The need to reduce costs associated with the production of microalgae biomass has encouraged the coupling of process with wastewater treatment. Emerging pollutants in municipal, industrial, and agricultural wastewaters, ranging from pharmaceuticals to metals, endanger public health and natural resources. The use of microalgae has, in fact, been shown to be an efficient method in water-treatment processes and presents several advantages, such as carbon sequestration, and an opportunity to develop innovative bioproducts with applications to several industries. Using a bibliometric analysis software, SciMAT, a mapping of the research field was performed, analyzing the articles produced between 1981 and 2018, aiming to identifying the hot topics and trends studied until now. The application of microalgae on water bioremediation is an evolving research field that currently focuses on developing efficient and cost-effective treatments methods that also enable the production of add-value products, leading to a blue and circular economy.

- bibliometric analysis

- microalgae

- water bioremediation

- algal biotechnology

Introduction

Water quality is a fundamental concern of the present century, considering the increasing scarcity of water resources. Degradation of water quality, either caused by anthropogenic activities (e.g., pollution; resources overexploitation) or natural phenomena (e.g., global warming; extreme climatic events) often leads to severe impacts on ecosystems, public health and economic growth, negatively affecting society and environment [[1]]. The improvement of water quality is a central issue included in the 2030 Agenda and on Sustainable Development Goals, recognizing the importance of good-quality water for a sustainable development of society and, therefore, the need to globally address this problem.

The discharge of untreated or inadequately treated effluents into rivers, lakes, aquifers and coastal waters supplies the aquatic environment with a myriad of chemical compounds that can impact aquatic organisms directly, by triggering hazardous effects, and indirectly, by changing some physicochemical features of the medium (e.g., oxygen concentration, pH, redox potential and nutrient concentration) [[2][3]].

Contaminants often result from domestic, agricultural and industrial effluents and their physical and chemical compositions differ according to their origins [[4]]. The most frequently found are metals [[5]], pesticides [[6]] and nutrients, such as nitrate [[7]] and phosphate [[8]]. Moreover, the occurrence of emerging organic and inorganic pollutants, such as microplastics [[9]], pharmaceuticals [[10]], flame retardants [[11]], personal care products [[12]], hazardous and noxious substances [[13]] has been increasing since conventional wastewater treatment plants (WWTP) are not yet equipped and suitable to remove these new contaminants.

The complexity of effluent composition is increasing as human activities intensify, so it is urgent to develop adequate wastewater treatment processes, which should be easily applicable, effective and eco-friendly, in order to prevent water quality degradation and to protect water resources.

Physicochemical processes alone are proven to be inefficient regarding the treatment of effluents with complex composition [[11]]. A possible solution can be the combination of physicochemical and biological treatment technologies aiming at the development of sustainable treatment processes.

Biological treatments often involve the cultivation of microalgae. The capacity of microalgae to remove nutrients [[14]], metals [[4]], pharmaceuticals [[15][16]], radioactive minerals [[17]] or pathogenic organisms [[18]] from the medium has been highlighted in literature. Using microalgae to remove pollutants from wastewaters or effluents before their discharge or reutilization is named phycoremediation [[6]]. The basic mechanism behind this process is inherent to the algal metabolism, nevertheless, the removal of pollutants will be variable accordingly to different microalgae used and effluents’ characteristics.

Therefore, the design of the cultivation system is a critical parameter for microalgae production in order to achieve optimal growth rates and minimize costs [[19]]. For microalgae production, several factors are important to take into account, namely, the biology of the microalgae, cultivation land area, light, nutrient supply, labor, energy, carbon dioxide, pH, temperature and the type of the final product [[20][21][22]].

Several methodologies of microalgae production have been developed over time, from laboratorial systems under accurate controlled conditions, to open systems in the field under natural, uncontrolled and unpredictable conditions [[20]]. Table 1 summarizes the main systems, methods and strategies used. Microalgae are typically cultivated in open or closed culture systems. Furthermore, diverse strategies, namely in batch, continuous and semi-continuous, are applied around the world and which differ mainly on nutrient supply and operation modes [[20]].

