Pollination is essential to maintain ecosystem balance and agricultural production. Domesticated bee pollination, which is easy to feed and manage, and mechanized pollination, which is not restricted by the environment, are considered the main technical means to alleviate the “pollinating insect crisis”. The selection of pollination method should be based on the physiological characteristics of crops and the actual environmental conditions of natural pollination. The pollination ability of bees is closely related to the status of the bees. Maintaining the pollination ability of bees in a reasonable range is the goal of bee pollination services. Colony state control technology needs to develop in two directions. First, there is a need to develop colony state monitoring technology based on multi-feature information fusion and to explore the self-regulation mechanisms of the colony in response to various factors. Second, based on these self-regulation mechanisms, there is a need to develop a low-cost and non-invasive bee colony state and pollination capacity estimation model, monitoring technology, and equipment based on single feature information. The goals of mechanized pollination are “efficiency” and “precision”. Mechanized pollination technology needs to be developed in two directions. First, the mechanisms of pollen abscission, transport, and sedimentation in different crops and mechanized pollination conditions should be explored. Second, research and development of efficient and accurate pollination equipment and technology based on the integration of multiple technologies such as pneumatic assistance, auxiliaries, static electricity, target, variables, and navigation, are needed.

- bee pollination

- mechanized pollination

- crops

- efficient pollination technology

1. Introduction

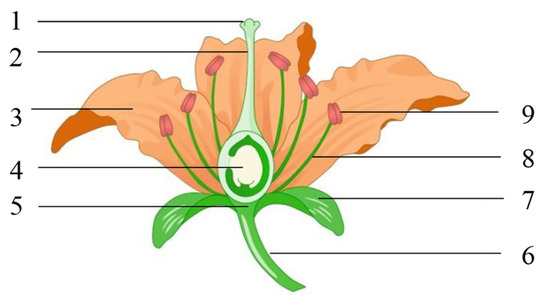

2. Pollination Methods for Different Crops

2.1. Basic Structural Features of Flowers

As shown in Figure 1, a flower comprises six parts: flower stalk, receptacle, calyx, corolla, stamen, and pistil. The stamens comprise filaments and anthers that contain a large amount of pollen; the pistil comprises the stigma, style, and ovary. The stigma is at the top of the pistil and is used to receive pollen grains. A flower with a calyx, corolla, stamen, and pistil is called a complete flower, whereas those lacking one or more parts are called incomplete flowers. Flowers with pistils and stamens are called hermaphroditic flowers. A flower lacking a stamen is called a unisexual flower; a flower with only stamens is a male flower, and a one with only pistils is a female flower. A plant with female and male flowers is called a hermaphrodite, whereas the separation of female and male flowers in different plants is called dioecism [10].

2.2. Self-Pollination and Cross-Pollination

2.3. Differences in Pollination Methods of Different Crops

3. Status of Efficient Bee Pollination Technology

3.1. Principle of Efficient Pollination of Bees

Bee pollination is a “bonus” of bees’ out-foraging behavior. In the long-term coevolution of bees and plants, bees have formed numerous characteristics suitable for plant pollination, including being easily attracted by bright colored entomophilous flowers that emit an aroma and secrete nectar; in addition, bees have identifying memory and pollination activity focused on specific species over a long period, high-frequency vibration generated by the wings during foraging that causes pollen to fall off, morphological structures such as villi and pollen baskets that easily adhere to pollen, social group structure, and numerous groups [21].

3.2. Breeding of High-Quality Pollinating Bee Varieties

There are 2 Apis species, and 9 Bombus species, and 8 solidary bee species that provide pollination services for crops. In addition, more bee varieties are waiting to be selected, including 6 bumble bees, 15 stingless bees, and 14 solitary bees. Europe, Asia, North America, and South America have more species that can be more easily used to breed high-quality pollinating bee varieties [22][25]. Fertility, population growth rate, bee sorting, collecting ability, pollination habit, disease resistance, and stress resistance are the biological characteristics that need to be closely investigated in pollinating bee breeding. Compared with bees, Bombus spp. have longer beaks, greater ability for nectar collection, and adaptability to low light density. Because bumblebees lack a developed information exchange system similar to bees, they are more suitable for pollination of crops in greenhouses where they are widely used [23][24][26,27].3.3. Climate and Environment Control Technology Outside the Hive

