Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Mostafa Yusefi and Version 2 by Sirius Huang.

Functional polymeric biomaterials (FPBMs) represent the most popular usage of natural, synthetic, or hybrid polymeric materials interacting with biological regimes and are used to protect against microbes and regenerate, repair, and treat any type of tissue in the organs, or improve the functions of the human body. FPBMs with bioactive characteristics obtained by radiation-induced graft copolymerisation (RIGC) have been subjected to intensive research and developed into many commercial products. Various studies have reported the development of a variety of radiation-grafted FPBMs.

- functional polymeric biomaterials

- radiation induced grafting

- medical and biomedical applications

1. Introduction

Functional polymeric biomaterials (FPBMs) are a class of materials that is receiving increasing interest because of their relevance to applications in various areas impacting human life and living [1]. FPBMs represent the most popular usage of natural, synthetic, or hybrid polymeric materials interacting with biological regimes and are used to protect against microbes and regenerate, repair, and treat any type of tissue in the organs, or improve the functions of the human body [2]. Thus, the research on FPBMs has enabled the development of various implants, medical devices, drug carriers, and scaffolds for tissue engineering with greater antimicrobial resistance, biocompatibility, and biofunctionality together with lower cytotoxicity against malignant cells [3]. FPBMs can be developed using various methods involving surface treatment such as etching, metallisation, ion sputtering, chemical grafting, and radiation-induced graft copolymerisation (RIGC) with low-energy radiation sources (plasma, laser treatment, and UV lamp) and high-energy radiation sources such as γ-rays and electron beam (EB) [4]. Each modification method has its pros and cons, and the selection of a particular method usually controls the developed topical structure and the level as well as the stability of the enhanced properties conferred to the polymer substrates.

Of all methods, RIGC is a distinctive technique for modification of polymer substrates that has been known for the past six decades. The versatility of this method is derived from its ability to permanently modify polymeric substrates by imparting new functionalities originated for the incoming polar monomers (acrylic or vinylic monomers) without compromising the inherent properties of the parent polymers. Such versatility enabled this technology to be used to develop many hybrid polymeric materials with desired properties [5][6][7][8][5,6,7,8]. The advantages of this method over its well-established chemically induced counterpart are not only in its ability to meticulously control the grafting yield by manipulation of the grafting parameters and the absence of detrimental impurities that maintain the purity of the product but also in the consumption of fewer chemicals and the ability to overcome product shaping problems. This is because grafting reactions can be started with polymer substrates of different physical forms, including films, non-woven fabric, particles, and fibres. Moreover, RIGC is also capable of achieving bulk modifications in the substrates when using γ-rays and EB sources, with the capability to scale up grafted products compared to plasma- and UV-induced grafting, which are limited to laboratory scale [9][10][9,10].

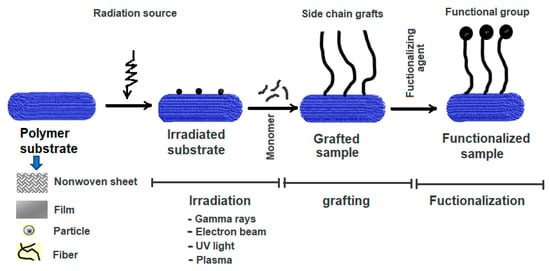

RIGC works by exposing a polymer substrate to ionising radiation, leading to the generation of active sites or radicals. The formed radicals initiate copolymerisation when exposed to monomer molecules, forming macroradicals that allow propagation of the molecular chains to form side chain grafts when terminated. RIGC can be carried out by the direct interaction between the monomer and the polymer substrate during irradiation, and this method is called simultaneous radiation grafting. Alternatively, the polymer substrate is initially irradiated and subsequently brought in contact with the monomer molecules in a separate step, and the technique is called pre-irradiation grafting. Introducing functional groups can be made by direct grafting of functional (acrylic) monomers or by a post-grafting reaction upon grafting vinylic monomers. Figure 1 shows a schematic diagram representing the preparation of functional polymeric materials by irradiation, grafting of the monomer, and subsequent functionalisation. More details on RIGC methods, including their advantages and disadvantages, can be found elsewhere [11].

Figure 1.

Schematic representation for preparation of functional polymeric materials by RIGC and functionalisation.

RIGC has been extensively used to endow interesting functional characteristics such as hydrophilicity, hydrophobicity, ion conduction, metal ion binding capacity, adhesion, microbial and fouling resistance, and biocompatibility to different polymer substrates. This led to the development of various functional polymeric materials through the integration of various monomer/polymer combinations enduring desired characteristics to polymer substrates. The resultant radiation-grafted functional materials’ applications include battery separators [12][13][14][12,13,14], polymer electrolyte membranes [15][16][15,16], chelating adsorbents [17][18][19][17,18,19], ion exchange membranes [20][21][20,21], and FPBMs [6][22][6,22].

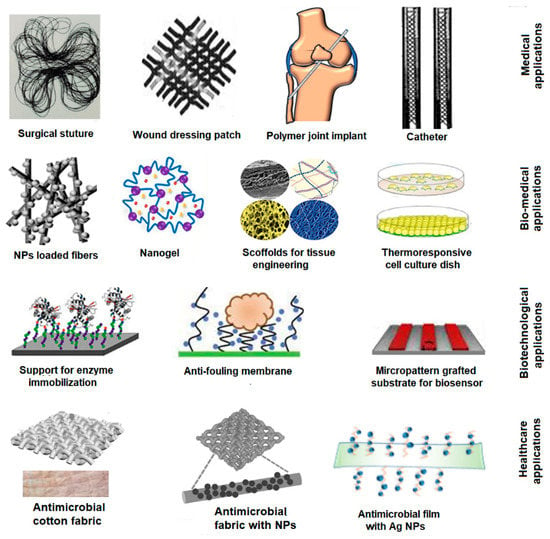

Particularly, the application of RIGC for the development of FPBMs is one of the areas that has received paramount efforts since the early days of the technique’s invention by A. Chapiro (a French scientist) [23] and A. Charlesby (a British scientist) [24]. Subsequently, many researchers used this technique to make enormous contributions to designing and developing innovative materials for medical, biomedical, health care, and biotechnological applications. Figure 2 shows some examples of FPBMs prepared by RIGC for various applications. This leads to the emergence of many potential radiation-grafted materials with great potential for commercialisation, and this field seems to be broadly opening for imaginative future developments.