Due to the high energy demand and operation costs of harvesting processes, solutions were investigated in order to simplify this process [[23]]. Therefore, new methods of microalgae cultivation, like the immobilization method on alginate beads and the development of bioreactors that use microalgae biofilm, have emerged and have been coupled to the treatment of wastewater [[24][25]]. Also, the biological interactions among microalgae and bacteria or fungi and microalgae’s ability to naturally flocculate under adverse conditions are under study as means to increase microalgae biomass productivity [[26][27]] and to reduce harvesting [[28]], respectively.

Phycoremediation shows great potential to complement traditional wastewater treatment processes. Microalgae cultivation is, thus, a promising approach for WWTP in municipalities or industries, promoting environmentally sustainable effluent treatment, and nutrient and carbon biosequestration; and yields economic benefits–cost reduction and revenue from innovative products originated from microalgae (e.g.,: pigments, enzymes, sugars, and lipids) [[6]]. Furthermore, this approach addresses the need to reduce the costs associated with microalgae biomass production [[29]], through the recycling of wastewater to obtain microalgal biomass instead of culture medium [[26]]. Nowadays, there are already several cases of enterprises worldwide using wastewater sources for microalgae production: United States—Algae Systems and Sundine Enterprises, Inc.; United Kingdom—I-PHYC; Australia—Algae Enterprises; Israel—Aquonos Energy Ltd. [[4],[30]].

Microalgae have indeed gained attention from the scientific community and have been a growing subject in research and development (R&D) or research and technology development (R&TD) studies and projects over the last decades, mainly focused on their resilience to grow on different types of wastewaters, performing phycoremediation and promoting decarbonization [[31]].

Table 1. Summary of different systems, methods and strategies of microalgae cultivation commonly used.

|

Microalgae Cultivation |

Description |

|

System |

|

|

Open Culture System |

Ponds, tanks, lakes and raceway ponds are examples of open culture systems. These outdoor systems were the first and are the most used for large-scale production of microalgae biomass due to their simple construction, easy operation and low energy demands [[32]]. However, open culture systems not only are affected by climate conditions and exterior contamination as they also show low productivity and loss of nutrients by evaporation [[33]]. |

|

Closed Culture System |

Closed systems are usually denominated by photobioreactors and are characterized by not allowing exchanges between the microalgae culture and the external environment [[20]], presenting different designs, such as tubular, plastic bags, flat-plate and bubble-column [[34]]. Closed-culture systems overcome some of the challenges faced by open systems, such as higher productivity, less nutrient evaporation and contamination [[35]]. Nevertheless, these systems present a high energy demand, being their implementation expensive [[34]]. |

|

Method |

|

|

Co-Culture Method |

Microalgae exist in nature as a part of a community, benefiting from the interaction among microorganisms [[36]]. In a co-culture method, more than one species is grown in the same medium, so it should be taken into account that the species selected have similar growth requirements [[37]]. Nowadays, co-culture of microalgae with yeast or bacteria has shown potential to enhance the phycoremediation and biomass yield [[26]]. In this cultivation method, microalgae synthesize higher contents of exopolysaccharides to support the growth in hostile conditions [[38]]. |

|

Immobilized Method |

When compared with microalgae free-cell cultivation, the immobilization process can overcome the biomass-harvesting challenge, ensuring that metabolic substances can diffuse through the polymer gel matrix [[39]]. Nevertheless, the costs of the polymer and the immobilization process, accumulation of metabolic products and the efficiency of the bioremediation are some of the drawbacks of this cultivation method [[6]]. Still, previous studies show the potential of immobilized microalgae in wastewater bioremediation and metal recovery [[40]]. |

|

Strategy |

|

|

Batch |

This is a simple closed system and low-cost strategy, since it does not require much control. This strategy is characterized by no renewal of culture medium, so the microalgae culture grows until it reaches the decline phase [[20]]. In practice, the culture could crash for several reasons such as nutrient or oxygen depletion, self-shading, pH variations or contamination [[41]]. |

|

Semi-Continuous |

This strategy is like a batch system but, in this case, the culture medium is renewed periodically, while effluent is removed at the same time [[20]]. Nevertheless, this strategy could not be appropriate for microalgae cultivation because light is a limiting-factor that affects biomass productivity [[42]]. |

|

Continuous |

A continuous strategy that consists in the constant renewal of growth medium, in which the volume of culture medium that is supplemented is the same as the volume of culture that is removed [[20]]. The advantage of continuous renewal of medium is the achievement of high biomass productivity [[43]]. Also, it is easy to scale-up for industrial microalgae production due to the simple operation of the cultivation system [[44]]. |