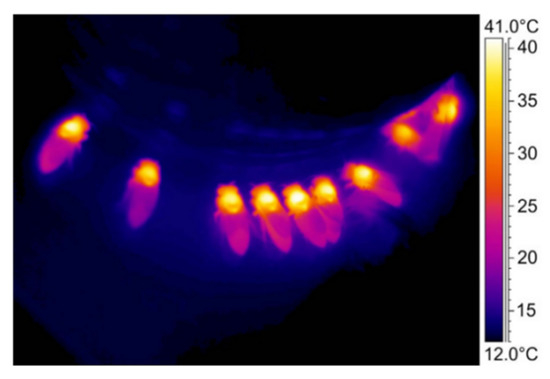

Climate and environmental factors (e.g., temperature, humidity, light, rain and wind) outside the hive directly affect the physiological function of bees, the secretion of nectar, and pollen germination of nectar crops, thus affecting the foraging behavior of bees and their pollination effects. In a subtropical climate, the initial temperature at which Apis Spp. commence foraging behavior on apple blossoms is 16 °C. As the temperature increases, the number of bees out-foraging continuously increases and reaches a relatively stable high level when the temperature exceedes 20 °C. Temperatures below 20 °C, wind speeds of over 15 mph, rain, and lower light levels limit bees’ out-foraging behavior [25][28]. In the regional climate of Lithuania, Apis mellifera almost stopped its foraging behavior on rape crops when the temperature reached 43 °C [26][29]. A light intensity of 600–1700 lx and solar radiation of 9–20 mW/cm2 are the minimum climatic and environmental conditions required for the four types of bees (Apis dorsata F; A. mellifera L; A. cerana F; and A. florea F) to go out for food [27][30]. Under high humidity conditions, the nectar secretion rate of crops is higher and the evaporation rate is lower; therefore, the foraging rate of bees is positively correlated with environmental humidity. However, considering both pollen collection and transportation of bees, researchers believe that a lower humidity environment is more conducive to bee foraging [28][31]. Fields and orchards are open-air spaces and bees require favorable natural climate conditions to go out for food. Bees can regulate their body temperature to ensure physiological functions, such as food absorption, respiration, metabolism, and energy supply [29][37]. As shown in Figure 3, foraging bees use solar energy to increase body temperature and save energy in a low-temperature environment. At the same time, they choose between “investment-oriented” and “energy-saving” thermoregulation strategies based on whether increasing body temperature can maximize the efficiency of food absorption [30][38]. In a high-temperature environment, foraging bees can dissipate heat and cool through the evaporation of honey sacs and oral water droplets [31][32][39,40].

3.4. Temperature and Humidity Control Technology in the Beehive

Healthy breeding of queen bees, drones, and worker bees is the basis for the health, strength, and stability of the colony. The beehive provides a breeding and living place that shields the bee colony from light, rain, and wind. Temperature and humidity in the beehive are the most critical factors that affect colony reproduction and are directly affected by the climate outside the beehive.

3.4.1. Influence of Temperature and Humidity on Beehive Colony Reproduction

The optimum temperature for the development of the fertilized eggs of Apis mellifera and the queen bee pupae in the capping platform is 35–36 °C; between 32 °C and 36 °C, the fertilized eggs and queen bee pupae develop normally. When the temperature reaches 37 °C, the queen bee pupae cannot develop normally [36][46]. The temperate ranges 29–37 °C and 31–37 °C are the development temperatures of Apis mellifera and Apis cerana, respectively. With a decrease in temperature, the development period of worker bee capping is significantly prolonged, and this affects developmental and morphological indicators such as birth weight, snout length, and forewing area. Beyond this temperature zone, bees are deformed or die [37][47]. The temperature of pupa development can significantly affect the behavioral performance of honeybee adults, thus affecting their foraging tasks. The learning and memory behavior of honeybee adults under a pupa development temperature of 36 °C is better than that under 32 °C and 34.5 °C [38][48]. The synaptic organization of the adult honeybee brain is mediated by the temperature experienced during pupal development, which affects its communication and learning behavior. In the olfactory input area of the mushroom body of the brain, the number of microglomers was highest in bees incubated at a temperature of 34.5 °C that is normally maintained by brood cells, and the number of microglomers was significantly reduced in bees incubated at 1 °C below or above this standard [39][49]. Pupal developmental temperature affected JH metabolism and octopamine levels in bee brains; bees developing at higher temperatures showed an earlier tendency to go out for food [40][50]. The optimum humidity range for normal hatching of bee eggs is 90% to 95%; outside this humidity range, the number of larvae that hatch normally decreases significantly [41][51]. In environments with high relative humidity, bees cannot excrete metabolized and food-dissolved water, which shortens their lifespan [42][52].3.4.2. Colony Self-Regulation Mechanism of Beehive Temperature and Humidity

