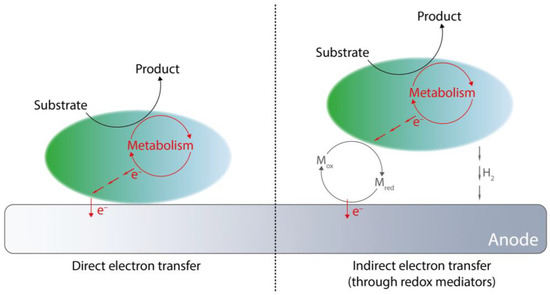

Mechanisms of electron transfer between micro-organisms and anode in MFCs.

3. Graphene Applications in Microbial Fuel Cells

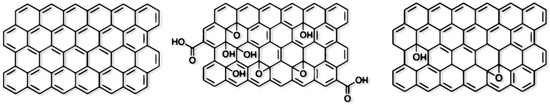

Since the first discovery of the two-dimensional nanomaterial graphene, there has been high interest in its potential applications according to its excellent conductivity, tremendous surface, and outstanding mechanical strength

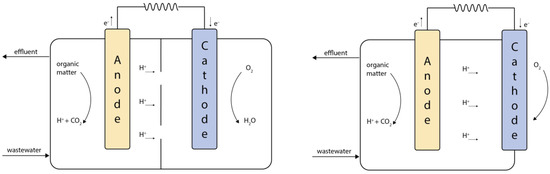

[13][14][15][33,34,35]. One of the promising solutions is a microbial fuel cell. The limited performance of MFC compared with other fuel cell technologies and the high cost of its components are two main barriers to its commercialization. Graphene, if technological developments make it cheaper to obtain, seems to offer a solution to this problem. Graphene can be used to build anodes in terms of increasing the efficiency of transporting electrons, to build cathodes, and used in a cathode chamber to efficiently catalyze the oxygen reduction reaction.

3.1. Anodes Based on Graphene Used in MFC

Graphene is considered a suitable additive for anodes due to its advanced properties, such as high conductivity, and good thermal and mechanical strength. Graphene has nonlinear and also higher diamagnetism compared to graphite

[16][36]. Used in anode, it ensures brilliant energy efficiency in comparison with other carbon-based materials. Graphene has no toxic effect on bacterial growth during MFC operation

[17][37]. Its modifications or connection with metals or conductive polymers can minimize the toxicity of other materials, such as copper

[18][38]. With its properties and application in MFCs, graphene can bring a kind of revolution in energy and wastewater treatment. Different forms of graphene, such as graphene oxide (GO), single/multilayered graphene, 2D/3D graphene, and reduced graphene (rGO), were used as anode materials in MFC.

In order to build a functional MFC system, bacteria must form dense biofilms on the surface of the anode to ensure efficient charge transfer from the individual bacteria to the external electrode, which is the source of the current and output of the MFC. Additions of certain substances can increase, and others decrease this process. Based on previous studies, it can be concluded that graphene is one of the materials whose addition significantly improves MFC efficiency. The method of chemical vapor deposition was used for three-dimensional graphene (3D) integration with an anode of a miniaturized microbial fuel cell (mini-MFC) (56-μL anode chamber). The structure of graphene showed fewer defects in layers, and the framework showed high REDOX peak current density. 3D graphene anode facilitated efficient mass transfer and effective electron transport, by forming denser biofilm

[19][39]. The graphene oxide was incorporated on the carbon brush using an electrophoretic technique. Sayed et al. (2021)

[20][40] used a modified hummer’s method to exploit a thin layer of graphene oxide on the anode. The authors used real wastewater in MFCs and obtained the power density increased more than 10 times compared to pure carbon brush (from 33 mW/m

2 to 381 mW/m

2), although the COD removal was nearly similar for the two MFCs. The authors proved by the electrochemical impedance spectroscopy measurements that the graphene improved the electron transfer from the micro-organism to the anode surface. To improve the efficiency of MFCs, researchers are experimenting with various types of bacteria that thrive in low-oxygen environments, such as

Shewanella oneidensis and

Geobacter [21][41]. The problem with MFC efficiency often comes down to the bacterial biofilm, through which electrons have difficulties getting through. Researchers at the University of California Los Angeles (UCLA) solved this problem by growing bacteria on electrodes made of graphene oxide with silver ions embedded in it. The bacteria began to reduce the ions to nanoparticles, which in turn went into their cells and thus helped more electrons escape outside. During the study, it was shown that with these improvements, the bacteria began transferring up to 81% of the electrons they produced to the electrode, an unprecedented figure at this time