Interest in this field of research is increasing related to the potential of microalgae cultivation for a circular economy, once the microalgal produced biomass can be used and valued in several industries (e.g., food, feed, textile, pharmaceutical, bioplastic, biofuel, biofertilizer and cosmetic [[33],[45][46]]). Nevertheless, cost efficacy of commercialization is still an issue and essential to attract investors to up-scale production, so the technology is still being developed in terms of research and development [[46]]. Current research lines focus on four strategic alignments: feedstock, process, products, and market uptake [[30],[47]].

This review aims to point out trends and hot topics concerning the use of microalgae in wastewater treatment and to identify potential paths for future research regarding microalgae-based bioremediation. In order to achieve this goal, available literature will be mapped using a bibliometric tool to assess and analyze the topics that attracted more attention among the science community and their evolution through time.

Bibliometric Performance Analysis

Publication Production

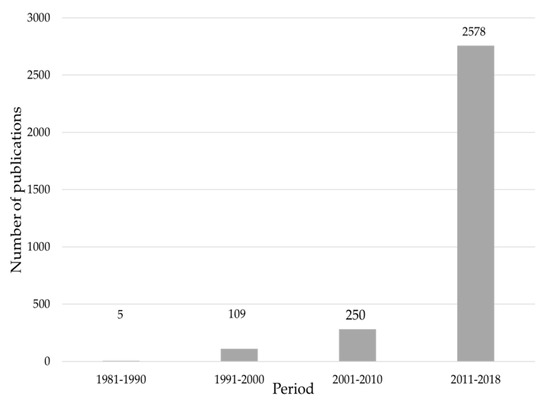

Over the last half a century, the progressive increment of publications in this research area showed the increasing interest in the study and development of microalgae applications for water bioremediation. Figure 1 clearly exhibits such interest: from 1981 to 1990, only the publication of 5 articles were registered within this research field, but a significant increment was observed in the time frame between 1991 and 2000, with 109 article publications. This trend continued in the subsequent analyzed time periods (2001–2010 and 2011–2018), corresponding to 250 and 2578 articles published, respectively. Therefore, it should be expected that this increasing trend will continue.

Figure 1. Number of articles published in each chosen period.

Within the period analyzed, several authors were quite prolific, producing a high number of publications and reaching high visibility and scientific impact. Table 2 summarizes the most productive authors according to the number of produced publications and h-index, which expresses the productivity of each author according to the impact of the publications.

Table 2. Most productive authors between 1981 and 2018.

