in Native-Type Collagen Fibrils. Proc. Natl. Acad. Sci. USA 1960, 46, 186–197.

- Kadler, K.; Prockop, D.J. Protein structure and the specific heat of water. Nature 1987, 325, 395.

- Mould, A.P.; Hulmes, D.J.; Holmes, D.F.; Cummings, C.; Sear, C.H.; Chapman, J.A. D-periodic assemblies of type I procollagen. J. Mol. Biol. 1990, 211, 581–594.

- Chao, Y.-H.; Sun, J.-S. Biomechanics of Skeletal Muscle and Tendon. In Frontiers in Orthopaedic Biomechanics; Springer: Berlin/Heidelberg, Germany, 2020; pp. 37–73.

- Parenteau-Bareil, R.; Gauvin, R.; Berthod, F. Collagen-based biomaterials for tissue engineering applications. Materials 2010, 3, 1863–1887.

- Harley, B.A.; Gibson, L.J. In vivo and in vitro applications of collagen-GAG scaffolds. Chem. Eng. J. 2008, 137, 102–121.

- Ryan, E.J.; Ryan, A.J.; González-Vázquez, A.; Philippart, A.; Ciraldo, F.E.; Hobbs, C.; Nicolosi, V.; Boccaccini, A.R.; Kearney, C.J.; O’Brien, F.J. Collagen scaffolds functionalised with copper-eluting bioactive glass reduce infection and enhance osteogenesis and angiogenesis both in vitro and in vivo. Biomaterials 2019, 197, 405–416.

- Rütsche, D.; Nanni, M.; Rüdisser, S.; Biedermann, T.; Zenobi-Wong, M. Enzymatically Crosslinked Collagen as Versatile Matrix for In Vitro and In Vivo Co-Engineering of Blood and Lymphatic Vasculature. Adv. Mater. 2022. ahead of print.

- Elgali, I.; Omar, O.; Dahlin, C.; Thomsen, P. Guided bone regeneration: Materials and biological mechanisms revisited. Eur. J. Oral Sci. 2017, 125, 315–337.

- Cochran, D.L.; Hermann, J.S.; Schenk, R.K.; Higginbottom, F.L.; Buser, D. Biologic width around titanium implants. A histometric analysis of the implanto-gingival junction around unloaded and loaded nonsubmerged implants in the canine mandible. J. Periodontol. 1997, 68, 186–197.

- Thoma, D.S.; Bienz, S.P.; Figuero, E.; Jung, R.E.; Sanz-Martín, I. Efficacy of lateral bone augmentation performed simultaneously with dental implant placement: A systematic review and meta-analysis. J. Clin. Periodontol. 2019, 46, 257–276.

- Feng, S.; Zhong, Z.; Wang, Y.; Xing, W.; Drioli, E. Progress and perspectives in PTFE membrane: Preparation, modification, and applications. J. Membr. Sci. 2018, 549, 332–349.

- Almazrooa, S.A.; Noonan, V.; Woo, S.-B. Resorbable collagen membranes: Histopathologic features. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. 2014, 118, 236–240.

- Lee, C.H.; Singla, A.; Lee, Y. Biomedical applications of collagen. Int. J. Pharm. 2001, 221, 1–22.

- Kinoshita, S.; Mera, K.; Ichikawa, H.; Shimasaki, S.; Nagai, M.; Taga, Y.; Iijima, K.; Hattori, S.; Fujiwara, Y.; Shirakawa, J.-I.; et al. Nω-(carboxymethyl) arginine is one of the dominant advanced glycation end products in glycated collagens and mouse tissues. Oxidative Med. Cell. Longev. 2019, 2019, 9073451.

- Bourne, J.W.; Lippell, J.M.; Torzilli, P.A. Glycation cross-linking induced mechanical–enzymatic cleavage of microscale tendon fibers. Matrix Biol. 2014, 34, 179–184.

- Radenković, M.; Alkildani, S.; Stoewe, I.; Bielenstein, J.; Sundag, B.; Bellmann, O.; Jung, O.; Najman, S.; Stojanović, S.; Barbeck, M. Comparative In Vivo Analysis of the Integration Behavior and Immune Response of Collagen-Based Dental Barrier Membranes for Guided Bone Regeneration (GBR). Membranes 2021, 11, 712.