[22][42]. In terms of testing the compactness and thickness of the biofilms formed, they used three different materials for anode electrodes—carbon paper, carbon paper with reduced graphene oxide (rGO), and carbon paper with reduced graphene oxide and silver nanoparticles added (rGO/Ag). It turned out that the maximum power density from the rGO/Ag electrode reached 6600 ± 300 mW/m

2, which was a much higher value than for carbon paper anodes (500 mW/m

2) or anodes of rGO (1300 mW/m

2). In addition, due to utilizing a composite built from carbon paper with the addition of graphene and silver nanoparticles, a very high coulombic efficiency was achieved at the previously mentioned level of 81%

[22][42]. The fabrication of the anode with graphene and adding metal oxides (ZnO and TiO

2) was tested in terms of electron transfer and cobalt remediation efficiency through microbial fuel cells (MFCs). The highest current density was obtained in the GO-ZnO composite anode (75.43 mA/m

2) and the lowest in GO anode (39.47 mA/m

2). The maximum remediation efficiency of cobalt (II) was noted in MFC with the GO-ZnO composite anode 91% on day 45

[23][43]. In addition, very high-power density through the use of graphene was achieved by using a three-dimensional (3D) macroporous graphene foam core/satellite structure with the addition of a nanocomposite Fe

3O

4/Au (Fe

3O

4/Au NCs-3DGF) to build anode

[24][44]. It was found that nanocomposites Fe

3O

4/Au improve anode–bacteria interaction, according to the high biological affinity between the Fe

3O

4/Au core and

Shewanella oneidensis MR-1. Due to the three-dimensional incorporation of macroporous graphene foam, the surface of the anode on which bacteria could settle expanded, and bacterial penetration into the anode also occurred. Taking advantage of these properties, the anode Fe

3O

4/Au NCs-3DGF showed enhanced bacterial carrying capacity and highly efficient extracellular electron transfer, which together contributed to a 71-fold increase in volumetric power density compared to the graphite counterpart (2980 ± 54 mW/m

2 in comparison with 41 ± 4 mW/m

2). In addition to the obtained graphene-based foams, the gels can also be used.

As described above, graphene is combined with elements or chemical compounds that can also modify other properties of the overall system. One of these elements was silver, often regarded as exhibiting antibacterial properties against bacteria such as

Escherichia coli. However, in the case of the

Shewanella sp., it did not significantly affect their viability. Researchers at UCLA

[22][42] supported this with a biocompatibility assessment study using a laser scanning microscope. Silver did not reduce the viability of

Shewanella sp. (93% viability for rGO/Ag versus 95% for carbon paper and 92% for rGO). With the addition of silver, the maximum output current density from the rGO/Ag electrode reached as high as 9200 mA/m

2, which was much higher than the carbon paper electrode (600 mA/m

2) or rGO without this addition (1200 mA/m

2). The pyrite (FeS

2) addition, an iron mineral from the sulfide cluster, resulted in an output current density of 3060 mA/m

2 in MFC powered by acetate

[25][46]. In order to improve the electron transfer rate, a study focusing on the fabrication of graphene-polyaniline composite anodes (GO-PANI) was also conducted

[26][50]. The construction of this type of anode based on graphene and polyanilines in the so-called benthonic microbial fuel cell (BMFC) resulted in a maximum current density of 87.71 mA/m

2. The modified graphene anode showed four times higher efficiency than the unmodified anode. Similarly, the GO-PANI remediation efficiency was 65.51% for cadmium (II) and 60.33% for lead (II), which was also higher than that of the unmodified graphene anode. Anodes based on polyaniline and graphene were also combined with titanium sub-oxides (TS) and compared to carbon cloth

[27][51]. The authors observed an enhanced voltage of 980 mV and the power density of 2073 mW/m

2. The combination of rGO-PANI/carbon cloth compared to pure carbon cloth increased power density twice and accelerated the growth of electrogenic biofilm

[28][52]. Li et al.

[29][53] used rGO modified with polydopamine as an anode and achieved power density of 2047 mW/m

2, which exceeded six-times the power density obtained by using pure carbon cloth.