|

Author |

Number of Publications |

h-Index |

Affiliation |

Country |

|

Raul Muñoz |

44 |

53 |

Valladolid University |

Spain |

|

Joan García |

34 |

58 |

Valencia University |

Spain |

|

Roger Ruan |

32 |

60 |

Minnesota University |

USA |

|

Paul Chen |

27 |

53 |

Minnesota University |

USA |

|

Ivet Ferrer |

27 |

36 |

Polytechnic University of Catalunya |

Spain |

|

Jo-Shuo Chang |

26 |

89 |

National Cheng Kung University |

Taiwan |

|

S. Venkata Mohan |

26 |

71 |

CSIR-Indian Institute of Chemical Technology |

India |

|

Enrica Uggetti |

25 |

17 |

Polytechnic University of Catalunya |

Spain |

|

Byong-Hun Jeon |

24 |

44 |

Hanyang University |

South Korea |

|

Wenguang Zhou |

24 |

26 |

Nanchang University |

China |

Content Analysis

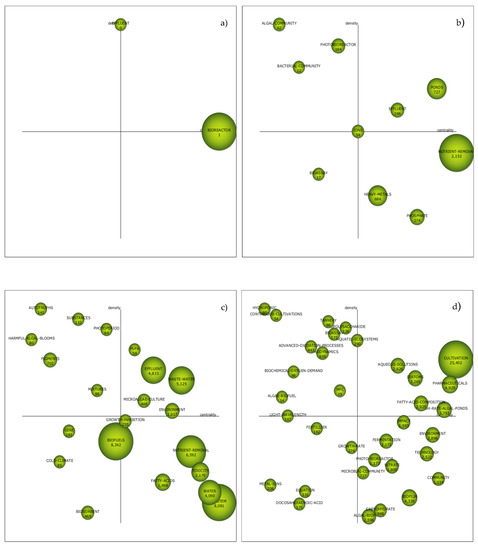

The research themes studied during the selected period were evaluated and plotted in a strategic diagram. Research themes are characterized by density and centrality. Density assesses the internal strength of the network whereas centrality assesses the interaction of the network with other networks. Figure 2 shows the strategic diagrams obtained for each chosen period. In these plots, the themes are represented by spheres and the size of each sphere is representative of the number of articles and includes the number of citations [[48]]. Furthermore, in Figure 2, the most emphasized themes in the field of bioremediation with microalgae for each period are presented. The interpretation of these diagrams is generally focused on the quadrants [[49]]:

- Quadrant Q1: considered motor themes, important for the development of the research field.

- Quadrant Q2: themes well developed.

- Quadrant Q3: represents emergent or declining themes.

- Quadrant Q4: characterized by basic and transversal themes, nevertheless not well developed.

Figure 2. Strategic diagrams. (a) Period 1981–1990. (b) Period 1991–2000. (c) Period 2001–2010. (d) Period 2011–2018. (SciMAT output).

References

- United Nations Educational, Scientific and Cultural Organization. International Initiative on Water Quality; United Nations Educational, Scientific and Cultural Organization: Paris, France, 2015.

- Shurair Mohamad; Almomani Fares; S.J. Judd; Rahul Bhosale; Anand Kumar; Ujjal K. Ghosh; MajedA Khreisheh; Advanced wastewater treatment using microalgae: effect of temperature on removal of nutrients and organic carbon. IOP Conference Series: Earth and Environmental Science 2017, 67, 12032, 10.1088/1755-1315/67/1/012032.

- Eve Menger-Krug; Jutta Niederste-Hollenberg; Thomas Hillenbrand; Harald Hiessl; Integration of Microalgae Systems at Municipal Wastewater Treatment Plants: Implications for Energy and Emission Balances. Environmental Science & Technology 2012, 46, 11505-11514, 10.1021/es301967y.

- Felix Wollmann; Stefan Dietze; Jörg‐Uwe Ackermann; Thomas Bley; Thomas Walther; Juliane Steingroewer; Felix Krujatz; Microalgae wastewater treatment: Biological and technological approaches. Engineering in Life Sciences 2019, 19, 860-871, 10.1002/elsc.201900071.

- Shakhawat Chowdhury; M.A. Jafar Mazumder; Omar Al-Attas; Tahir Husain; Heavy metals in drinking water: Occurrences, implications, and future needs in developing countries. Science of The Total Environment 2016, 569, 476-488, 10.1016/j.scitotenv.2016.06.166.

- Q Emparan; Razif Harun; Michael Kobina Danquah; Role of phycoremediation for nutrient removal from wastewaters: A review. Applied Ecology and Environmental Research 2019, 17, 889-915, 10.15666/aeer/1701_889915.

- Menció, A.; Mas-Pla, J.; Otero, N.; Regàs, O.; Boy-Roura, M.; Puig, R.; Bach, J.; Domènech, C.; Zamorano, M.; Brusi, D.; et al.et al. Nitrate pollution of groundwater; all right…, but nothing else?. Sci. Total Environ. 2016, 539, 241–251.

- Schaum, C.; Phosphorus: Polluter and Resource of the Future-Removal and Recovery from Wastewater. Water Intell. Online 2018, 17, 450–457.

- Dafne Eerkes-Medrano; Heather Leslie; Brian Quinn; Microplastics in drinking water: A review and assessment. Current Opinion in Environmental Science & Health 2019, 7, 69-75, 10.1016/j.coesh.2018.12.001.