Honeybee antennae are multimodal sensory organs that can sense various information, such as temperature, humidity, smell, taste, and mechanical stimuli, among others. Their temperature sensitivity is 0.25 °C. Honeybees receive real-time information on temperature, humidity, and spleen temperature in the hive through their antennae [43][44][45][53,54,55]. When the temperature, humidity, and temperature of the spleen in the hive are beyond the reasonable range for breeding and life, the bee colony takes measures to modify it. When the temperature in the hive or spleen is low, thermogenic bees raise the temperature of their thoracic cavity and attach the breast to the wax cover of the sealing lid, transferring this heat to maintain the temperature in the hive and spleen. Non-thermogenic bees gather and squeeze the cell comb to increase the sealing performance of the hive and reduce heat loss [46][47][56,57]. When the temperature in the beehive or spleen is high, the bee colony increases airflow between the inside of the beehive and the outside world through ordered directional fans to discharge the overheated air in the beehive; furthermore, the bee colony is also scattered in the beehive, further improving ventilation and heat dissipation [48][58].

3.4.3. Temperature and Humidity Monitoring Technology in Beehives

The existing temperature and humidity control in the beehive mainly relies on the self-regulating ability of the bee colony. A healthy, strong, and stable bee colony can maintain the temperature and humidity in the beehive within a reasonable range to ensure the breeding and life of the bee colony. A typical winter colony of 17,500 bees can survive for over 300 h even when the temperature outside the hive is as low as −25 °C [49][61]. However, when the state of the bee colony changes because of, for example, the occurrence of disease and insect pests, separation of bees, escape, or changes in the temperature and humidity inside the beehive caused by external changes that exceed the ability of the existing bee colony to adjust, the survival of the entire bee colony is seriously threatened.

3.5. Bee Colony State Management and Control Technology

Colony state is a broad concept that includes multi-characteristic information about the queen bee, drones, and worker bees (e.g., breeding status, population structure, number, nest, spleen status, degree of diseases, and insect pests). In actual production, beekeepers still need to manually estimate the status of the bee colony regularly before implementation of strategic management; this approach is labor intensive, low efficiency, extremely dependent on professional experience, and interferes with the life of the bee colony and pollination operations. With the development of modern information technologies such as artificial intelligence and the internet of things, researchers have attempted to use non-invasive intelligent equipment to obtain real-time bee colony information using images, sound, vibration, weight, and incoming and outgoing bee activity.3.5.1. Image Monitoring Technology in Beehives

Image-based information from the beehive is the most intuitive technical means to assess the state of the bee colony. As honey bees have phototaxis and cannot recognize red light, image monitoring technology in beehives often uses red light irradiation or infrared thermal imaging to obtain image information.3.5.2. Sound and Vibration Monitoring Technology in Beehives

The sound and vibration emitted by bees are an essential part of the communication mechanism of the bee colony. The temperature and humidity regulation of the colony, group activities such as going out for food, separating bees, escaping, losing the king, and disease can all be reflected by sound and vibration information.

3.5.3. Bee Colony Weight Monitoring Technology

The colony weight includes the main colony elements such as the adult bee colony, larvae, honey, and pollen, and its changes can accurately reflect the productivity, health, robustness, and stability of the colony in the beehive. To obtain bee colony weight information, professional electronic balances or electronic scales are often used to weigh beehives, comb spleens, adult bees, honey, and pollen.3.5.4. Bee Colony Monitoring Technology in the Hive Gate Area

Monitoring bee colony activities in the hive gate area can not only directly provide information on the foraging enthusiasm of bee colonies but also indirectly estimate bee colony status. Research on bee colony monitoring technology outside the hive focuses mainly on the number of bees and the number entering and leaving the hive gate area. Four main technical solutions are currently used: radio frequency identification tags, capacitive sensors, photoelectric sensors, and machine vision [50][51][52][53][54][95,96,97,98,99]. However, radio frequency identification tags, capacitive sensors, and photoelectric sensors suffer from regular beehive modifications, high costs, and complex maintenance. The bee colony monitoring system based on machine vision is a non-invasive solution that is easy to install and maintain, low cost, easy to popularize and apply, and has attracted increasing research attention.3.5.5. Bee Colony Monitoring Technology Based on Multi-Feature Information Fusion

The climate outside the hive and the temperature and humidity inside the hive affect bees’ behaviors such as foraging and breeding, thus affecting the colony status. Human activities, pesticides, bee habits, and other factors also significantly affect the state of bee colonies; moreover, these factors are interdependent. Currently, there is no effective model to reasonably estimate the influence of these factors and the self-adjustment mechanism of the colony on the colony state. Furthermore, it is inaccurate to estimate the state of a bee colony only based on single feature such as the climate outside the beehive or the temperature, humidity, sound, or weight inside the beehive.