Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Marlon Andres Osorio and Version 2 by Camila Xu.

Tumor organoids are defined as self-organized three-dimensional assemblies of heterogeneous cell types derived from patient samples that mimic the key histopathological, genetic, and phenotypic characteristics of the original tumor. This technology is proposed as an ideal candidate for the evaluation of possible therapies against cancer, presenting advantages over other models which are currently used.

- 3D cell culture

- cancer

- extracellular matrix

- organoids

- tomoroids

1. Organoids and Their Production

Three-dimensional cell culture is mainly represented by spheroids and organoids, the spheroids are simple structures, made up of only one type of cell, while the organoids are three-dimensional structures with complexity and heterogeneous cellular conformation, which mimic the morphology and physiology of their tissue of origin (recapitulation). The above is achieved in conditions that allow the cells that form the organoid to achieve self-renewal and provide mitogenic stimuli (culture medium that provides nutrients, growth factors that allow cell signaling, and extracellular matrix that provides support and adhesion of cells. Organoids can be initiated from embryonic stem cells, somatic adult stem cells, and induced pluripotent stem cells, although they can also originate from primary cultures of cancerous tissue samples [1][36]. Tumor-like organoids (also called tumoroids) are also defined as self-organized 3D assemblages of neoplastic cells derived from patient-specific tissue samples, which mimic the key histopathological, genetic, and phenotypic characteristics of the original tumor [2][14].

Different types of organoids have been generated from immortalized cell lines; for example, pancreatic cancer cell lines expressing the membrane marker (FC1245) [3][12] have been used individually or in co-culture with another line of pancreatic cancer, which express the GFP (green fluorescent protein) marker seeded in Matrigel to generate individual organoids [4][37]. Organoids have also been established from different types of breast cancer cell lines or primary cultures in Matrigel [5][38]. The above systems, with the appropriate growth factors, grow and differentiates to simulate the structure of a human tumor. In clinical research, the use of patient-derived organoids has great relevance for personalized medicine [6][7][8][39,40,41] For example, cells can be obtained from solid or liquid biopsies and used to generate a primary culture in a 3D matrix [2][9][14,42]. The solid biopsy has shown greater success in obtaining organoids. The tissue is digested enzymatically and/or mechanically, and is seeded on the matrix that will support the organoid. In this tissue, several types of cells that make up the tumor can be obtained, which contributes to preserving its heterogeneity [10][43].

Conversely, liquid biopsies have the advantage of the presence of circulating tumor cells (CTCs), which have markers and physical elements responsible for tumor spread and metastasis [11][44]. However, growing cultures derived from CTCs may be slow, given the low concentration of cells present in these fluids. Organoids have been generated from CTCs for pancreatic, breast, gastric, colon, and other cancers [12][13][14][15][16][17][45,46,47,48,49,50]. After the isolation of the solid or liquid biopsies, they are seeded in a biomaterial that allows biomimetics of the extracellular matrix (ECM).

2. Techniques for the Development of Tumor Organoids

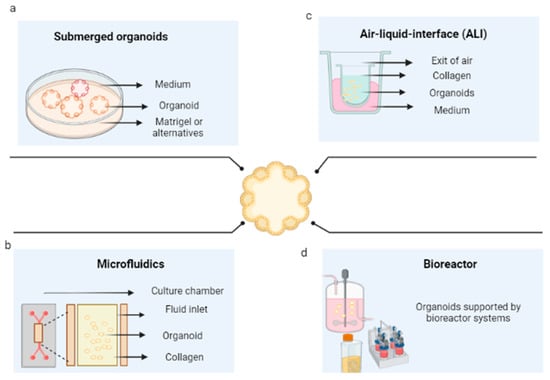

The initial conditions of the organoid contribute to its variability, including the initial cell population, its positioning and aggregation [18][135], its niche or extracellular environment, its physicochemical characteristics, and its culture conditions. At first, organoid cultures may start as spheroids or agglomerated cells. After cell differentiation, promoted by growth factors, they acquire their organoid characteristics [19][136]. These, once spread, are maintained under controlled CO2 and temperature conditions (5% v/v of CO2 and 37 °C). In systems used for organoids, they are submerged in culture medium and microfluidics, and cultured in an air–liquid interface, or in bioreactors [20][13].2.1. Submerged Culture in Scaffolding

The first method consists of the immersion of the organoid promoter cells or spheroids of tumorigenic cells, supported by a scaffold that will allow their growth in 3D. These are immersed in the culture medium, then supplemented with growth factors that can vary according to the type of tissue. The culture media that have been reported for the cultivation of organoids are Dulbecco’s modified Eagle medium (DMEM), Eagle’s minimum essential medium (EMEM), Roswell Park Memorial Institute (RPMI) medium, and Ham’s F12 culture medium (F12). This is conducted in the presence or absence of fetal bovine or equine serum and antibiotics, in addition to other supplements, such as L-glutamine, HEPES buffer, and GlutaMAX supplement; however, the critical components of the organoid media are a set of growth factors that include epidermal growth factor (EGF), fibroblast growth Factor 10 (FGF10), hepatocyte growth factor (HGF), R-spondin 1, and noggin. Figure 14a shows the general scheme of this technique for the development of organoids.

Figure 14. Organoid culture techniques. (a) Culture of organoids immersed in an extracellular matrix. (b) Organoids cultured in microfluidics. (c) Organoids cultured in an air–liquid interface (d) Organoid culture in bioreactors. Created with BioRender.com.