- Ivan Muñoz; María José Gómez Ramos; A. Agüera; Amadeo R. Fernández-Alba; Juan F. García-Reyes; Antonio Molina-Díaz; Chemical evaluation of contaminants in wastewater effluents and the environmental risk of reusing effluents in agriculture. TrAC Trends in Analytical Chemistry 2009, 28, 676-694, 10.1016/j.trac.2009.03.007.

- Donna Sutherland; Peter Ralph; Microalgal bioremediation of emerging contaminants - Opportunities and challenges.. Water Research 2019, 164, 114921, 10.1016/j.watres.2019.114921.

- Zane Norvill; Andy Shilton; Benoit Guieysse; Emerging contaminant degradation and removal in algal wastewater treatment ponds: Identifying the research gaps. Journal of Hazardous Materials 2016, 313, 291-309, 10.1016/j.jhazmat.2016.03.085.

- Yue Wang; Shih-Hsin Ho; Chieh-Lun Cheng; Wanqian Guo; Dillirani Nagarajan; Nan-Qi Ren; Duu-Jong Lee; Jo-Shu Chang; Perspectives on the feasibility of using microalgae for industrial wastewater treatment. Bioresource Technology 2016, 222, 485-497, 10.1016/j.biortech.2016.09.106.

- Jing-Han Wang; Tian-Yuan Zhang; Guo-Hua Dao; Xue-Qiao Xu; Xiao-Xiong Wang; Hong-Ying Hu; Microalgae-based advanced municipal wastewater treatment for reuse in water bodies. Applied Microbiology and Biotechnology 2017, 101, 2659-2675, 10.1007/s00253-017-8184-x.

- Lijian Leng; Liang Wei; Qin Xiong; Siyu Xu; Wenting Li; Sen Lv; Qian Lu; Liping Wan; Zhiyou Wen; Wenguang Zhou; Use of microalgae based technology for the removal of antibiotics from wastewater: A review. Chemosphere 2020, 238, 124680, 10.1016/j.chemosphere.2019.124680.

- Francesco G. Gentili; Jerker Fick; Algal cultivation in urban wastewater: an efficient way to reduce pharmaceutical pollutants. Journal of Applied Phycology 2016, 29, 255-262, 10.1007/s10811-016-0950-0.

- Varjani, S.; Agarwal, A.K.; Gnansounou, E.; Gurunathan, B. Bioremediation: Applications for Environmental Protection and Management; Springer: Berlin/Heidelberg, Germany, 2018.

- Adriano E. Marchello; Ana T. Lombardi; Maria José Dellamano-Oliveira; Clovis Souza; Microalgae population dynamics in photobioreactors with secondary sewage effluent as culture medium. Brazilian Journal of Microbiology 2015, 46, 75-84, 10.1590/S1517-838246120131225.

- Junying Zhu; Junfeng Rong; Baoning Zong; Factors in mass cultivation of microalgae for biodiesel. Chinese Journal of Catalysis 2013, 34, 80-100, 10.1016/s1872-2067(11)60497-x.

- Algae: anatomy, biochemistry, and biotechnology. Choice Reviews Online 2006, 44, 44-44, 10.5860/choice.44-0924.

- Guanqun Chen; Feng Chen; Growing Phototrophic Cells without Light. Biotechnology Letters 2006, 28, 607-616, 10.1007/s10529-006-0025-4.

- Lihua Cheng; Lin Zhang; Huanlin Chen; Congjie Gao; Carbon dioxide removal from air by microalgae cultured in a membrane-photobioreactor. Separation and Purification Technology 2006, 50, 324-329, 10.1016/j.seppur.2005.12.006.

- Preeti Pal; Kit Wayne Chew; Hong-Wei Yen; Jun Wei Lim; Man Lam; Pau Loke Show; Cultivation of Oily Microalgae for the Production of Third-Generation Biofuels. Sustainability 2019, 11, 5424, 10.3390/su11195424.

- Yunlong Luo; Pierre Le-Clech; Rita Henderson; Simultaneous microalgae cultivation and wastewater treatment in submerged membrane photobioreactors: A review. Algal Research 2017, 24, 425-437, 10.1016/j.algal.2016.10.026.