- Rahighi, R.; Panahi, M.; Akhavan, O.; Mansoorianfar, M. Pressure-engineered electrophoretic deposition for gentamicin loading within osteoblast-specific cellulose nanofiber scaffolds. Mater. Chem. Phys. 2021, 272, 125018.

- Liu, Y.; Zhang, Y.; An, Z.; Zhao, H.; Zhang, L.; Cao, Y.; Mansoorianfar, M.; Liu, X.; Pei, R. Slide-ring structure-based double-network hydrogel with enhanced stretchability and toughness for 3D-bio-printing and its potential application as artificial smalldiameter blood vessels. ACS Appl. Bio Mater. 2021, 4, 8597–8606.

- Rider, P.; Kačarević, P.; Elad, A.; Rothamel, D.; Sauer, G.; Bornert, F.; Windisch, P.; Hangyási, D.; Molnar, B.; Hesse, B.; et al. Analysis of a Pure Magnesium Membrane Degradation Process and Its Functionality When Used in a Guided Bone Regeneration Model in Beagle Dogs. Materials 2022, 15, 3106.

- Rider, P.; Kačarević, P.; Elad, A.; Tadic, D.; Rothamel, D.; Sauer, G.; Bornert, F.; Windisch, P.; Hangyási, D.B.; Molnar, B.; et al. Biodegradable magnesium barrier membrane used for guided bone regeneration in dental surgery. Bioact. Mater. 2022, 14, 152–168.

- Chvapil, M. Collagen sponge: Theory and practice of medical applications. J. Biomed. Mater. Res. 1977, 11, 721–741.

- Schoof, H.; Apel, J.; Heschel, I.; Rau, G. Control of pore structure and size in freeze-dried collagen sponges. J. Biomed. Mater. Res. 2001, 58, 352–357.

- Offeddu, G.; Ashworth, J.; Cameron, R.; Oyen, M. Structural determinants of hydration, mechanics and fluid flow in freeze-dried collagen scaffolds. Acta Biomater. 2016, 41, 193–203.

- Zhang, Y.; Wang, C.; Jiang, W.; Zuo, W.; Han, G. Influence of stage cooling method on pore architecture of biomimetic alginate scaffolds. Sci. Rep. 2017, 7, 16150.

- Murphy, C.M.; Haugh, M.G.; O’Brien, F.J. The effect of mean pore size on cell attachment, proliferation and migration in collagen–glycosaminoglycan scaffolds for bone tissue engineering. Biomaterials 2010, 31, 461–466.

- Loh, Q.L.; Choong, C. Three-dimensional scaffolds for tissue engineering applications: Role of porosity and pore size. Tissue Eng. Part B Rev. 2013, 19, 485–502.

- Briquez, P.S.; Tsai, H.-M.; Watkins, E.A.; Hubbell, J.A. Engineered bridge protein with dual affinity for bone morphogenetic protein-2 and collagen enhances bone regeneration for spinal fusion. Sci. Adv. 2021, 7, eabh4302.

- Acri, T.M.; Laird, N.Z.; Jaidev, L.R.; Meyerholz, D.K.; Salem, A.K.; Shin, K. Nonviral gene delivery embedded in biomimetically mineralized matrices for bone tissue engineering. Tissue Eng. Part A 2021, 27, 1074–1083.

- Borrego-González, S.; Rico-Llanos, G.; Becerra, J.; Díaz-Cuenca, A.; Visser, R. Sponge-like processed D-periodic selfassembled atelocollagen supports bone formation in vivo. Mater. Sci. Eng. C 2021, 120, 111679.

- Cyr, J.A.; Husmann, A.; Best, S.M.; Cameron, R.E. Complex architectural control of ice-templated collagen scaffolds using a predictive model. Acta Biomater. 2022, 153, 260–272.

- Joukhdar, H.; Seifert, A.; Jüngst, T.; Groll, J.; Lord, M.S.; Rnjak-Kovacina, J. Ice templating soft matter: Fundamental principles and fabrication approaches to tailor pore structure and morphology and their biomedical applications. Adv. Mater. 2021, 33, 2100091.

- Xue, X.; Hu, Y.; Deng, Y.; Su, J. Recent advances in design of functional biocompatible hydrogels for bone tissue engineering. Adv. Funct. Mater. 2021, 31, 2009432.