3.2. Graphene Used in the Cathode Chamber of MFC

In addition to the characteristics of anodes, cathodes must have a catalytic capacity, enabling efficient reduction of terminal electron acceptors. The catalytic activity can be improved if the cathodes are modified with nanomaterials. The most common cathode catalyst is the expensive precious metal platinum (Pt). Cathode catalysts account for more than 50% of the total cost of MFCs, which is considered the most expensive component

[30][54]. Therefore, exploring other stable and simple materials that can be effectively used to build MFC electrodes is crucial. Graphene-based materials are among the attractive non-precious oxygen reduction reaction (ORR) catalysts due to their low cost compared to Pt and their unique properties.

Graphene in the cathode space can be used in various forms and, when used properly, can effectively increase the efficiency of the entire cell. High power densities have been achieved using three-dimensional graphene nanosheets (3D-GNS). Such sheets were used as cathode catalysts in MFCs operating under inert conditions. Compared to activated carbon, the 3D-GNS catalysts showed high efficiency

[31][55]. Researchers tested graphene nanosheets using alternating current with three loads—2, 6, and 10 mg/cm

2. The use of 3D-GNS yielded the highest power density values: 2059 ± 3 mW/m

2, 1855 ± 7 mW/m

2, and 1503 ± 5 mW/m

2, respectively, for a load of 10, 6, and 2 mg/cm

2. The addition of 3D-GNS also lowered ohmic losses at a level of 14–25%, letting the 3D-GNS-based microbial fuel cell achieve maximal power P

max = 5746 ± 186 mW/m

2. Yang et al.

[32][56] tested nanocomposites based on cobalt and zinc oxygen nanoparticles on a carrier covered by graphene oxygen (GO-Zn/Co). They were synthesized by hydrothermal treatment of graphene oxide and cobalt and zinc acetates, followed by pyrolysis at controlled temperatures. The porosity of the obtained nanocomposites changed with pyrolysis temperature and Zn/Co molar ratios. The resulting GO-Zn/Co nanocomposites exhibited apparent antibacterial activity, inhibiting the formation of biofilms on the cathode surface. MFCs using GO-Zn/Co prepared in this way as a cathode catalyst achieved a maximum power density of 773 mW/m

2, which was even higher than the most advanced Pt/C catalyst, 744 mW/m

2, and the output power remained unchanged during constant operation for one month. Improving the performance of MFCs with graphene-based nanocomposites can also be achieved by combining them with other materials, such as titanium dioxide (TiO

2). By synthesizing sulfonated graphene oxide (SGO) as a potential conductive matrix and using titanium dioxide nanoparticles and polyaniline (PANI) anchored on SGO, nanocomposites SGO-TiO

2-PANI can be obtained and used as a potential cathode catalyst in MFCs. Xin et al.

[33][59] examined the output voltage, coulombic efficiency, and microbial population in a single-cell MFC with a cathode catalyst made of copper (I) oxide nanoparticles and reduced graphene oxide (Cu

2O/rGO). They compared this voltage with a commercial platinum/carbon (Pt/C) catalyst. The study showed that MFCs with the Cu

2O/rGO cathode catalyst exhibited higher output voltage (0.223 V) and coulombic efficiency (92.5%) compared to commercial Pt/C (0.206 V, 90.3%, respectively). Moreover, the Cu

2O/rGO cathode catalyst exhibited excellent catalytic activity in the oxygen reduction reaction and promoted O

2 diffusion to the cathode surface. Interestingly, the relative abundance of

Geobacter electrogenic micro-organisms in the MFC anode biofilm with Cu

2O/rGO cathode catalyst (49.28%) was higher than that of commercial Pt/C (32.33%). The total abundance and diversity of the MFC cathode biofilm with Cu

2O/rGO catalyst was lower than that of commercial Pt/C due to the antibacterial properties of Cu

2O/rGO. However, according to the researchers, this phenomenon may have exposed more active catalytic sites on the cathode and further improved the power generation efficiency of the MFC.

3.3. Graphene Advantages in Terms of Microbial Fuel Cells

Graphene is a next-generation material with excellent physical and chemical properties. Due to these properties, the functioning of microbial fuel cells can be improved in several aspects compared to traditional materials. Anodes based on graphene can increase electron transfer efficiency

[29][53]. They also have a larger specific surface area compared to typical electrodes and promote more active microbe–electrode–electrolyte interaction. When it comes to processes in the cathodic chamber, the oxygen reduction reaction is effectively catalyzed by graphene-based materials due to the clear pathway and increased active sites and conductivity of the material

[34][60]. Of course, there are many challenges, such as synthesis complexity and property degeneration. However, despite them, graphene-based electrodes hold promise in developing microbial fuel cells and other bioelectrochemical systems to achieve sustainable wastewater treatment and bioenergy production.