- Feng Gao; Wei Cui; Jing-Ping Xu; Chen Li; Wei-Hong Jin; Hong-Li Yang; Lipid accumulation properties of Chlorella vulgaris and Scenedesmus obliquus in membrane photobioreactor (MPBR) fed with secondary effluent from municipal wastewater treatment plant. Renewable Energy 2019, 136, 671-676, 10.1016/j.renene.2019.01.038.

- Guilllermo Quijano; Juan S. Arcila; G. Buitron; Microalgal-bacterial aggregates: Applications and perspectives for wastewater treatment. Biotechnology Advances 2017, 35, 772-781, 10.1016/j.biotechadv.2017.07.003.

- Saifeldin M. Siddeeg; Mohamed Tahooon; Faouzi Ben Rebah; Agro-industrial waste materials and wastewater as growth media for microbial bioflocculants production: a review. Materials Research Express 2019, 7, 012001, 10.1088/2053-1591/ab5980.

- Aigars Lavrinovičs; Tālis Juhna; Review on Challenges and Limitations for Algae-Based Wastewater Treatment. Construction Science 2017, 20, 17-25, 10.2478/cons-2017-0003.

- Rawat, I.; Gupta, S.K.; Shriwastav, A.; Singh, P.; Kumari, S.; Bux, F.; Microalgae Applications in Wastewater Treatment. Algae Biotechnol. 2016, no, 249–268.

- Herrador, M. The Microalgae/Biomass Industry in Japan -An Assessment of Cooperation and Business Potential With European Companies; EU Japan Centre Industrial Cooperation: Tokyo, Japan, 2016.

- Muhamad Maulana Azimatun Nur; Anita G. J. Buma; Opportunities and Challenges of Microalgal Cultivation on Wastewater, with Special Focus on Palm Oil Mill Effluent and the Production of High Value Compounds. Waste and Biomass Valorization 2018, 10, 2079-2097, 10.1007/s12649-018-0256-3.

- Yong Chen; Li-Ping Sun; Zhihui Liu; Greg Martin; Zheng Sun; Integration of Waste Valorization for Sustainable Production of Chemicals and Materials via Algal Cultivation. Topics in Current Chemistry 2017, 375, no, 10.1007/s41061-017-0175-y.

- K. G. Satyanarayana; André Bellin Mariano; Jose Vargas; A review on microalgae, a versatile source for sustainable energy and materials. International Journal of Energy Research 2011, 35, 291-311, 10.1002/er.1695.

- Fazal, T.; Mushtaq, A.; Rehman, F.; Ullah Khan, A.; Rashid, N.; Farooq, W.; Rehman, M.S.U.; Xu, J.; Bioremediation of textile wastewater and successive biodiesel production using microalgae. Renew. Sustain. Energy Rev. 2018, 82, 3107–3126.

- Emeka G. Nwoba; Jeremy M. Ayre; Navid Reza Moheimani; Benjamin E. Ubi; James C. Ogbonna; Growth comparison of microalgae in tubular photobioreactor and open pond for treating anaerobic digestion piggery effluent. Algal Research 2016, 17, 268-276, 10.1016/j.algal.2016.05.022.

- Gloria Padmaperuma; Rahul Vijay Kapoore; Daniel James Gilmour; Seetharaman Vaidyanathan; Microbial consortia: a critical look at microalgae co-cultures for enhanced biomanufacturing. Critical Reviews in Biotechnology 2017, 38, 690-703, 10.1080/07388551.2017.1390728.

- Neha Arora; Alok Patel; Juhi Mehtani; Parul A Pruthi; Vikas Pruthi; Krishna Mohan Poluri; Co-culturing of oleaginous microalgae and yeast: paradigm shift towards enhanced lipid productivity.. Environmental Science and Pollution Research 2019, 26, 16952-16973, 10.1007/s11356-019-05138-6.

- S. Magdouli; S.K. Brar; Jean Francois Blais; Co-culture for lipid production: Advances and challenges. Biomass and Bioenergy 2016, 92, 20-30, 10.1016/j.biombioe.2016.06.003.