- Nabavi, M.H.; Salehi, M.; Ehterami, A.; Bastami, F.; Semyari, H.; Tehranchi, M.; Semyari, H. A collagen-based hydrogel containing tacrolimus for bone tissue engineering. Drug Deliv. Transl. Res. 2020, 10, 108–121.

- Zeimaran, E.; Pourshahrestani, S.; Fathi, A.; Razak, N.A.B.A.; Kadri, N.A.; Sheikhi, A.; Baino, F. Advances in bioactive glass-containing injectable hydrogel biomaterials for tissue regeneration. Acta Biomater. 2021, 136, 1–36.

- Kadler, K.E.; Hojima, Y.; Prockop, D.J. Assembly of collagen fibrils de novo by cleavage of the type I pC-collagen with procollagen C-proteinase. Assay of critical concentration demonstrates that collagen self-assembly is a classical example of an entropy-driven process. J. Biol. Chem. 1987, 262, 15696–15701.

- Ngo, P.; Ramalingam, P.; Phillips, J.A.; Furuta, G.T. Collagen gel contraction assay. Cell-Cell Interact. 2006, 341, 103–109.

- Gharati, G.; Shirian, S.; Sharifi, S.; Mirzaei, E.; Bakhtirimoghadam, B.; Karimi, I.; Nazari, H. Comparison capacity of collagen hydrogel and collagen/strontium bioglass nanocomposite scaffolds with and without mesenchymal stem cells in regeneration of critical sized bone defect in a rabbit animal model. Biol. Trace Elem. Res. 2022, 200, 3176–3186.

- Yin, B.; Yang, H.; Yang, M. Integrating Soft Hydrogel with Nanostructures Reinforces Stem Cell Adhesion and Differentiation. J. Compos. Sci. 2022, 6, 19.

- Magister, S.; Kolaczko, J.; Sattar, A.; Wetzel, R.J. Clinical parameters and radiographic resorption of a novel magnesium based bone void filler. Injury 2022, 53, 947–952.

- Yang, X.; Wang, X.; Yu, F.; Ma, L.; Pan, X.; Luo, G.; Lin, S.; Mo, X.; He, C.; Wang, H. Hyaluronic acid/EDC/NHS-crosslinked green electrospun silk fibroin nanofibrous scaffolds for tissue engineering. RSC Adv. 2016, 6, 99720–99728.

- Lu, Z.; Liu, S.; Le, Y.; Qin, Z.; He, M.; Xu, F.; Zhu, Y.; Zhao, J.; Mao, C.; Zheng, L. An injectable collagen-genipin-carbon dot hydrogel combined with photodynamic therapy to enhance chondrogenesis. Biomaterials 2019, 218, 119190.

- Amirian, J.; Makkar, P.; Lee, G.H.; Paul, K.; Lee, B.T. Incorporation of alginate-hyaluronic acid microbeads in injectable calcium phosphate cement for improved bone regeneration. Mater. Lett. 2020, 272, 127830.

- Gélébart, P.; Cuenot, S.; Sinquin, C.; Halgand, B.; Sourice, S.; Le Visage, C.; Guicheux, J.; Colliec-Jouault, S.; Zykwinska, A. Microgels based on Infernan, a glycosaminoglycanmimetic bacterial exopolysaccharide, as BMP-2 delivery systems. Carbohydr. Polym. 2022, 284, 119191.

- Glenske, K.; Donkiewicz, P.; Köwitsch, A.; Milosevic-Oljaca, N.; Rider, P.; Rofall, S.; Franke, J.; Jung, O.; Smeets, R.; Schnettler, R.; et al. Applications of Metals for Bone Regeneration. Int. J. Mol. Sci. 2018, 19, 826.

- Kargozar, S.; Mozafari, M.; Ghodrat, S.; Fiume, E.; Baino, F. Copper-containing bioactive glasses and glassceramics: From tissue regeneration to cancer therapeutic strategies. Mater. Sci. Eng. C Mater. Biol. Appl. 2021, 121, 111741.

- Kaur, K.; Paiva, S.S.; Caffrey, D.; Cavanagh, B.L.; Murphy, C.M. Injectable chitosan/collagen hydrogels nano-engineered with functionalized single wall carbon nanotubes for minimally invasive applications in bone. Mater. Sci. Eng. C 2021, 128, 112340.

- McKay, W.F.; Peckham, S.M.; Badura, J.M. A comprehensive clinical review of recombinant human bone morphogenetic protein-2 (INFUSE® Bone Graft). Int. Orthop. 2007, 31, 729–734.