Figure 2.

Schematic diagram of examples of FPBMs prepared by RIGC for various applications.

Several articles have been devoted to reviewing the use of RIGC for the development of adsorbents for purifications and separations in environmental applications, including wastewater treatment and CO2 capture [25][26][25,26], polymer electrolyte membranes and separators for energy conversion and storage [9][10][27][9,10,27], and protein capture [21]. The preparation and applications of biomaterials such as stimuli-responsive polymer systems and their polymer-biomolecule (protein) conjugates were also reviewed on two occasions [28][29][28,29]. Likewise, the use of RIGC or crosslinking to produce hydrogels of various size ranges (microgels and nanogels) and their applications in various medical and biomedical applications were extensively reviewed in many publications [30][31][32][33][34][30,31,32,33,34] with some attention recently paid to reviewing current approaches for crosslinking polysaccharides for hydrogel formation [35]. On the other hand, FPBMs obtained by RIGC have also been reviewed on various occasions, but with the focus limited to biomedical applications [6][26][27][28][29][6,26,27,28,29], cell sheet engineering, and the characteristics of thermo-responsive scaffolds [36][37][36,37]. Most of the published reviews mainly discussed strategies to construct a variety of radiation-grafted biomaterials with desired structure, properties, dynamic functionality, and biological complexity, taking the target application into account and elaborating on the challenges to the endurance of the imparted functionality.

2. Classification and Applications of FPBMs Prepared by RIGC

The design of FPBMs by RIGC was found to focus on the broad aspects of polymer surface modifications, inculcating antimicrobial resistance, biofilm formation prevention, biocompatibility, cytotoxicity resistance, bio-functionality, control-release of therapeutic agents in drug delivery, and healing functionalities in tissue engineering and regenerative medicine [2]. The advantages of this method for the preparation of FPBMs include the use of high-energy radiation for clean initiation (without chemical initiators) and the ability to obtain sterilised products [38][51]. Applications of FPBMs prepared by RIGC have been frequently reported in the literature, which prevailed the emergence of many urgently needed innovative materials capable of meeting the requirements of diversified applications [6]. Particularly, radiation-grafted FPBMs, such as drug release carriers [39][40][52,53], antimicrobial surgical sutures [41][54], thermo-responsive cell culture plates [42][55], scaffolds for tissue engineering [43][56], water-absorbing polymers [44][57], enzyme carriers [45][58], antimicrobial catheters [46][59], implants [47][60], antimicrobial gauze [48][61], antimicrobial fabrics [49][50][62,63], antibacterial food packing films [51][52][64,65], and antifouling membranes [53][66], have been widely investigated to design efficient, safe, and viable products. Such a wide spectrum of applications emphasises a need for a deep understanding of the knowledge underlying not only radiation chemistry and radiation processing of polymers but also biomedicine, biochemistry, and biomaterials characteristics. The various applications of FPBMs can be classified into four categories, including: (i) medicine, (ii) biomedicine, (iii) biotechnology, and (iv) healthcare, as shown in Table 1.Table 1.

Classification of FPBMs prepared by RIGC.

| Field | Applications | References |

|---|---|---|

| Medical | Implants | [47][54][55][56][57][58],68[,6959,70,71],72[60][61][60,67,73,74] |

| Catheter | [45][46][62][63][64][65][66][67][68][58,59,75,76,77,78,79,80,81] | |

| Surgical sutures | [41][69][70][71][72][73][74][75][76][77][78][79][80][81][82][83][84][85][54,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98] | |

| Wound dressing hydrogels/patches | [48][86][87][88][89][90][91][92][61,99,100,101,102,103,104,105] | |

| Biomedical | Scaffolds for tissue engineering | [43][93][94][95][96][97,108],109[,11098][99][100][101][,111102,112],113[103][104][56,106,107,114,115,116,117] |

| Cell culture plates | [42]55[105][106][107][108][109][110][111][,118112,119],120[113,121][114][,122,123,124,125,126,127] | |

| Drug release carrier/delivery | [39][40][41][70][89][115][116][117][118][119][120][121][122][123][124][125][126][127134][135][136][137][138[141][49,50][128][129][,52][130][131]139][,53140,54],83,102,128,129,130,131,132[132,133][133,134],135,136,137,138,139,140,141,142,143,144[,145,146,147,148,149,150,151,152] | |

| Biotechnological | Biosensors | [116][135][136][137][138][139][140][50,146,147,148,149,150,151] |

| Support for enzyme immobilization/release | [45][142][143][144][149][150][58,153,154[145,155][146,156][147,157][148,158],159,160,161] | |

| Antifouling membranes | [53][151][152][153][154][159][160][161][66,162155],163[,164156,165][157][158],166[,167,168,169,170,171,172] | |

| Health care | Antimicrobial fabrics and films | [50][162][163][164][165][166,175][167][168][169][170],176[,177171,178,179],180,181[,182172],183[173],184[174][175][176][177][178][63,173,174,185,186,187,188,189] |

| Protective face mask | [49][50][179][62,63,190] | |

| Packaging films | [51][52][180][181][64,65,191,192] |