- Ela Eroglu; Vipul Agarwal; Michael Bradshaw; Xianjue Chen; Alison M. Smith; Colin L. Raston; K. Swaminathan Iyer; Nitrate removal from liquid effluents using microalgae immobilized on chitosan nanofiber mats. Green Chemistry 2012, 14, 2682, 10.1039/c2gc35970g.

- Nirupama Mallick; Biotechnological potential of immobilized algae for wastewater N, P and metal removal: a review.. BioMetals 2002, 15, 377-390, 10.1023/a:1020238520948.

- Niels Thomas Eriksen; Torben Geest; J. J. Lønsman Iversen; Phototrophic growth in the lumostat: a photo-bioreactor with on-line optimization of light intensity. Journal of Applied Phycology 1996, 8, 345-352, 10.1007/bf02178577.

- Zohri, A.-N.A.; Ragab, S.W.; Mekawi, M.I.; Mostafa, O.A.A.; Comparison between batch, fed-batch, semi-continuous and continuous techniques for bio-ethanol production from a mixture of egyptian cane and beet molasses. Egypt. Sugar J. 201, 9, 89–111.

- Shih-Hsin Ho; Xiaoting Ye; Tomohisa Hasunuma; Jo-Shu Chang; Akihiko Kondo; Perspectives on engineering strategies for improving biofuel production from microalgae — A critical review. Biotechnology Advances 2014, 32, 1448-1459, 10.1016/j.biotechadv.2014.09.002.

- Eleonora Sforza; Mattia Enzo; Alberto Bertucco; Design of microalgal biomass production in a continuous photobioreactor: An integrated experimental and modeling approach. Chemical Engineering Research and Design 2014, 92, 1153-1162, 10.1016/j.cherd.2013.08.017.

- Balasubramani Ravindran; Mahmoud Nasr; Won-Mo Cho; Jung Kon Kim; Sang-Ryong Lee; Kwang-Hwa Jeong; Dong Jun Lee; Hee-Chul Choi; Microalgae Potential and Multiple Roles—Current Progress and Future Prospects—An Overview. Sustainability 2016, 8, 1215, 10.3390/su8121215.

- Manoj Kumar Enamala; Swapnika Enamala; Murthy Chavali; Jagadish Donepudi; Rajasri Yadavalli; Bhulakshmi Kolapalli; Tirumala Vasu Aradhyula; Jeevitha Velpuri; Chandrasekhar Kuppam; Production of biofuels from microalgae - A review on cultivation, harvesting, lipid extraction, and numerous applications of microalgae. Renewable and Sustainable Energy Reviews 2018, 94, 49-68, 10.1016/j.rser.2018.05.012.

- Judita Koreivienė; Jūratė Karosienė; Jūratė Kasperovičienė; Ričardas Paškauskas; Bogusława Łęska; Radosław Pankiewicz; Loreta Juškaitė; Alvydas Zagorskis; Elźbieta Wilk-Woźniak; Vaidotas Valskys; et al.Zenonas GulbinasEdward WalusiakWojciech KrztonDmitrij MorudovKostas RadzevičiusEwa TreskaŁukasz TabiszMonika PapsdorfZuzanna PiotrowiczBeata Messyasz EU Project of LIFE Programme ‘Algae Service for LIFE’ Develops Ecologicaly Sustainable Bioproducts from Freshwater Cyanobacteria and Macroalgae Biomas. Botanica 2019, 25, 176-185, 10.2478/botlit-2019-0019.

- Manuel Jesús Cobo; Antonio Gabriel López-Herrera; Enrique Herrera-Viedma; Francisco Herrera; An approach for detecting, quantifying, and visualizing the evolution of a research field: A practical application to the Fuzzy Sets Theory field. Journal of Informetrics 2011, 5, 146-166, 10.1016/j.joi.2010.10.002.

- José Ricardo López-Robles; Jose Ramon Otegi-Olaso; Igone Porto-Gomez; M.J. Cobo; 30 years of intelligence models in management and business: A bibliometric review. International Journal of Information Management 2019, 48, 22-38, 10.1016/j.ijinfomgt.2019.01.013.