- James, A.W.; LaChaud, G.; Shen, J.; Asatrian, G.; Nguyen, V.; Zhang, X.; Ting, K.; Soo, C. A review of the clinical side effects of bone morphogenetic protein-2. Tissue Eng. Part B Rev. 2016, 22, 284–297.

- Oryan, A.; Alidadi, S.; Moshiri, A.; Bigham-Sadegh, A. Bone morphogenetic proteins: A powerful osteoinductive compound with non-negligible side effects and limitations. Biofactors 2014, 40, 459–481.

- Schneider, H.; Sedaghati, B.; Naumann, A.; Hacker, M.C.; Schulz-Siegmund, M. Gene silencing of chordin improves BMP-2 effects on osteogenic differentiation of human adipose tissue-derived stromal cells. Tissue Eng. Part A 2014, 20, 335–345.

- Wong, D.S.H.; Li, J.; Yan, X.; Wang, B.; Li, R.; Zhang, L.; Bian, L. Magnetically Tuning Tether Mobility of Integrin Ligand Regulates Adhesion, Spreading, and Differentiation of Stem Cells. Nano Lett. 2017, 17, 1685–1695.

- Wong, S.H.D.; Yin, B.; Yang, B.; Lin, S.; Li, R.; Feng, Q.; Yang, H.; Zhang, L.; Yang, Z.; Li, G.; et al. Anisotropic Nanoscale Presentation of Cell Adhesion Ligand Enhances the Recruitment of Diverse Integrins in Adhesion Structures and Mechanosensing-Dependent Differentiation of Stem Cells. Adv. Funct. Mater. 2019, 29, 1806822.

- Chamieh, F.; Collignon, A.-M.; Coyac, B.R.; Lesieur, J.; Ribes, S.; Sadoine, J.; Llorens, A.; Nicoletti, A.; Letourneur, D.; Colombier, M.-L.; et al. Accelerated craniofacial bone regeneration through dense collagen gel scaffolds seeded with dental pulp stem cells. Sci. Rep. 2016, 6, 38814.

- Park, H.; Collignon, A.-M.; Lepry, W.C.; Ramirez-GarciaLuna, J.L.; Rosenzweig, D.H.; Chaussain, C.; Nazhat, S.N. Acellular dense collagen-S53P4 bioactive glass hybrid gel scaffolds form more bone than stem cell delivered constructs. Mater. Sci. Eng. C 2021, 120, 111743.

- Raftery, R.M.; Walsh, D.P.; Ferreras, L.B.; Castaño, I.M.; Chen, G.; LeMoine, M.; Osman, G.; Shakesheff, K.M.; Dixon, J.E.; O’Brien, F.J. Highly versatile cell-penetrating peptide loaded scaffold for efficient and localised gene delivery to multiple cell types: From development to application in tissue engineering. Biomaterials 2019, 216, 119277.

- Boda, S.K.; Almoshari, Y.; Wang, H.; Wang, X.; Reinhardt, R.A.; Duan, B.; Wang, D.; Xie, J. Mineralized nanofiber segments coupled with calciumbinding BMP-2 peptides for alveolar bone regeneration. Acta Biomater. 2019, 85, 282–293.

- Egberink, R.O.; Zegelaar, H.M.; El Boujnouni, N.; Versteeg, E.M.M.; Daamen, W.F.; Brock, R. Biomaterial-Mediated Protein Expression Induced by Peptide-mRNA Nanoparticles Embedded in Lyophilized Collagen Scaffolds. Pharmaceutics 2022, 14, 1619.

- Wang, P.; Perche, F.; Midoux, P.; Cabral, S.; Malard, V.; Correia, I.J.; Ei-Hafci, H.; Petite, H.; Logeart-Avramoglou, D.; Pichon, C. In Vivo bone tissue induction by freeze-dried collagennanohydroxyapatite matrix loaded with BMP2/NS1 mRNAs lipopolyplexes. J. Control. Release 2021, 334, 188–200.

- Fan, L.; Körte, F.; Rudt, A.; Jung, O.; Burkhardt, C.; Barbeck, M.; Xiong, X. Encapsulated vaterite-calcite CaCO3 particles loaded with Mg2+ and Cu2+ ions with sustained release promoting osteogenesis and angiogenesis. Front. Bioeng. Biotechnol. 2022, 10, 983988.